Patents

Literature

78results about How to "Uniform temperature drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

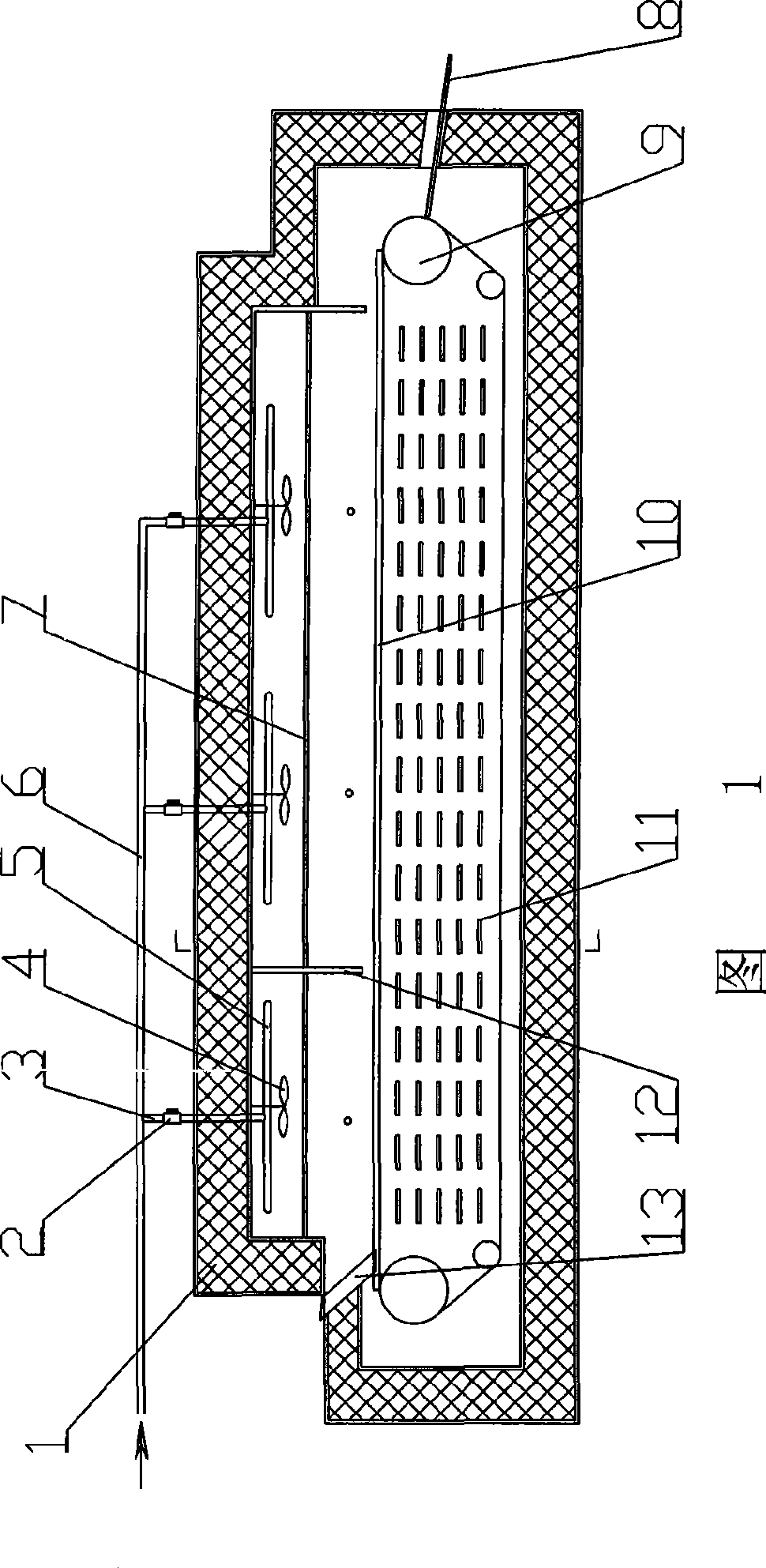

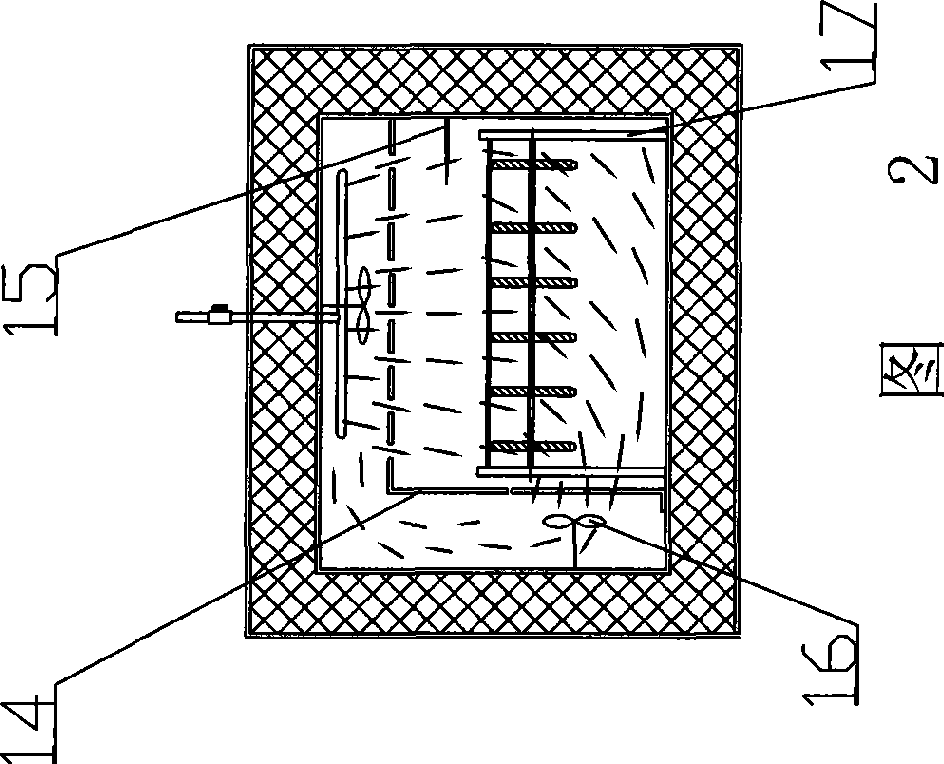

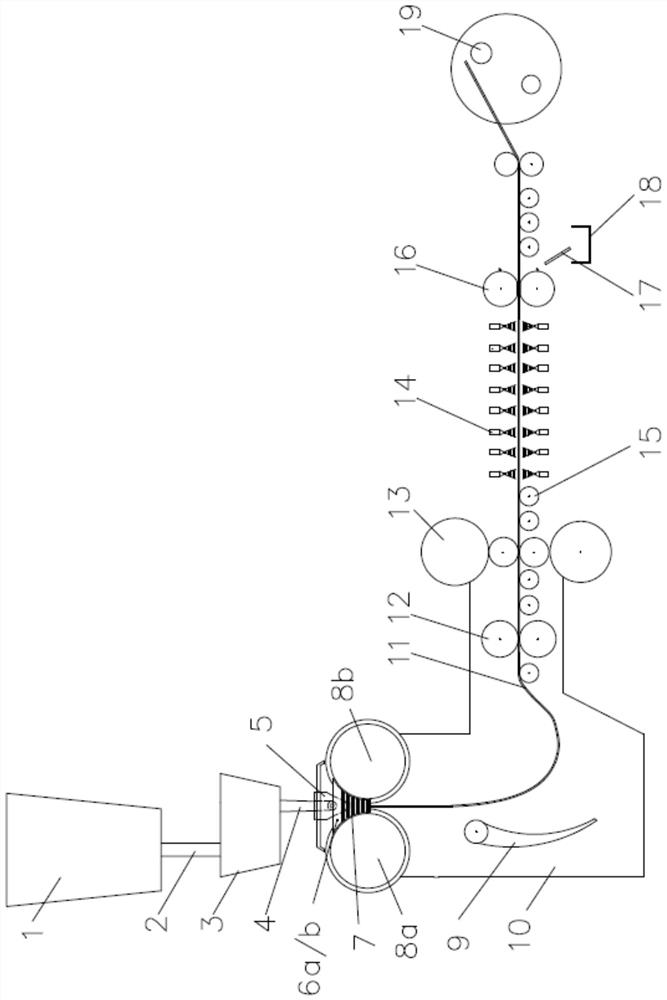

Conveyer belt type cryogenic treatment apparatus

A conveyer belt type sub-zero treatment device comprises a heat insulation box body, a liquid nitrogen distributing and sprinkling device and an upper blower, wherein, the liquid nitrogen distributing and sprinkling device is connected with a liquid nitrogen tank, a liquid spraying pipe of the liquid nitrogen distributing and sprinkling device extends into the heat insulation box body, the upper blower is arranged at the upper part of the inner cavity of the heat insulation box body which is provided with a conveyer belt, the front end and the rear end of the conveyer belt are respectively sheathed on a drive wheel which is connected with a drive unit, the front part of the heat insulation box body is provided with a feeding guide plate, and the rear part of the heat insulation box body is provided with an outlet vibrating feed plate, an upper mesh baffle is respectively arranged under the liquid spraying pipe of the liquid nitrogen distributing and sprinkling device and the upper blower, a side mesh baffle is arranged on the side of the conveyer belt, and the lower part of the side mesh baffle is provided with side meshes which are arranged under the upper conveyer belt. The sub-zero treatment device can be applicable to conveyer belt type production line operation.

