Patents

Literature

114results about How to "Avoid hot and cold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Side-blown depletion copper smelting slag production method

ActiveCN106367605ALow costImprove heat transfer performanceProcess efficiency improvementShaft furnaceMelting tankMass ratio

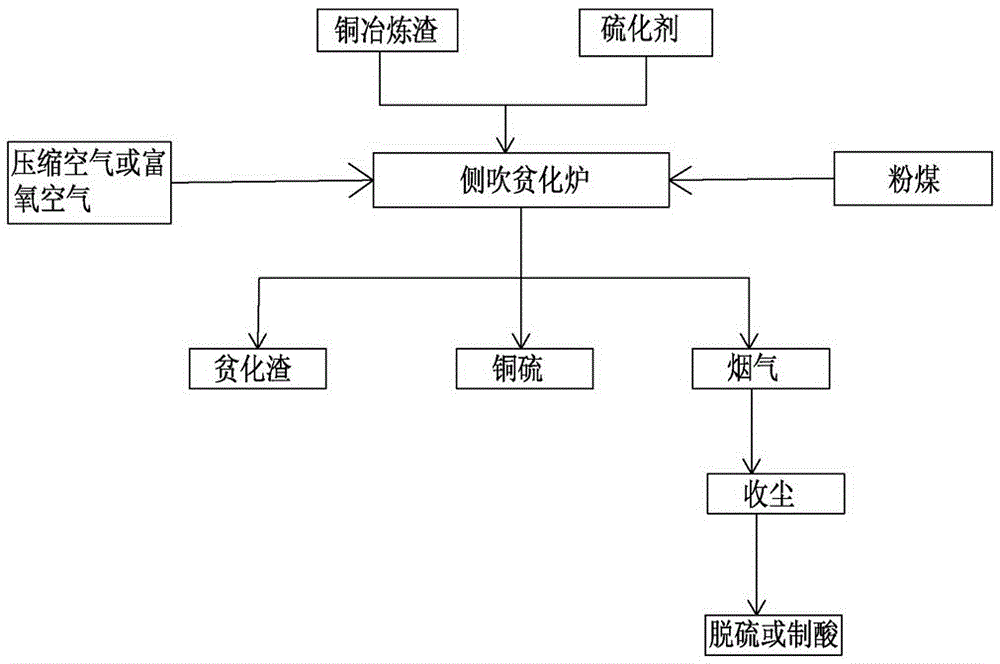

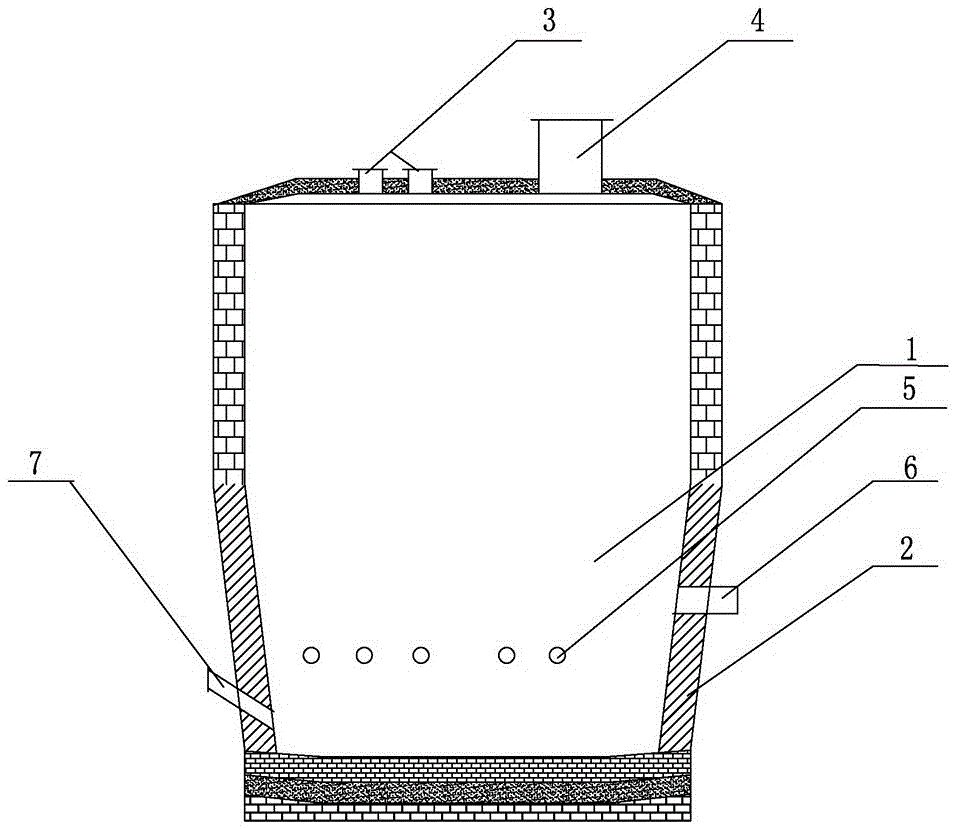

The invention belongs to the technical field of copper smelting, and particularly relates to a side-blown depletion copper smelting slag production method. The side-blown depletion copper smelting slag production method includes the following steps that a vulcanizing agent and copper smelting slag are added into a side-blown depletion furnace from a feeding opening, wherein the mass ratio of the copper smelting slag to the vulcanizing agent is 100:0-15, and the copper smelting slag is molten copper smelting slag or solid copper smelting slag; fuel is jetted into a molten pool through a spraying gun opening formed in the side portion of the depletion furnace, wherein the fuel is a mixture of pulverized coal and compressed air or a mixture of pulverized coal and oxygen-enriched air, the fuel is used for achieving stirring, heat transferring and medium transferring in the depletion furnace, the temperature in the furnace ranges from 1100 DEG C to 1300 DEG C, the pressure ranges from 0.1 Mpa to 0.4 Mpa, and the depth of the molten pool ranges from 800 mm to 2000 mm; copper matte is placed in through a copper matte opening, and depletion slag is discharged through a slag outlet; and smoke enters a gas desulfurization system after being subject to cooling and dust collection, is subject to desulfuration and is released after the standard is met. The process has the beneficial effects of saving investment, and being low in energy consumption, low in cost, high in automatic degree, environment-friendly and the like.

Owner:HENAN YUGUANG GOLD & LEAD

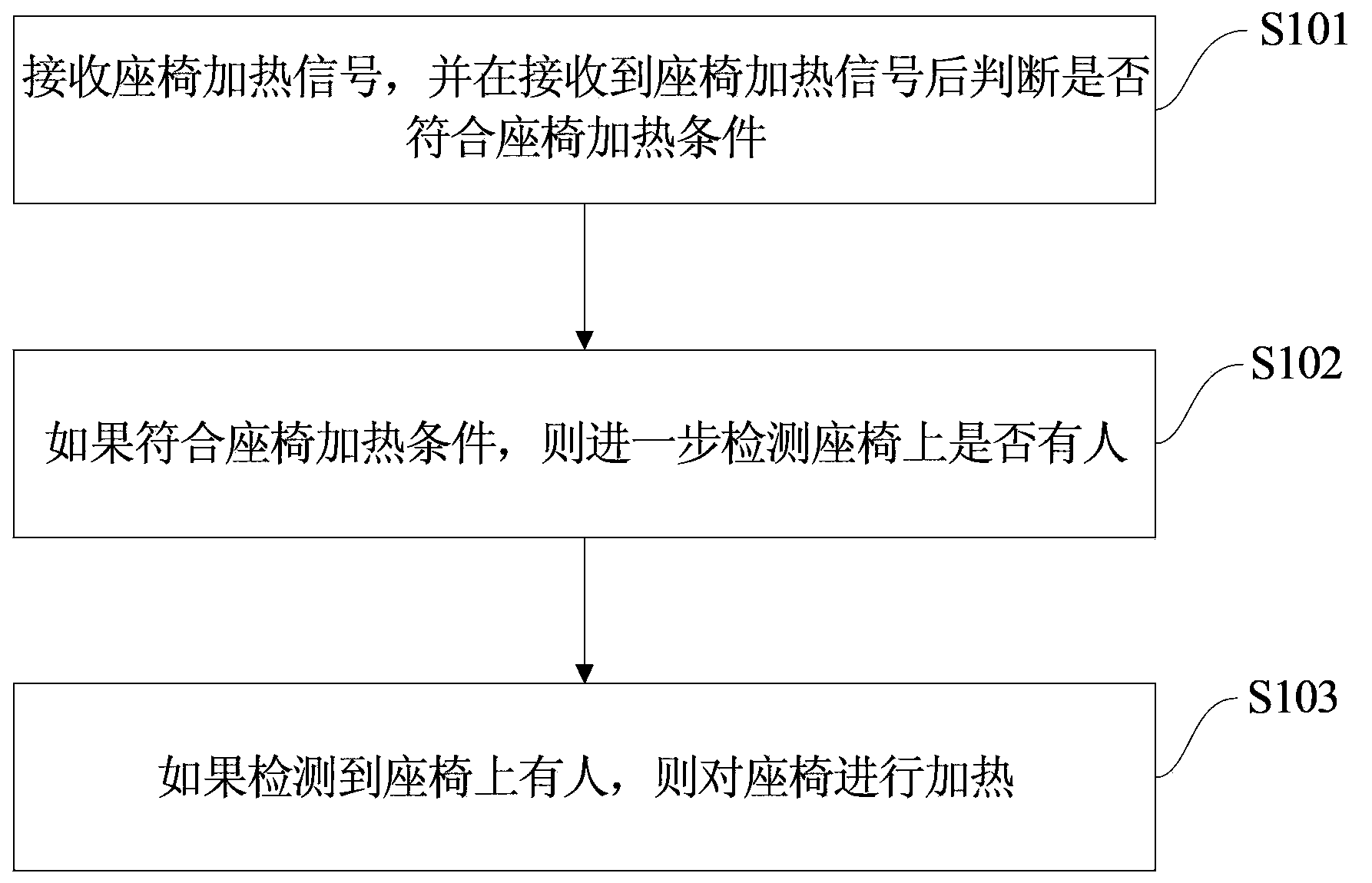

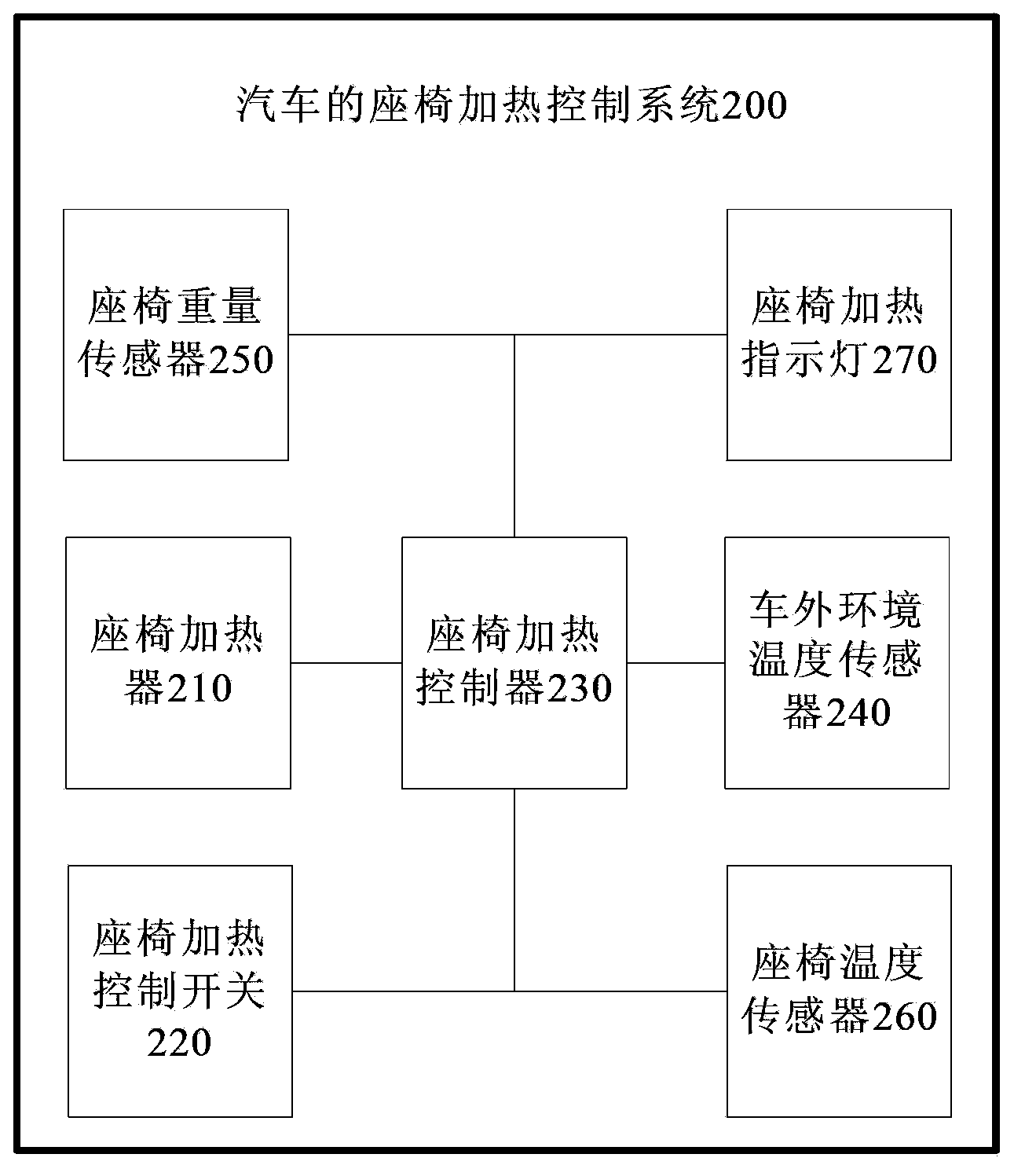

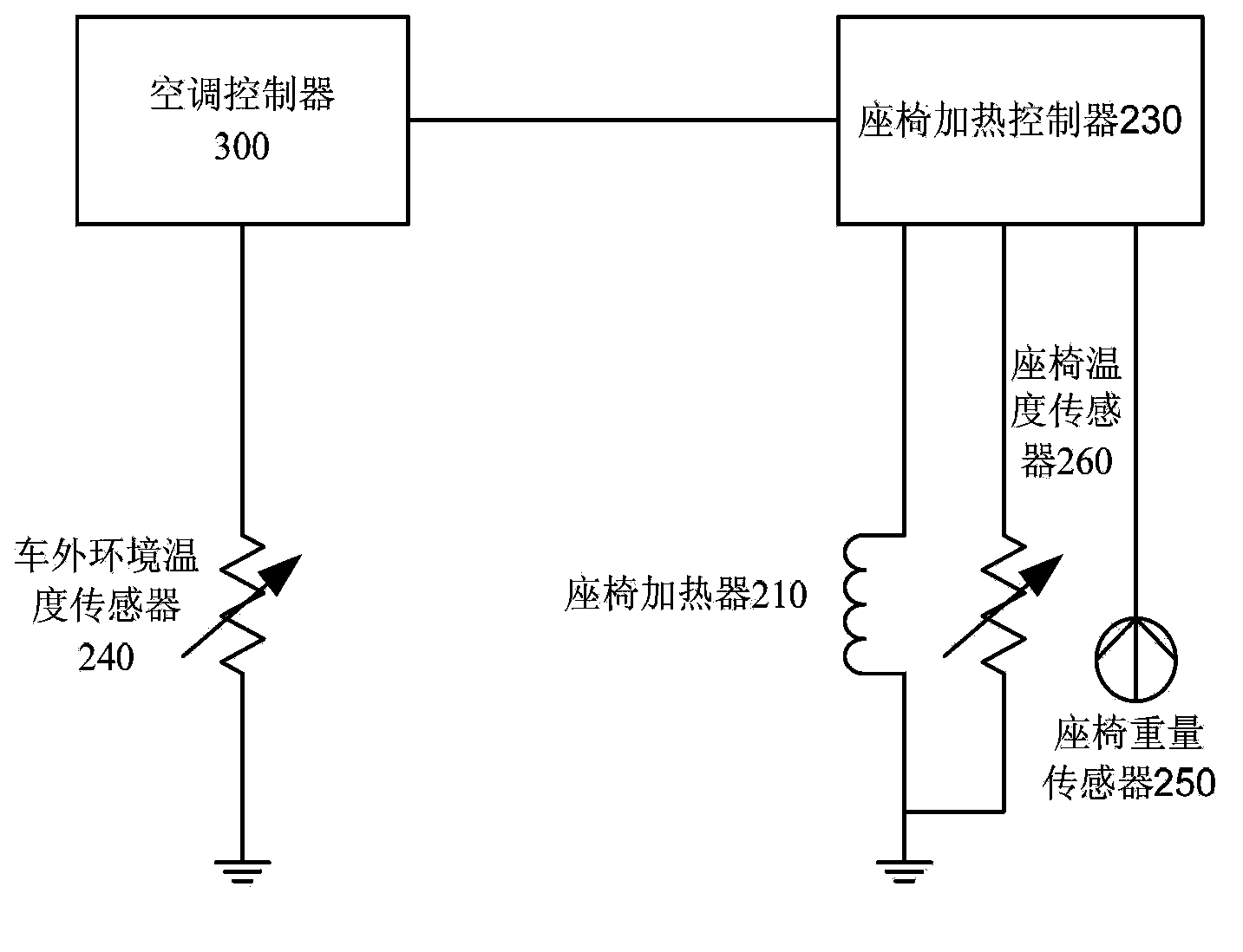

Seat heating control method and system for automobile and automobile

InactiveCN104325911APrevent openingAvoid power lossSeat heating/ventillating devicesOptical signallingElectricitySupply management

