Detection tool structure of rear bumper assembly

A bumper and assembly technology, applied in the field of auto parts inspection tool structure, can solve the problems of complex process, large error, low efficiency, etc., and achieve the effect of simple inspection process, high accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

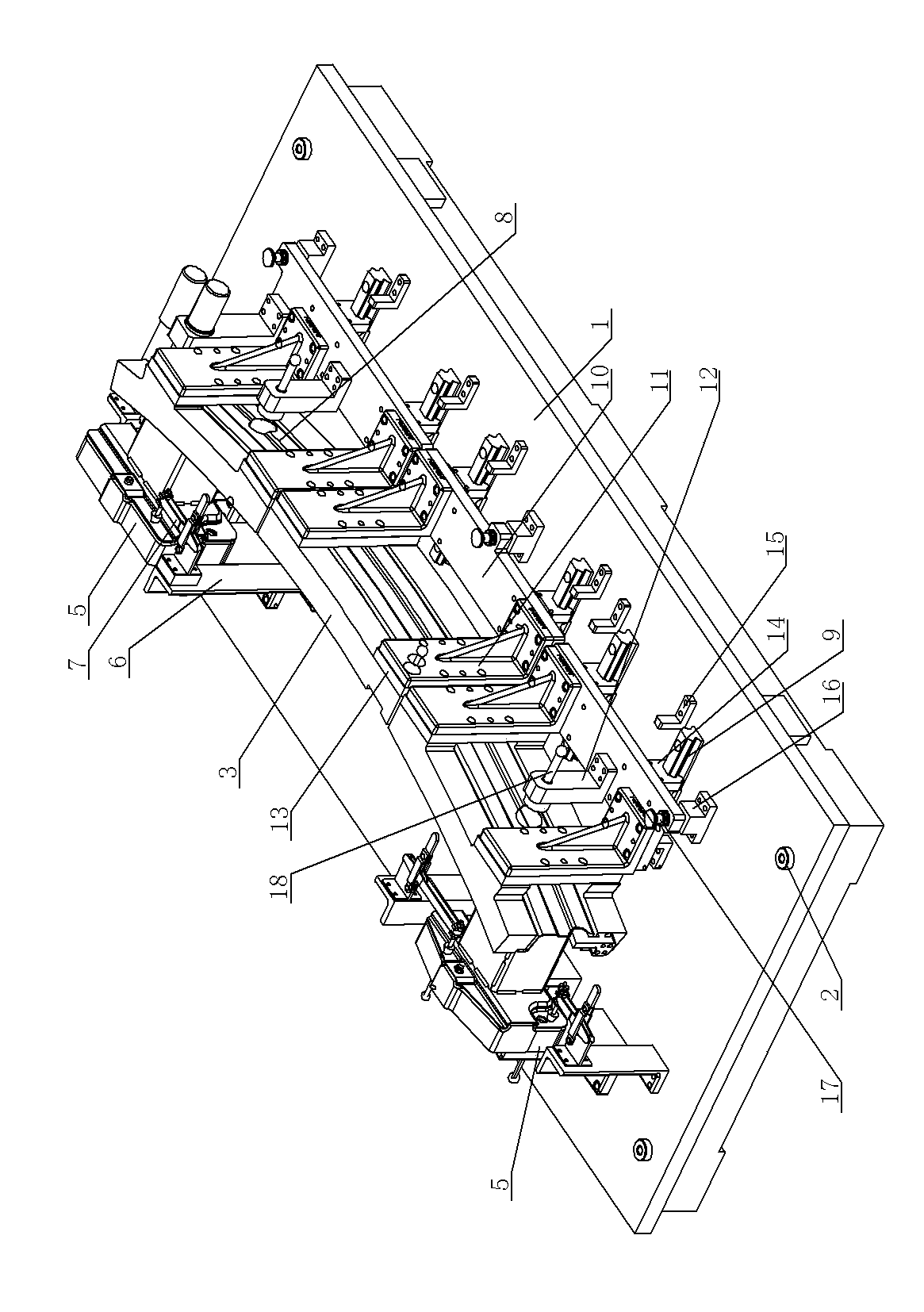

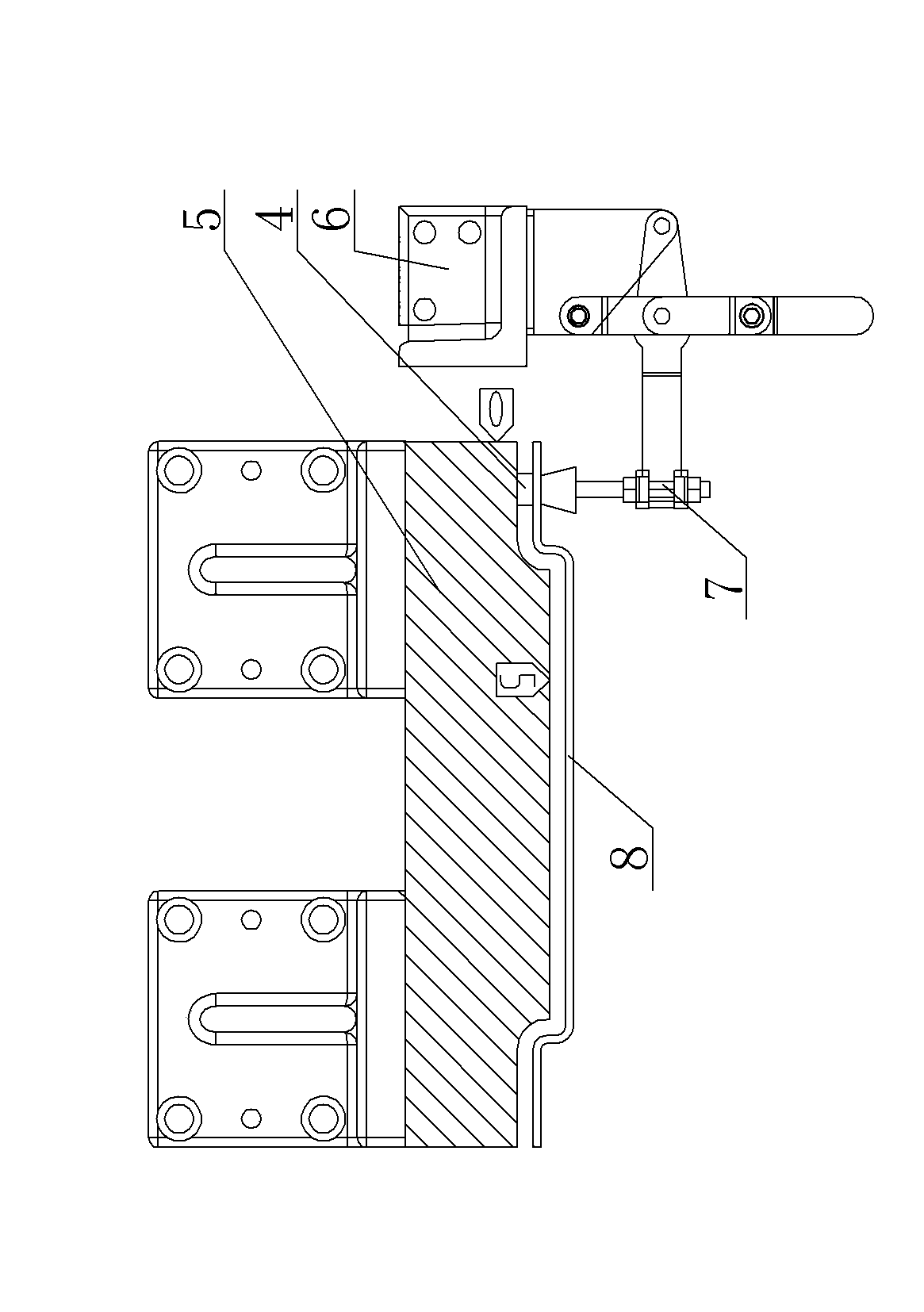

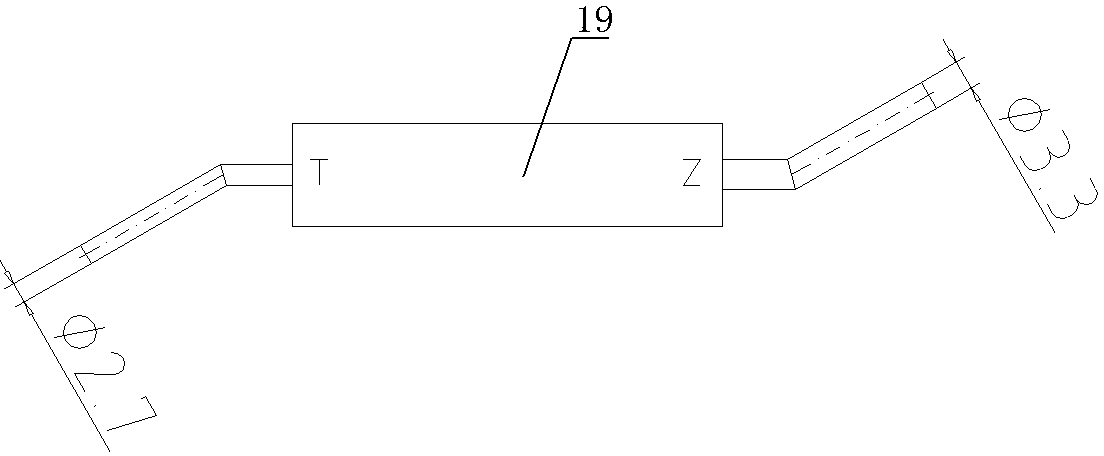

[0009] See Figure 1 ~ Figure 3 , which includes a bottom plate 1, three corner positions of the bottom plate 1 are respectively provided with reference sleeves 2, and the simulation block 3 is supported on the upper end surface of the bottom plate 1. Protrusion 4, the rear of the two ends of the outer facade of simulation block 3 is provided with positioning simulation block 5, and the both sides of positioning simulation block 5 protrudes with positioning projection 4, and the thickness of positioning projection 4 is 5mm, and positioning simulation block 5 The corresponding bottom plate 1 on both sides of the positioning protrusion 4 is fastened with a press clamp bracket 6, and a press clamp 7 is arranged on the vertical surface of the press clamp bracket 6, and the press clamp 7 is pressed on the rear bumper assembly under the detection state. The outer surfaces of the two ends of 8, the overall inner surface of the center of the rear bumper assembly 8 in the detection sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com