Control method for adjusting exhaust superheat degree of air conditioner, and air conditioner

A technology of exhaust superheat and control method, which is applied in the field of exhaust superheat control of refrigeration equipment compressors, can solve the problems of compressor frequency increase, capacity decrease, and poor user comfort, and achieve the goal of avoiding changes in refrigeration capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

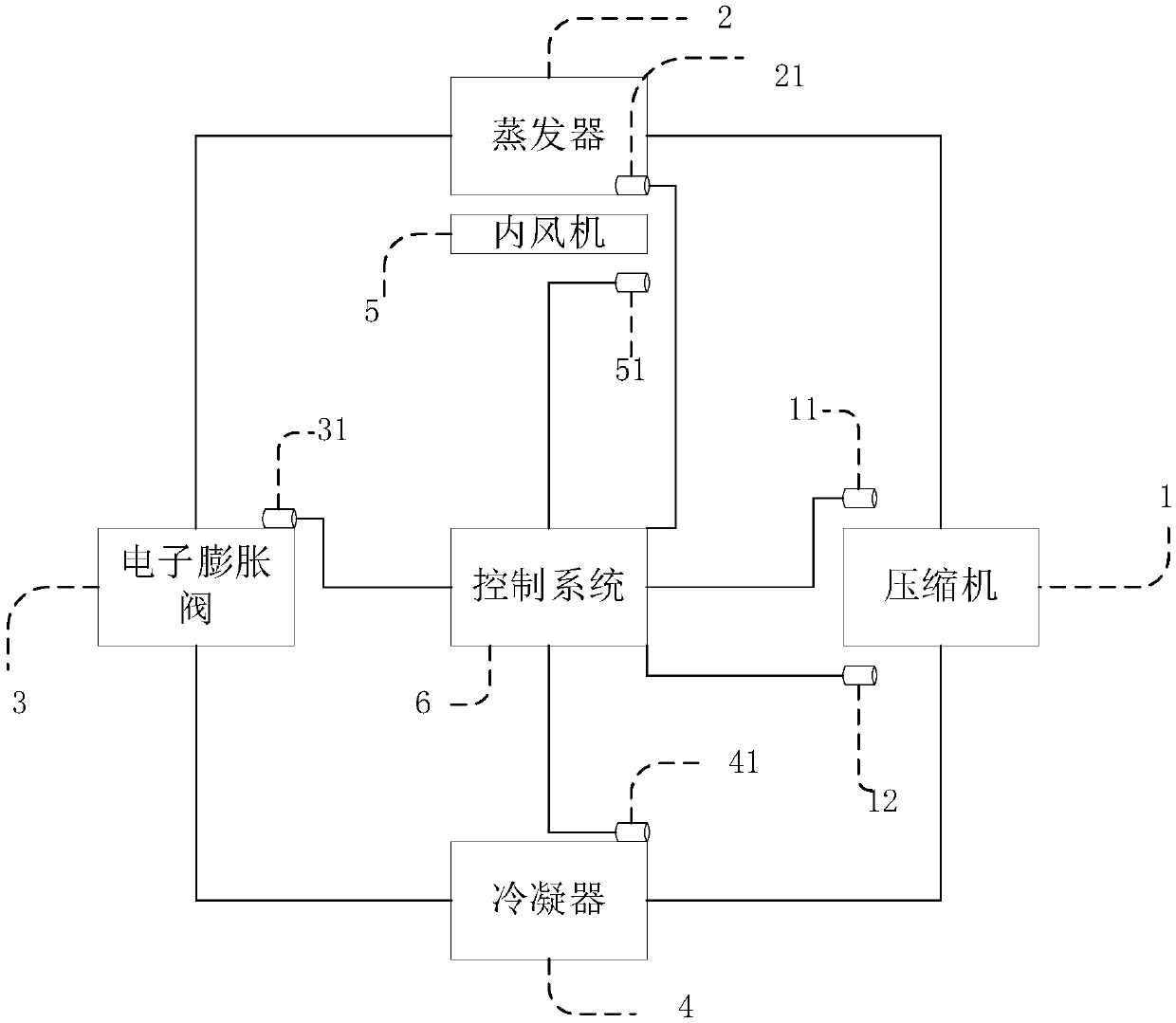

[0028] With the help of figure 1 The air conditioner system of the present invention is schematically illustrated. According to the air conditioner of the present invention, it includes a compressor 1, an evaporator 2, an electronic expansion valve 3, a condenser 4, an internal fan 5 and a control system 6. A discharge temperature sensor 12 is provided at the outlet of the compressor, a suction temperature sensor 11 is provided at the suction port of the compressor, and a pressure sensor 21 is provided on the evaporator 2 to detect the evaporation pressure, which is equal to the discharge pressure of the compressor. Pressure, a pressure sensor 41 is provided on the condenser 4 for detecting the suction pressure, a speed detector 51 is provided near the internal fan 5, and a temperature sensor 31 is provided on the side of the electronic expansion valve 3 attachment.