Owner:ZHEJIANG UNIV OF TECH

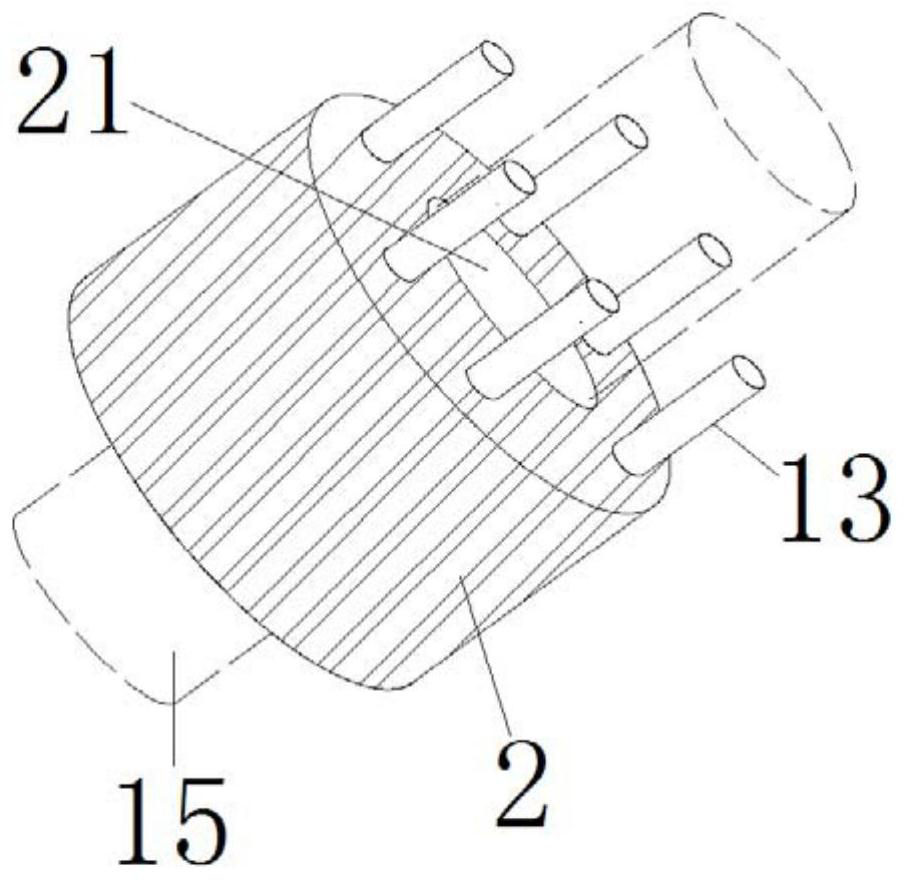

Water-cooled reactor

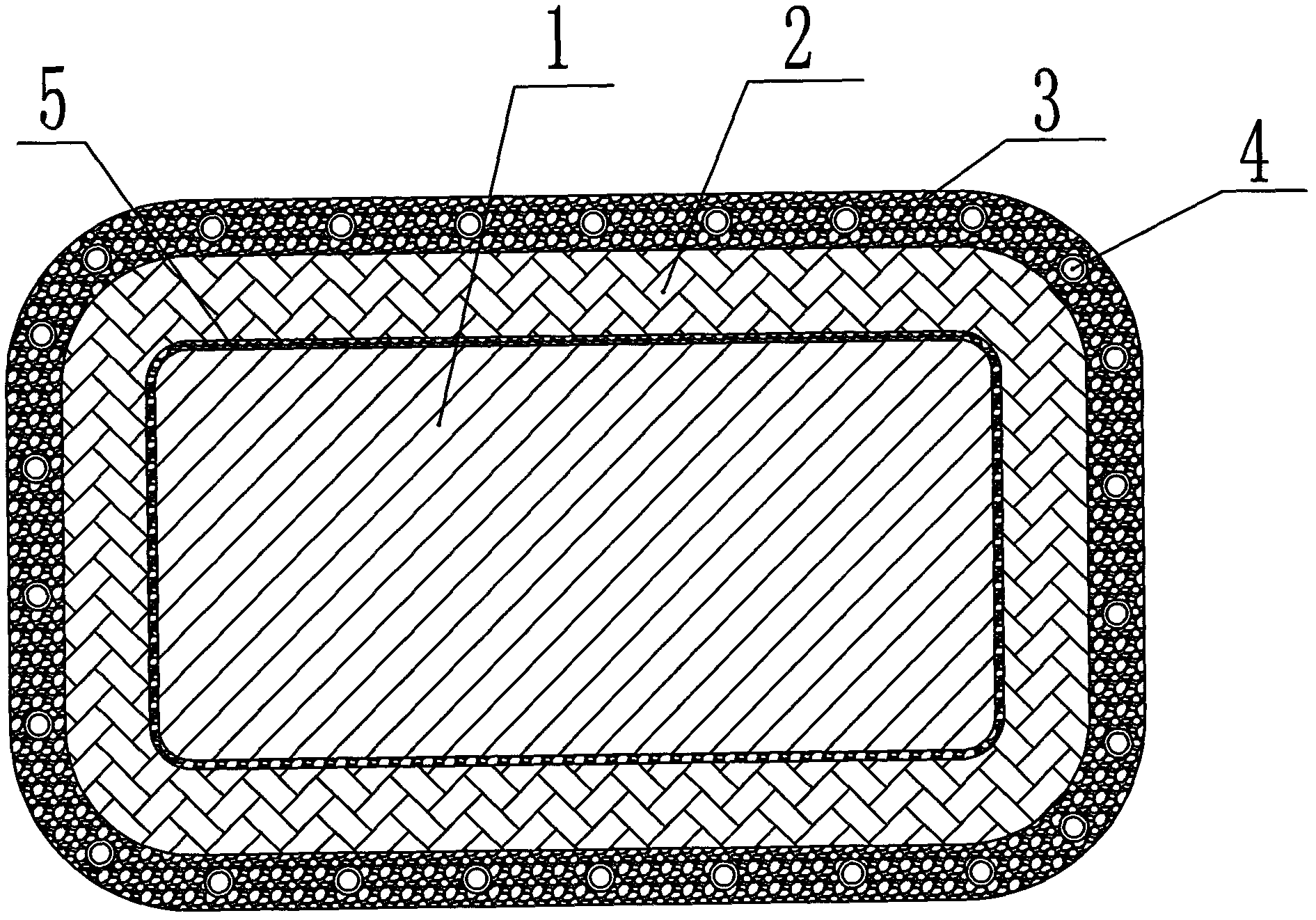

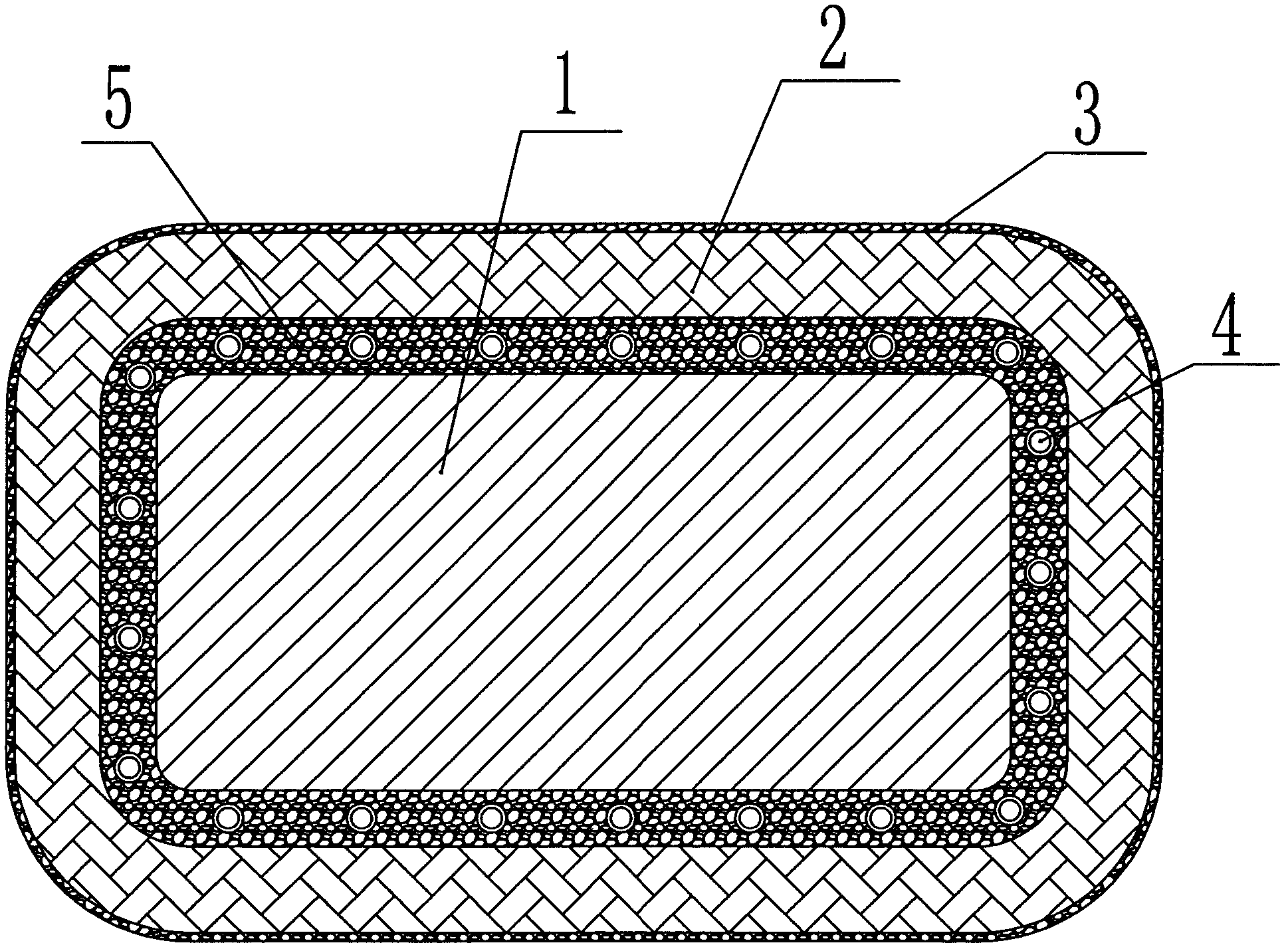

InactiveCN102568765AOvercoming high manufacturing costsOvercome uneven heat transferTransformers/inductances coolingWater pipeNuclear engineering

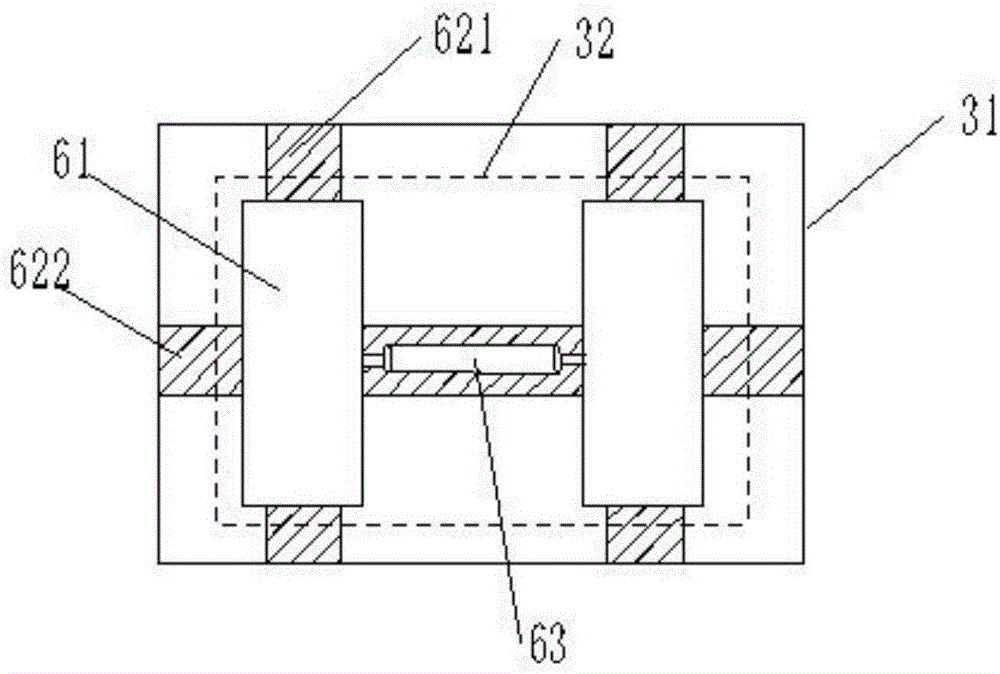

A water-cooled reactor comprises an iron core and a conductive coil arranged on the outer side of the iron core, and is characterized by further comprising a cooling water pipe arranged on the inner side or the outer side of the conductive coil, a water inlet and a water outlet are arranged on the cooling water pipe, and heat conduction medium materials are packaged between the cooling water pipe and the conductive coil. By the water-cooled reactor, the defects of high manufacturing cost and stoppage of an existing hollow copper pipe cooling manner and ununiform heat exchange of an existing plate type cooling manner are overcome. The water-cooled reactor with the advantages in the technical scheme can be applied to electronic equipment, such as transformers and the like.

