V-shaped part pin expanding and shrinking shaping device

A technology for shaping devices and parts, which is applied in the field of V-shaped part pin expansion and shaping devices, which can solve the problems of low operation efficiency and difficulty in reducing the missed inspection rate, so as to achieve the effect of improving operation efficiency and avoiding missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

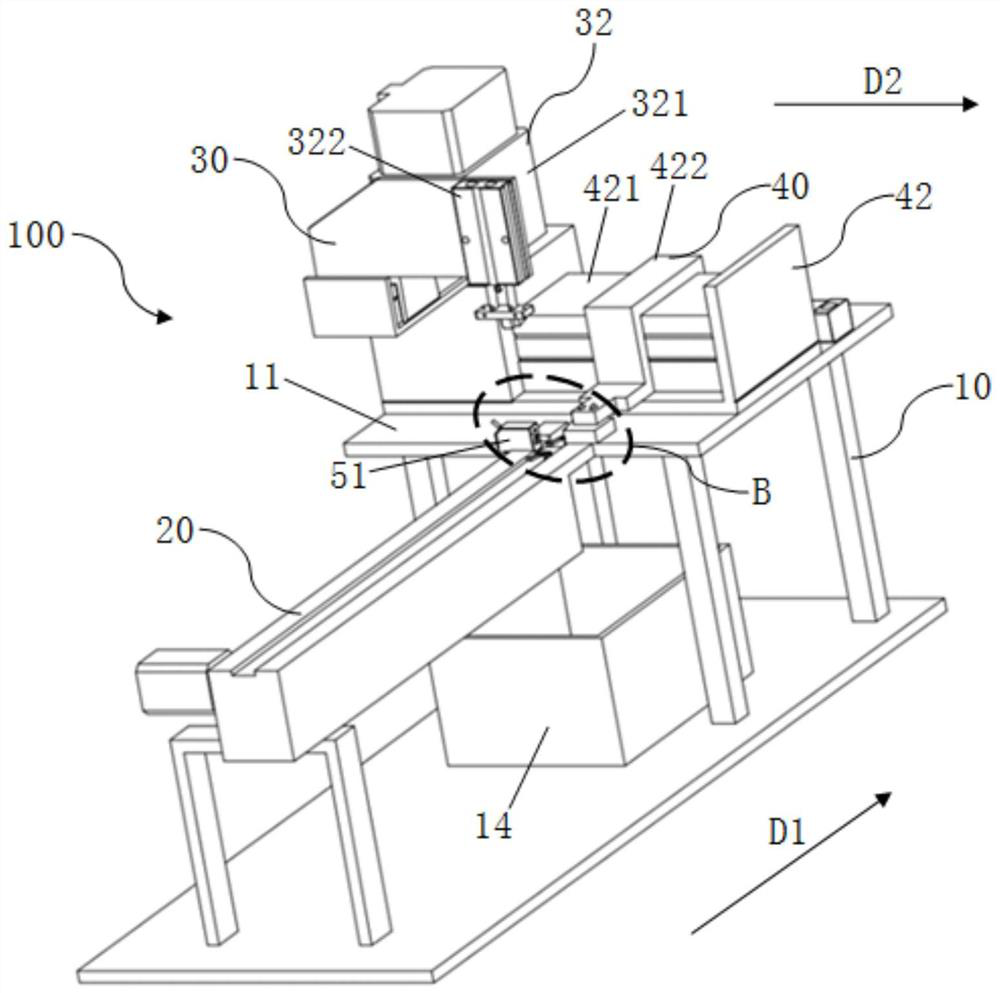

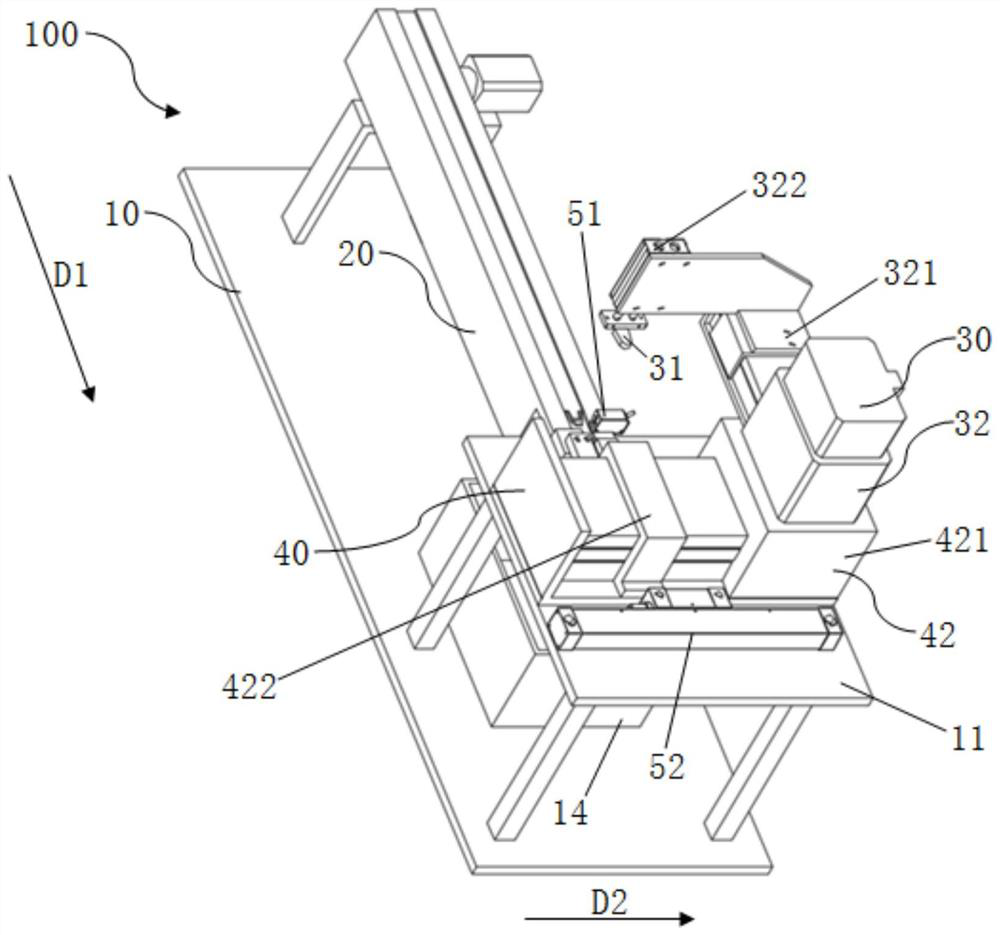

[0025] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following embodiments will specifically elaborate the V-shaped part pin expansion and shaping device of the present invention in conjunction with the accompanying drawings. It should be