Sprue bush demoulding and installing structure

A technology of installation structure and sprue bushing, which is applied in the field of sprue bushing demoulding installation structure, and can solve problems such as easy installation danger and complicated mold installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

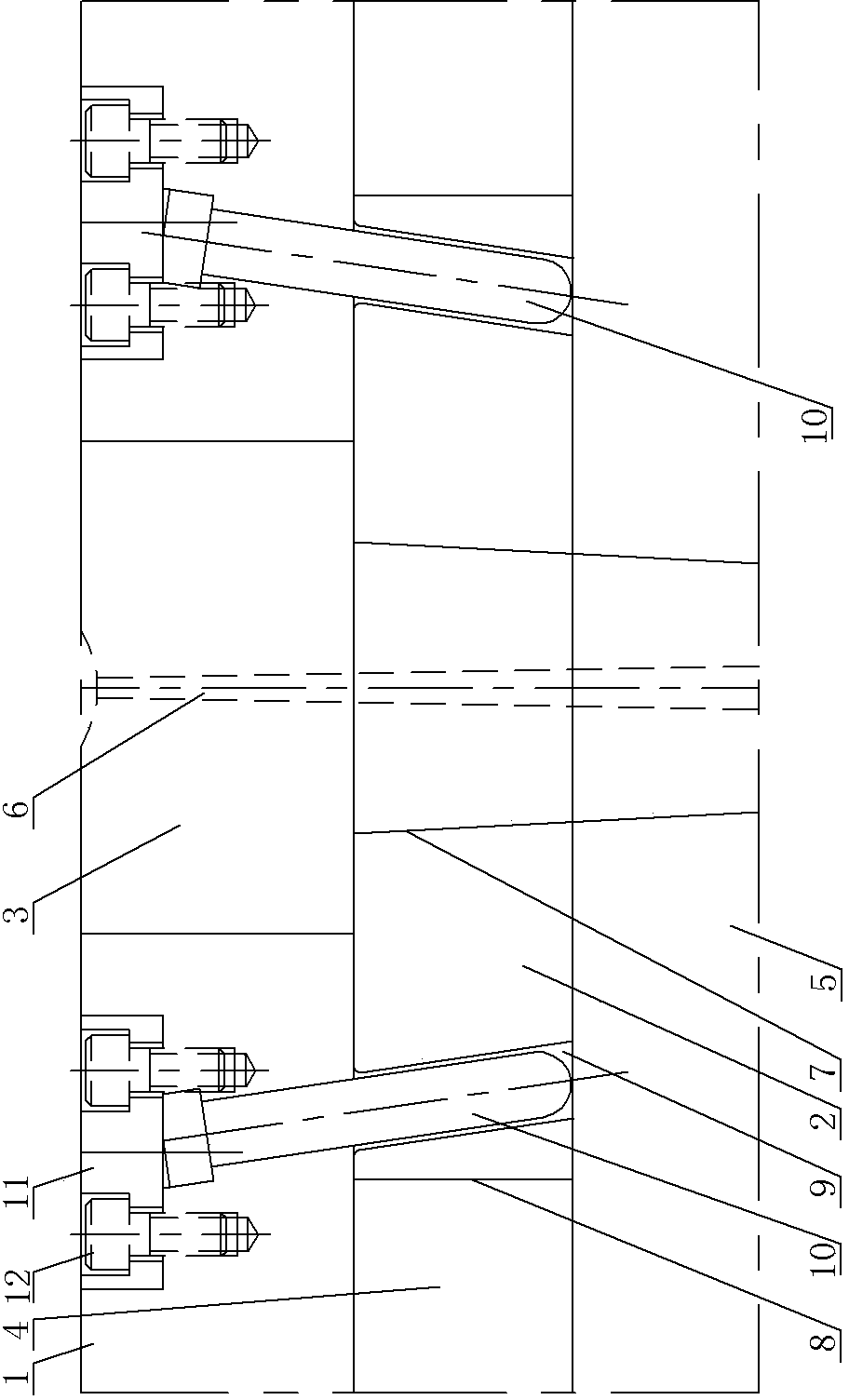

[0007] See figure 1 , which includes a sprue plate 1, a backing plate 2, a sprue sleeve 3, a plate A 4, and a front mold 5. A runner 6 is arranged in the sprue sleeve 3, and the runner 6 runs through the A plate 4, the front mold 5, and the gate The upper part of the sleeve 3 is located in the installation cavity of the sprue plate 1, the closing structure of the lower part of the gate sleeve 3 is located in the closing installation cavity 7 of the backing plate 2, the backing plate 2 is located in the backing plate installation cavity 8 of the A plate 4, and the backing plate 2 Supported on the front mold 5, the two sides of the backing plate 2 are respectively provided with inclined guide grooves 9 that are closed inwardly from top to bottom, and two inclined guide columns 10 respectively penetrate through the sprue plate 1 and then are inserted into the corresponding inclined guides. Groove 9, the top of inclined guide post 10 is press-fitted with cover plate 11, and screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com