Owner:EAGLERISE ELECTRIC & ELECTRONICS (CHINA) CO LTD

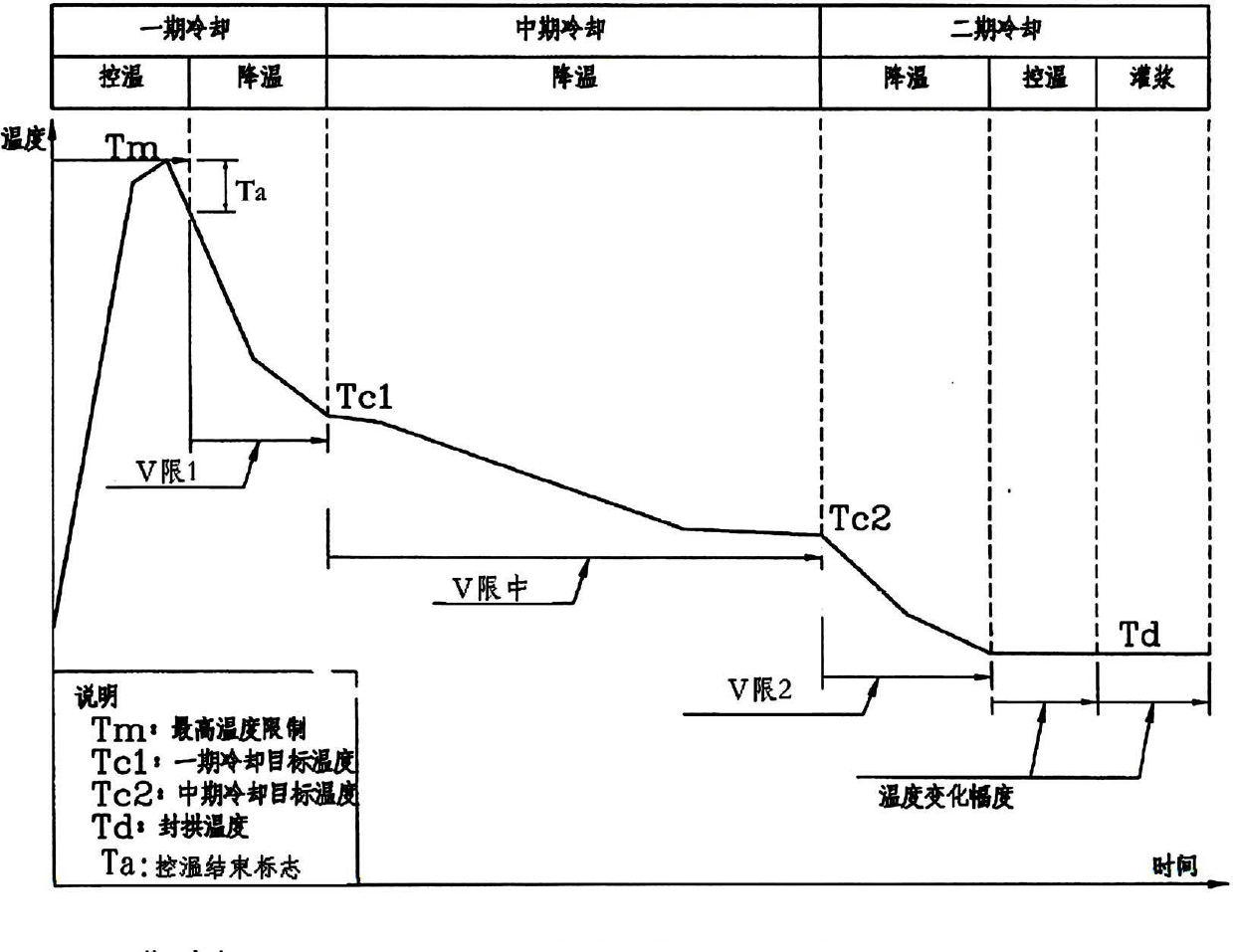

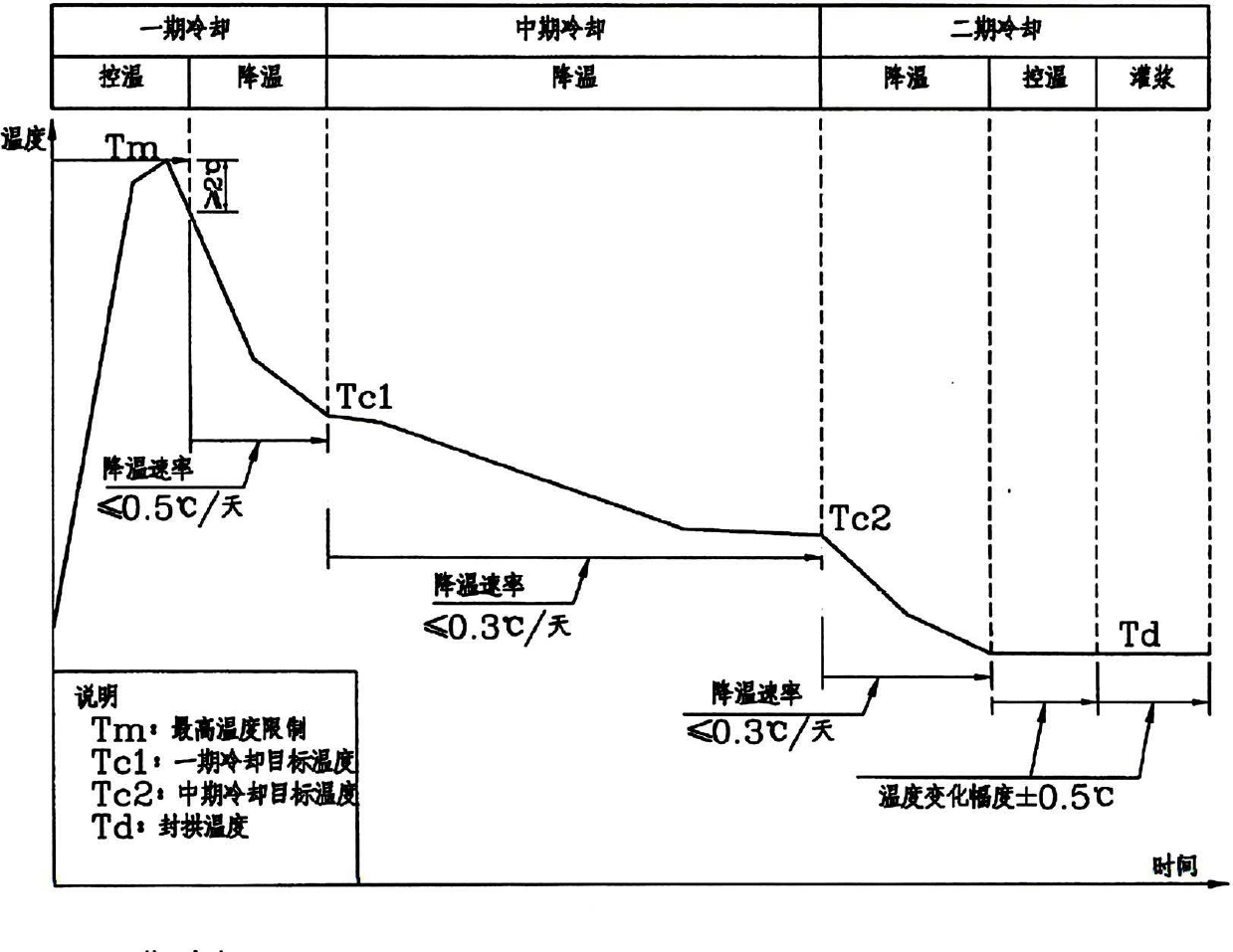

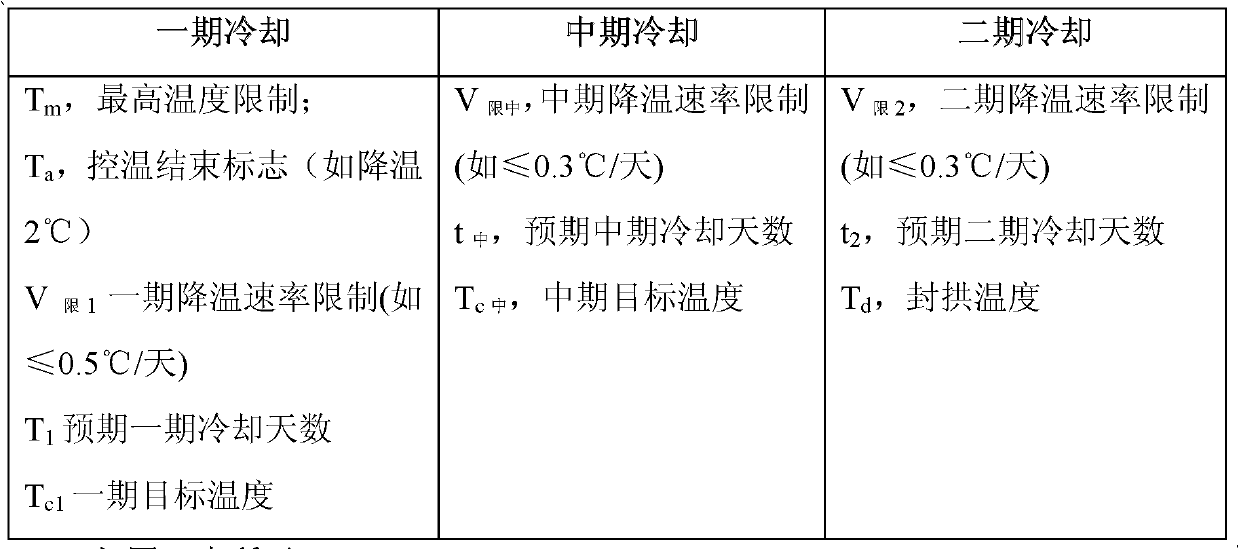

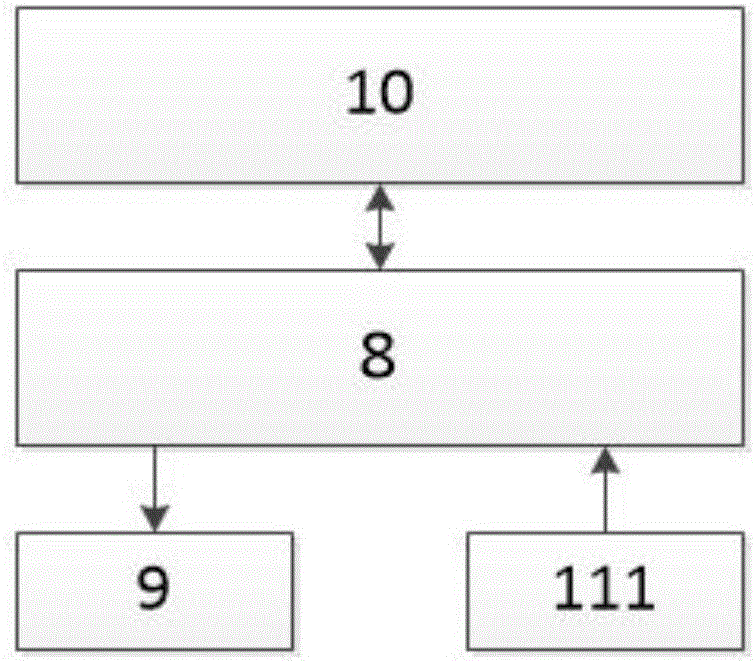

Method for controlling mass concrete cooling introduced water flow

ActiveCN102508499AUniform temperature dropCorrection errorTemperature control without auxillary powerFlow controlWater flowLag

