Conveyer belt type cryogenic treatment apparatus

A cryogenic treatment and conveyor belt technology, which is applied in the field of cryogenic treatment equipment for metal materials and non-metallic material products, can solve the problems of not being able to adapt to the conveyor belt production line, and achieve the effect of increasing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

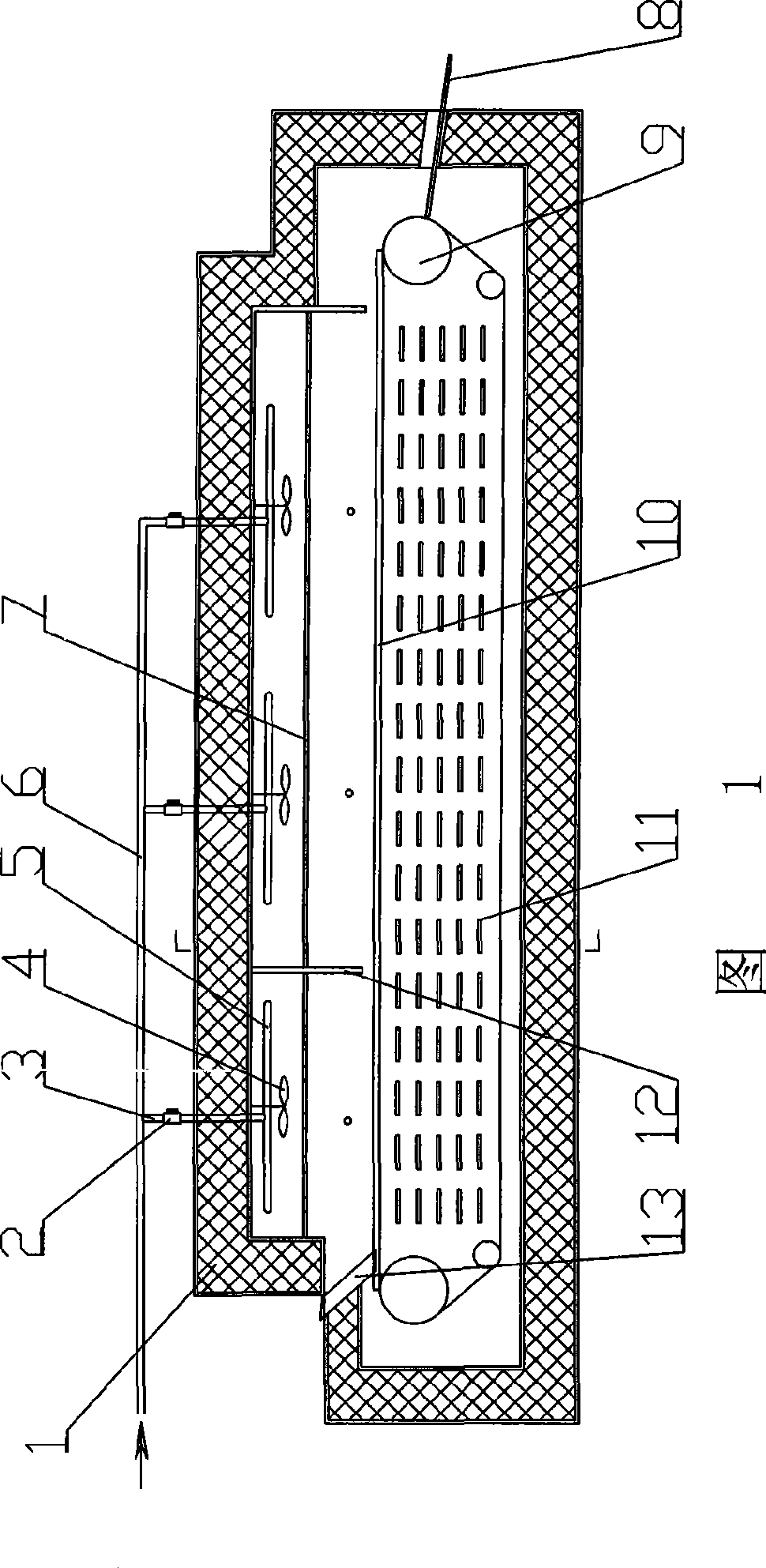

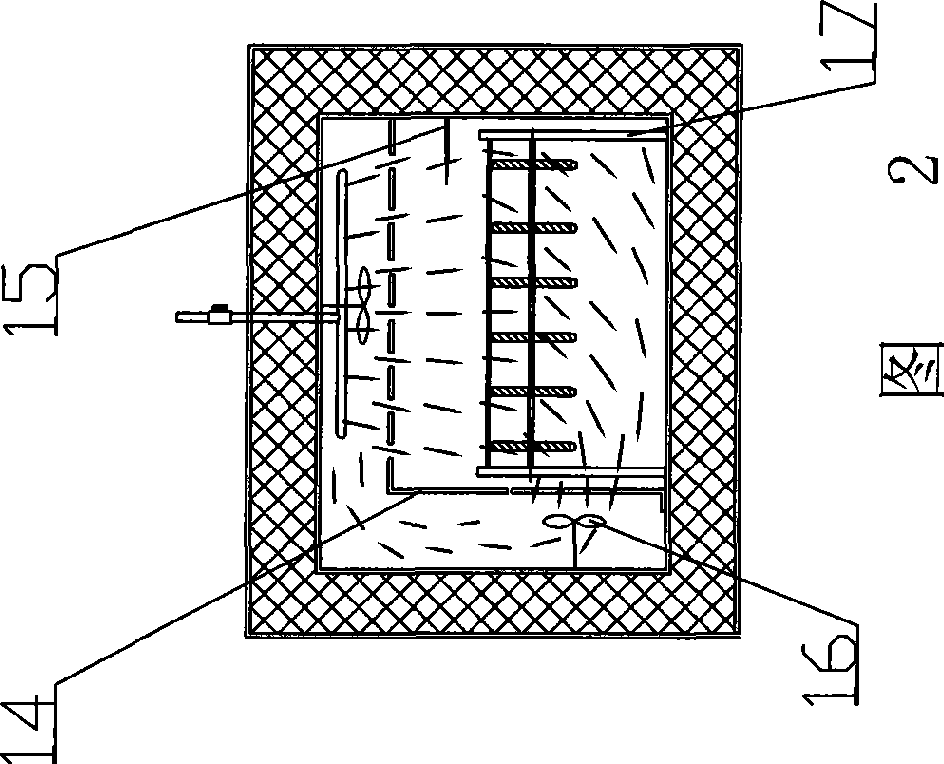

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] Referring to Fig. 1 and Fig. 2, a conveyer-type cryogenic treatment device includes a thermal insulation box 1, a liquid nitrogen distribution and spraying device and an upper blower 4, and the liquid nitrogen distribution and spraying device is connected to the liquid nitrogen tank through a pipeline 6 connected, the spray pipe 5 of the liquid nitrogen distribution and spraying device extends into the heat insulation box 1, the upper blower 4 is located at the upper part of the inner cavity of the heat insulation box 1, and the conveyor belt 5 is installed in the heat insulation box 1 , the front and rear ends of the conveyor belt 5 are respectively set on the transmission wheel 9, the transmission wheel 9 is connected to the driving device, the front part of the heat insulation box 1 is equipped with a feed guide plate 13, and the front of the heat insulation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com