Owner:BEIQI FOTON MOTOR CO LTD

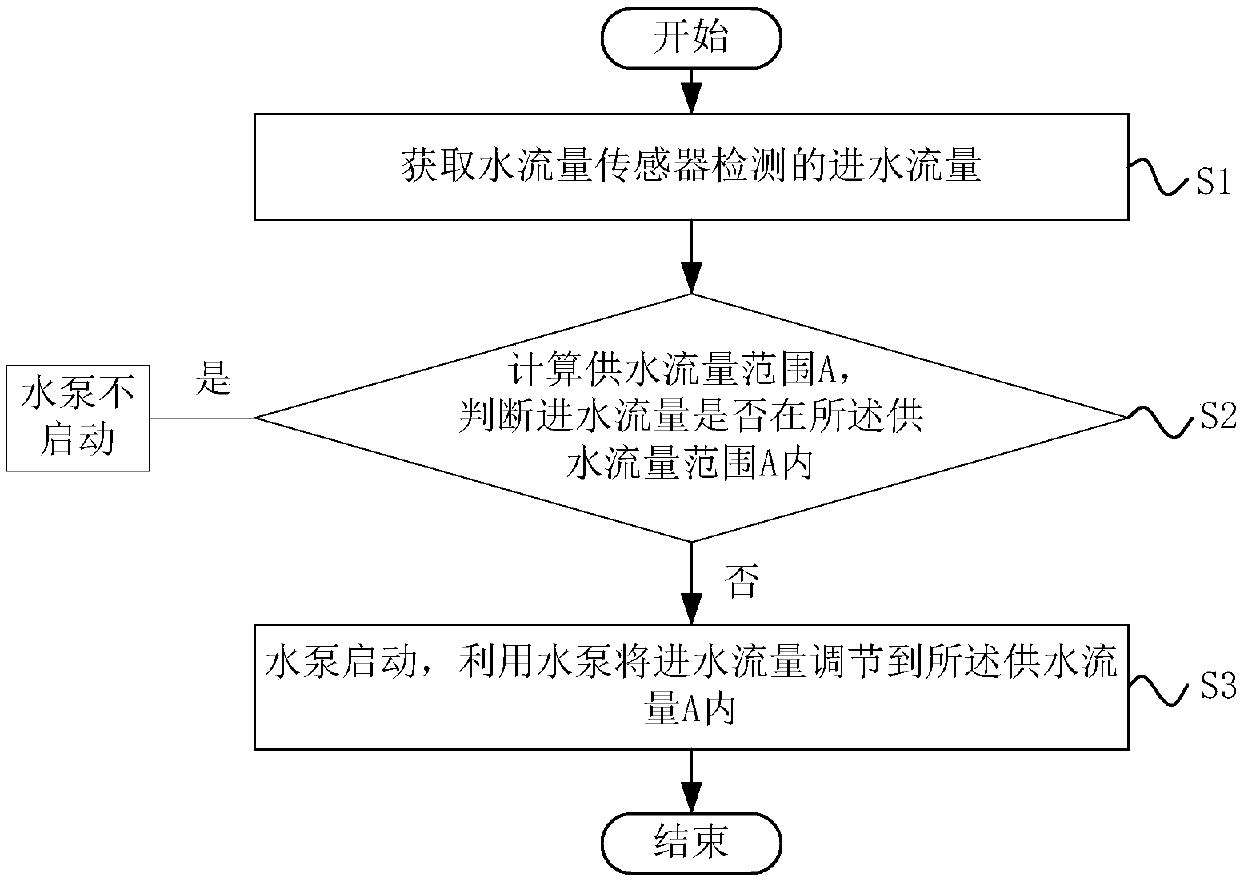

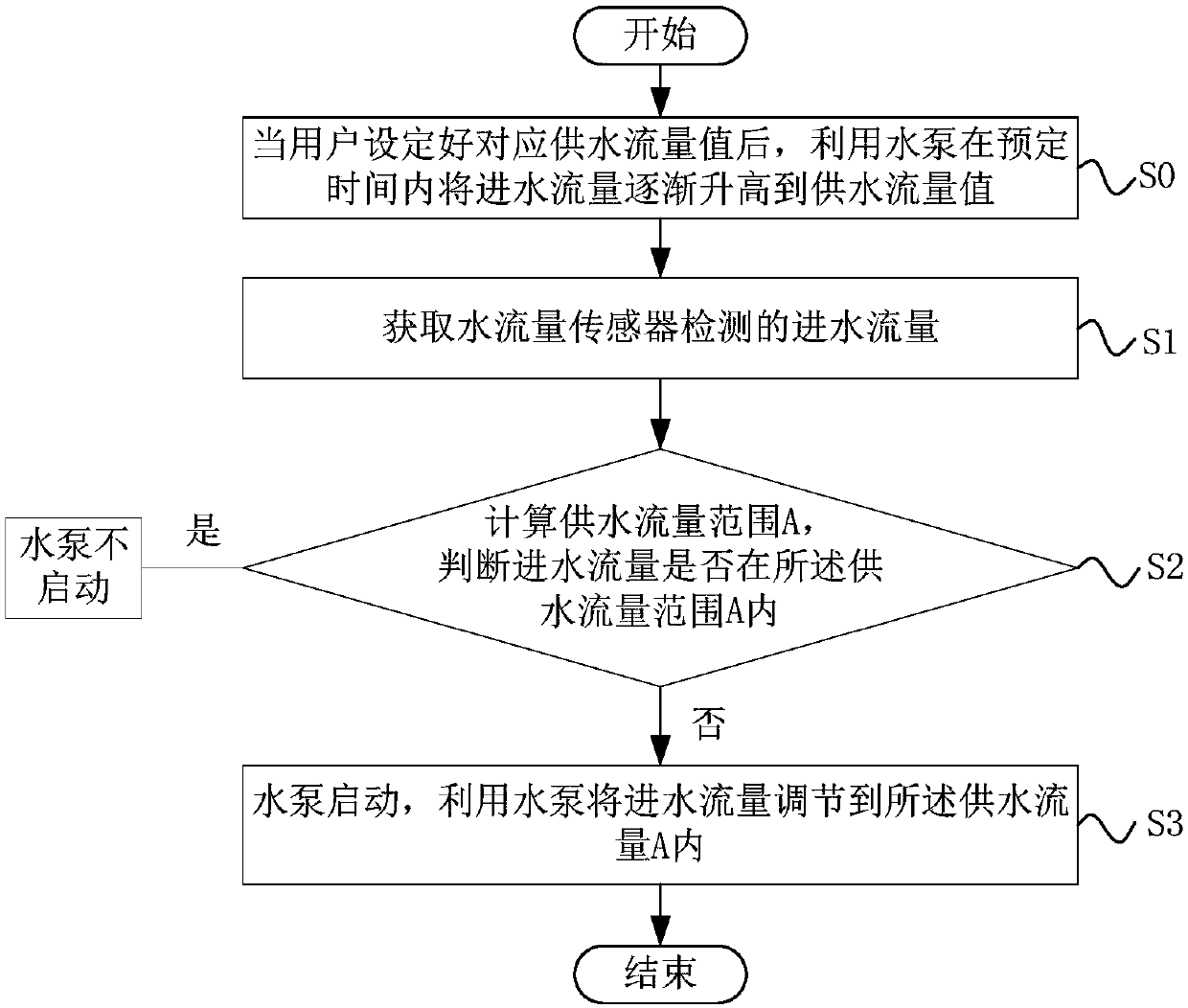

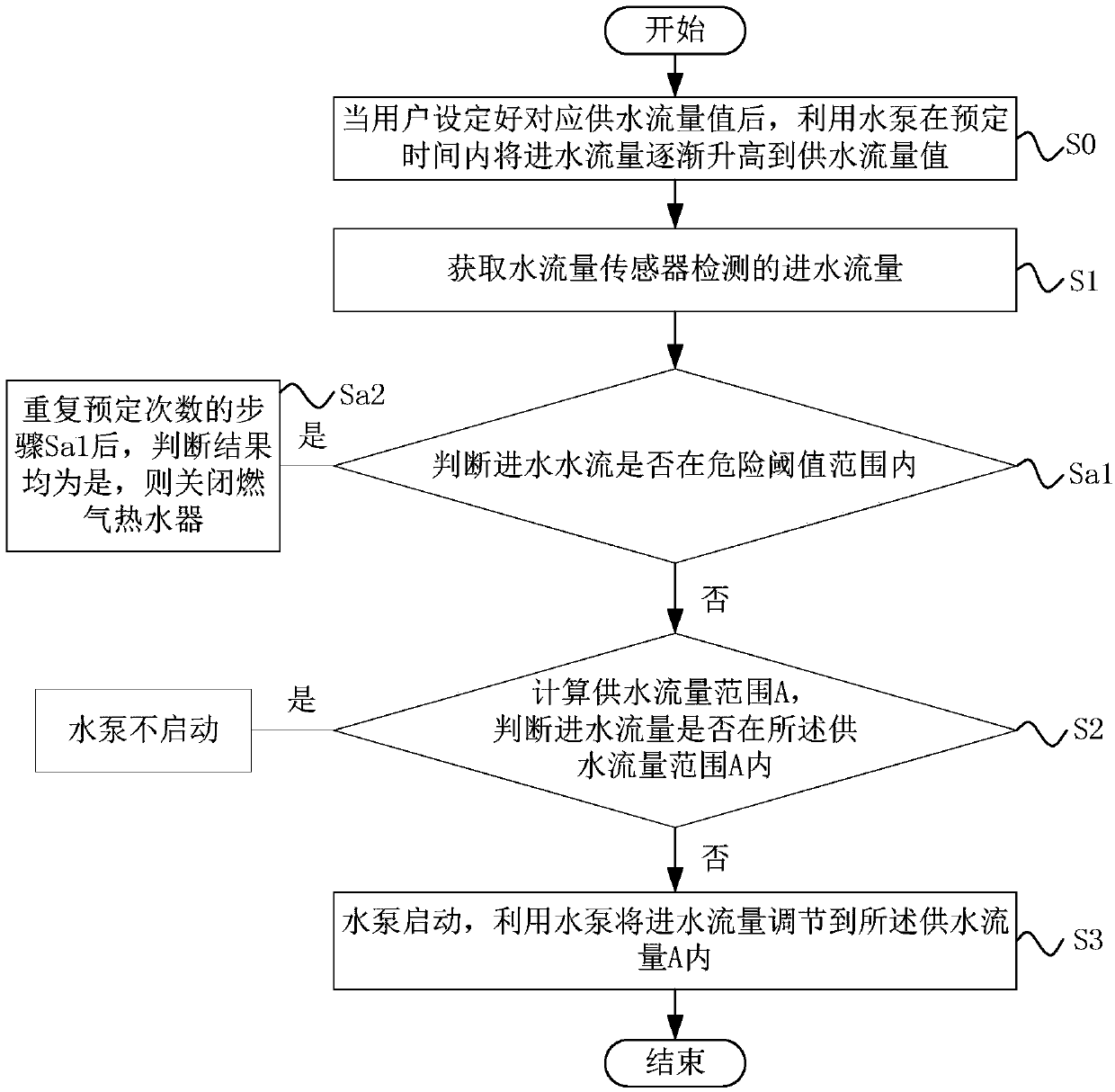

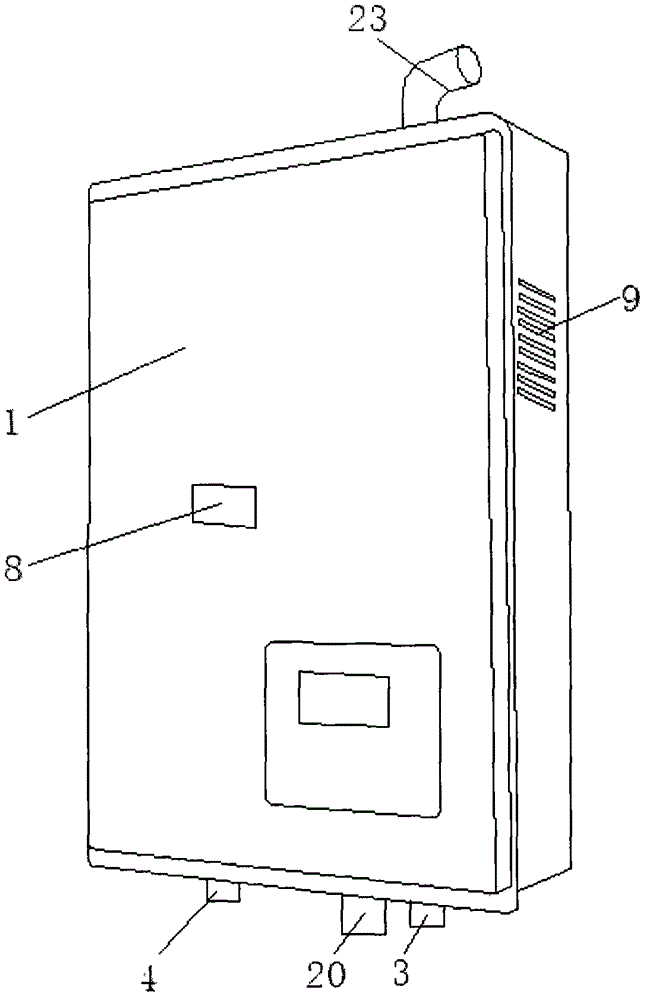

Water flow control method and gas water heater

ActiveCN107917534AMeet the needs of water temperatureImprove usage requirementsFluid heatersWater flowEngineering

The invention discloses a water flow control method and a gas water heater, wherein the water flow control method comprises the steps that Step 1, inlet flow detected by a water flow sensor is obtained; Step 2, a water supply flow range A is calculated to determine whether the inlet flow is within the water supply flow range A; if a judgment result is yes, a water pump is not started; if the judgment result is no, process proceeds to Step 3; Step 3, the water pump is started, and the inlet flow is adjusted to the water supply flow range A by the water pump. According to the gas water heater, the inlet flow is adjusted to the water supply flow range required by users through the water pump, so that user requirements of a water temperature can be fulfilled when water flows out of a water outlet of the gas water heater regardless of a water pressure at a water inlet, thereby avoiding the problem that the water temperature at the water outlet of the gas water heater always changes along with the inlet flow and further increasing the usage requirements of users.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +2

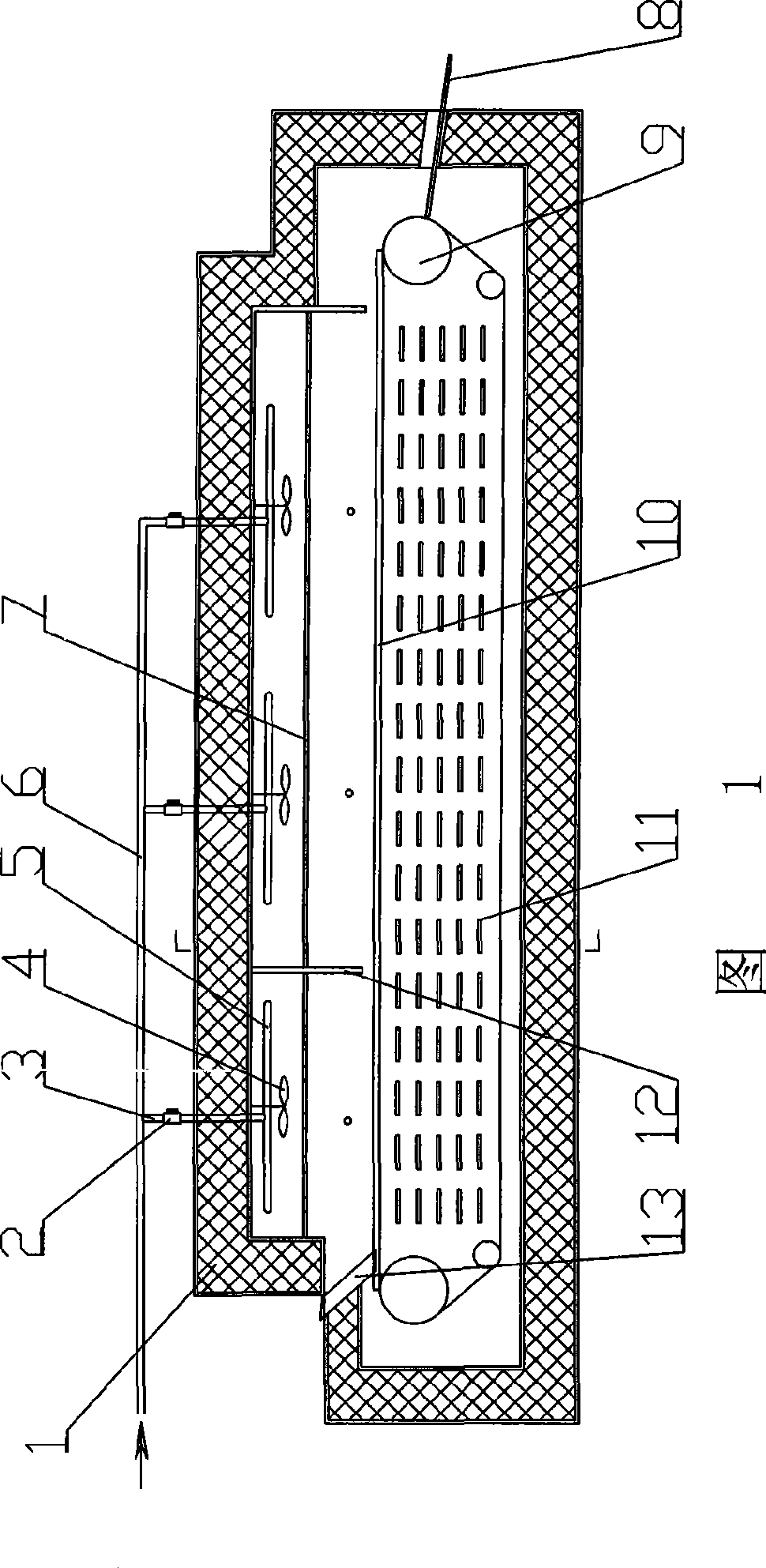

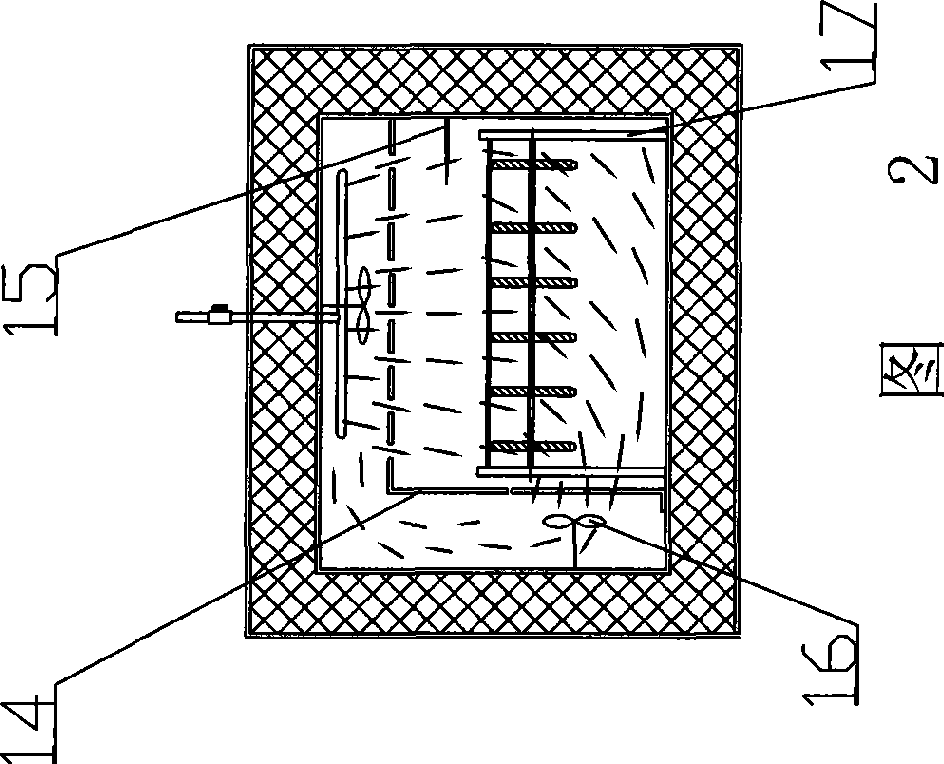

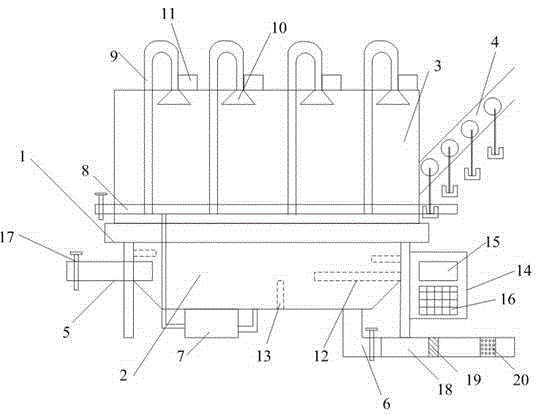

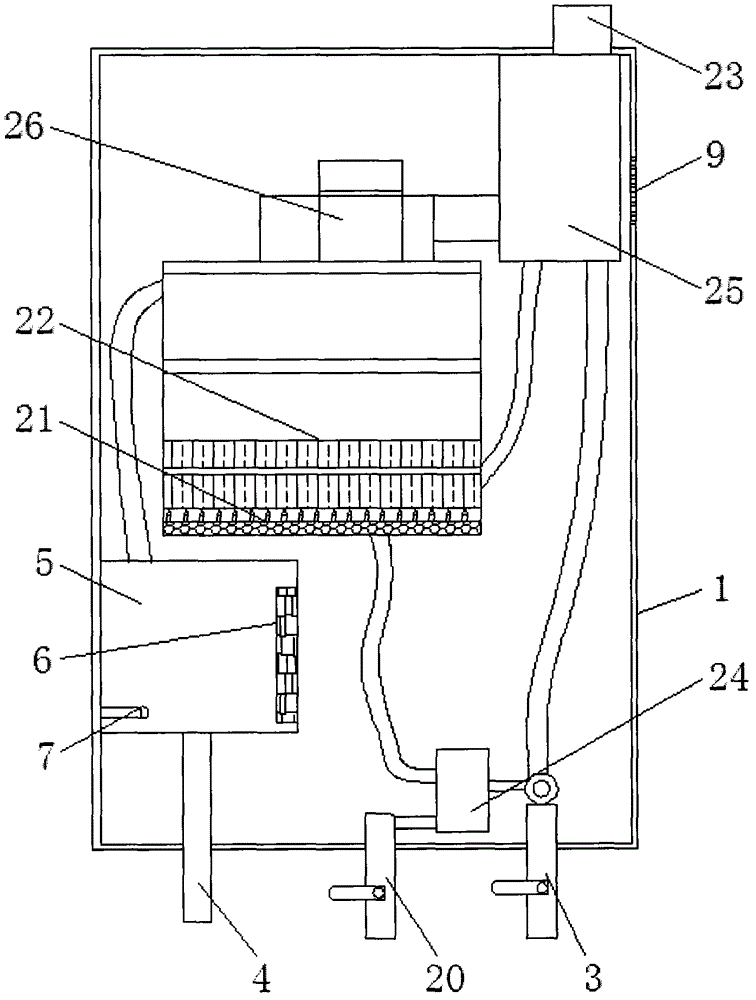

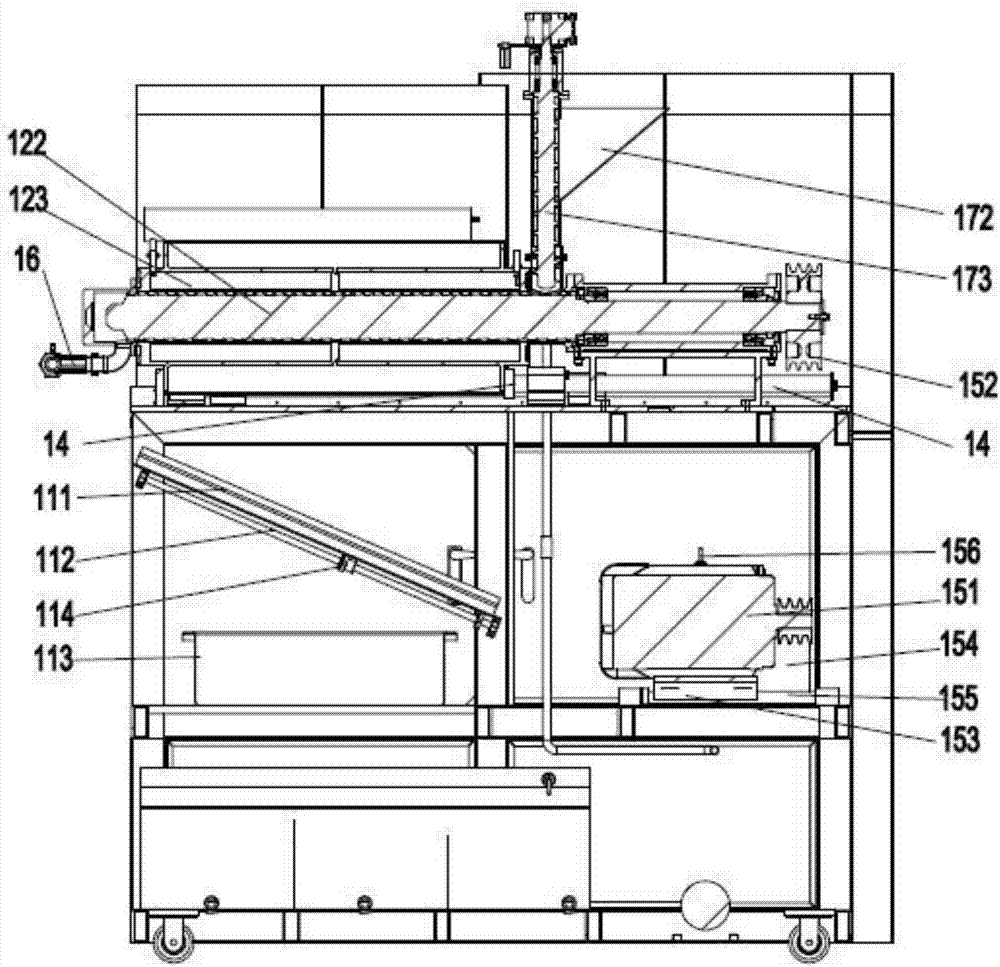

Conveyer belt type cryogenic treatment apparatus

A conveyer belt type sub-zero treatment device comprises a heat insulation box body, a liquid nitrogen distributing and sprinkling device and an upper blower, wherein, the liquid nitrogen distributing and sprinkling device is connected with a liquid nitrogen tank, a liquid spraying pipe of the liquid nitrogen distributing and sprinkling device extends into the heat insulation box body, the upper blower is arranged at the upper part of the inner cavity of the heat insulation box body which is provided with a conveyer belt, the front end and the rear end of the conveyer belt are respectively sheathed on a drive wheel which is connected with a drive unit, the front part of the heat insulation box body is provided with a feeding guide plate, and the rear part of the heat insulation box body is provided with an outlet vibrating feed plate, an upper mesh baffle is respectively arranged under the liquid spraying pipe of the liquid nitrogen distributing and sprinkling device and the upper blower, a side mesh baffle is arranged on the side of the conveyer belt, and the lower part of the side mesh baffle is provided with side meshes which are arranged under the upper conveyer belt. The sub-zero treatment device can be applicable to conveyer belt type production line operation.