The invention relates to a method for controlling a mass concrete cooling introduced water flow. The method comprises the following steps of: (1), obtaining a value of a historical concrete introduced water cooling efficiency; and (2), calculating a required next flow control value according to the value of the historical concrete introduced water cooling efficiency and a cooling amplitude and a cooling time interval to be required in the future, and uniformly decreasing concrete temperature according to design requirements through the above steps. According to the method for controlling the mass concrete cooling introduced water flow, provided by the invention, by introducing dynamic adjustment of a practical cooling flow coefficient alpha and by matching with auxiliary modification of a lag coefficient ksi, internal temperature of concrete can be uniformly and stably decreased, and the purpose of controlling a target temperature can be achieved during an expected time; furthermore, automatic calculation of a cooling water flow is realized, manual control arbitrariness can be excluded, and the construction quality of mass concrete can be further increased.

Owner:CHINA GEZHOUBA GROUP CO LTD

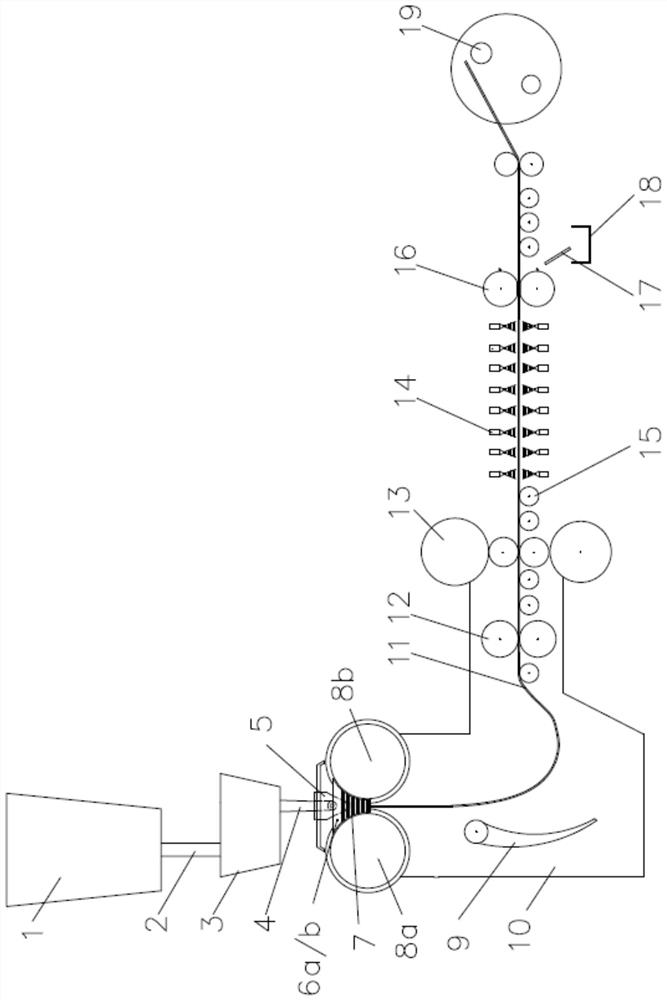

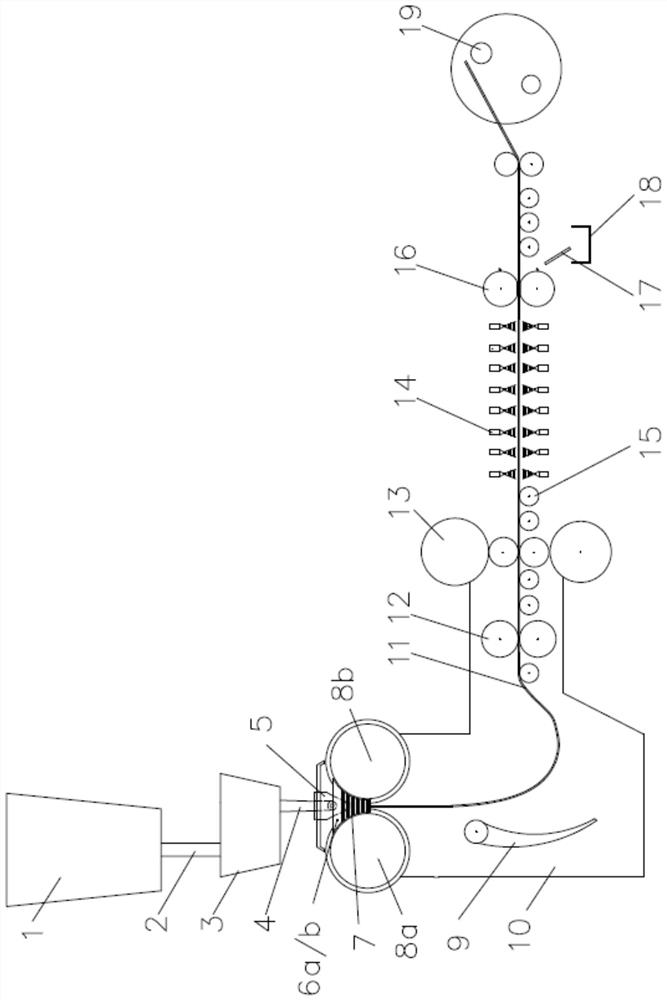

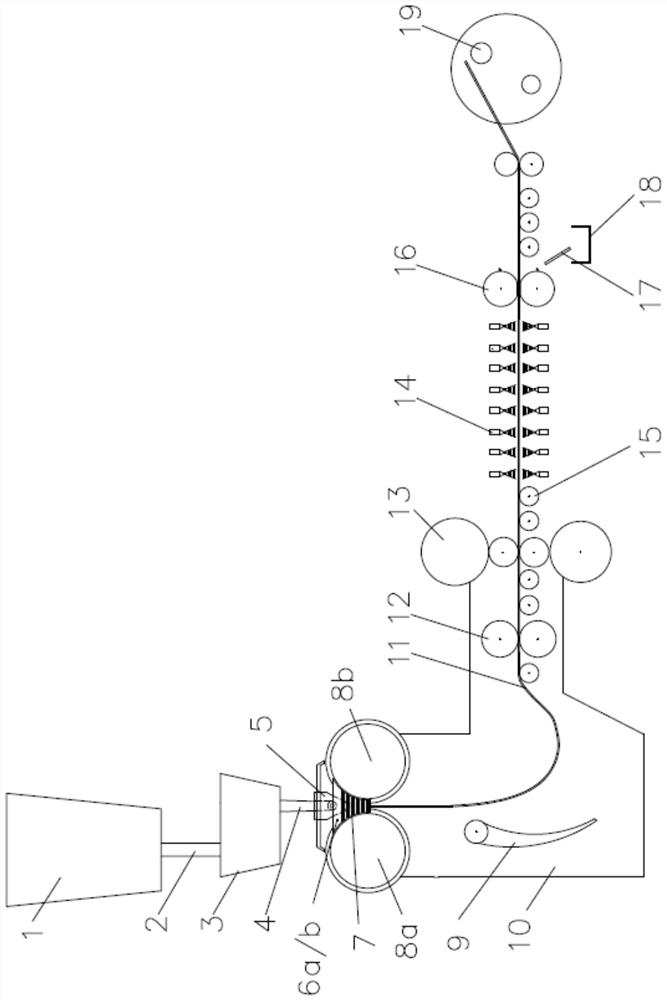