[0029] Example 1

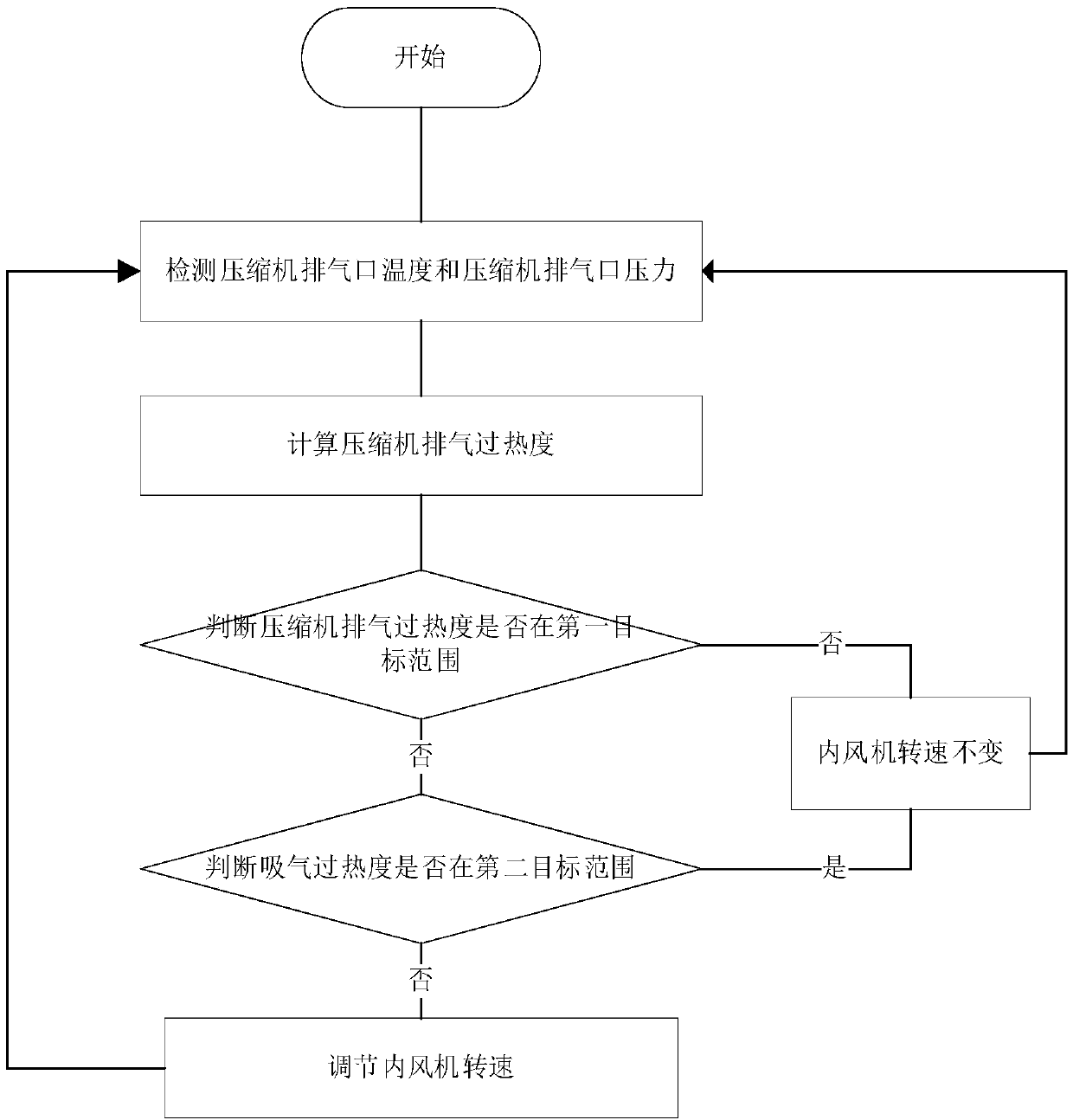

[0030] figure 2 Shown is the control flowchart of the air conditioner control method of ...