Owner:ZHEJIANG UNIV OF TECH

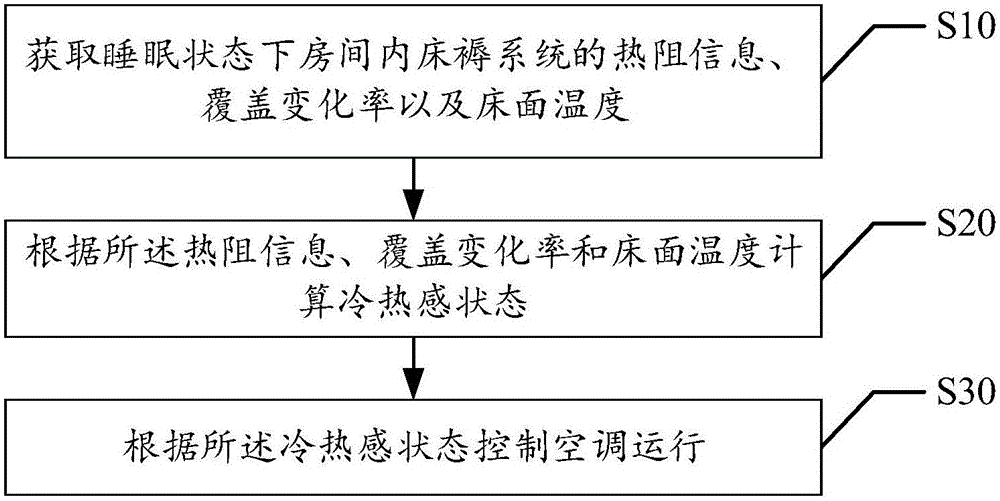

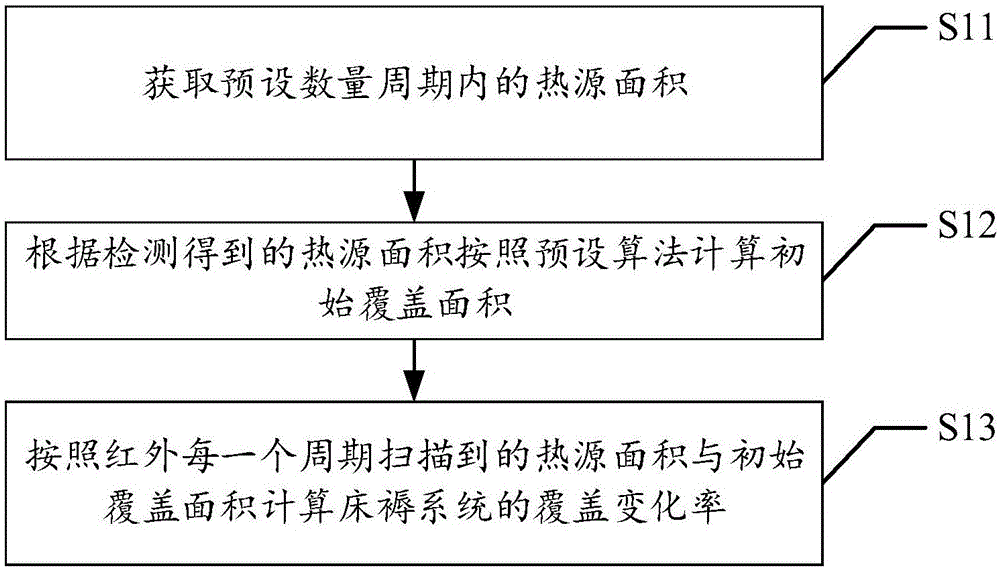

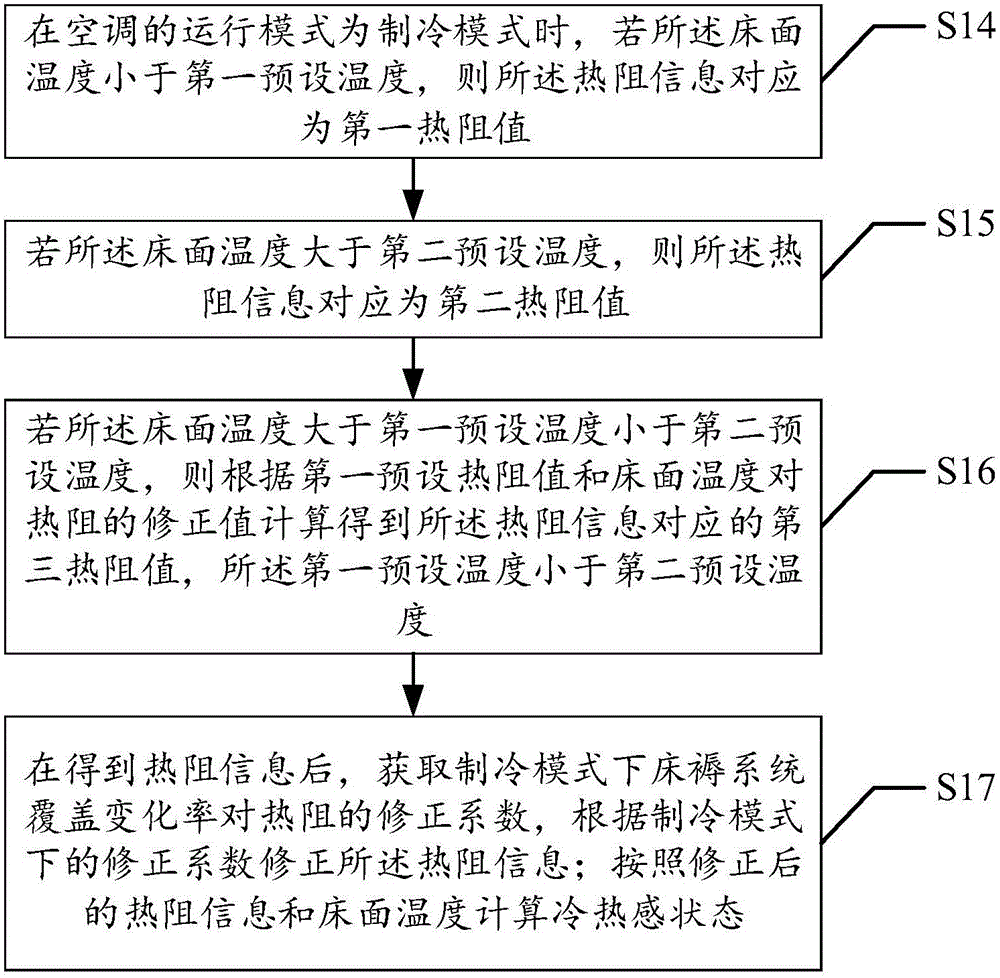

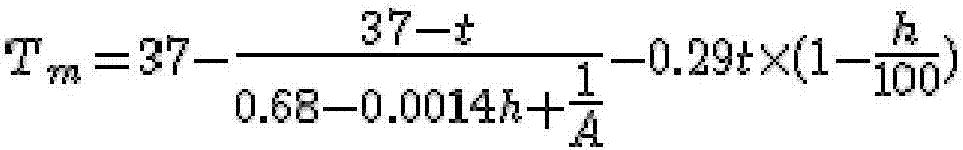

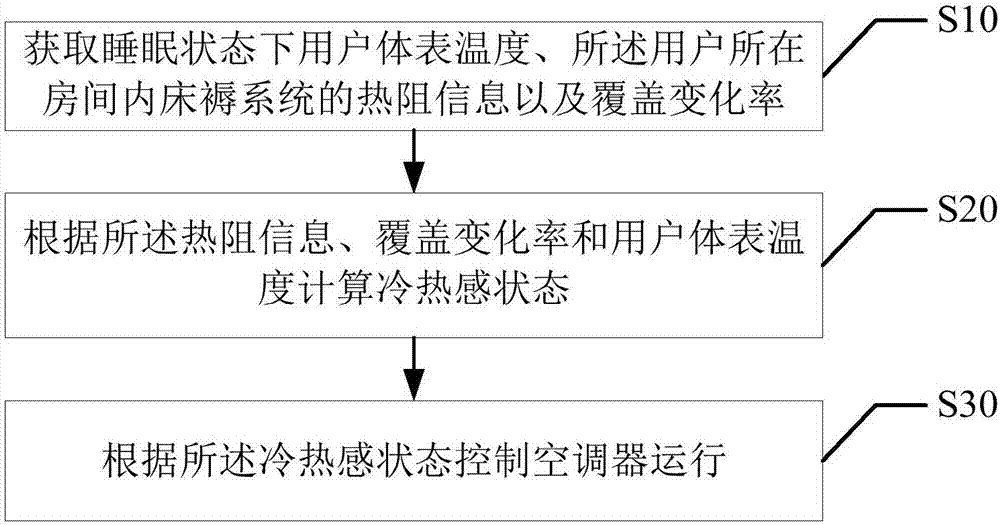

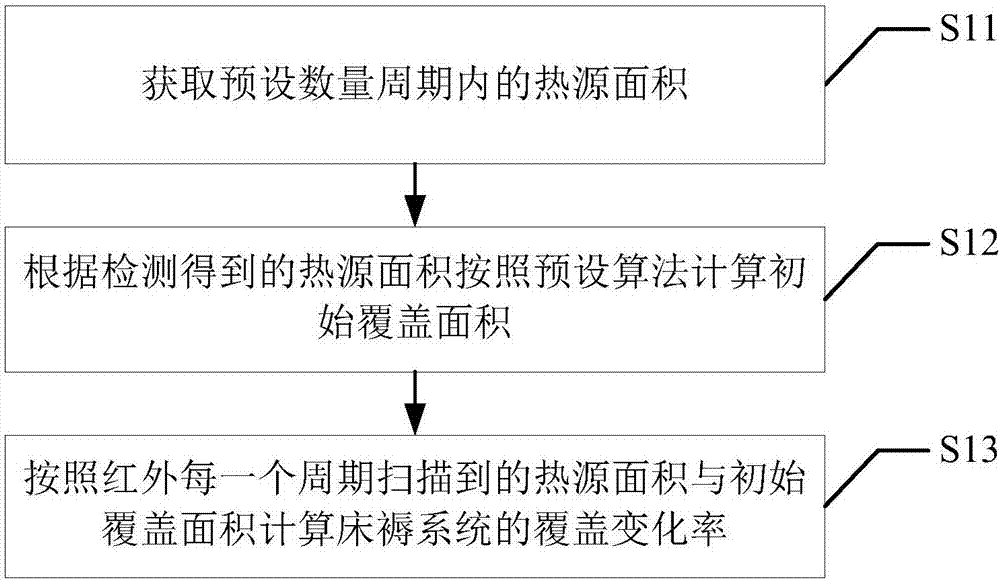

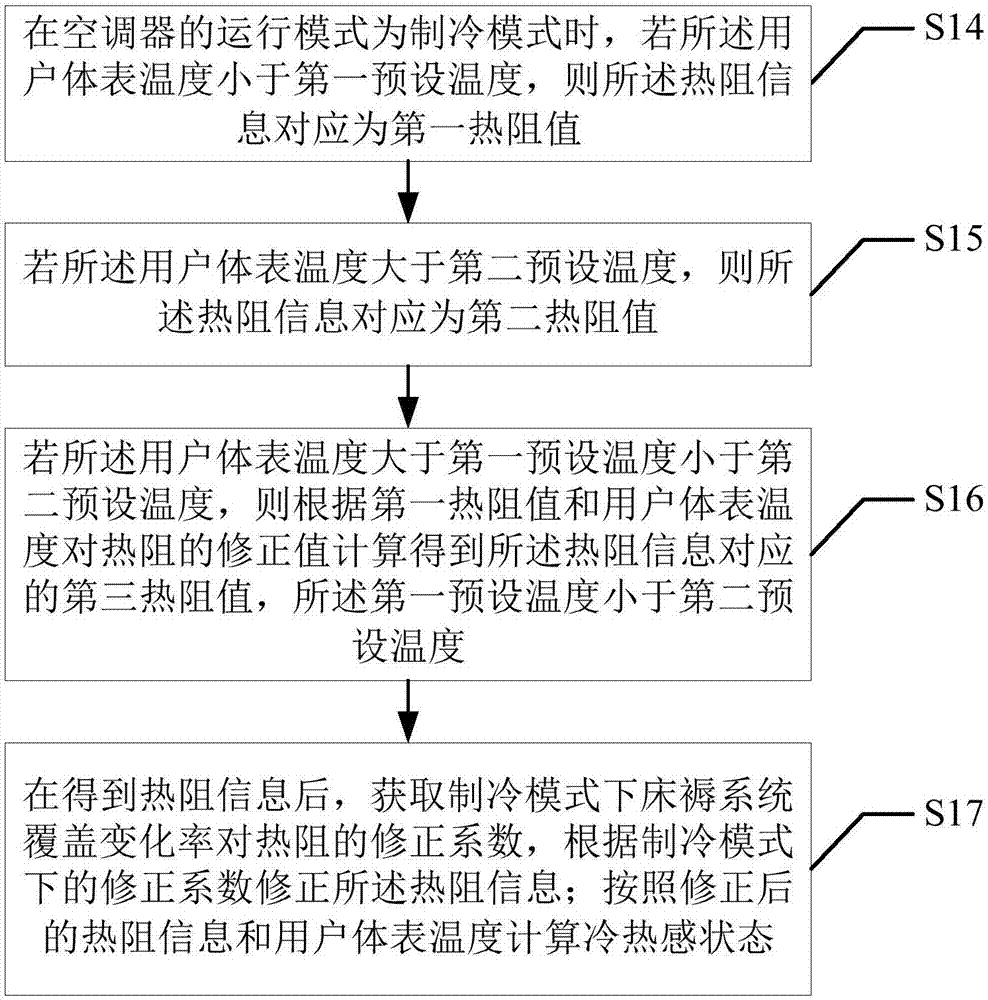

Control method and device for air conditioner

ActiveCN106225161AImprove accuracyImprove comfortMechanical apparatusSpace heating and ventilation safety systemsSleep stateHeat resistance

The invention discloses a control method for an air conditioner. The control method for the air conditioner comprises the steps of obtaining the heat resistance information, coverage change rate and bed surface temperature of a sleeping pad system in a room in a sleep state, working out the cold and hot feeling status according to the heat resistance information, coverage change rate and bed surface temperature, and controlling operation of the air conditioner according to the cold and hot feeling status. The invention further discloses a control device for the air conditioner. Through the control method and device for the air conditioner, the cold and hot feeling status of a user is accurately provided, the control accuracy of the air conditioner is further improved, and the comfort level of the air conditioner is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

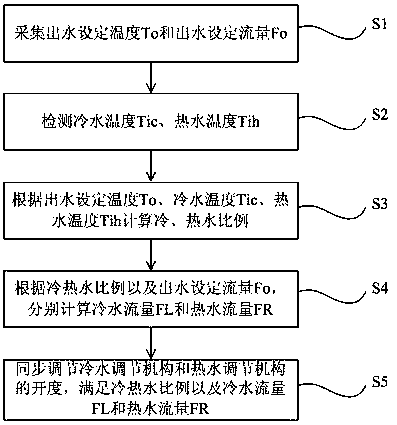

Constant-temperature constant-flow water outlet control method and constant-temperature constant-flow valve

InactiveCN108799610AEasy to controlAvoid hot and coldOperating means/releasing devices for valvesWater flowThermal water

The invention discloses a constant-temperature constant-flow water outlet control method and a constant-temperature constant-flow valve. The constant-temperature constant-flow water outlet control method comprises the following steps that (1) the water outlet set temperature To and the water outlet set flow Fo are collected; (2) the cold water temperature Tic and the hot water temperature Tih aredetected; (3) the proportion of cold water and hot water is calculated according to the water outlet set temperature To, the cold water temperature Tic and the hot water temperature Tih; (4) the coldwater flow FL and the hot water flow FR are calculated according to the proportion of the cold water and the hot water and the water outlet set flow Fo correspondingly; and (5) the opening degree of acold water adjusting mechanism and the opening degree of a hot water adjusting mechanism are synchronously adjusted, so that the requirements of the proportion of the cold water and the hot water, the cold water flow FL and the hot water flow FR are met. According to the constant-temperature and constant-flow water outlet control method, the cold and hot water temperature, the water inlet and outlet temperature, the water outlet flow are used as the detection variable for realizing control, accurate detection is carried out on the detection variable, moreover, the proportion of the cold waterand the hot water and the flow of the cold water and the hot water are accurately calculated, then the opening degree of the cold water adjusting mechanism and the opening degree of the hot water adjusting mechanism are adjusted, so that the control is more accurate, and the bathing comfort is improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

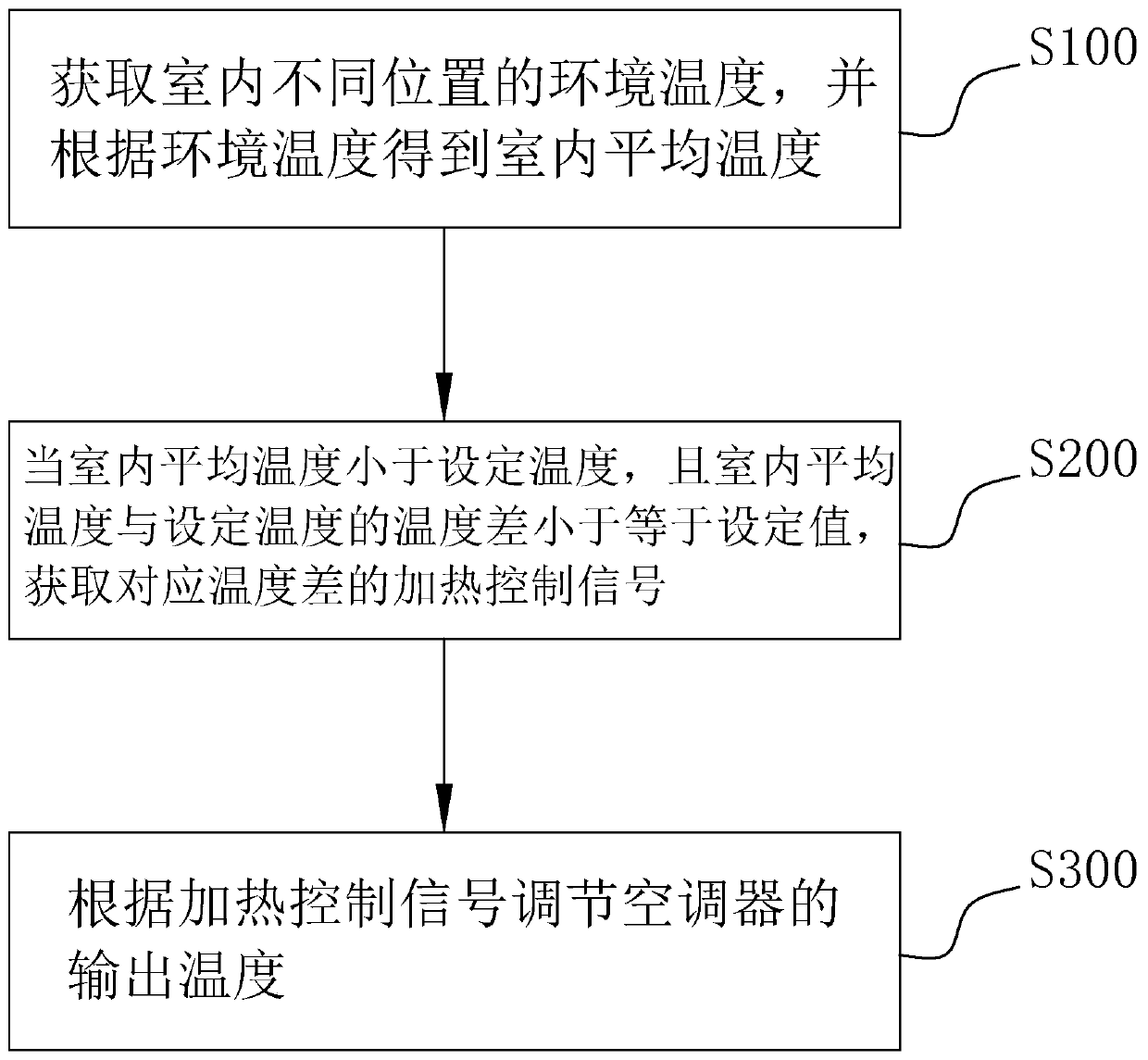

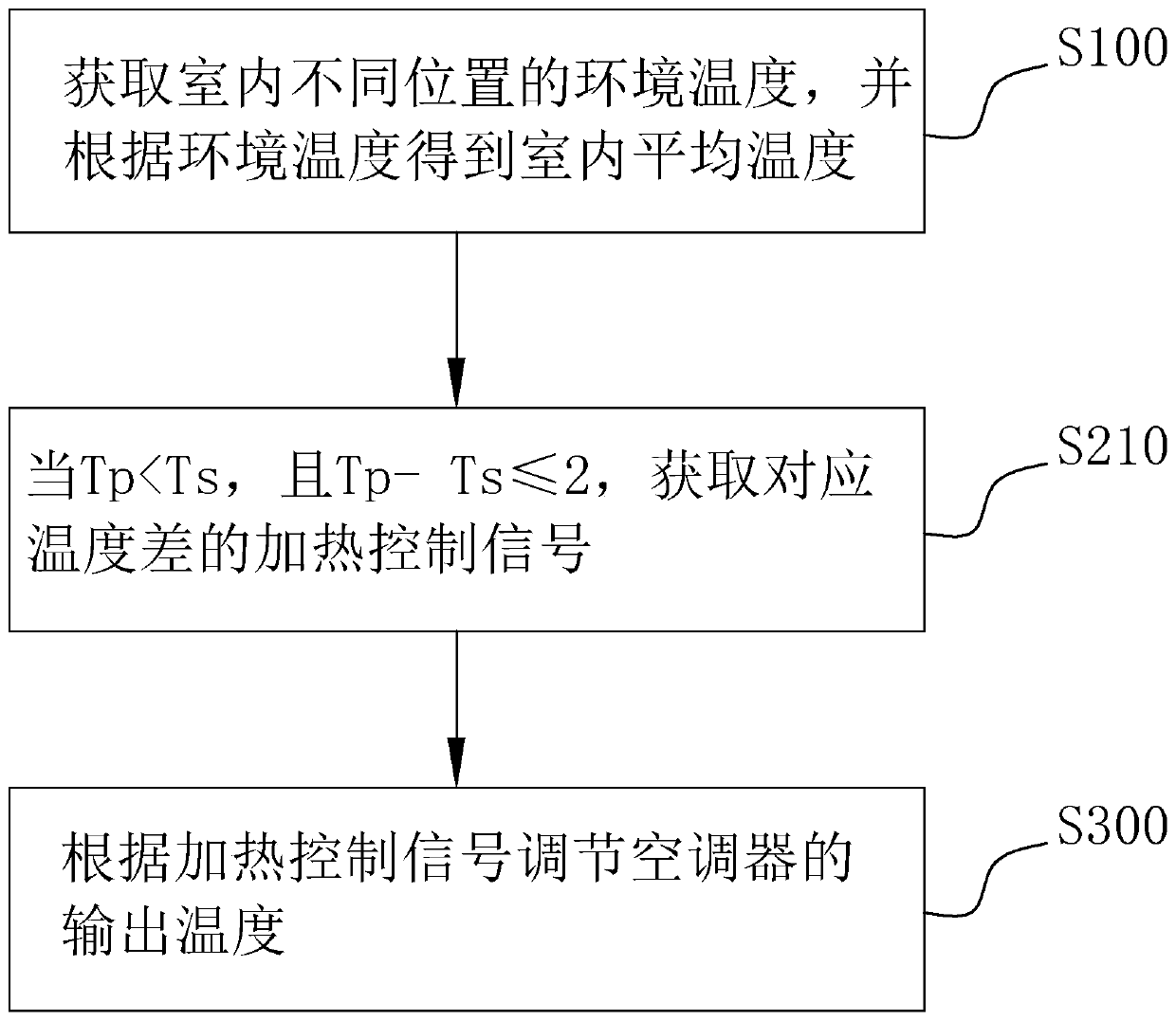

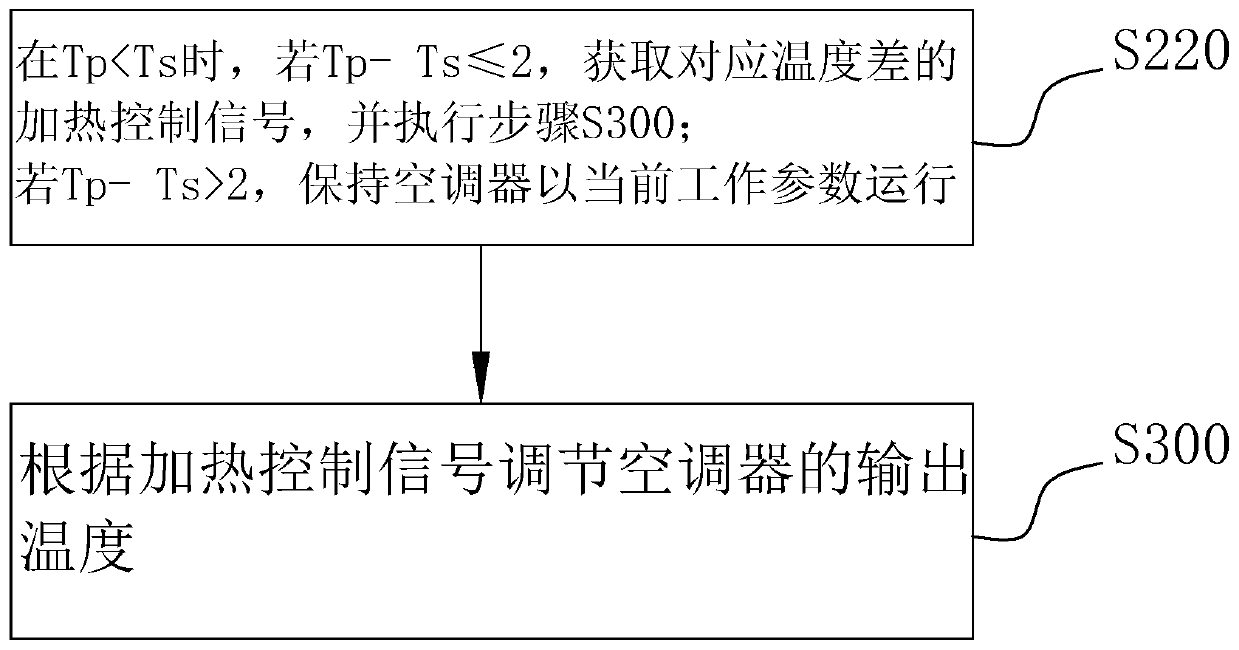

Heating control method of air conditioner and air conditioner thereof

PendingCN110701743AAvoid hot and coldImprove user comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringTemperature.ambient

The invention discloses a heating control method of an air conditioner and the air conditioner thereof. The heating control method of the air conditioner comprises the following steps: acquiring the ambient temperature of different positions in a room, and obtaining the average indoor temperature according to the ambient temperature; when the indoor average temperature is less than a set temperature and the temperature difference between the indoor average temperature and the set temperature is less than or equal to a set value, acquiring a heating control signal corresponding to the temperature difference; and adjusting the output temperature of the air conditioner according to the heating control signal. The indoor average temperature is obtained by collecting the environment temperatures at different positions, the influence of uneven distribution of the indoor environment temperature can be reduced, the output temperature of the air conditioner is adjusted, the indoor environment temperature can accurately reach the set temperature position, the temperature control effect is realized, the heating temperature control accuracy is high, the problem that the temperature is too highor too low is avoided, the use comfort of a user is improved, and the energy consumption is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

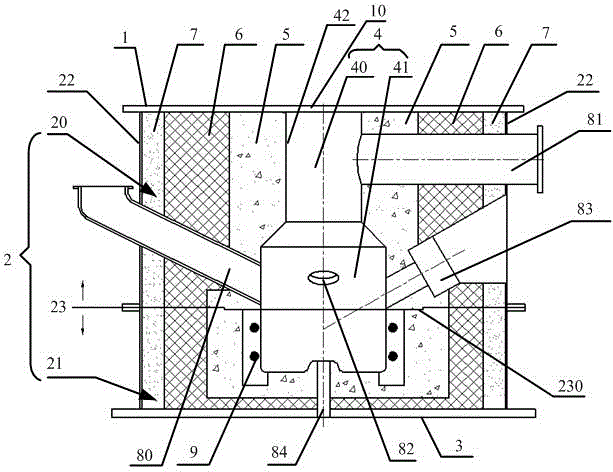

Plasma furnace for comprehensively treating solid and liquid wastes

ActiveCN104676605APrevent penetrationAvoid pollutionIncinerator apparatusRadioactive decontaminationLiquid wastePlasma generator

The invention discloses a plasma furnace for comprehensively treating solid and liquid wastes. The plasma furnace comprises a furnace body consisting of a top cover, a furnace body and a furnace bottom, wherein a hearth is formed in the furnace body and is divided into a gasifying area and a melting area; a high-temperature refractory fiber layer, a high-temperature insulating layer and an insulating fiber layer are sequentially arranged between the hearth and a casing of the furnace body from the inside to the outside; a solid feeding channel, an exhaust channel, a waste liquid feeding spray opening, a plasma generator installation interface and a discharging interface are arranged on the furnace body. By implementing the plasma furnace disclosed by the invention, the capability of simultaneously treating solid waste and liquid waste can be realized; in addition, the plasma furnace has the characteristics of simple structure, good convenience for detaching and maintaining, high utilization rate of heat and the like.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD

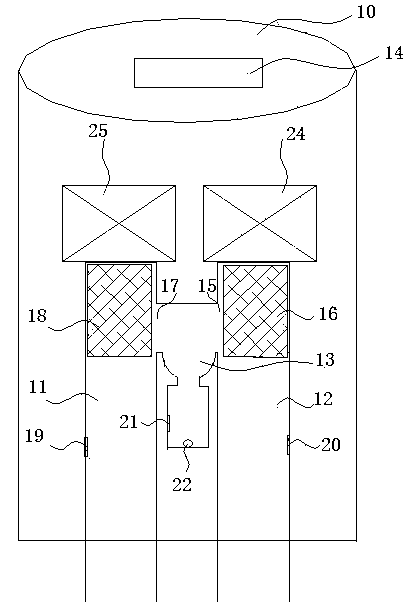

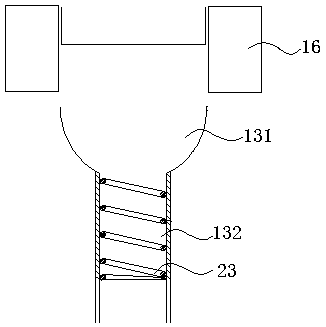

Flow-guiding solar water heater

InactiveCN1851350ASimple structureLow costSolar heating energySolar heat collectors with working fluidsEngineeringThermal water

The invention relates to diversion type solar water heater. It includes frame and at least one heat collection tube. The latter is made up of outer vacuum glass tube and inner metal tube. The out wall of the metal tube is coated by selective absorption coating. And its upper end is welded sealing cover. The sealing cover is set water inlet and back water opening. The former is set water pipe. And the latter is set back water tube. It can simplify structure, reduce cost, and has many mounting means to fit different buildings.