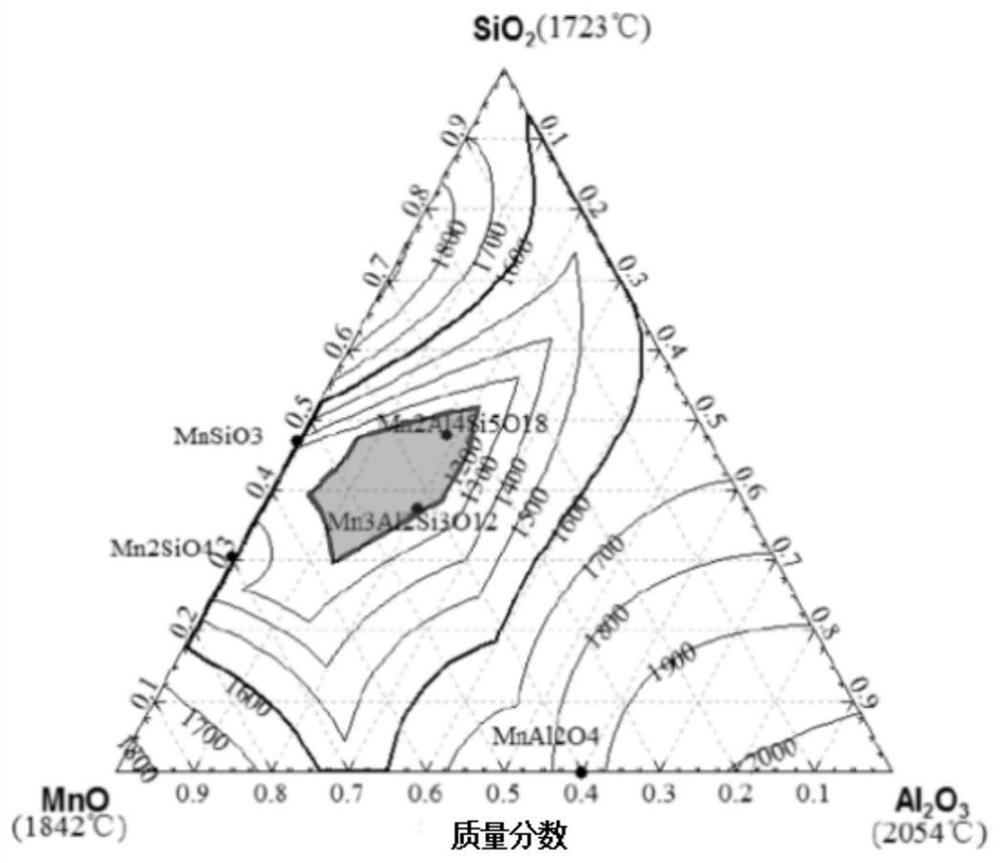

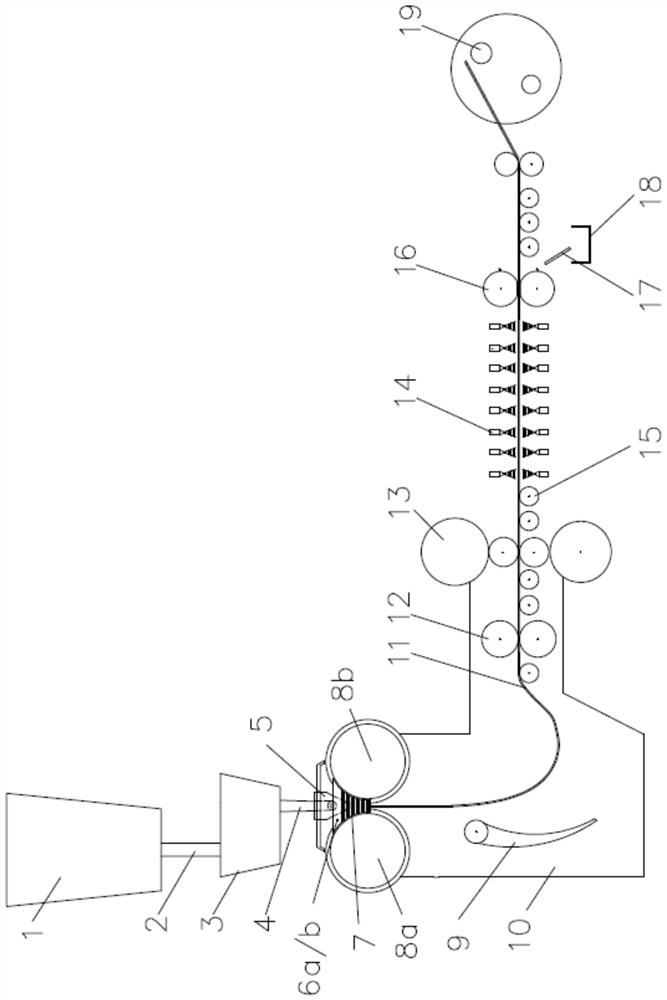

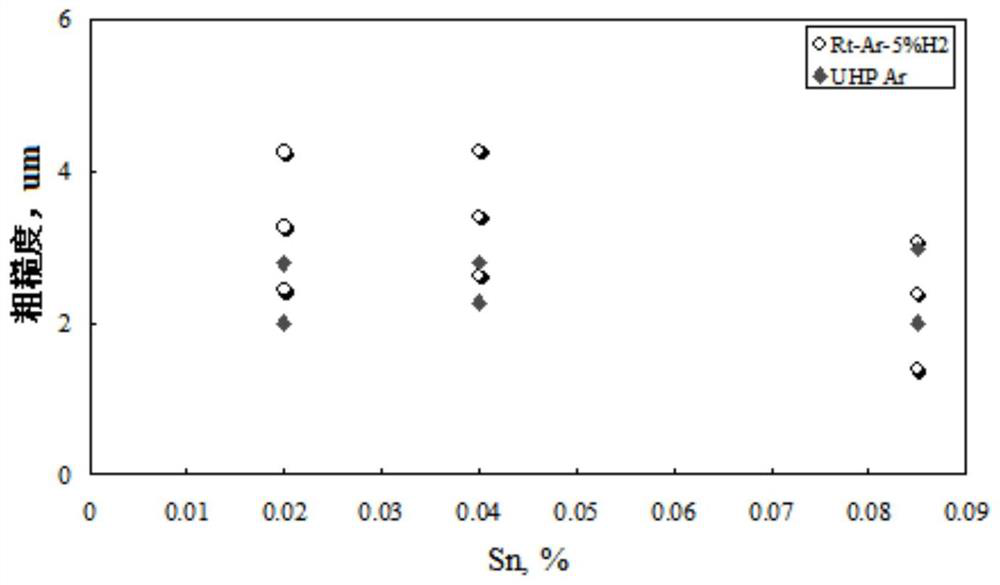

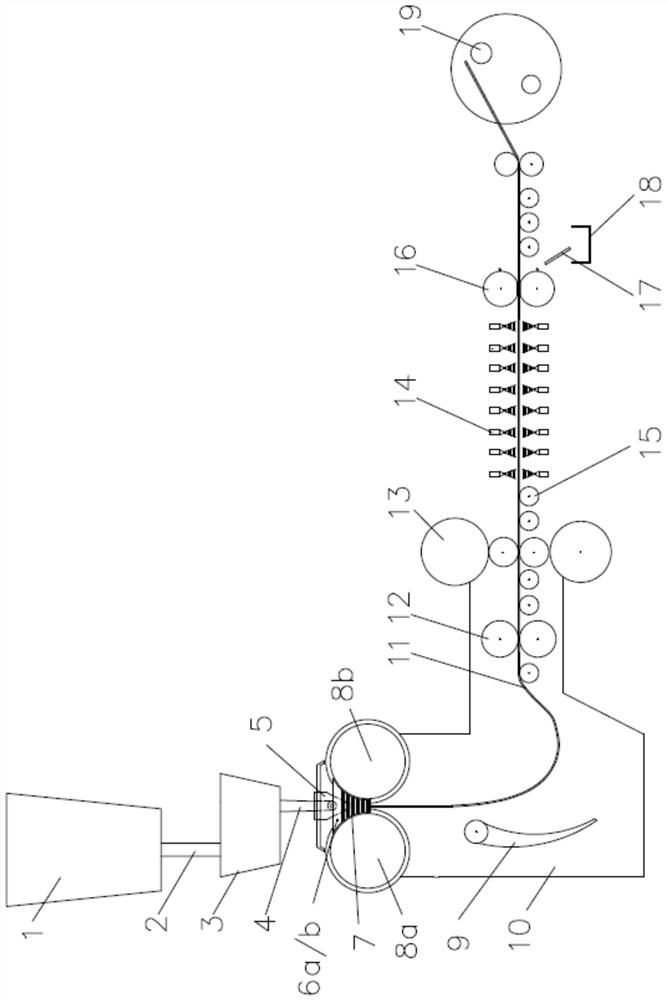

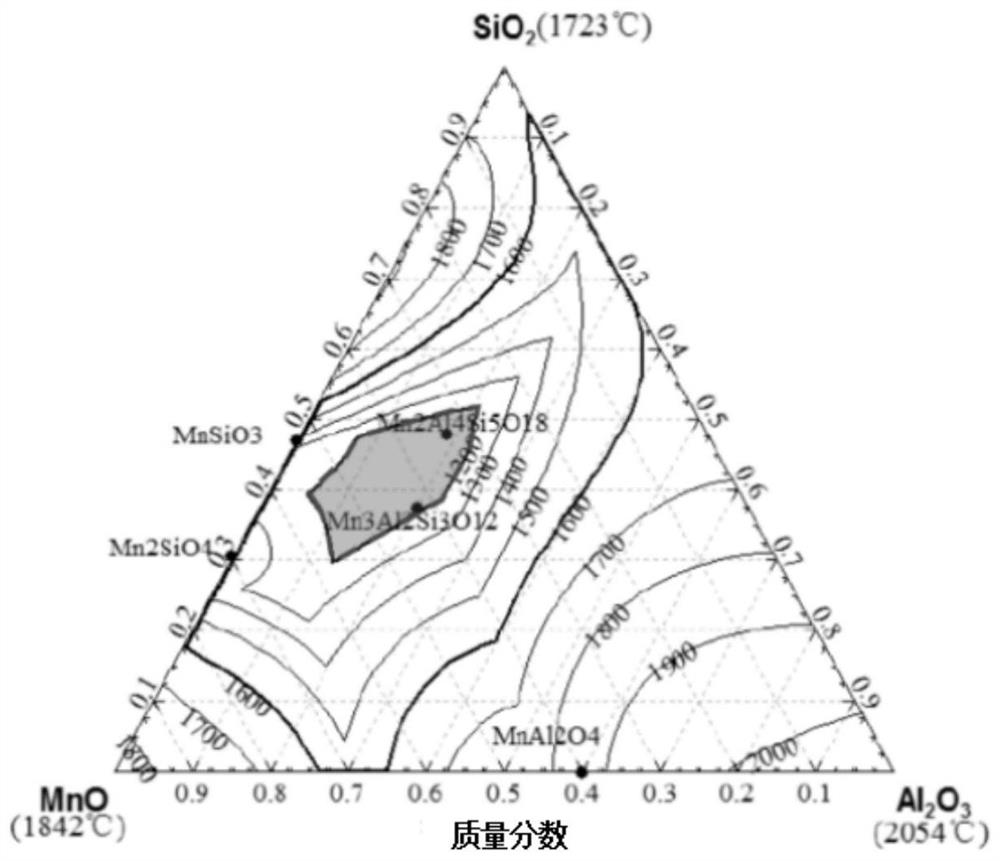

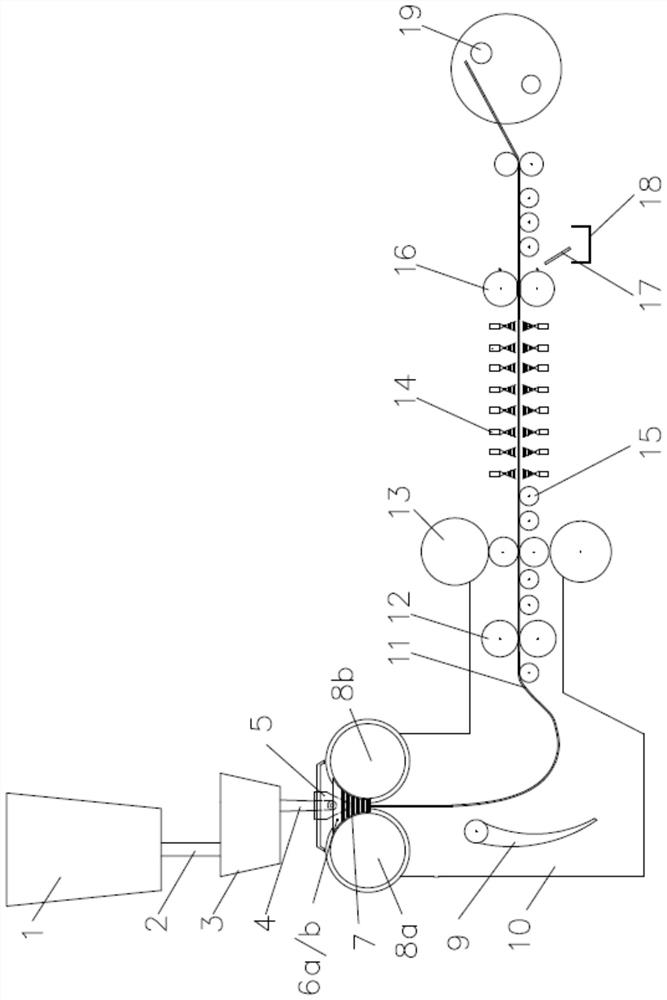

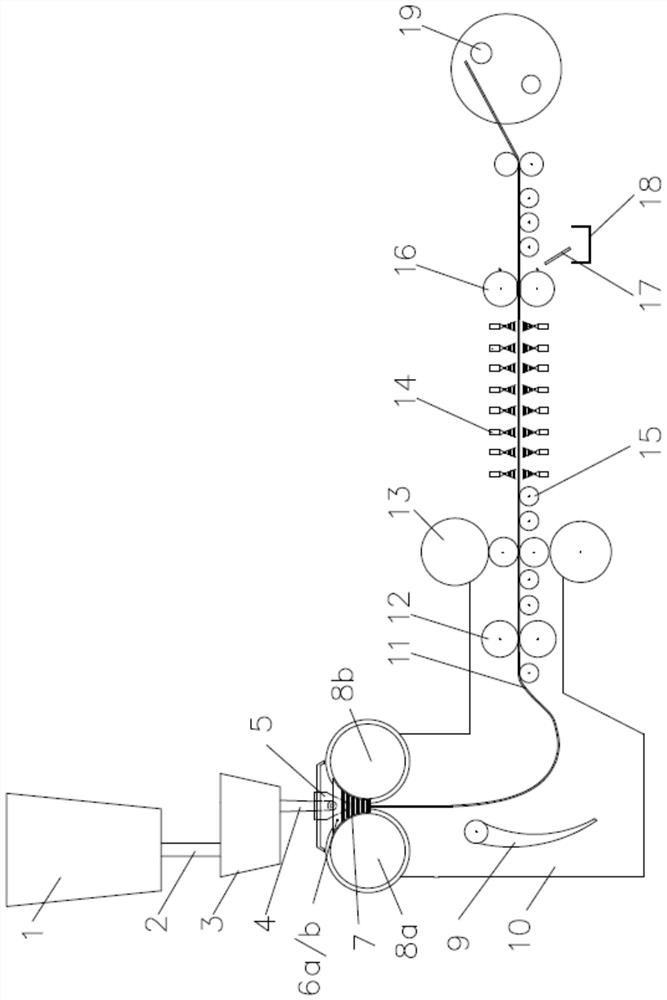

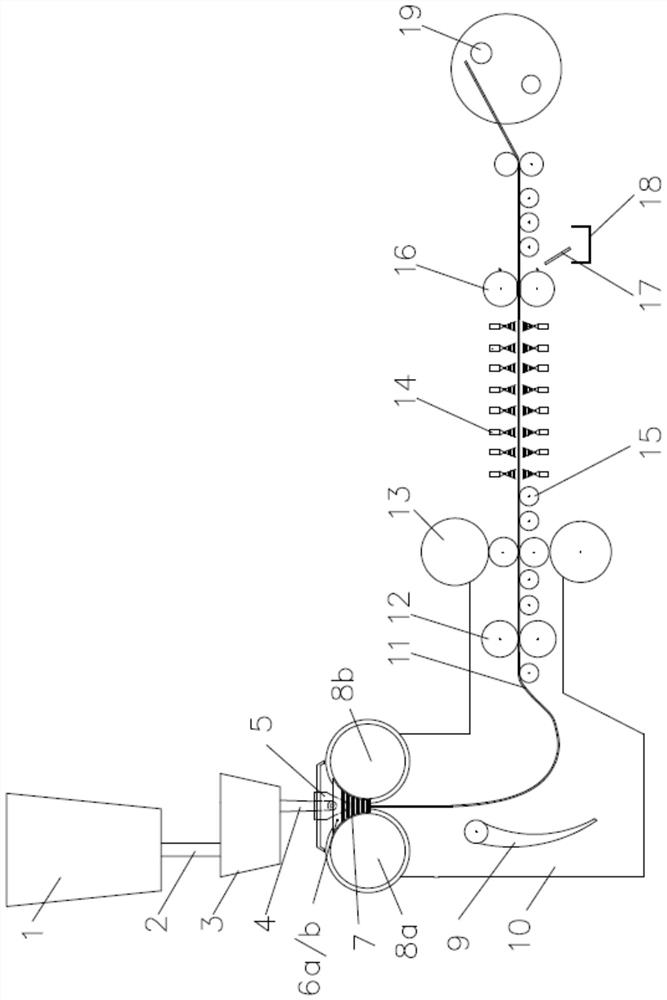

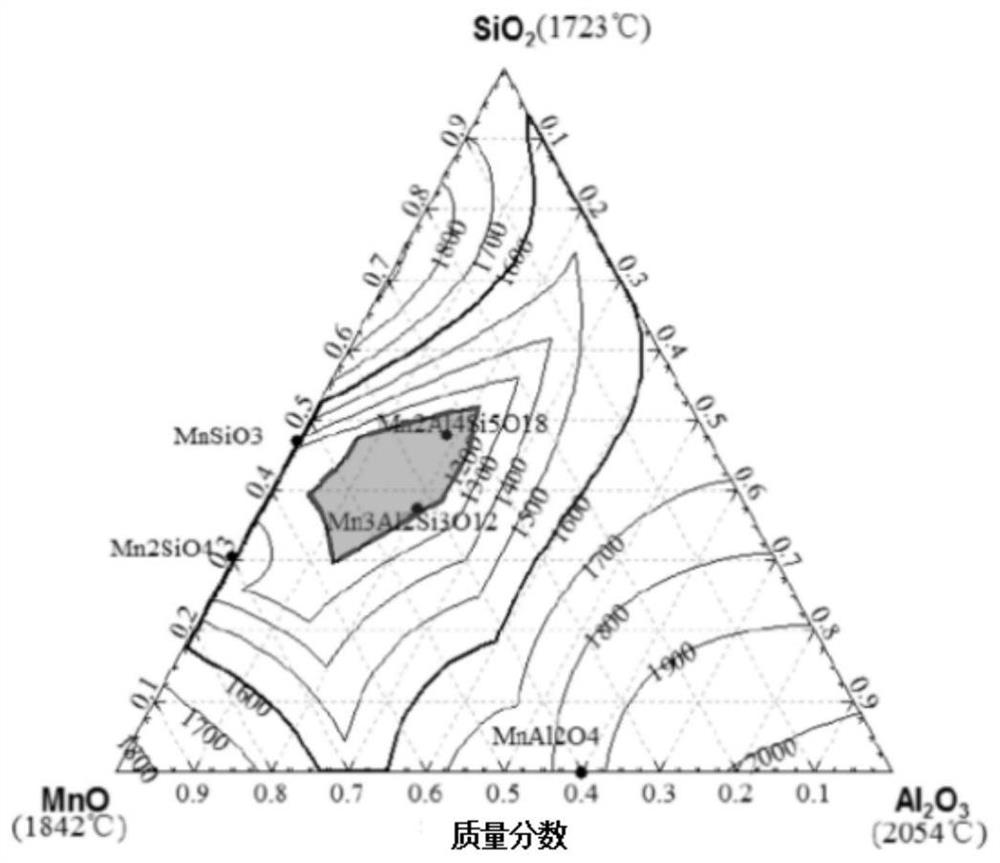

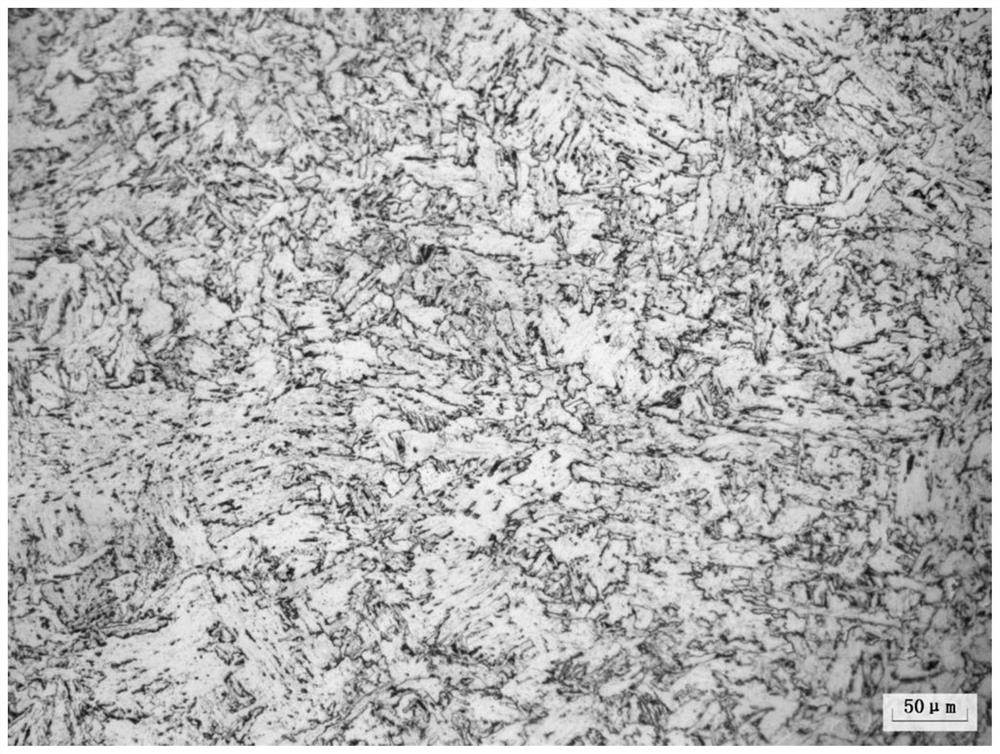

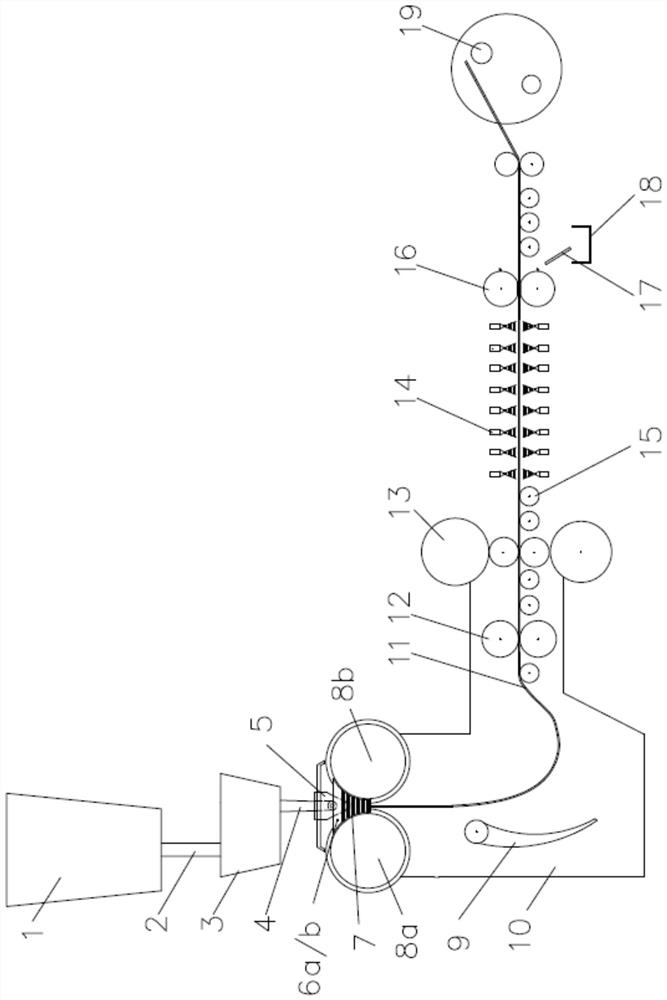

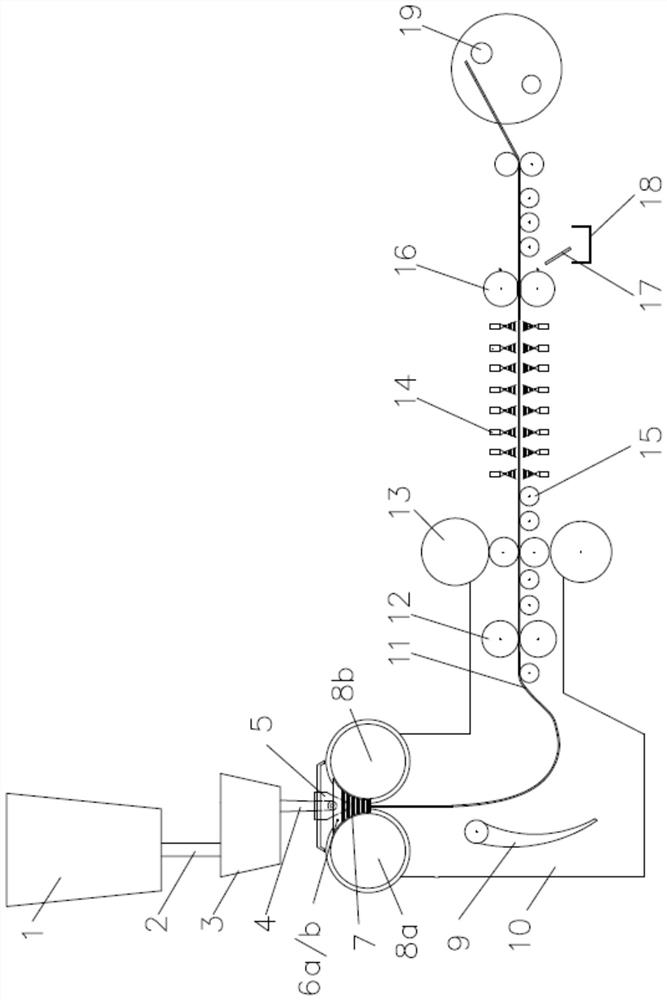

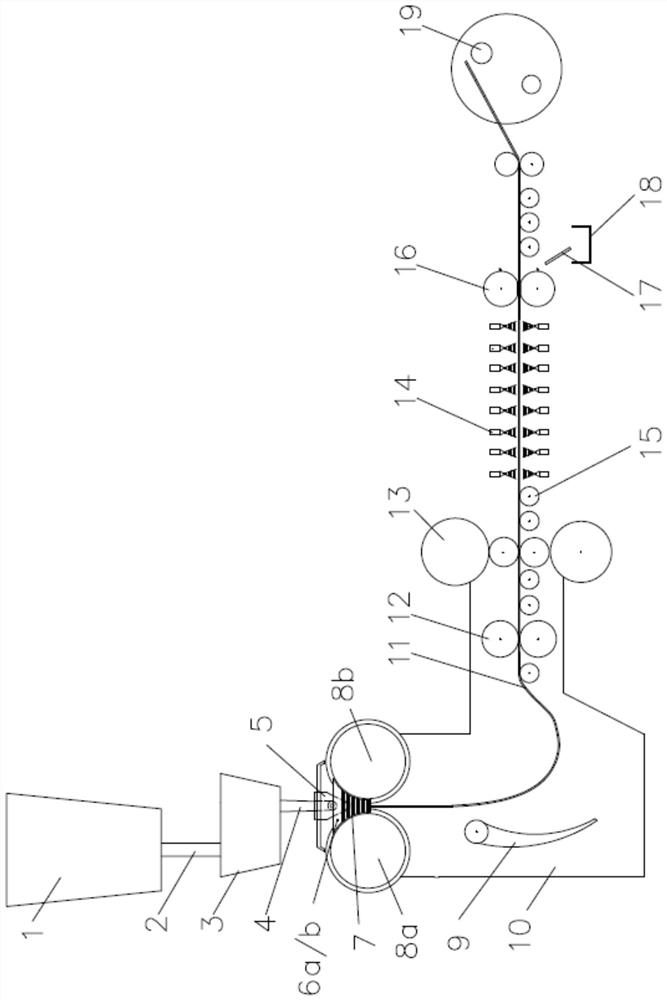

Method for producing martensitic steel strip through twin-roll thin-strip continuous casting

