Deep Hole Chip Blowing Air Gun

An air gun and deep hole technology, which is applied in the direction of spraying device, liquid spraying device, spraying device, etc., can solve the problem of inability to complete blowing debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

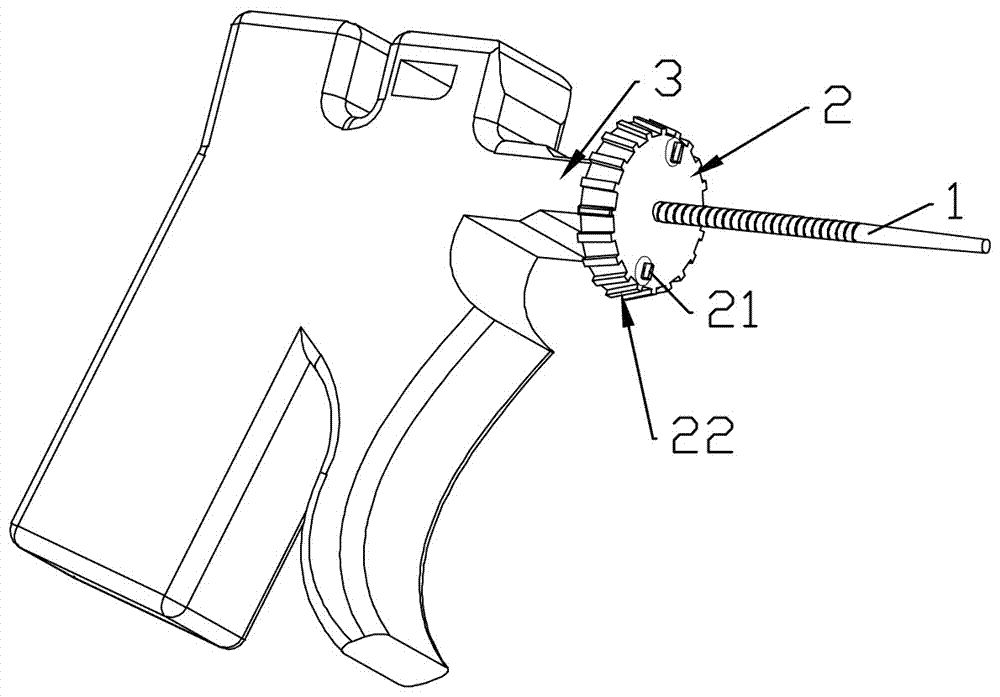

[0008] combined with figure 1 As shown, the body of the deep hole chip blowing air gun is provided with an air nozzle 3, wherein the air nozzle 3 is provided with a mounting head 2, and the mounting head 2 is provided with a variable-length gas nozzle rod 1. The installation head 2 is rotatably connected to the air spray head 3, and the air nozzle rod 1 is screwed to the installation head 2. Anti-slip protrusions 22 are uniformly distributed on the side wall of the mounting head 2 . The installation head 2 is provided with an installation groove 21, and the installation groove 21 is provided with a sealing cover 21. The air spray head 3 is provided with an air guide port opposite to the direction of spraying, and the installation head 2 is fixedly connected with an impeller that matches the two air guide ports. The direction of gas sprayed from the two gas guide ports is opposite to the switch of the gas guide port, and the high-pressure gas is sprayed to realize the forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com