Owner:王雪霖

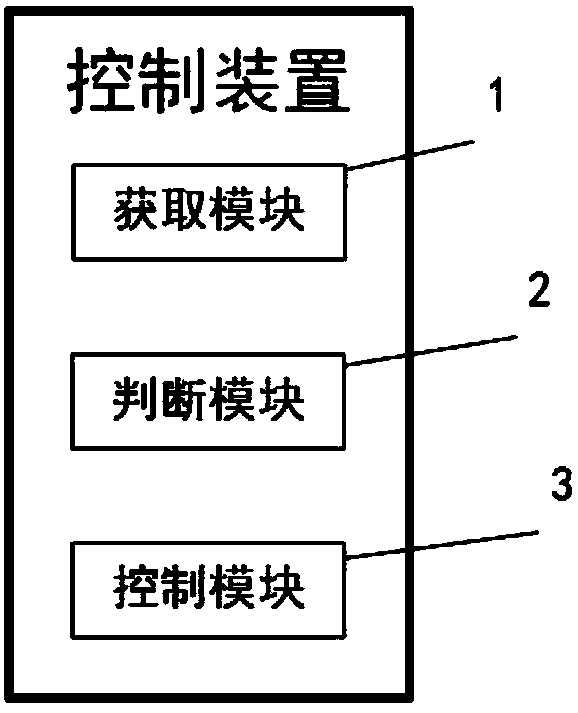

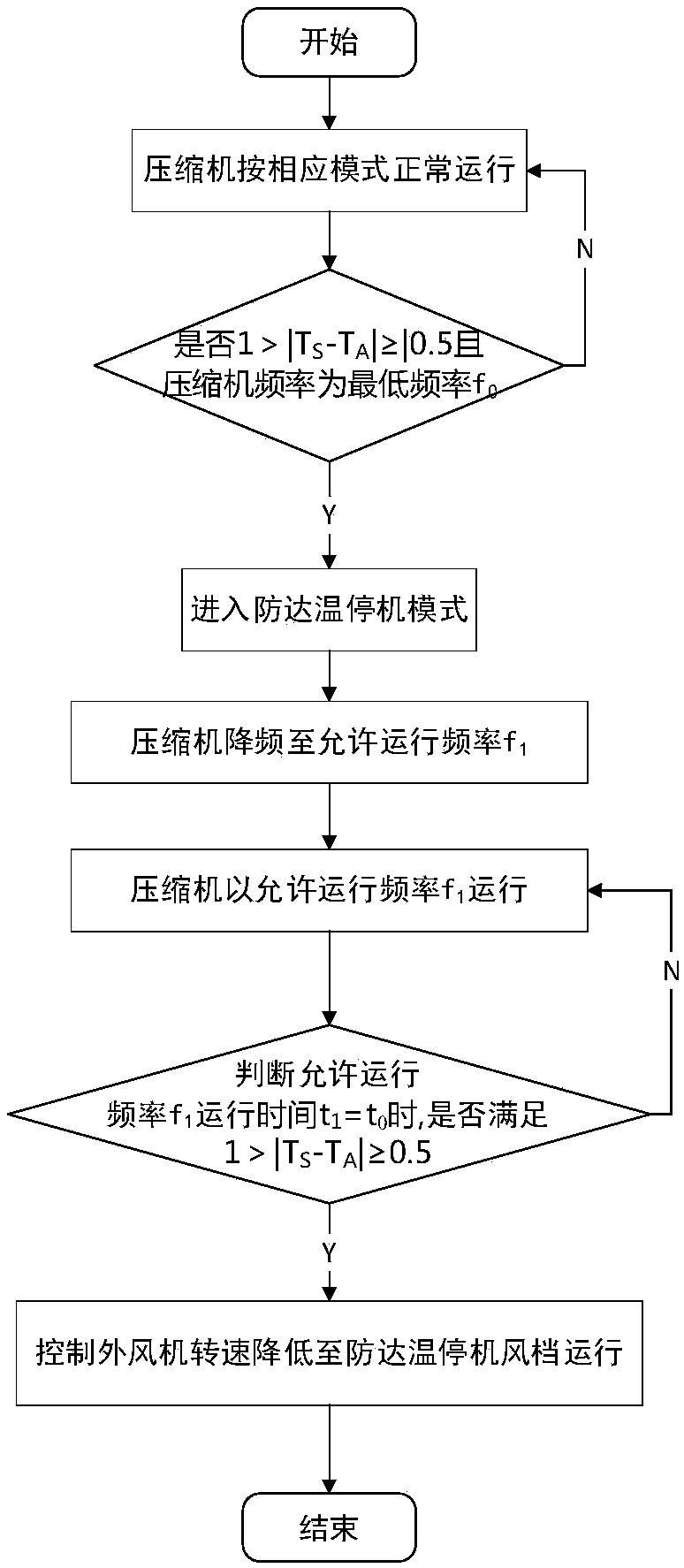

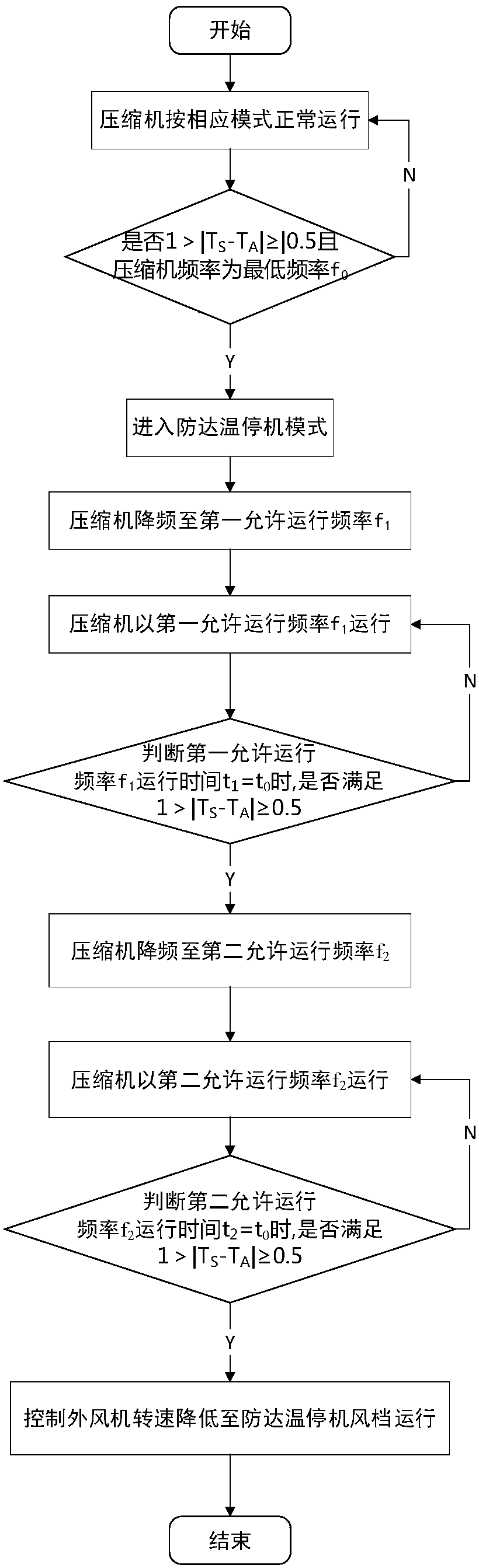

Control method for preventing temperature-reaching halting of variable-frequency air conditioner

ActiveCN109489217AImprove comfortAvoid hot and coldMechanical apparatusSpace heating and ventilation safety systemsEngineeringPower consumption

The invention discloses a control method for preventing temperature-reaching halting of a variable-frequency air conditioner. The air conditioner comprises a control device, the triggering condition for a temperature-reaching halting preventing mode, the temperature-reaching halting preventing running frequency f, the temperature-reaching halting condition and the temperature-reaching halting preventing wind gear are preset in the control device, f meets the driving reliability, and pipeline stress vibration is qualified. The method comprises the steps that (1), whether the triggering condition for the temperature-reaching halting preventing mode is met or not is judged, if not, the current mode is kept, and if yes, the air conditioner enters in the temperature-reaching halting preventing mode; (2), the frequency is decreased to f, wherein the initial value of i is 1, i is smaller than or equal to n, n is larger than 1, and n is an element of a set N<+>; (3), whether the temperature-reaching halting condition is met or not is judged, if not, the current mode is kept, if yes, whether i is equal to n or not is judged, if not, the step (4) is conducted, and if yes, the step (5) is conducted; (4), the formula i=i+1 is conducted, and the step (2) is conducted; and (5), the rotation speed of an outer fan is decreased to the temperature-reaching halting preventing wind gear.According to the control method, the product comfortableness can be improved, the sudden cold and hot problem generated by temperature-reaching halting is avoided, and power consumption is reduced.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

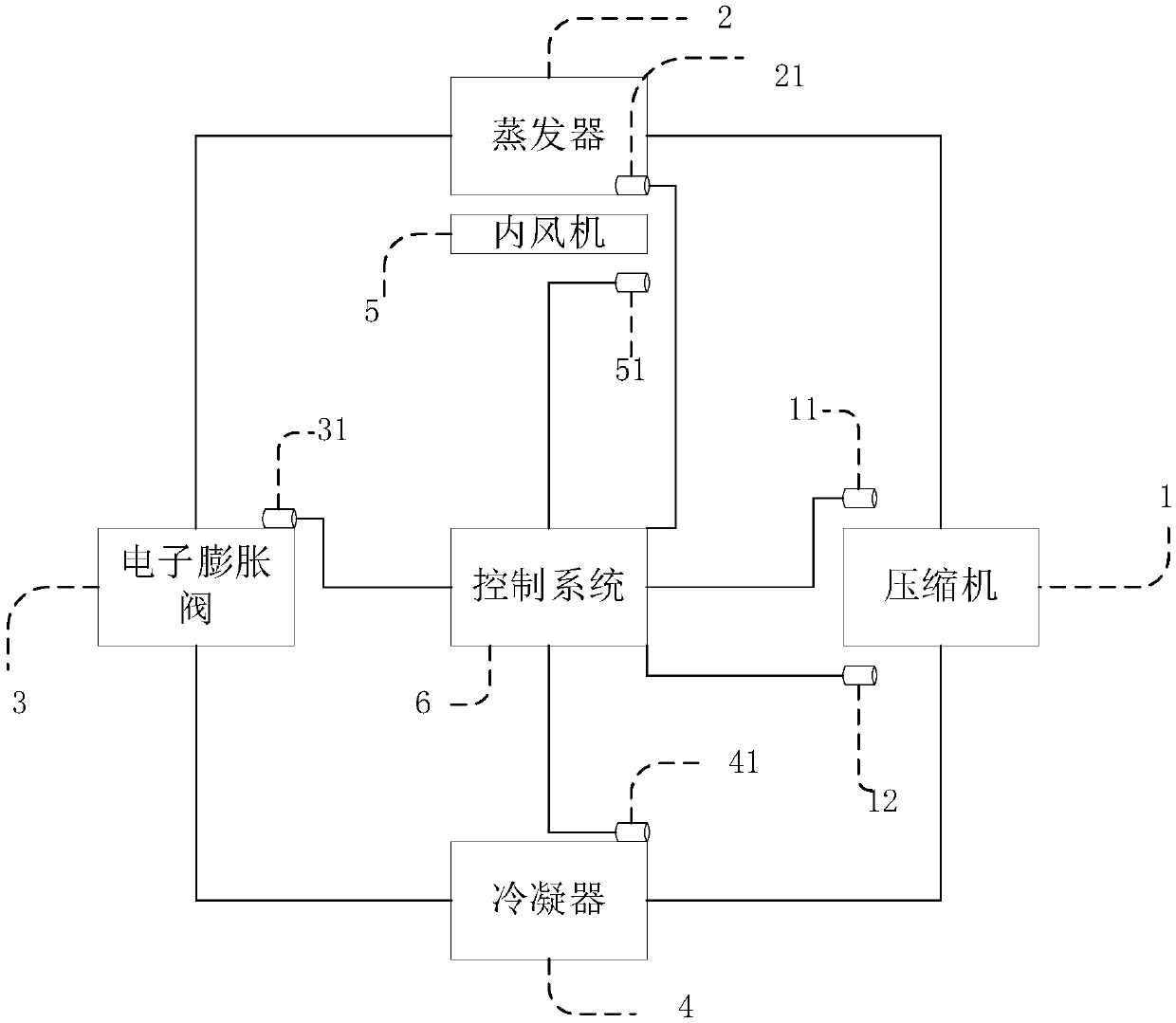

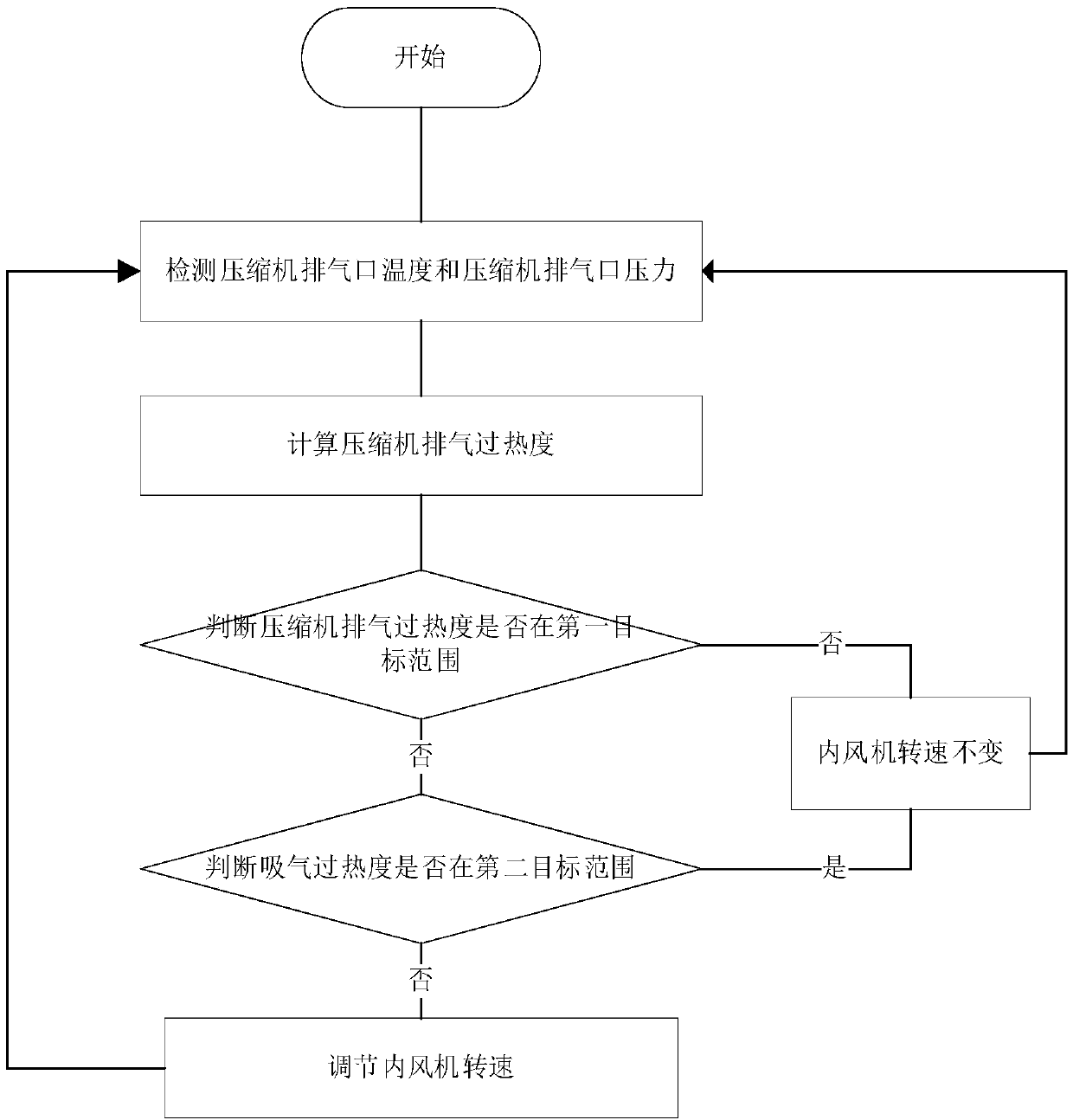

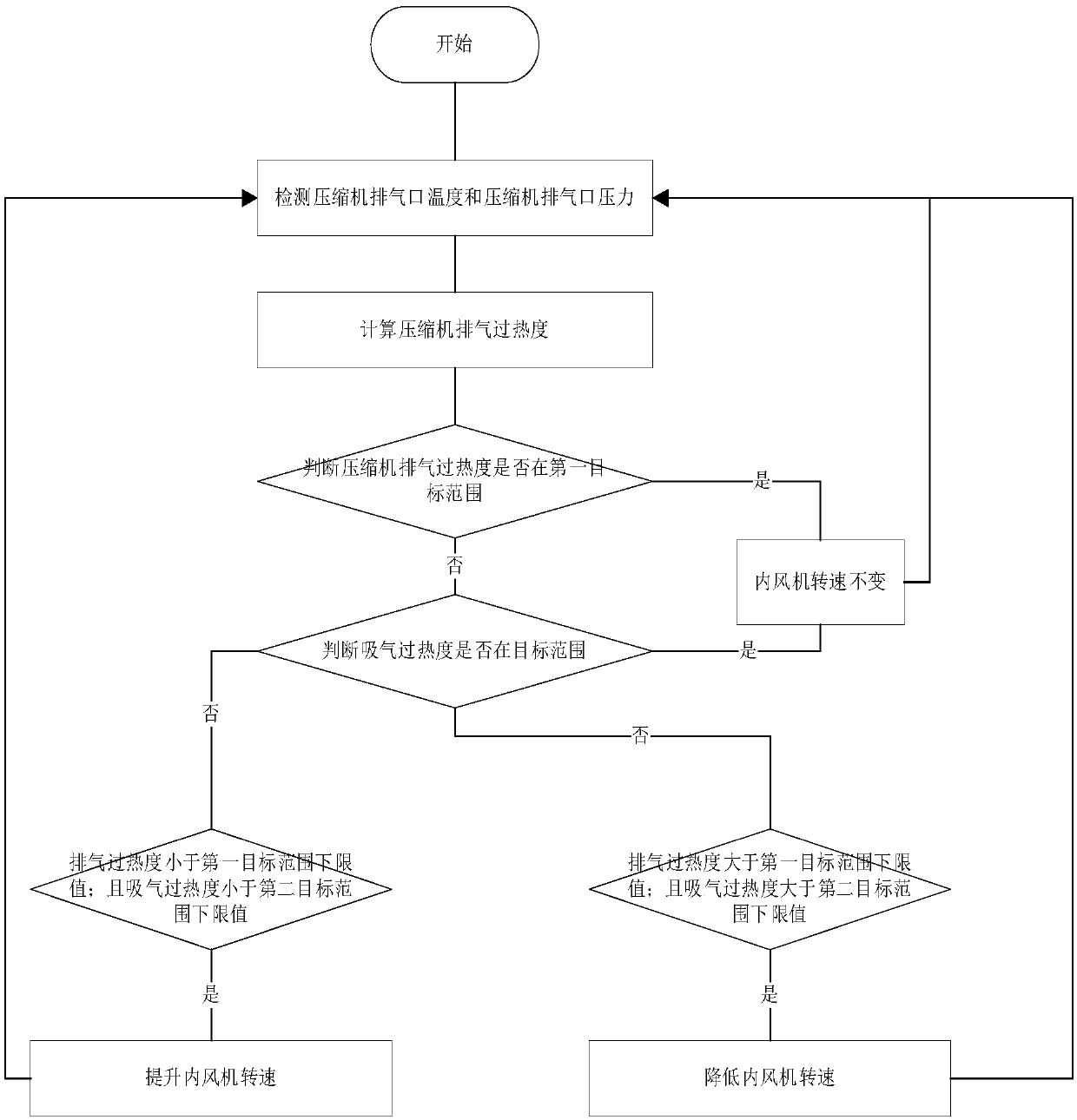

Control method for adjusting exhaust superheat degree of air conditioner, and air conditioner

ActiveCN109612018AAvoid hot and coldMechanical apparatusEfficient regulation technologiesRefrigerationOperating frequency

The invention discloses a control method of an air conditioner. The control method comprises the steps that the exhaust temperature T<exhaust> and the exhaust pressure P<exhaust> of a compressor are detected, the difference between saturation temperatures Tp corresponding to the exhaust temperature T<exhaust> and the exhaust pressure P<exhaust> is calculated, and the exhaust superheat degree of the compressor is obtained; when the exhaust superheat degree is within the first preset temperature range, the rotating speed of an inner fan is controlled to keep unchanged; and when the exhaust superheat degree is not within the first preset temperature range, whether the suction superheat degree is within the second preset temperature range or not is judged, if yes, the rotating speed of the fanis controlled to keep unchanged, and if not, the rotating speed of the inner fan is adjusted. The rotating speed of the inner fan is controlled by comprehensively judging the two parameters of the exhaust superheat degree and the suction superheat degree, the blowing-out temperature is not changed due to change of the rotating speed of the inner fan, and thus the problem that in related technologies, the working frequency of the compressor is adjusted, then the refrigeration capacity of the compressor is changed, and consequently sudden changes of the temperature occur is avoided.

Owner:NINGBO AUX ELECTRIC +1

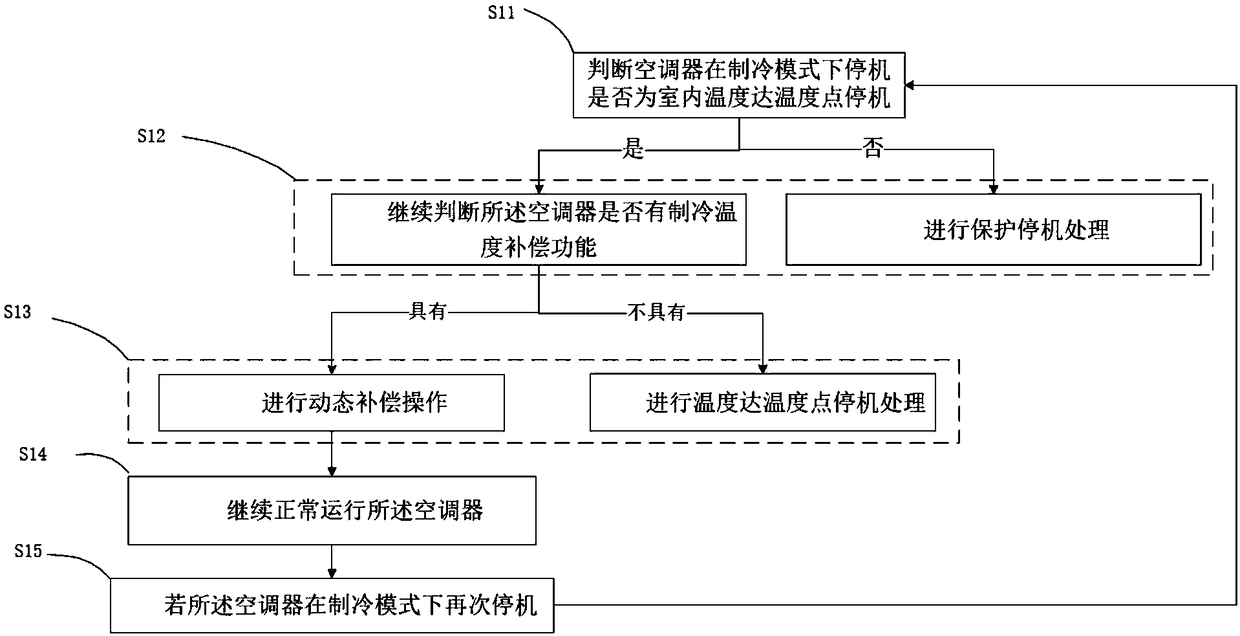

Control method for improving refrigeration comfort of frequency conversion air conditioner

InactiveCN109489188AImprove use comfort performanceSolve the problem of low load and frequent shutdownMechanical apparatusLow loadFrequency conversion

The invention provides a control method for improving the refrigeration comfort of a frequency conversion air conditioner, and relates to the technical field of air conditioners. The control method for improving the refrigeration comfort of the frequency conversion air conditioner comprises the following steps that in a refrigeration mode, if the air conditioner shuts down since the indoor temperature reaches the temperature point and the air conditioner has the refrigeration temperature compensation function, the dynamic compensation operation is conducted, wherein according to the specific dynamic compensation operation, the dynamic compensation value delta t DEG C is added for the refrigeration temperature compensation value on the basis of the fixed compensation value. The provided control method for improving the refrigeration comfort of the frequency conversion air conditioner can solve the problem that frequent shutdown is likely to happen due to low loads, wherein the problem cannot be solved through the fixed refrigeration temperature compensation value; and the problem that in the refrigeration mode, the temperature point is reached, and sudden cold and heat happen due torepeated startup and shutdown is solved, and the usage comfort of users is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

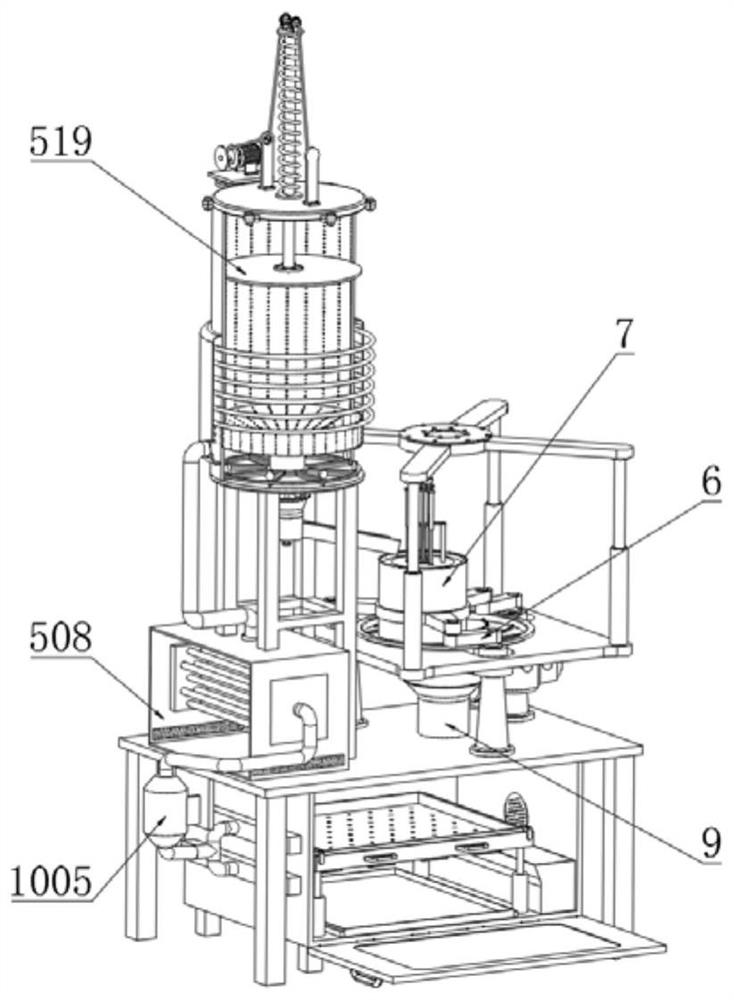

Spraying scalding machine

The invention belongs to the field of poultry processing machinery and in particular relates to a spraying scalding machine. The spraying scalding machine comprises a rack, a hot water tank, a heat preservation tank cover and a conveying belt, wherein a water inlet pipe and a water outlet pipe are arranged at the front end and the rear end of the hot water tank respectively, a motor is arranged at the bottom of the hot water tank, the motor is connected with a water guide pipe which is connected with a spraying pipe, a pressurizing motor is arranged at the top end of the heat preservation tank cover, a heating plate is arranged at the bottom end of the hot water tank, three or four water temperature sensors are arranged on the inner wall of the hot water tank, and the heating plate and the water temperature sensors are controlled by a controller arranged at the lower end of the rack. The spraying scalding machine solves the problem that water temperature of the general scalding machine is not constant, the follow-up operating efficiency is improved by a high-pressure spraying device, the quality of a product is improved, water and electricity are saved, and the resource waste is reduced; and besides, polluted industrial wastewater is treated, environment-protection and sanitary effects are achieved and the spraying scalding machine is very suitable for promotion vigorously.