Embodiment 2

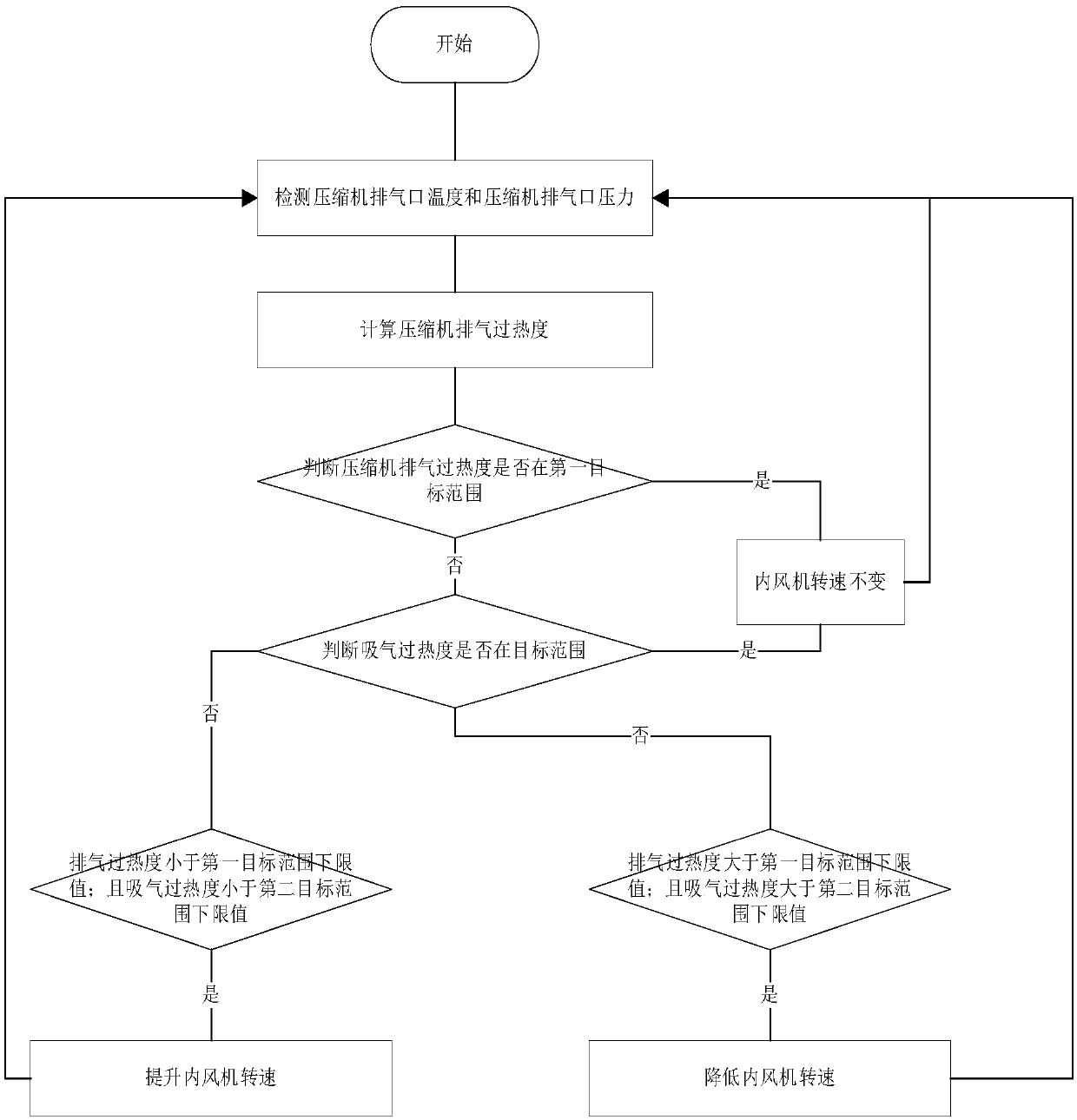

[0037] In Embodiment 2 of the present invention, the control method is further optimized on the basis of Embodiment 1 above. For example, in Embodiment 1, when the rotational speed of the internal fan 5 reaches the maximum or minimum limit value, if the exhaust superheat or the suction superheat is still not The target range, the fan speed control will be invalid or continue to adjust the speed according to the above method, there may be safety hazards, such as Figure 4As shown, in the control of the speed increase of the internal fan 5, it is judged whether the speed of the internal fan 5 has reached the maximum value, and the maximum value can be a set maximum limit value. Air temperature T 排 and compressor discharge pressure P 排 Steps to perform a new round of loop control. If the rotation speed of the internal fan 5 reaches the maximum value, the electronic expansion valve 3 is controlled to reduce the opening degree, and the electronic expansion valve 3 returns to dete...

Embodiment 3

[0040] Such as figure 1 The illustrated embodiment of the present invention provides an air conditioner, including a compressor 1, an evaporator 2, an electronic expansion valve 3, a condenser 4, an internal fan 5 and a control system 6, and an exhaust port is provided at the exhaust port of the compressor. A temperature sensor 12, a suction temperature sensor 11 is set at the suction port of the compressor, and a pressure sensor 21 is set on the evaporator 2 to detect the evaporation pressure, which is equal to the discharge pressure of the compressor. 4 is provided with a pressure sensor 41 for detecting the suction pressure, a rotational speed detector 51 is provided near the internal fan 5, and a temperature sensor 31 is provided at the side of the electronic expansion valve 3 attachment. The control system 6 controls the operation of the air conditioner according to the control method of Embodiment 1 or 2.

[0041] It should be noted that the control methods of Embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com