noted that for these implementations The description of the method is used to help the understanding of the present invention, but does not constitute a limitation to the present invention.

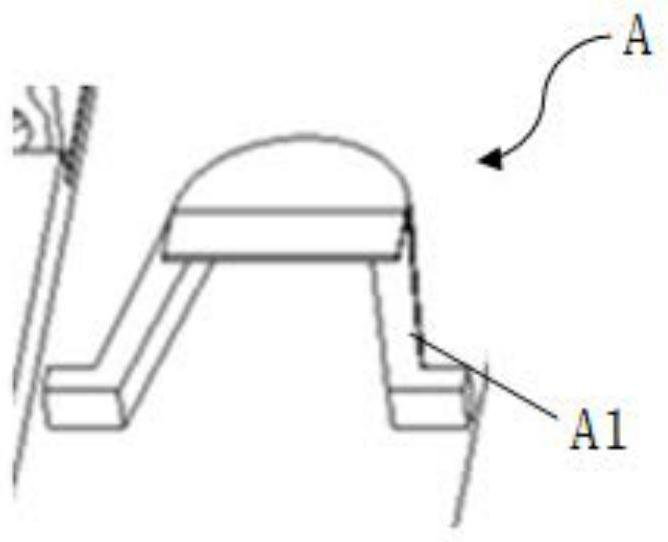

[0026] Such as figure 1 As shown, the V-shaped part pin expansion and shaping device in this embodiment is used to adjust the distance between the free ends of the two equal-length part pins A1 of the V-shaped part A, and the two part pins A1 are symmetrical, etc. Long, the opening formed by the free ends of the two part pins A1 is taken as a V-shaped opening, and the spacing is taken as the distance of the V-shaped opening. The minimum distance of the V-shaped opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com