Owner:山东洋利电气有限公司

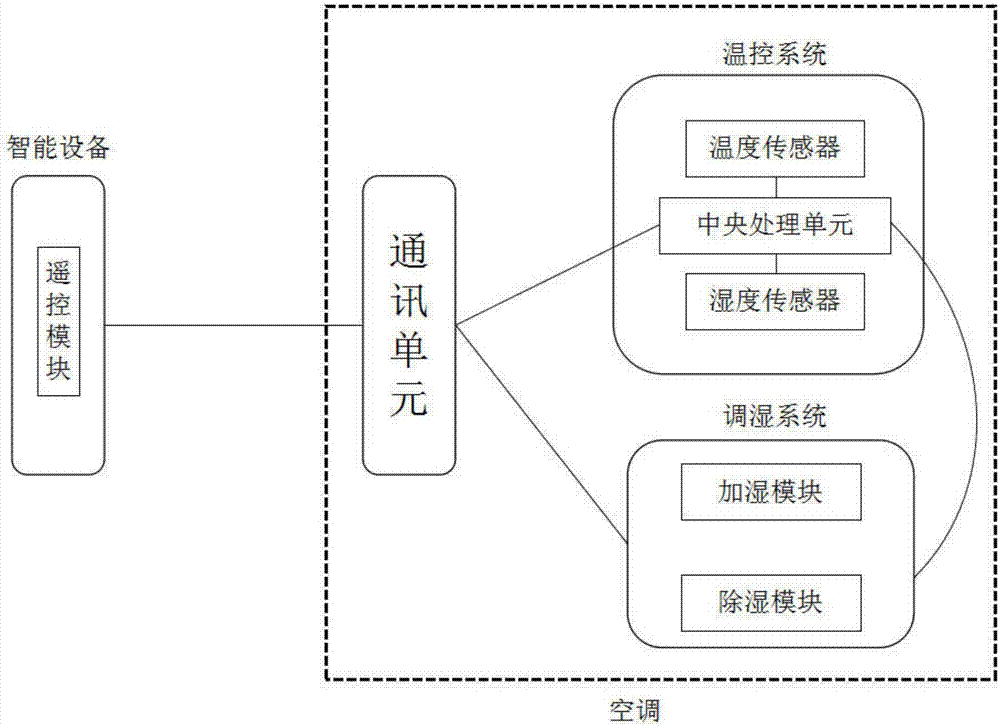

Method and equipment for automatically controlling temperature based on humidity

InactiveCN107328033AImprove comfortReduce the Risk of Air Conditioning SicknessSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlMoisture sensor

Owner:珠海晖达科技有限公司

Thermostat of gas water heater and constant-temperature water drainage control method

The invention discloses a thermostat of a gas water heater. The thermostat of the gas water heater is arranged on a water outlet of the gas water heater and comprises a flow distributing valve, a water storage tank, a stop valve and a controller, wherein the flow distributing valve is connected with the water outlet of the gas water heater; the water storage tank and the stop valve are respectively connected with two water draining branches of the flow distributing valve; the controller is used for controlling the opening degree of the two branches of the flow distributing valve; and the water storage tank and the water outlet of the stop valve form a hot water outlet jointly. Compared with the prior art, the thermostat of the gas water heater has the advantages that the starting and heating speed is increased, and the circumstance that water is cold or hot irregularly due to water stopping temperature rise and water pressure fluctuation in a hot water using process is avoided. The invention also provides a constant-temperature water drainage control method of the gas water heater.

Owner:GUANGDONG MACRO GAS APPLIANCE

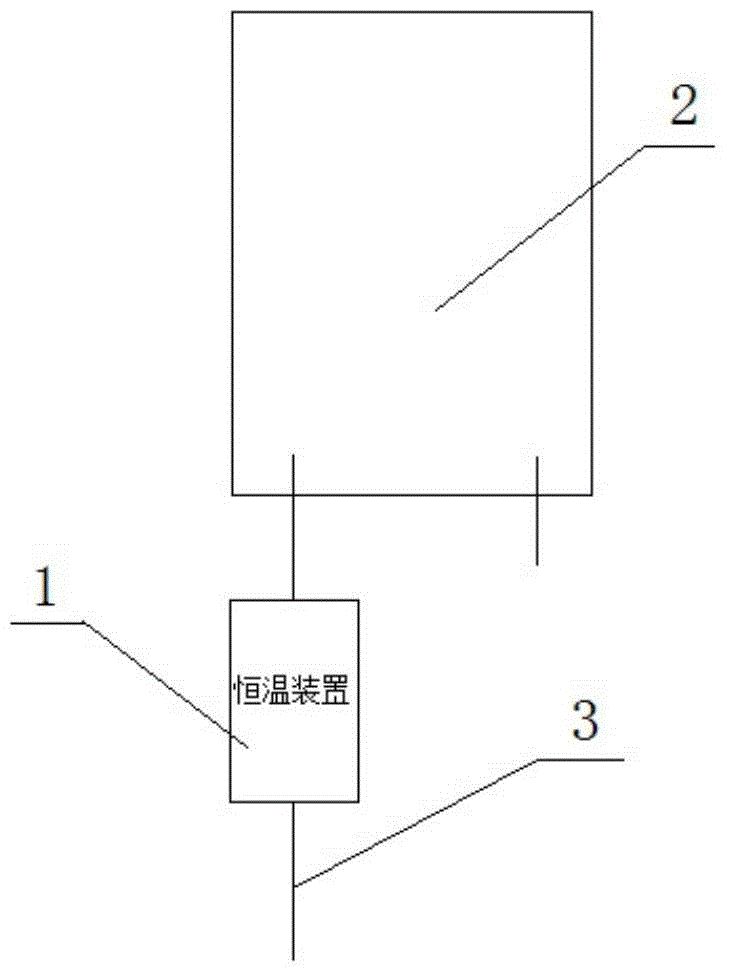

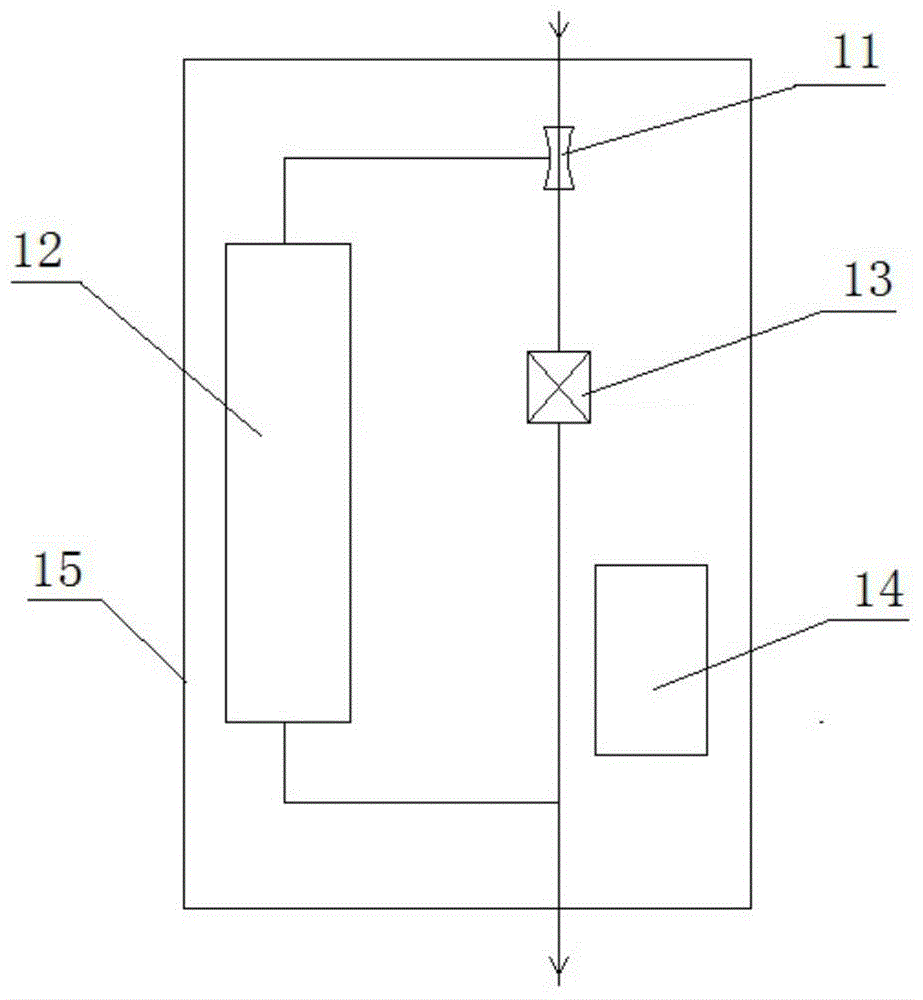

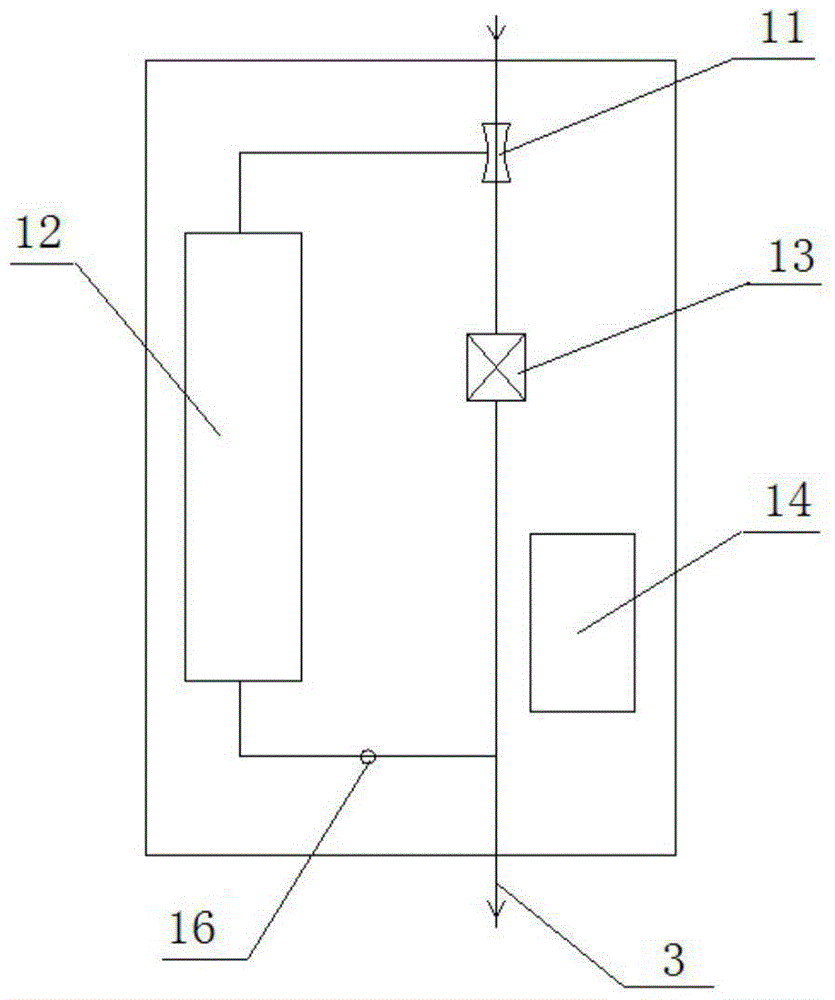

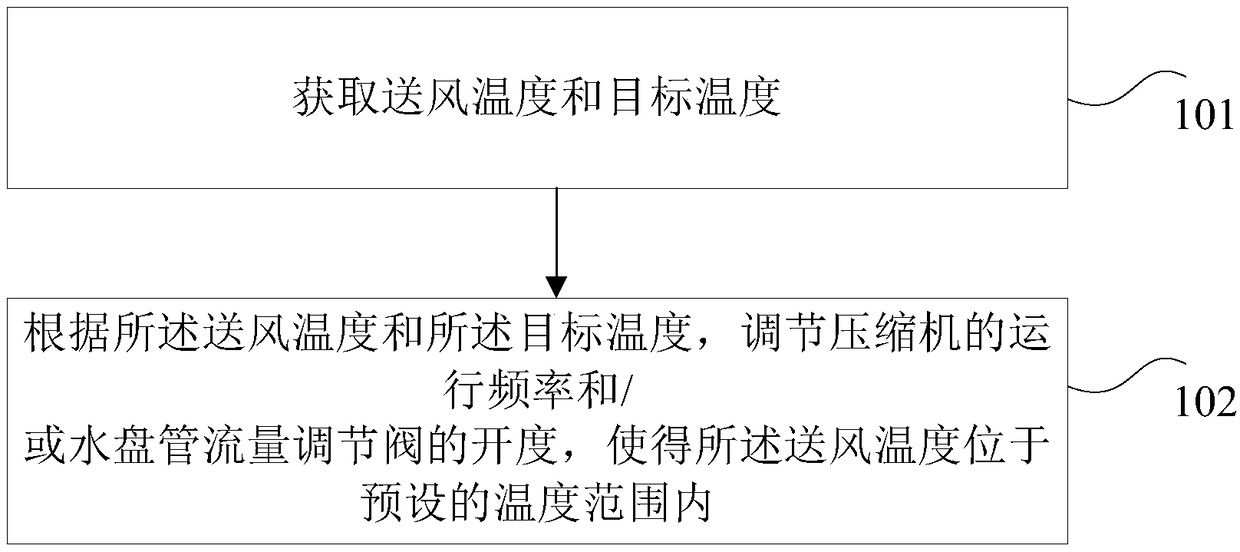

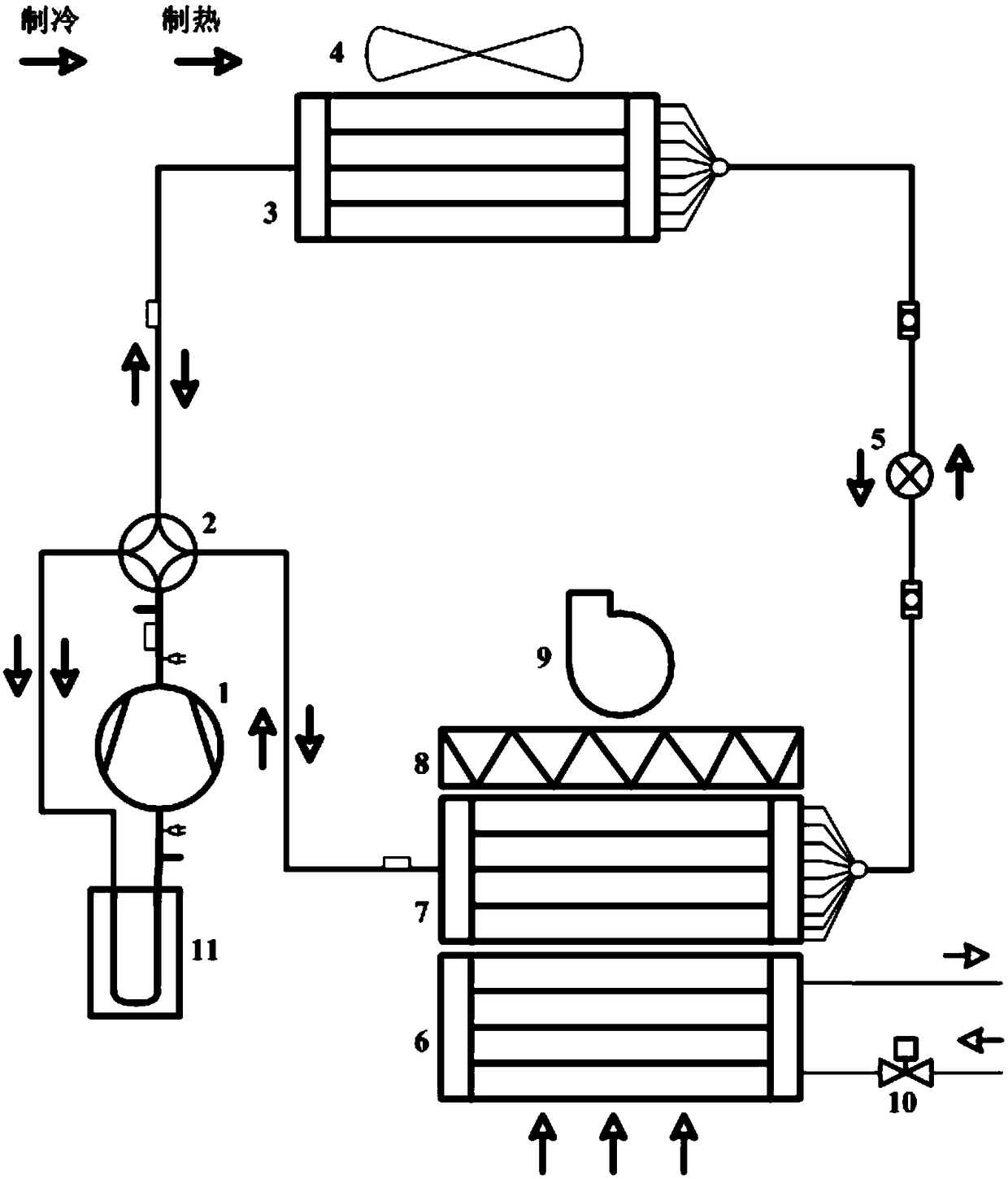

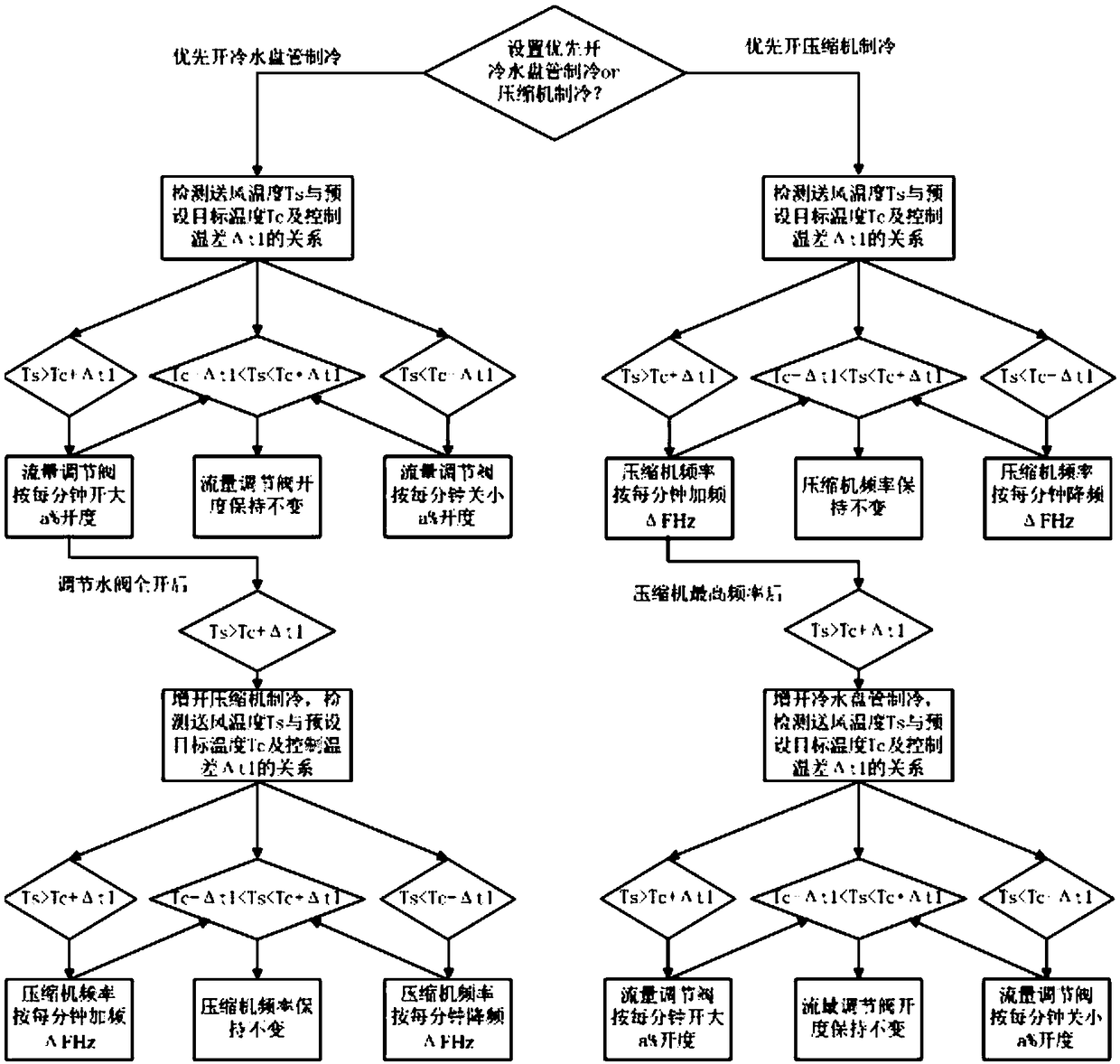

Method and device for adjusting air conditioner

InactiveCN109269046AAvoid hot and coldImprove comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringElectric control

The invention provides a method and device for adjusting an air conditioner, wherein the method includes the following steps: acquiring a supply air temperature and a target temperature; and adjustingthe operation frequency of a compressor and / or the opening degree of a water coil flow adjusting valve according to the supply air temperature and the target temperature, so as to enable the supply air temperature to be within a preset temperature range. Through the above scheme, the user's comfort is effectively improved, and further, because the compressor and the water coil are adjusted, namely, electric control and water control are utilized, so that resources are effectively utilized.

Owner:GREE ELECTRIC APPLIANCES INC

Breakage-proof tea processing device

InactiveCN112273478AScientific and reasonable structureSafe to usePre-extraction tea treatmentHollow article cleaningHorticultureEngineering

The invention discloses a breakage-proof tea processing device. A connecting support is welded to one side of the top end of a mounting support, a fixation tank is welded to the top end of the connecting support, a feeding port is welded to the top of one side of the fixation tank, a discharging pipe is fixedly connected to the middle of the bottom end of the fixation tank, and the top, corresponding to the internal position of the fixation tank, of the discharging pipe is clamped with a fixation screen cylinder; according to the present invention, with the downward pressing of a lifting roundplate, the tea leaves in the fixation screen drum are compact, and the gap between the tea leaves is reduced, such that the water loss speed of the tea leaves during the fixation process is effectively reduced, and the charring phenomenon of the tea leaves with the low water content is avoided; the breakage-proof tea processing device ensures that the tea leaves after fixation still have sufficient moisture, ensures that the tea leaves on the inner and outer rings of the fixation screen cylinder can be uniformly heated, and can discharge surplus water vapor accumulated in the fixation tank during next pressing, optimizes the fixation process of the tea leaves, ensures high-quality fixation of the tea leaves, and improves the fixation quality of the tea leaves.