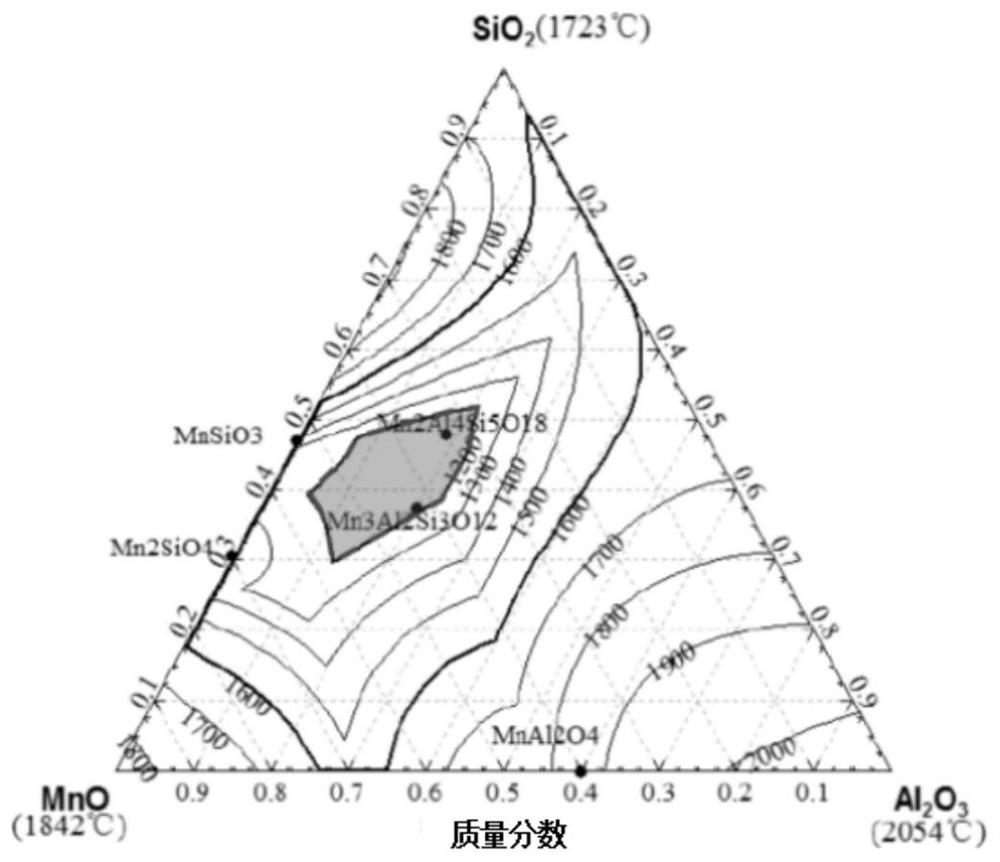

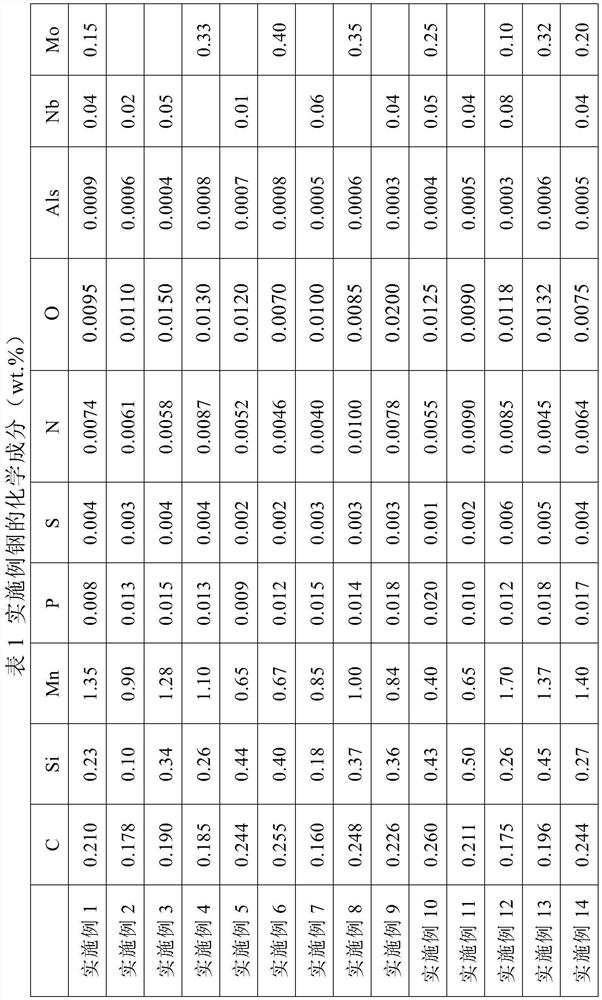

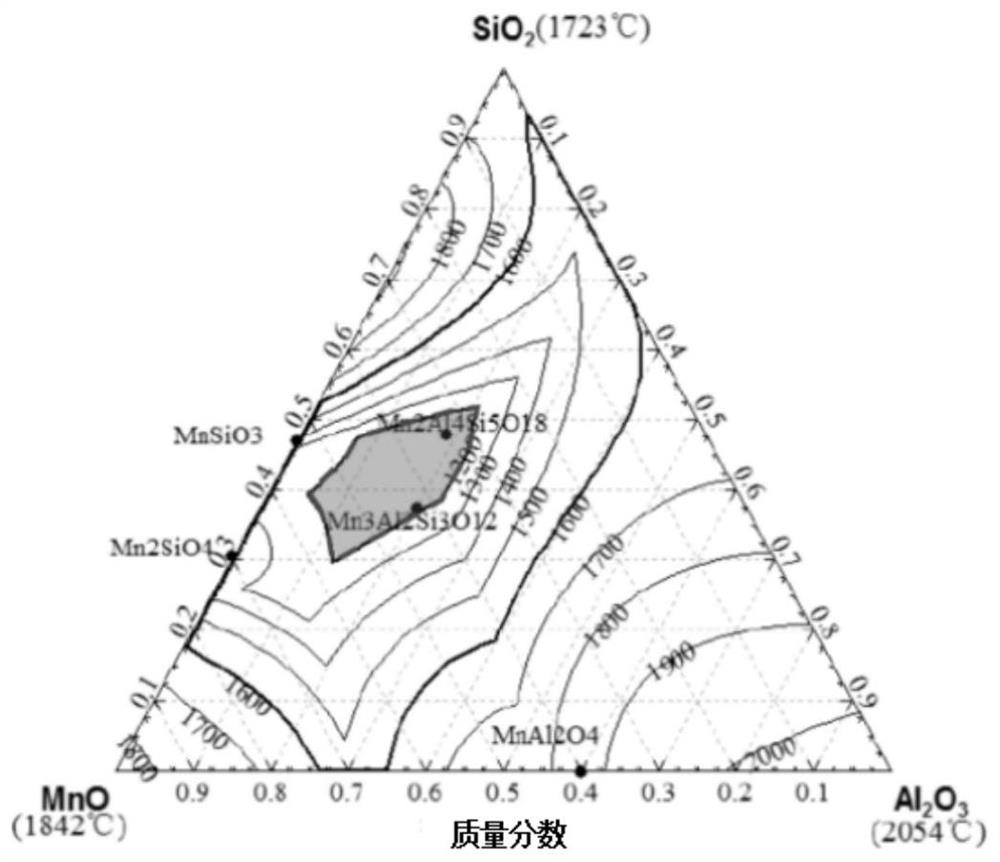

