Blasting Method for Shallow Buried Section of Modern Railway Tunnel

A tunnel and shallow burial technology, applied in blasting and other directions, can solve the problems of difficult to grasp the impact of blasting, and cannot ensure that the roof layer of shallow buried tunnels and other buildings are not damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

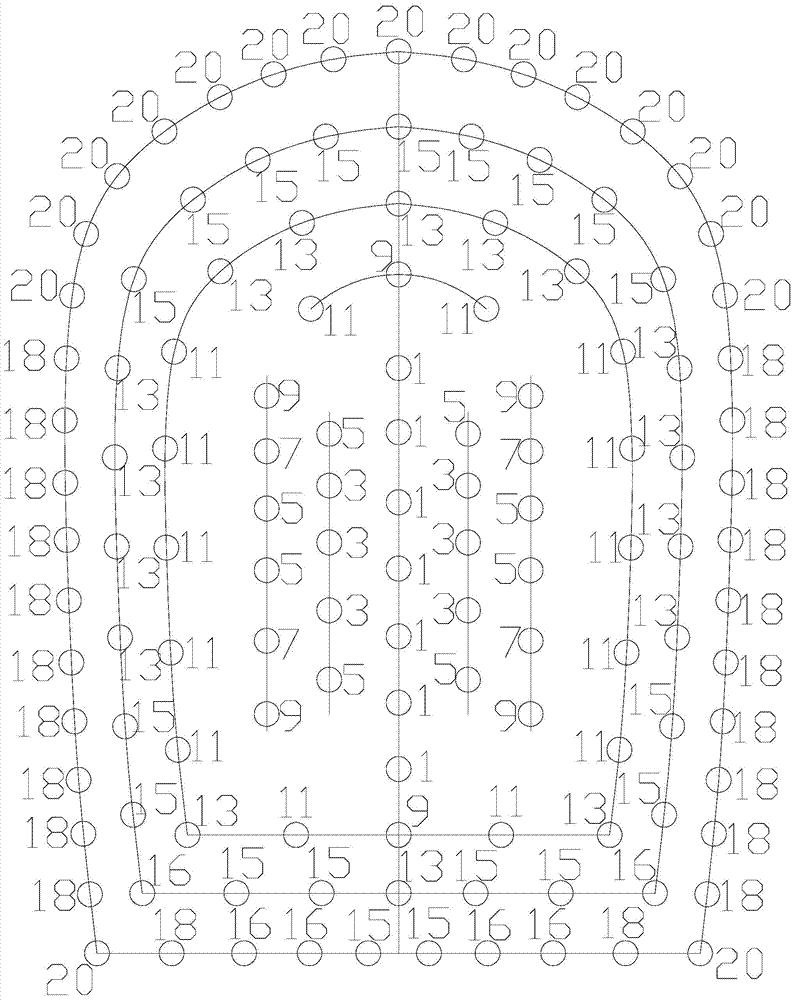

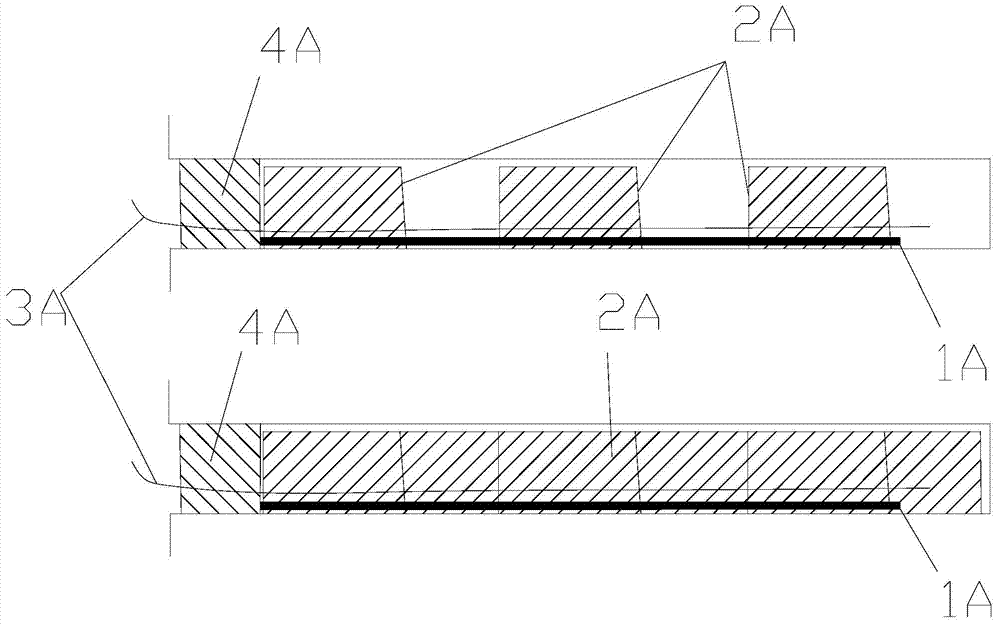

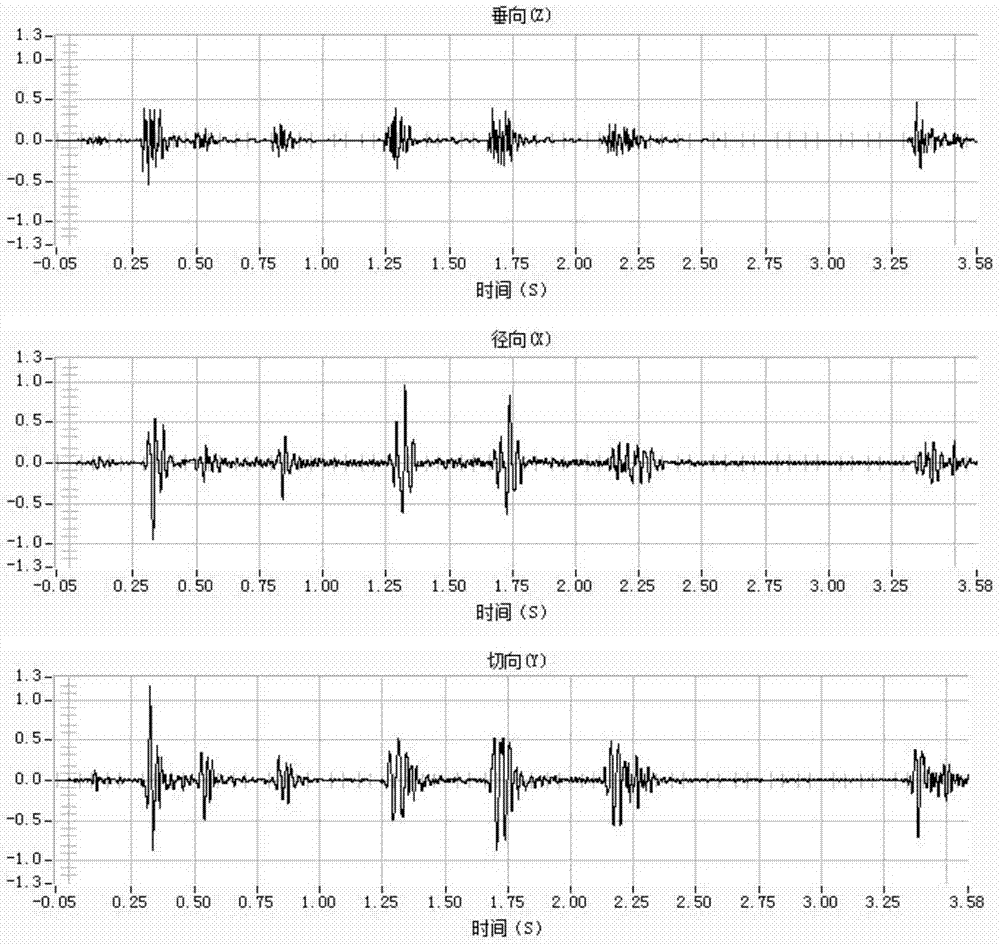

[0024] This blasting method was used in the shallow buried section of the T9 Tunnel of the Georgian Modern Railway. The actual construction proved that the blasting method can greatly reduce the blasting impact, meet the requirements of the blasting code, and create conditions for the smooth construction of the longest single-track tunnel of the Georgian Modernization Project Control Engineering. At the same time, it has demonstrated the level of tunnel construction technology to international friends, and has been recognized by the owners and supervisors, creating tens of millions of benefits for the company; therefore, here is an example of the shallow buried section of the T9 tunnel of the Georgian modern railway. A blasting method for a shallow buried section of a tunnel, the steps of which are as follows:

[0025] Step 1. Evaluate the houses around the blast site;

[0026] The west entrance of the tunnel is located in the middle and low mountainous area, with large terrai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com