Owner:韦世林

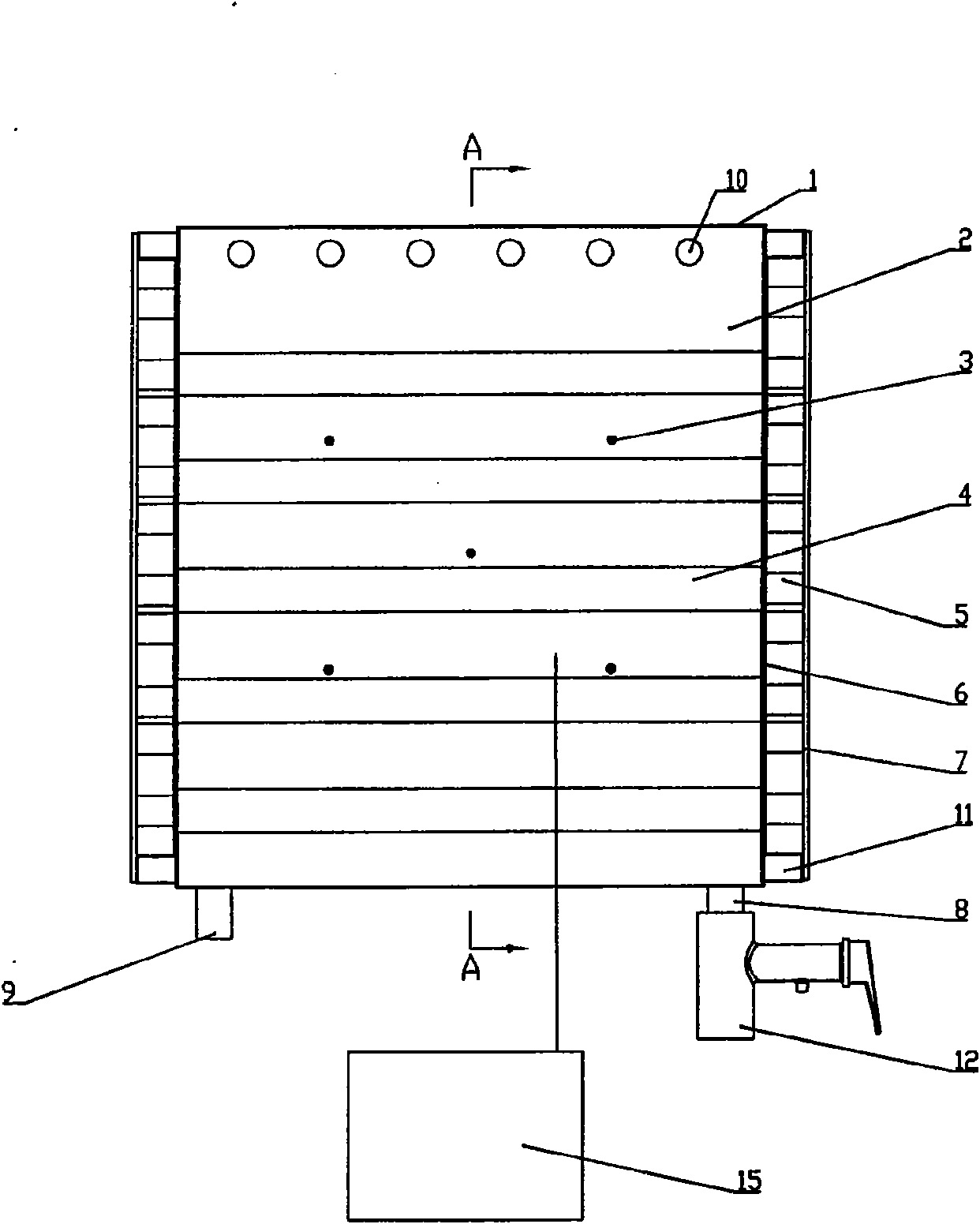

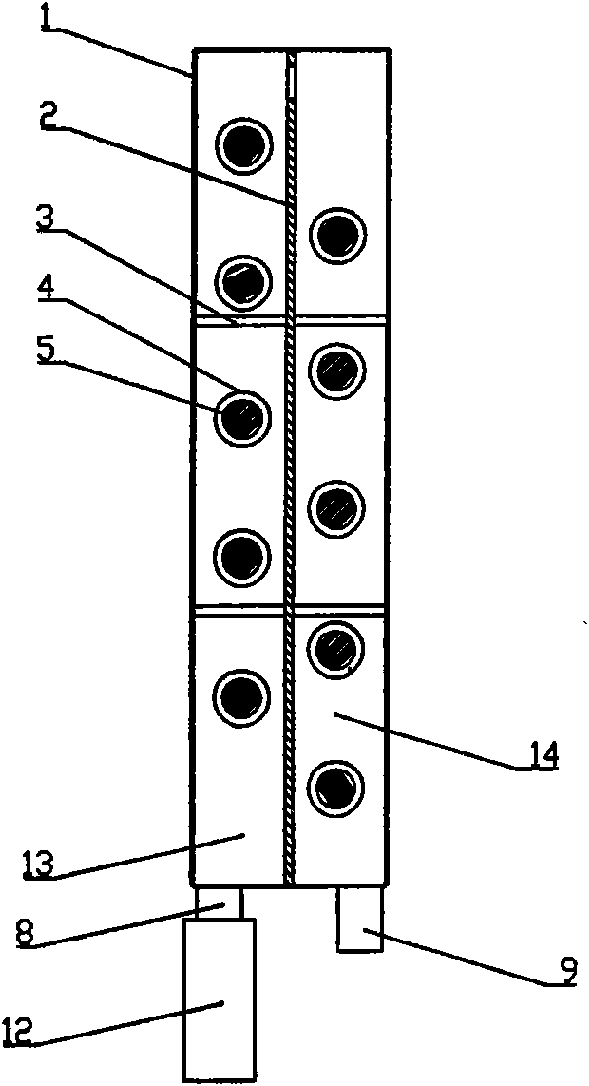

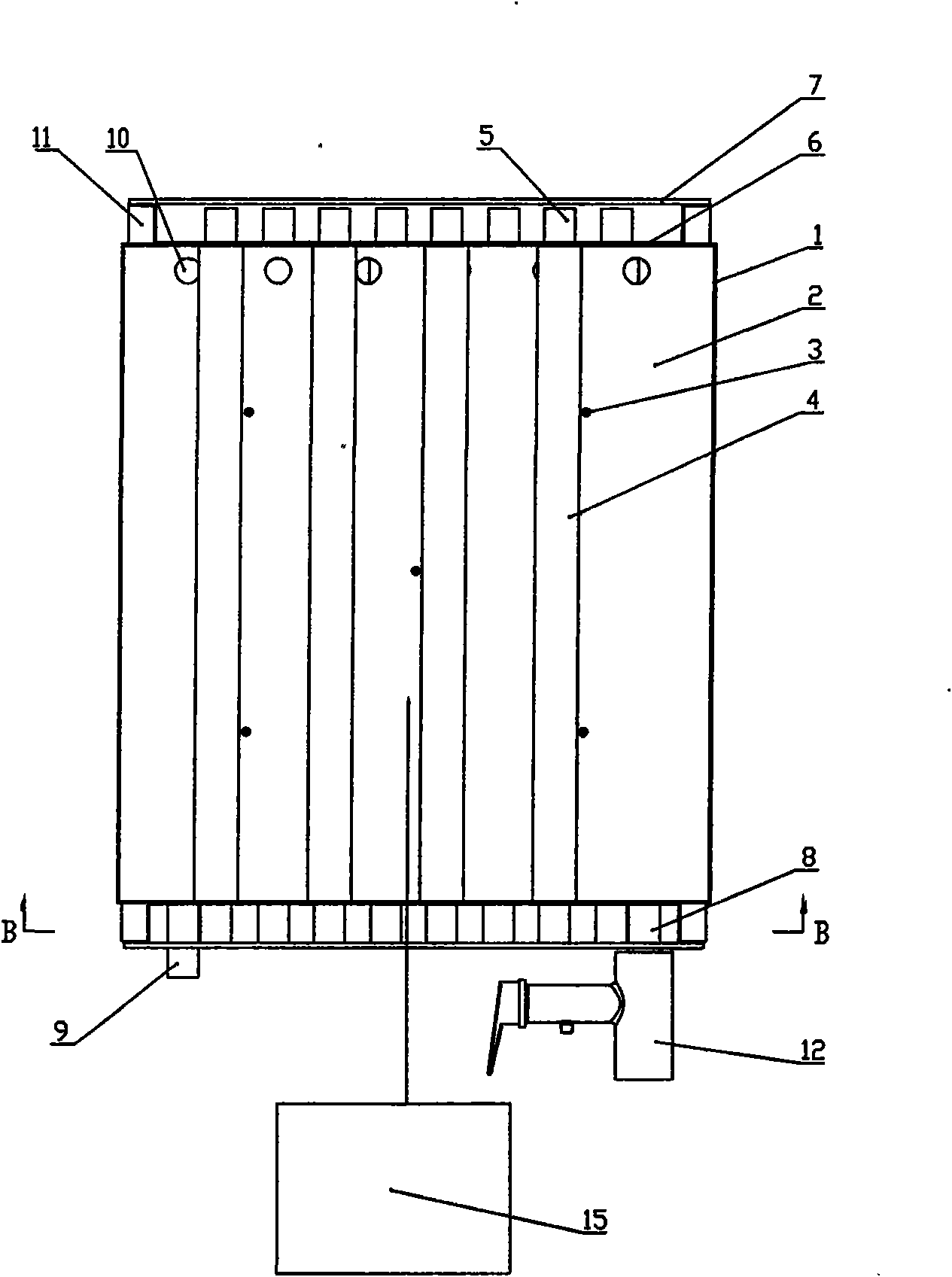

Instant electric water heater

The invention discloses an instant electric water heater; a vertical shunting clapboard is arranged in the middle part between the front and back sides of a box body to form a first cavity and a second cavity, a group of stream guidance holes are arranged at top part of the shunting clapboard, a group of stainless steel thermal energy pipes are uniformly distributed in the first cavity and the second cavity horizontally or vertically, and ports of the stainless steel thermal energy pipes are welded with the corresponding side plates of a box body in a penetrating way, a group of carbon fiber far infrared heating tubes are respectively arranged in the group of the stainless steel thermal energy pipes and are fixed by fixed clamping plates, a power supply input end of each carbon fiber far infrared heating tube body is electrically connected with an automatic thermostat by a wiring groove circuit board. the instant electric water heater has rapid heating, low power consumption, high hotwater yield, high electric-heating conversion efficiency, good safety and long service life and is energy saving and environmental protection.

Owner:霍海凌

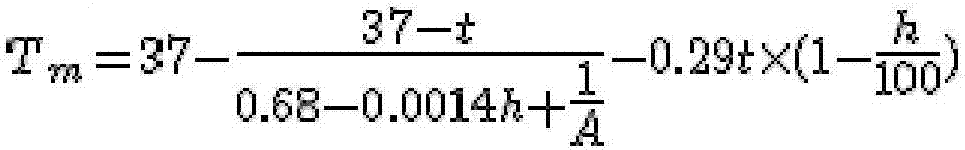

Air conditioner control method and device and air conditioner

InactiveCN106907832AAvoid hot and coldImprove accuracyMechanical apparatusSpace heating and ventilation safety systemsSleep stateHeat resistance

The invention discloses an air conditioner control method. The method comprises the steps of obtaining heat resistance information, the covering change rate and the user body surface temperature of a bedding system in a room under the sleeping state; according to the heat resistance information, the covering change rate and the user body surface temperature, calculating the cold and heat feeling state; according to the cold and heat feeling state, controlling an air conditioner to run. The invention further discloses an air conditioner control device and the air conditioner. The cold and heat feeling state of the user can be accurately provided, accuracy of air conditioner control can be improved, and comfort of the air conditioner is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

Gas-electric combined type water heater

The invention relates to the field of household appliances, in particular to a water heater. A gas-electric combined type water heater comprises a casing, a gas heating mechanism, a cold water inlet pipe and a hot water outlet pipe, wherein the gas heating mechanism is arranged in the casing, the cold water inlet pipe and the hot water outlet pipe are arranged at the bottom of the casing, the cold water inlet pipe is communicated with a water inlet of the gas heating mechanism, a water storage box is further arranged in the casing, an electric heating pipe and a temperature sensor are arranged in the water storage box, a water outlet of the gas heating mechanism is communicated with a water inlet of the water storage box, and a water outlet of the water storage box is communicated with the hot water outlet pipe. The gas-electric combined type water heater provided by the invention has the advantages that water in the water storage box is firstly preheated when the water heater is needed for use; during use, the water stored in the water storage box can neutralize the temperature of discharged water, so that the discharged water can be prevented from abrupt temperature changes; when the discharged water is cooled, additional heating can be further achieved through the electric heating pipe in the water storage box. Therefore, the gas-electric combined type water heater improves the bathing comfort, and is particularly suitable for users suffering from an unstable water pressure.

Owner:宁波奉化科创科技服务有限公司

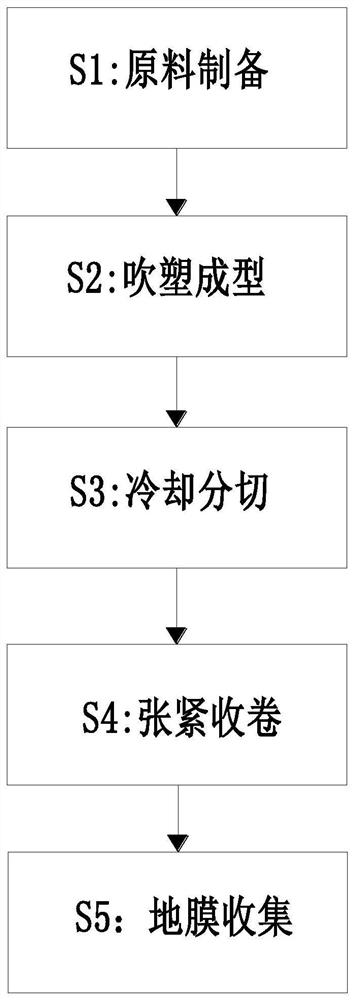

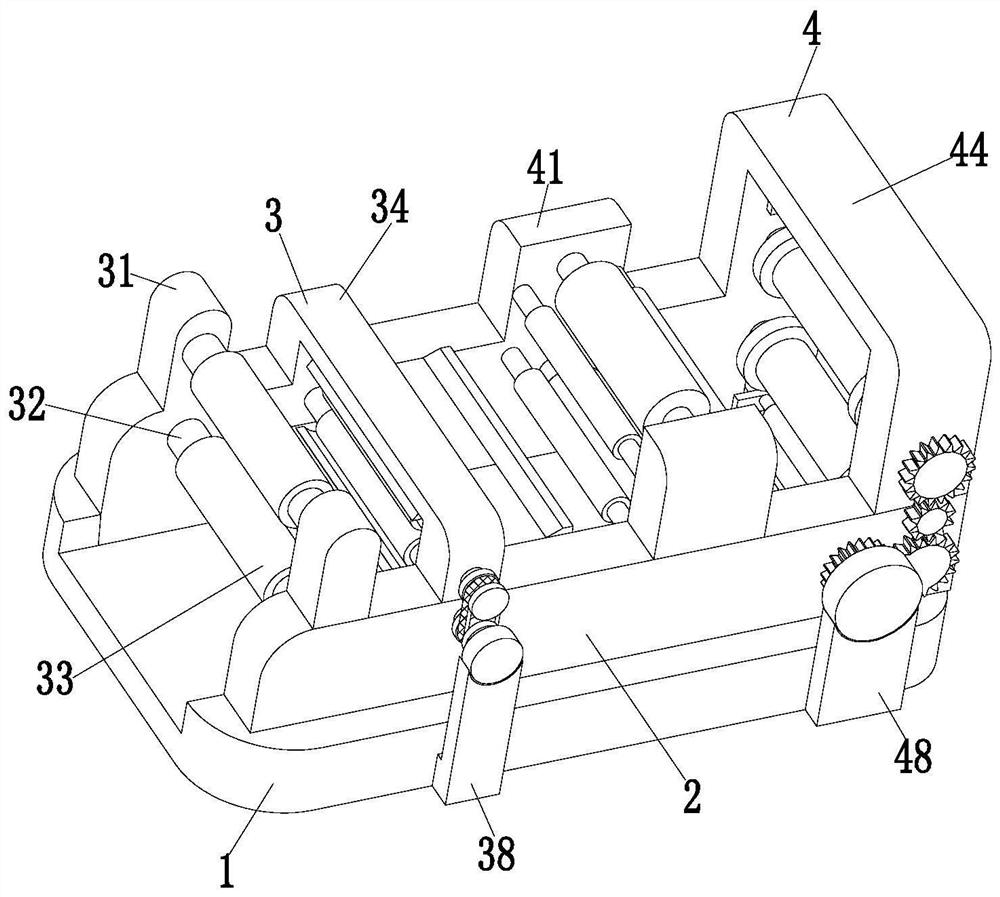

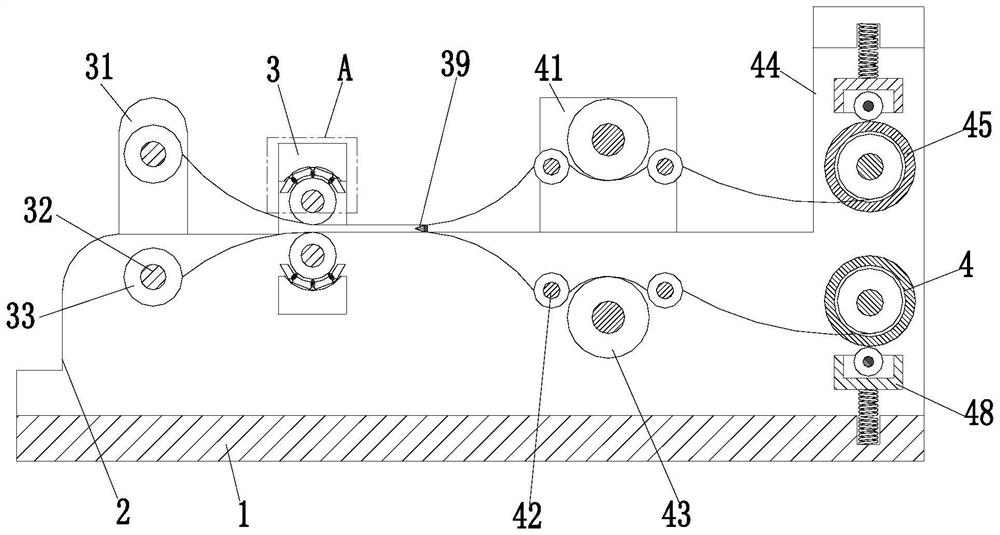

Degradable composite mulching film forming process

ActiveCN112406147AImprove winding efficiencyAvoid creasesFlat articlesMetal working apparatusPolymer sciencePlastic mulch

The invention relates to a degradable composite mulching film forming process, in particular to a degradable composite mulching film forming device. The degradable composite mulching film forming device comprises a bottom plate, a supporting frame, a cooling slitting mechanism and a tensioning winding mechanism, wherein the supporting frame is installed on the bottom plate, and the cooling slitting mechanism is installed at the left side of the upper end face of the supporting frame; and the tensioning winding mechanism is installed at the right side of the upper end face of the supporting frame. According to the degradable composite mulching film forming process and device, the problems that the cooling effect of a mulching film is affected due to the fact that the surface of the mulchingfilm is uneven in temperature caused by the fact that cooling liquid cannot be evenly smeared on the surface of a composite mulching film when the composite mulching film is cooled, and the winding efficiency of the mulching film is affected due to the fact that the part making contact with a knife edge is wrinkled when the mulching film is slit can be solved, and the problems that because the mulching film cannot be tensioned before the composite mulching film is wound and the winding tension cannot be increased, the mulching film cannot be tightly attached to a winding roller during winding, loosening occurs, and even winding disengagement occurs can be solved.

Owner:江华诚德新型材料有限公司

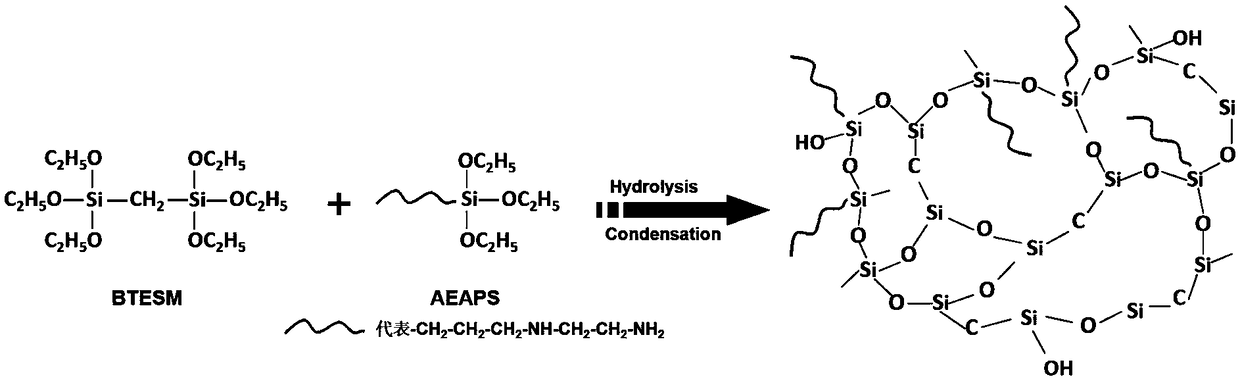

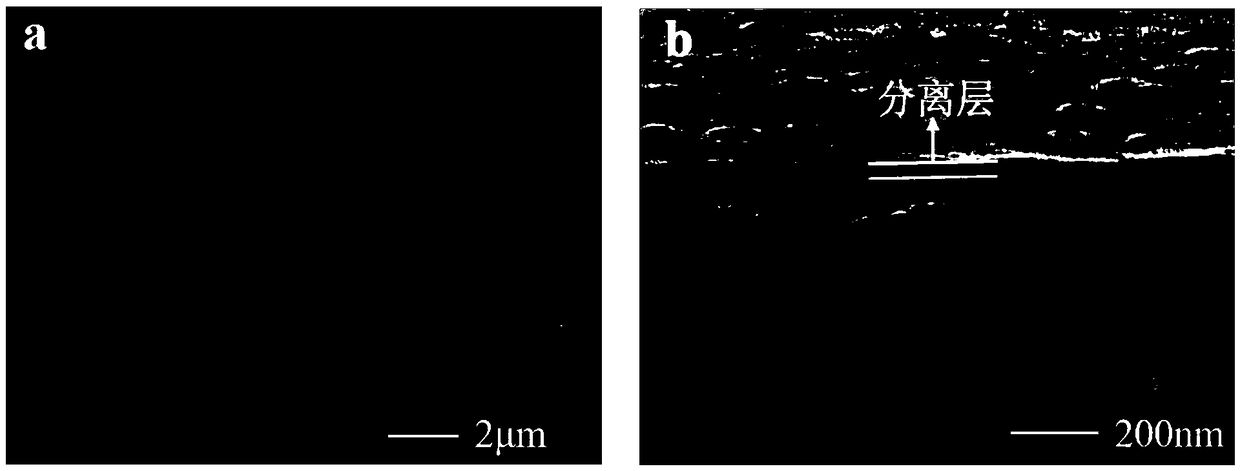

Preparation method of ultrathin silicon-based alcohol water separation film with thickness smaller than 50 nm

ActiveCN109433018AImprove uniformityIncrease deposition rateSemi-permeable membranesAlcoholDip-coating

The invention belongs to the field of film material preparation, and particularly relates to a preparation method of an ultrathin silicon-based alcohol water separation film with thickness smaller than 50 nm. A common dip-coating method in a current film preparation process has the problems that the thickness of a separating layer is larger than 300 nm, flux is small and the preparation process cannot be regulated and controlled accurately, and even the thickness layer of the separating film prepared with a spin-coating method, an infriction method and the like cannot be 200 nm or smaller. Aiming at the problems, organic silica sol with low concentration is atomized by ultrasonic waves, sol is enabled to be dispersed into numerous tiny droplets, the atomized sol is deposited on a porous polymer support by carrier gas purging, finally, drying is performed, and the ultrathin silicon-based alcohol water separation film with the separating film thickness smaller than 50 nm is prepared.

Owner:CHANGZHOU UNIV

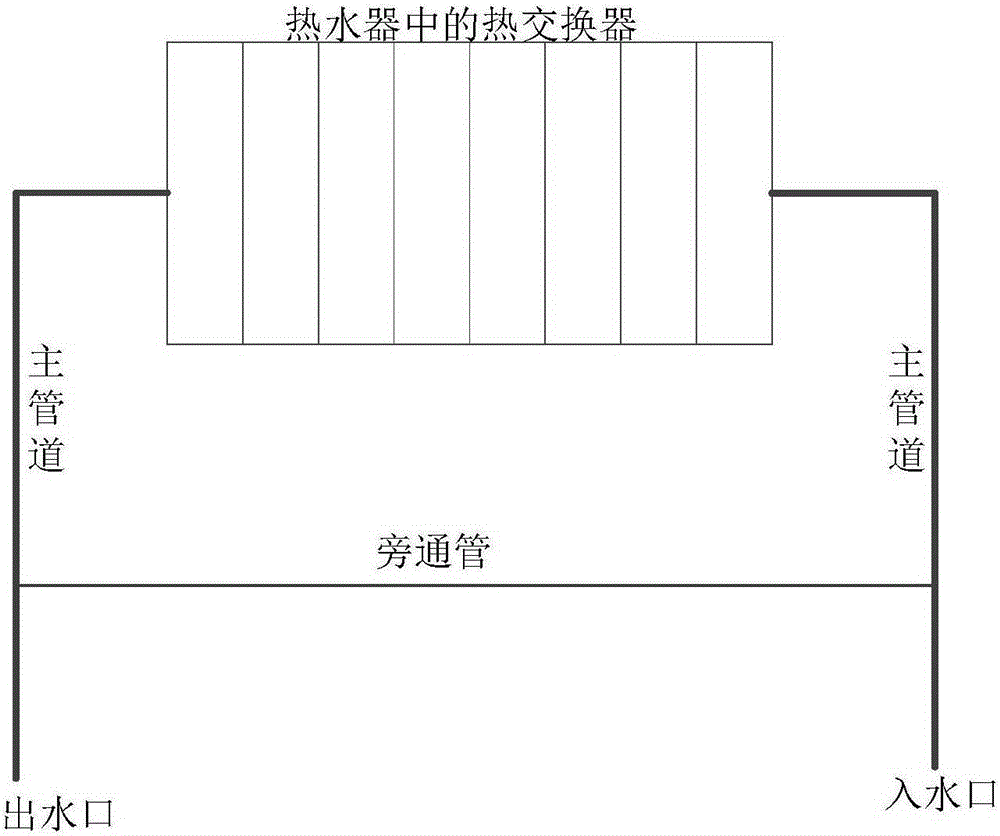

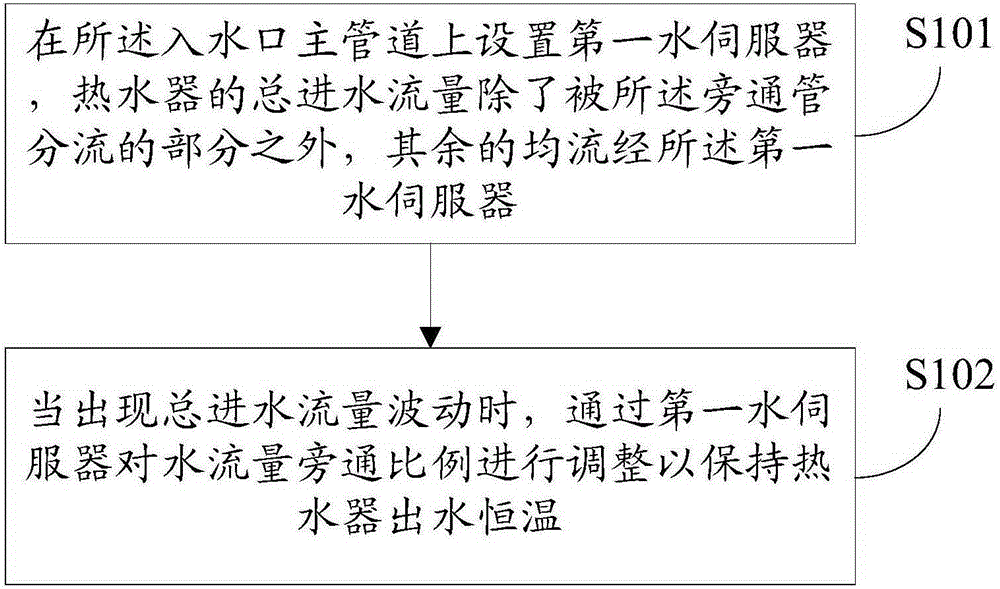

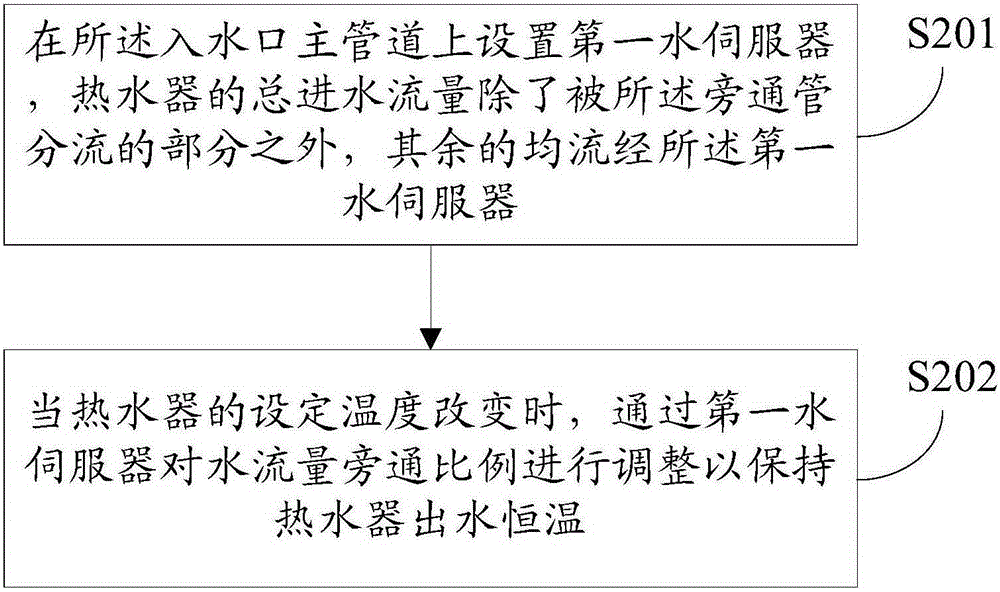

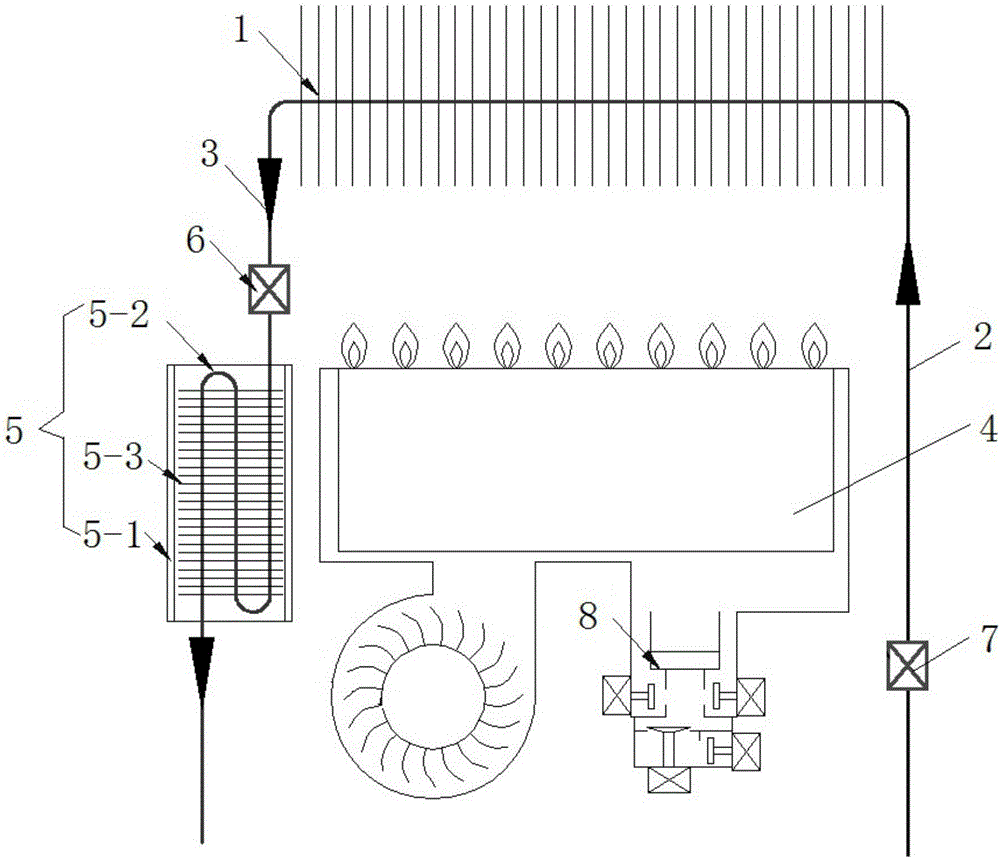

Constant-temperature control method and device for water heater

InactiveCN105276822AShorten the timeGood constant temperature effectFluid heatersTemperature controlWater flow

The invention provides a constant-temperature control method and device for a water heater. A bypass tube is bridged between a main water inlet pipeline and a main water outlet pipeline of the water heater. The method comprises that a first water server is arranged on the main water inlet pipeline; according to the water flow, all the incoming water of the water heater, excepting the water flowing through the bypass tube, flows through the first water server; when the total incoming water flow fluctuates or the set temperature of the water heater changes, the first water server can be controlled to adjust the bypassing ratio of the water flow so as to keep the constant temperature of the outgoing water of the water heater. According to the constant-temperature control method and device for the water heater, the water server capable of accurately adjusting the bypassing ratio of the water flow is additionally arranged on the water heater equipped with the bypass tube, so that the time of a gas water heater reaching the constant temperature can be further decreased, the problem of temperature delay can be solved, and the constant temperature performance of the gas water heater can be improved.

Owner:QINGDAO HAIER TECH

Water temperature fluctuation preventing fuel water heater

InactiveCN106168410AAvoid hot and coldAvoid discomfortStationary conduit assembliesWater heatersTemperature controlCombustor

The invention discloses a water temperature fluctuation preventing fuel water heater which comprises a heat exchanger, a water inlet pipe, a water outlet pipe and a combustor, wherein the water inlet pipe and the water outlet pipe are connected to the heat exchanger, and the combustor provides heat for the heat exchanger. The fuel water heater is characterized in that a heat storage device is connected to the water outlet pipe and comprises a shell, a heat exchange pipe arranged in the shell and connected with the water outlet pipe in series, and fins connected to the heat exchange pipe. By connecting the heat storage device to the water outlet pipe in series, when the water temperature suddenly rises, the heat in high-temperature water is absorbed and stored, and discomfort caused by too high water temperature is prevented; when the water temperature suddenly drops, the heat released in the heat storage device prevents water temperature from dropping. Meanwhile, through the combination of a memory alloy temperature control water valve, when the water outlet temperature is too high, the valve is automatically switched on to increase the water amount and prevent the water temperature from being too high; when the temperature is too low, the valve is automatically switched off to decrease the water amount and make the constant temperature quite precise.

Owner:GUANGDONG MACRO GAS APPLIANCE

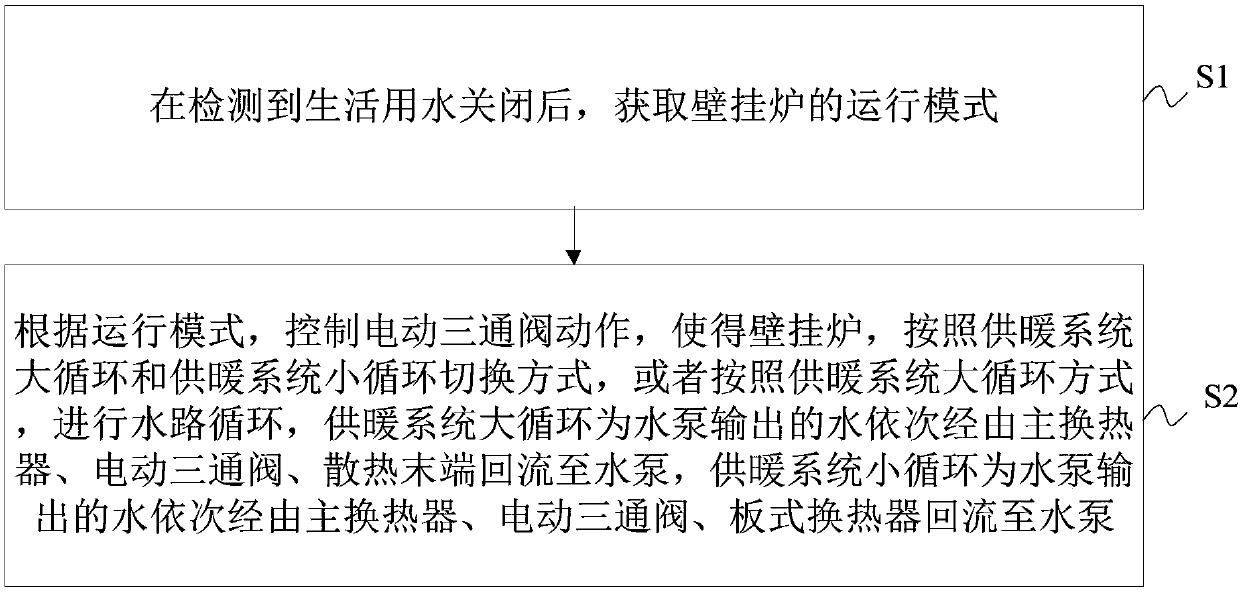

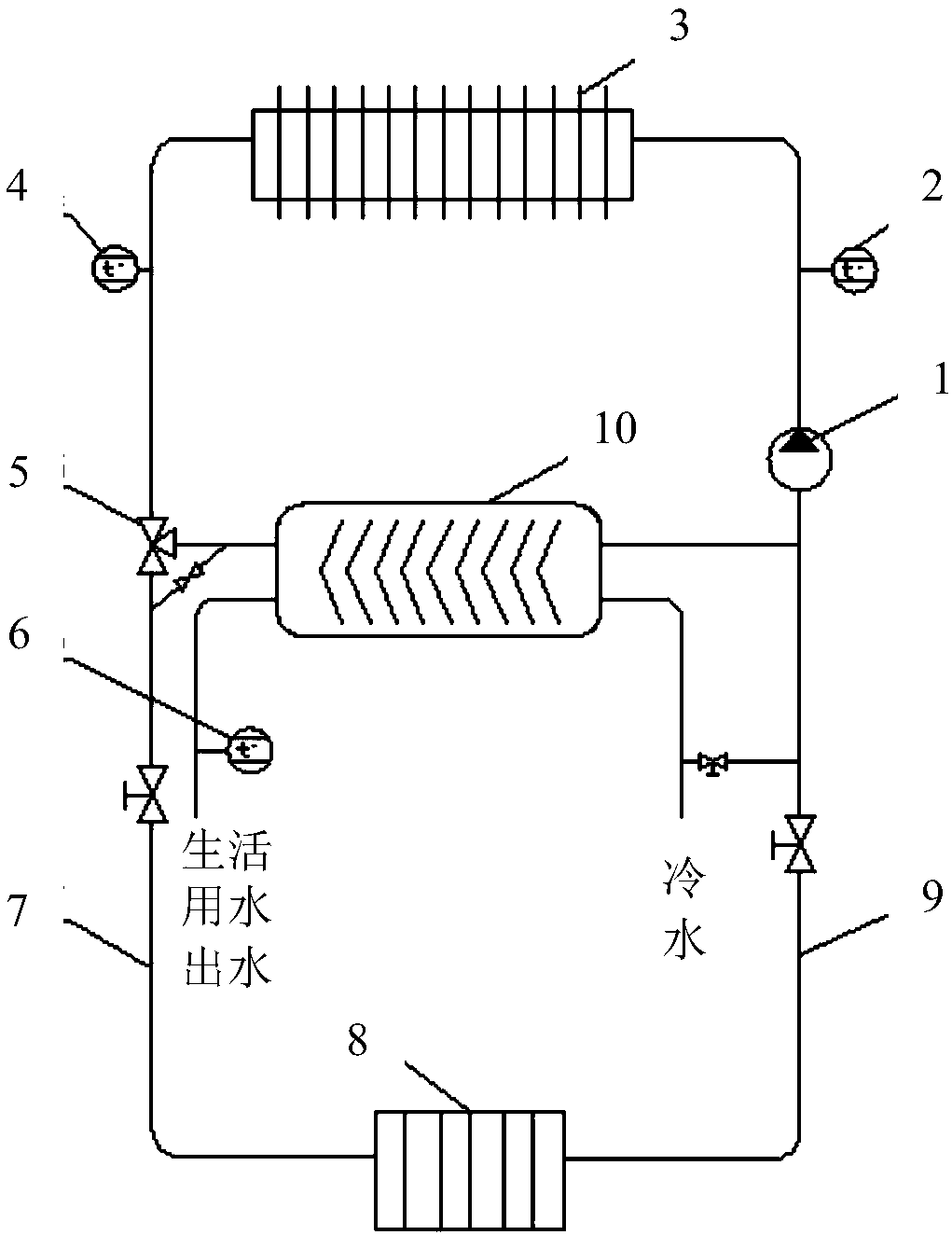

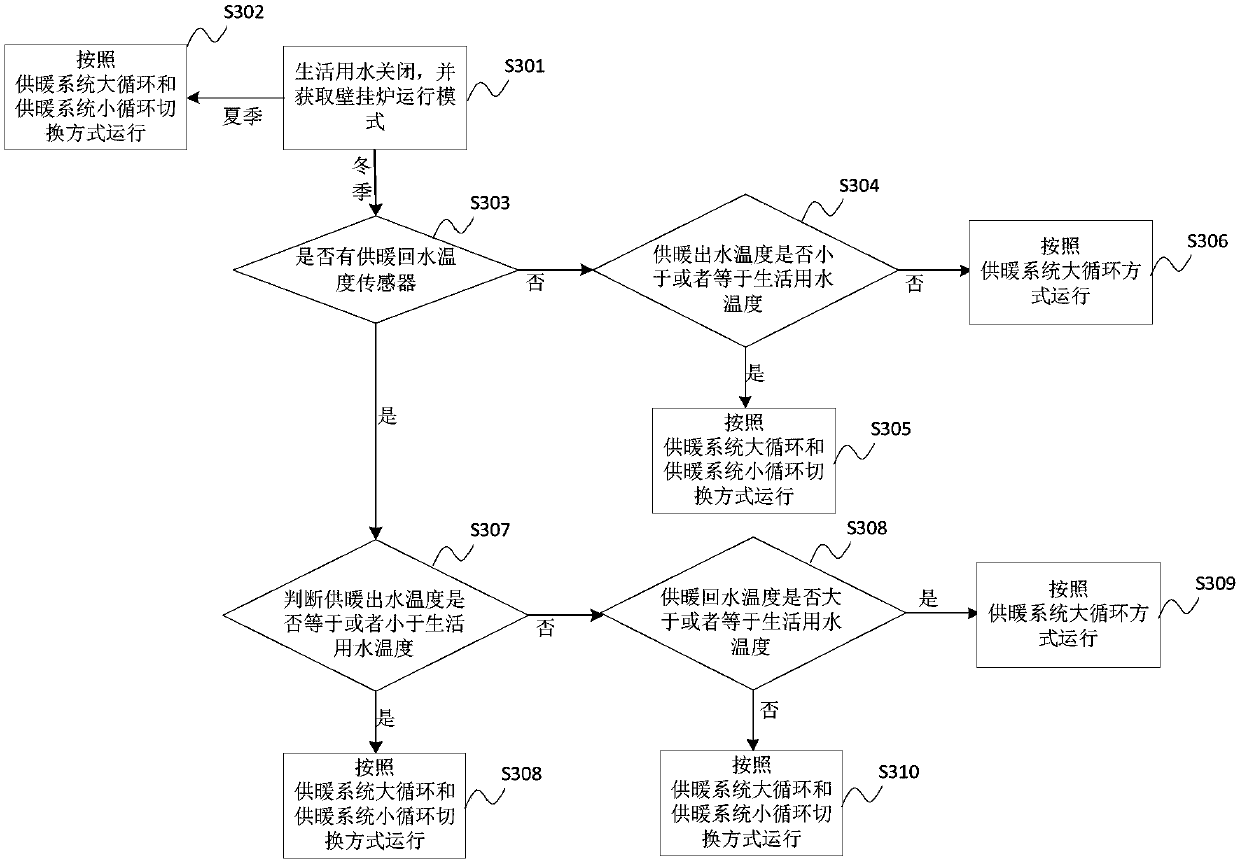

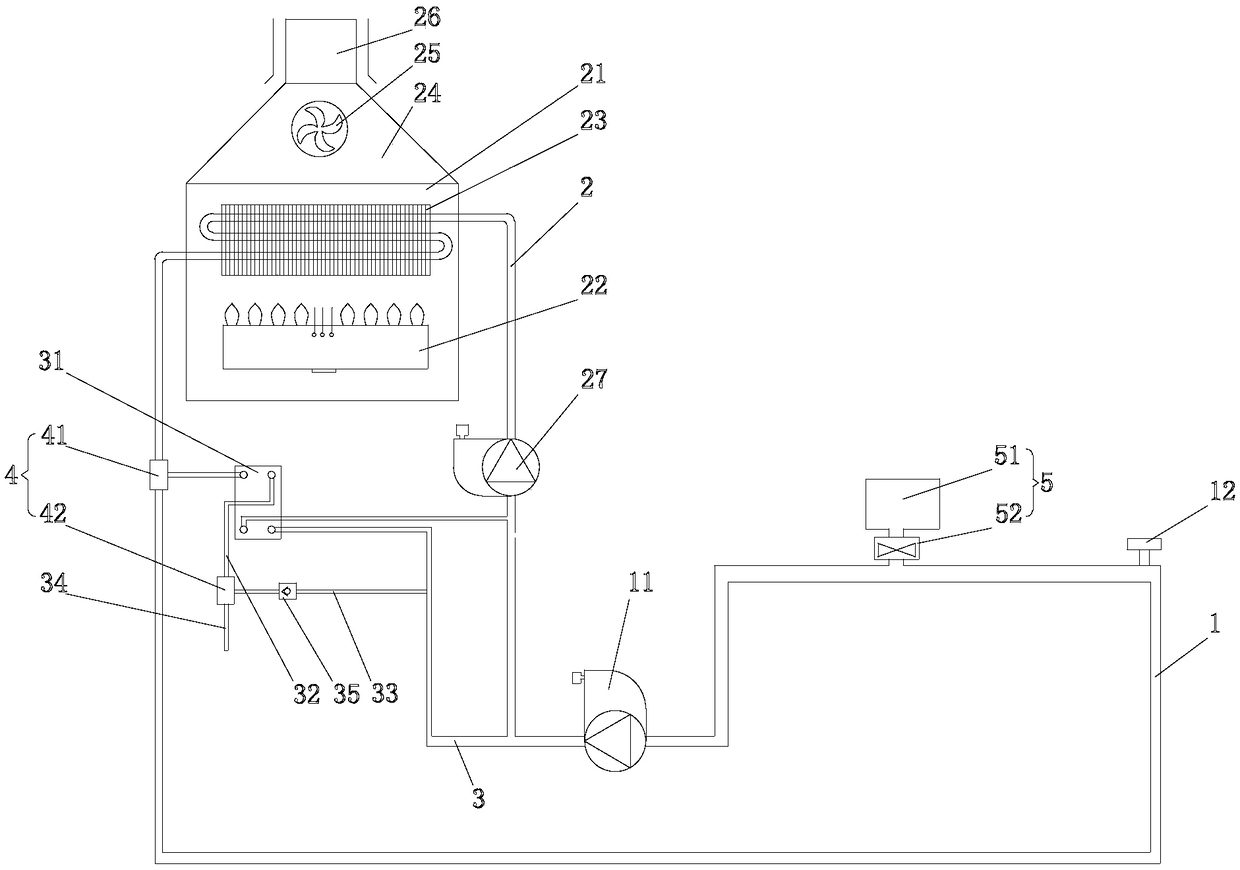

Wall hanging stove waterway circulation control method, device and system

PendingCN110579023AReduce water temperature riseImprove comfortFluid heatersHeating fuelEngineeringOperation mode

The invention discloses a wall hanging stove waterway circulation control method, device and system. The method comprises the steps that after it is detected that domestic water is turned off, an operation mode of a wall hanging stove is obtained; according to the operation mode, an electric three-way valve is controlled to act to make the wall hanging stove carry out waterway circulation according to the mode of switching a major cycle of a heating system and a minor cycle of the heating system or according to the major circle mode of the heating system, wherein according to the major cycle of the heating system, water output by a water pump passes through a main heat exchanger, the electric three-way valve and the heat dissipating tail end in sequence and flows back to the water pump, and according to the minor cycle of the heating system, water output by the water pump passes through the main heat exchanger, the electric three-way valve and a plate heat exchanger in sequence and then flows back to the water pump. By means of the method, after the domestic water is turned off, waterway circulation can be carried out in the mode of switching the major cycle of the heating system and the minor cycle of the heating system or in the mode of the major cycle of the heating system, water stopping temperature rising of the wall hanging stove can be effectively relieved, the comfortableness of domestic water can be improved, and the use experience of users can be improved.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

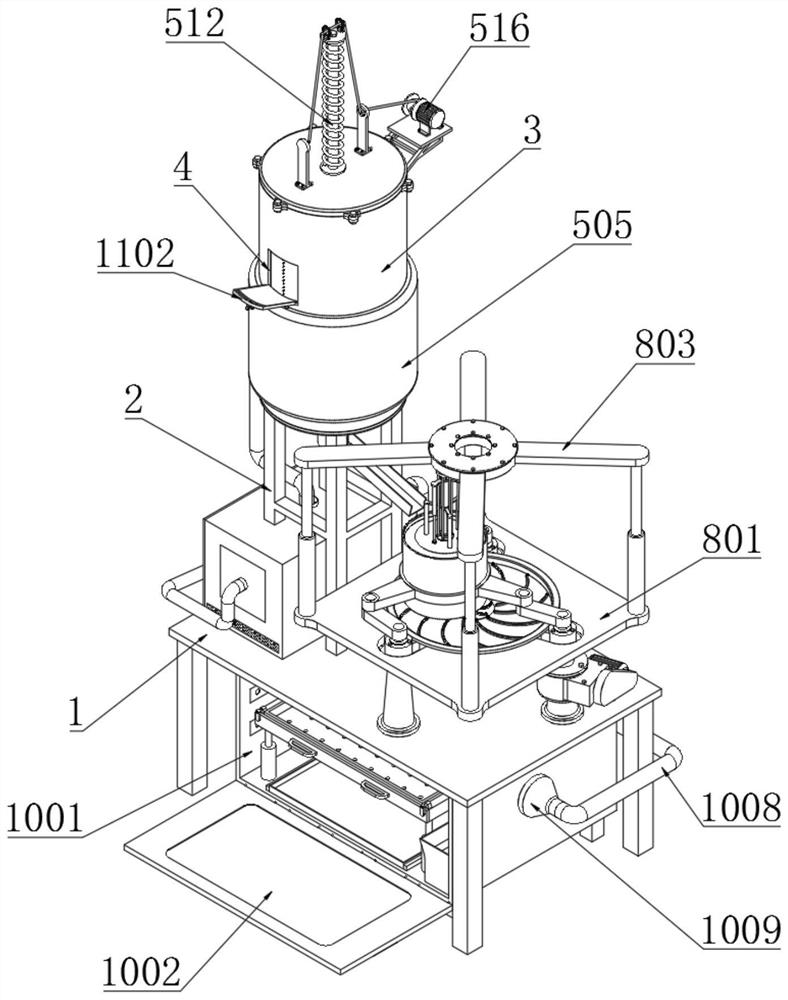

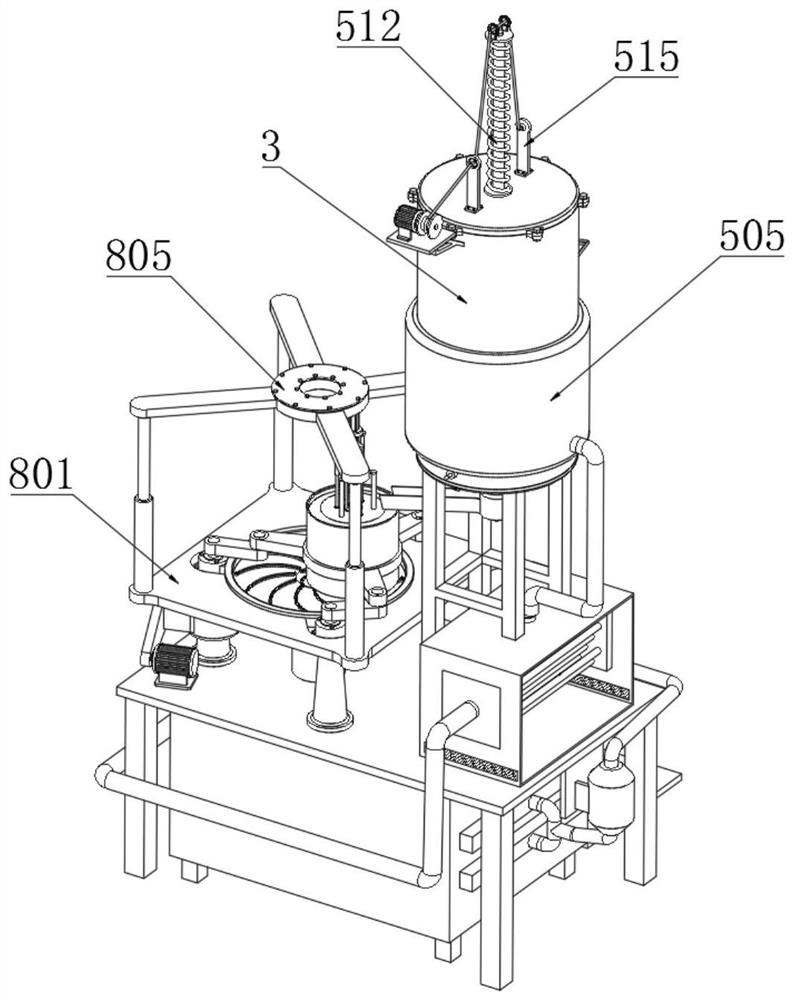

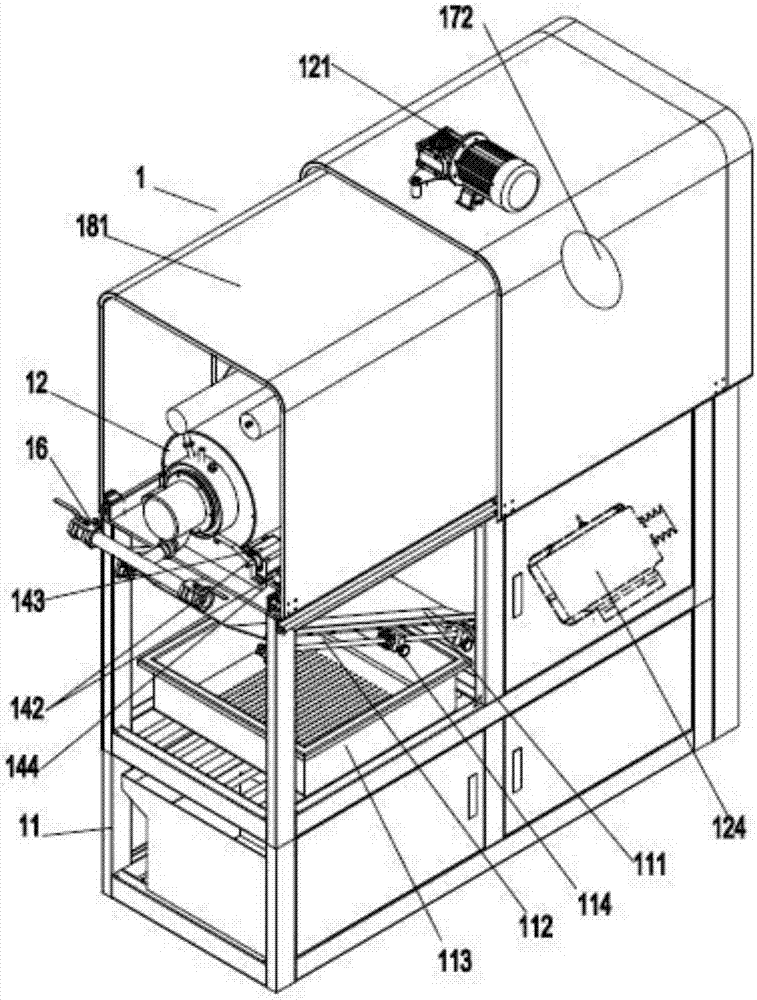

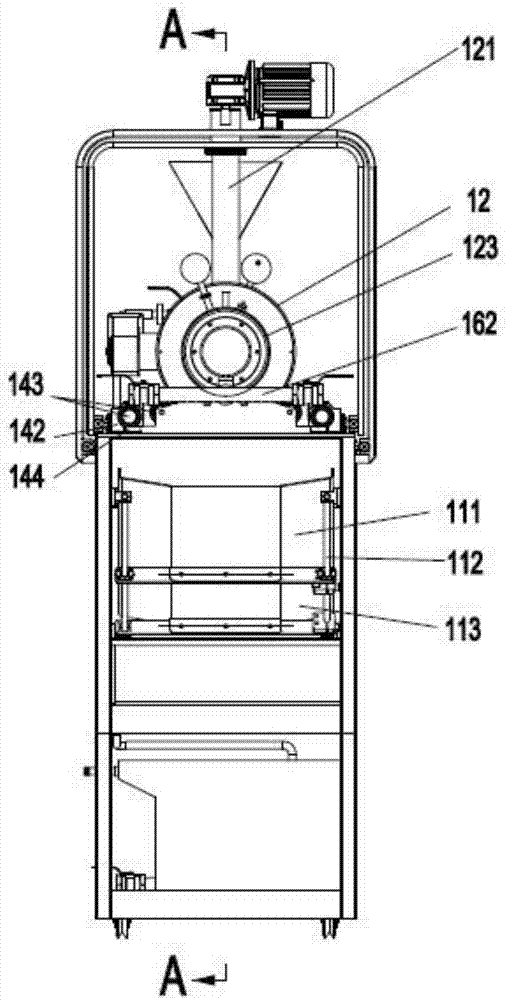

Rice flour preparation device

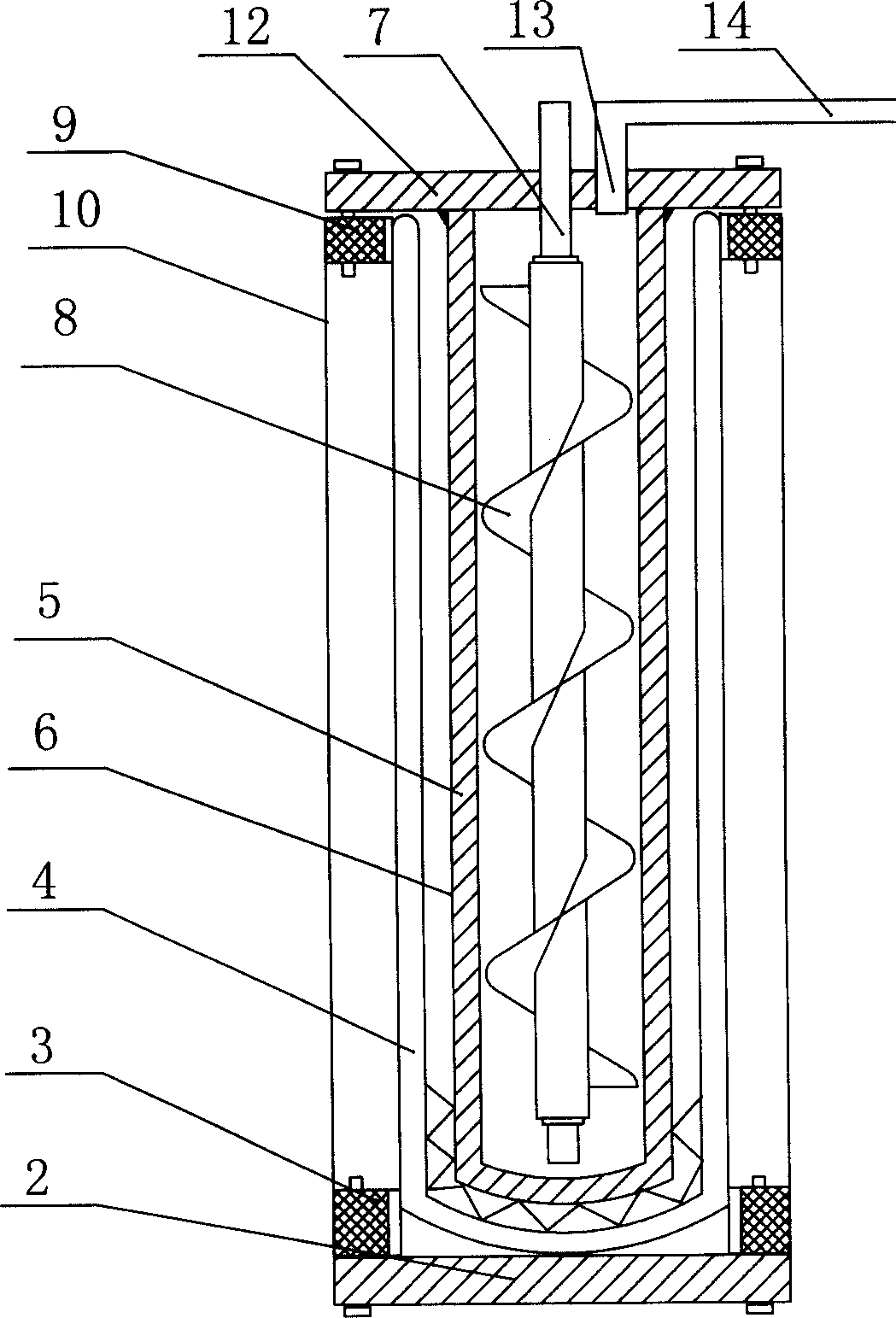

PendingCN107348342AHigh degree of automationImprove toughnessFood shapingEngineeringElectromagnetic heating

The invention discloses a rice flour preparation device which is characterized in that a heating device is composed of a heating cylinder, an electromagnetic heating coil and an insulation cover; a heat storage cavity which surrounds a material extrusion channel and is filled with heat conduction oil is arranged in the heating cylinder; the insulation cover is arranged at the periphery of the heating cylinder, and the electromagnetic heating coil is arranged in a heating cavity formed between the insulation cover and the heating cylinder; a spiral material extrusion rod extends into the material extrusion channel from the right side of the heating cylinder; and a rice flour forming assembly is arranged at the left end of the heating cylinder and is communicated with the material extrusion channel. The rice flour preparation device has the advantages of compact and scientific structure, safe and reliable work, long service life, short production cycle and high degree of automation, and the produced rice flour is safe and guaranteed; the rice flour preparation device has the characteristics of small volume, small production site occupation area, energy saving and environmental protection, and is convenient and fast to maintain, very convenient to assemble, disassemble and clean and convenient to operate; and furthermore, the processed rice flour is high in degree of curing, the vermicelli is fine and uniform, has good toughness, is not easy to break, is smooth and delicate and has good taste, and the produced flour is not sticky.

Owner:广东名得科技有限公司

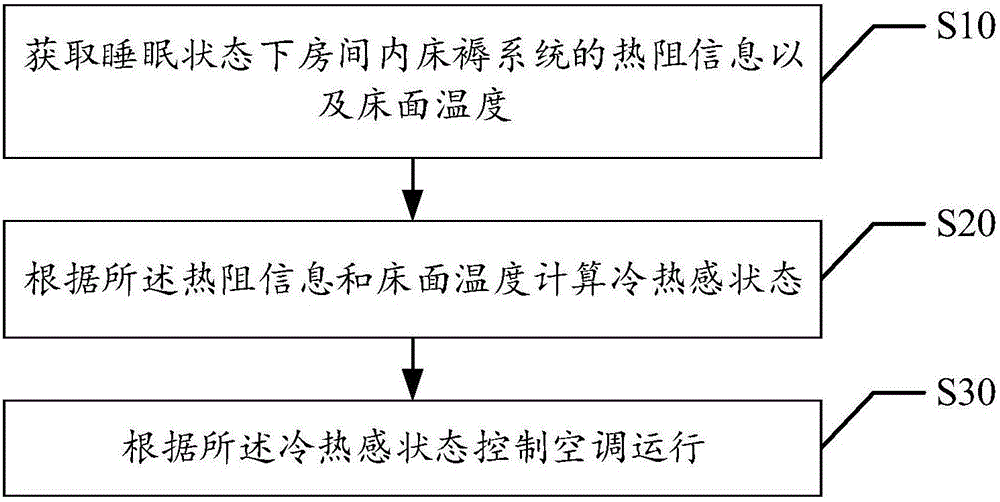

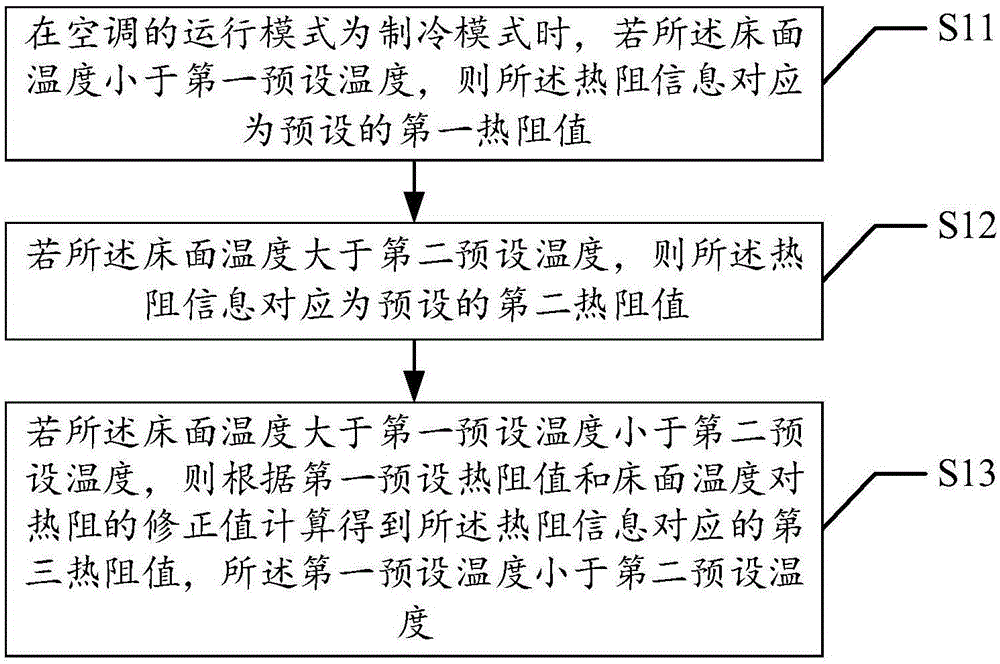

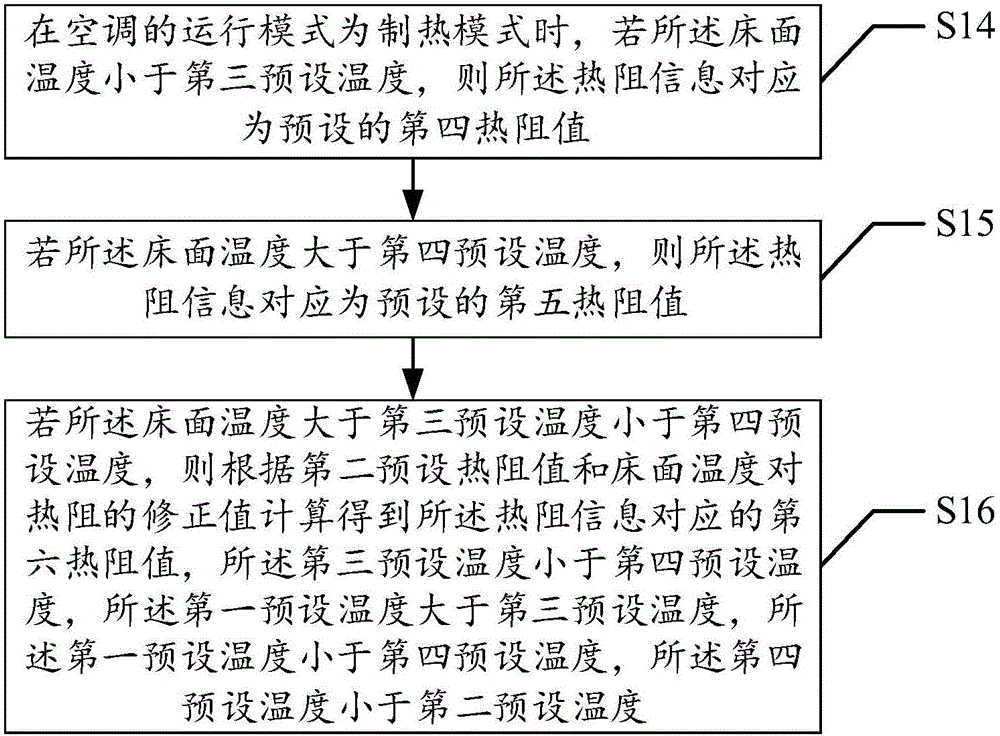

Air conditioner control method and device

ActiveCN106288145AImprove accuracyImprove comfortMechanical apparatusSpace heating and ventilation safety systemsSleep stateEngineering

The invention discloses an air conditioner control method. The method comprises steps as follows: acquiring thermal resistance information of a bedding system in a room in a sleep state and the bed surface temperature; calculating cold and thermal sensation states according to the thermal resistance information and the bed surface temperature; controlling an air conditioner to operate according to the cold and thermal sensation states. The invention further discloses an air conditioner control device. According to the air conditioner control method and device, the cold and thermal sensation states of a user are accurately provided, so that accuracy of air conditioner control is improved, and comfort of the air conditioner is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

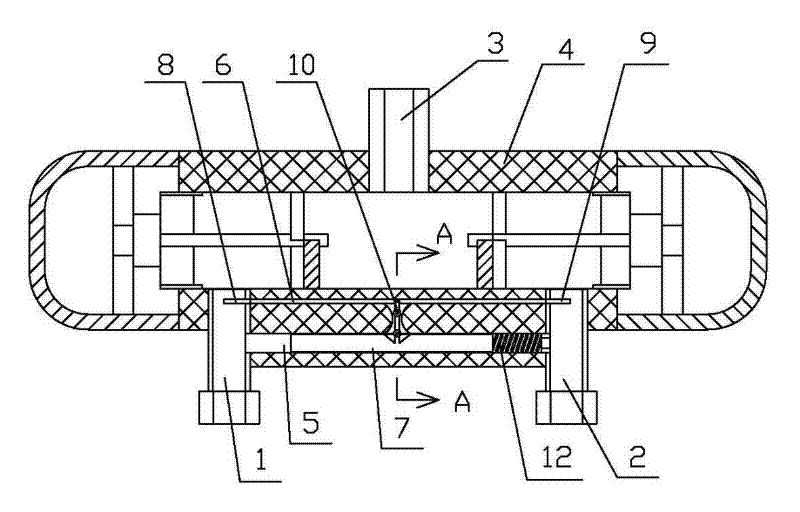

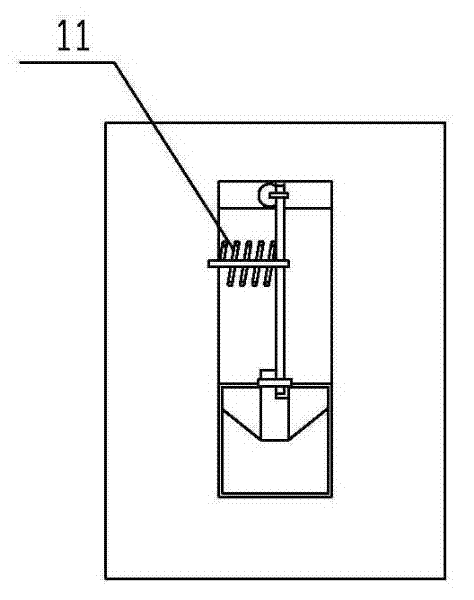

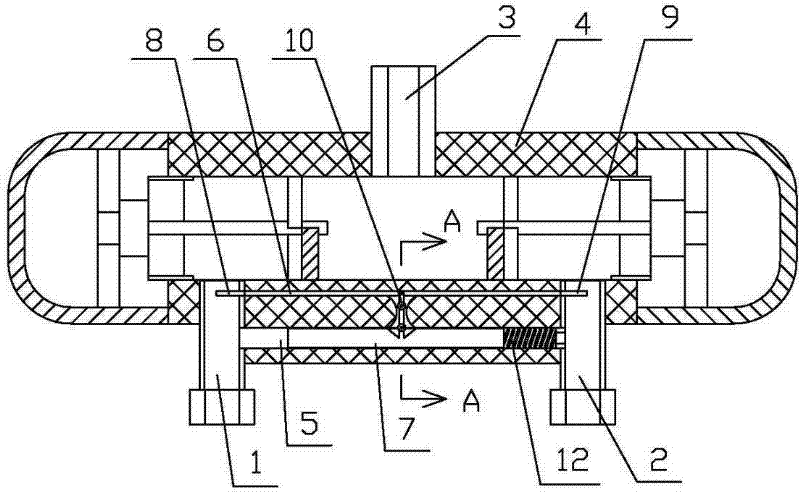

Water mixing valve with pressure balancing mechanism

InactiveCN102518831AEasy to operateEasy to useEqualizing valvesMultiple way valvesInstabilityEngineering

The invention relates to a water mixing valve with a pressure balancing mechanism. The water mixing valve comprises a casing with a first inlet, a second inlet and a water outlet. The water mixing valve is characterized in that a pressure sensing channel and a sliding rod channel are arranged between the first inlet and the second inlet; one end of the pressure sensing channel is communicated with the first inlet; the other end of the pressure sensing channel is communicated with the second inlet; a sliding block is arranged in an inner cavity of the pressure sensing channel; one end of the sliding rod channel is communicated with the first inlet; the other end of the sliding rod channel is communicated with the second inlet; a sliding rod is arranged in an inner cavity of the sliding rod channel; two ends of the sliding rod are respectively connected with a first gate plate and a second gate plate; the pressure sensing channel is mutually parallel to the sliding rod channel; a connecting rod cavity is arranged between the pressure sensing channel and the sliding rod channel; a connecting rod is arranged in the connecting rod cavity; an intermediate section of the connecting rod is pivoted on the inner wall of the connecting rod cavity; two ends of the connecting rod are respectively hinged on the sliding block and the sliding rod; and in addition, a return device acting on the connecting rod is arranged in the casing. The water mixing valve is simple in structure and is convenient to use; and according to the water mixing valve, the pressures of two water inlet ends can be automatically adjusted according to the change of the water pressure; the pressure difference between two ends can be reduced as much as possible; accurate adjustment of the temperature is facilitated; and the phenomenon of blow hot and cold due to the instability of the water pressure can be avoided.

Owner:潍坊百乐卫浴制品有限公司

Wall-hanging stove with self cleaning function and self cleaning method thereof

InactiveCN109489252AWith self-cleaning functionRealize self-cleaningMechanical apparatusWater heatersProcess engineeringControl valves

The invention relates to the technical field of wall-hanging stoves, in particular to a wall-hanging stove with a self cleaning function and a self cleaning method of the wall-hanging stove. The wall-hanging stove comprises a return water pipeline, a heating pipeline, a domestic hot water pipeline, a valve assembly and a detergent supply device. During self cleaning, the domestic hot water pipeline, the heating pipeline and the return water pipeline form a loop through the valve assembly, the detergent supply device includes a detergent storage tank and a control valve, the detergent storage tank is connected to the loop composed of the return water pipeline, the heating pipeline and the domestic hot water pipeline, and the control valve controls the detergent storage tank to be opened andclosed. The wall-hanging stove is provided with the valve assembly and the detergent supply device, during cleaning, the domestic hot water pipeline or the heating pipeline can be switched to be connected with the return water pipeline through the valve assembly, cleaning of the domestic hot water pipeline and the heating pipeline can be simultaneously achieved, meanwhile, the detergent supply device can be automatically opened or closed through the control valve, and the self cleaning function is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

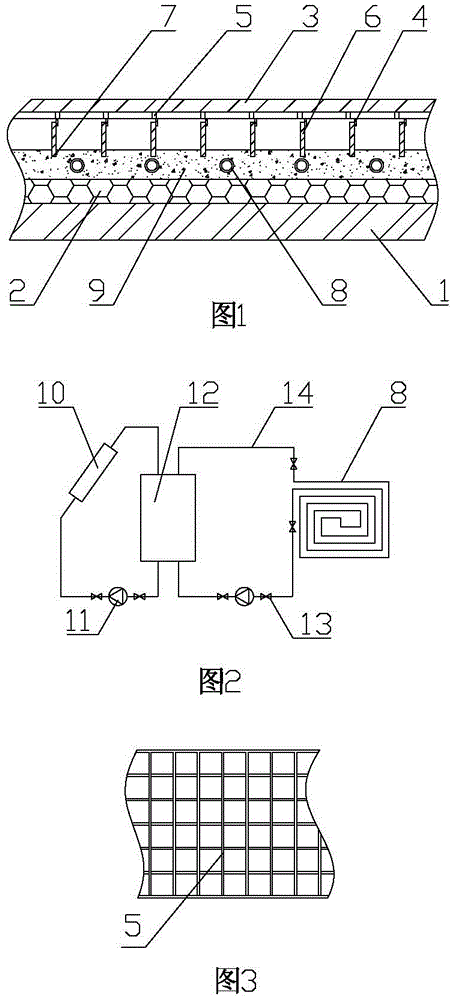

Phase change heat storage floor radiation device capable of preventing overheating

InactiveCN105841214ALarge thermal resistanceReduce lossLighting and heating apparatusFlooring insulationsHeat transmissionHeat conducting

The invention relates to the technical field of floor heating systems and provides a phase change heat storage floor radiation device capable of preventing overheating. The phase change heat storage floor radiation device comprises a structural layer, a thermal insulating layer, a phase change heat storage layer, an overheating preventing layer and a floor layer, wherein the structural layer, the thermal insulating layer, the phase change heat storage layer, the overheating preventing layer and the floor layer are sequentially overlapped together from bottom to top; and the overheating preventing layer comprises hot bimetallic strips, and the hot bimetallic strips are distributed between the phase change heat storage layer and the floor layer from the left to the right at intervals. Through promoting the hot bimetallic strips heated to have curved deformation, the thermal resistance of the overheating preventing layer can be increased, heat losses are reduced, and indoor overheating is prevented. When temperature suffered by the hot bimetallic strips is lower than the lower threshold, through restoring the hot bimetallic strips and promoting the hot bimetallic strips to be in contact with flexible heat conducting strips, heat radiation is promoted, and heat transmission efficiency is increased. Therefore, the regulation of heat radiation can be realized, and the keeping of a constant indoor temperature range is facilitated. Besides, through storing excessive heat and releasing the excessive heat when needed, resource wastes can be avoided, indoor temperature fluctuation can be effectively prevented, the range of temperature differences is reduced, and the comfort of users is improved.

Owner:XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com