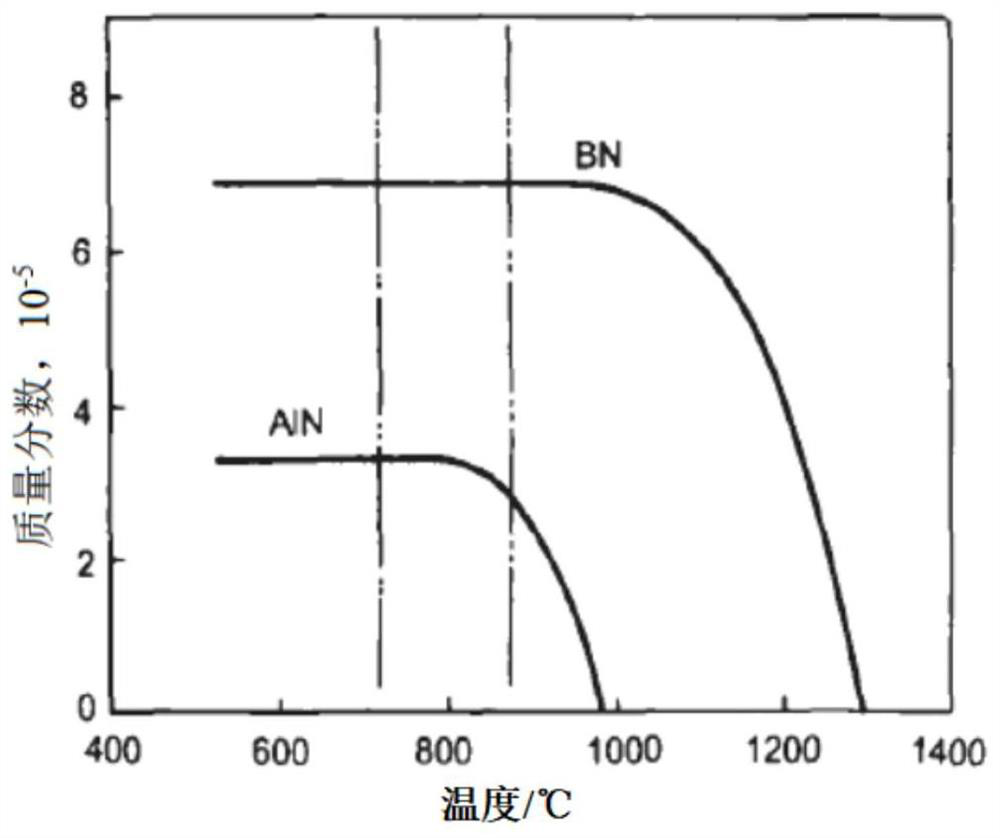

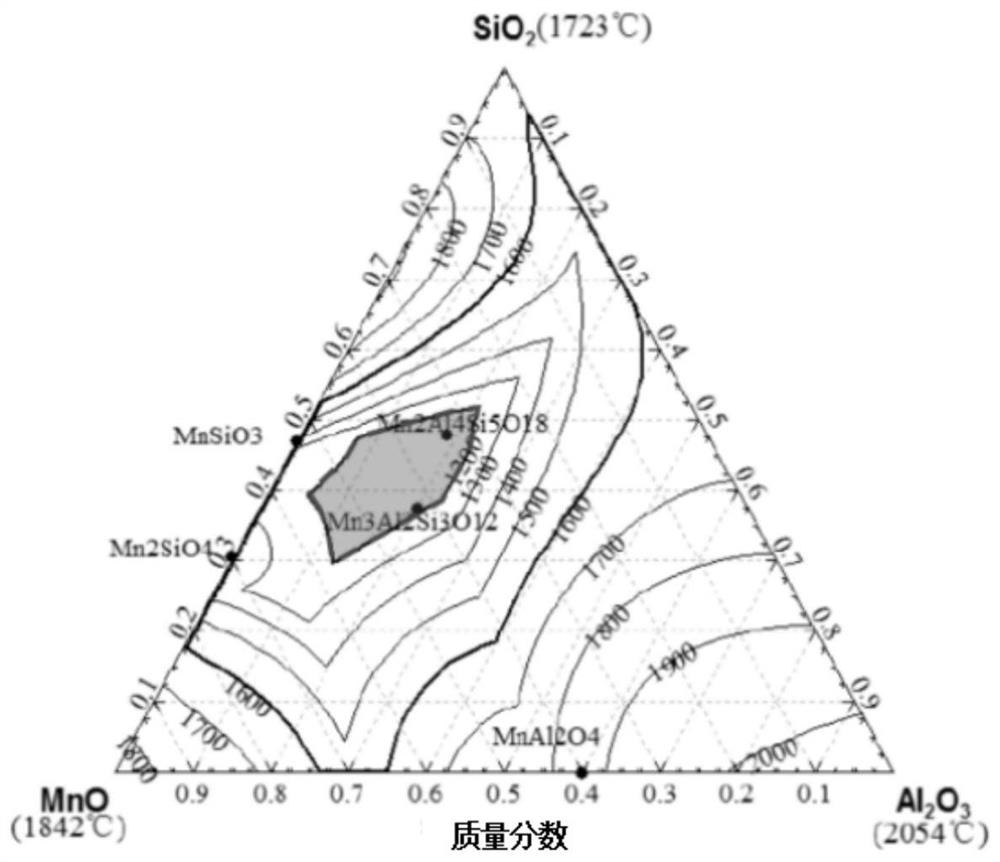

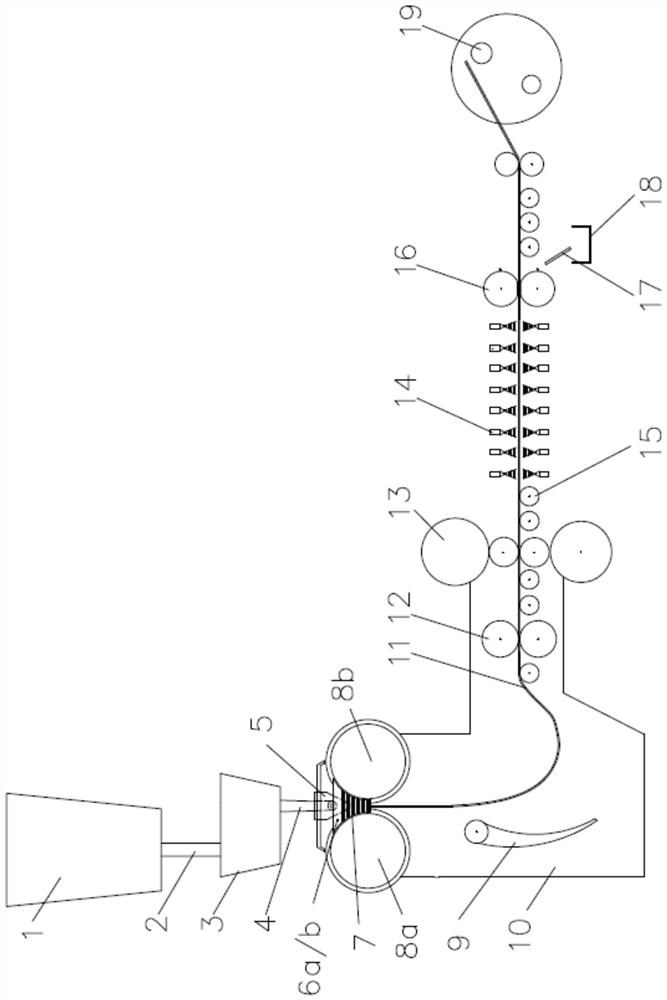

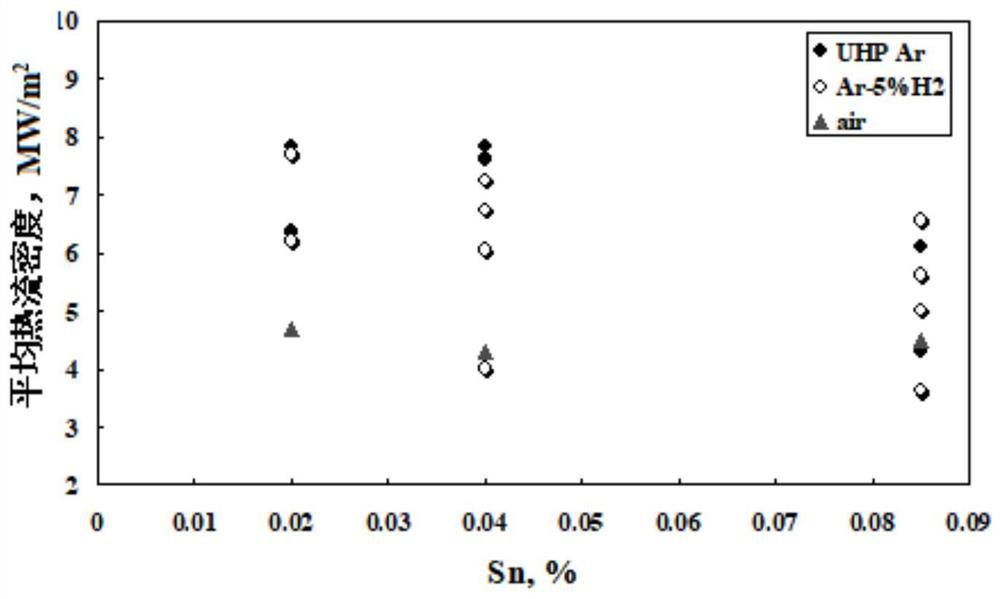

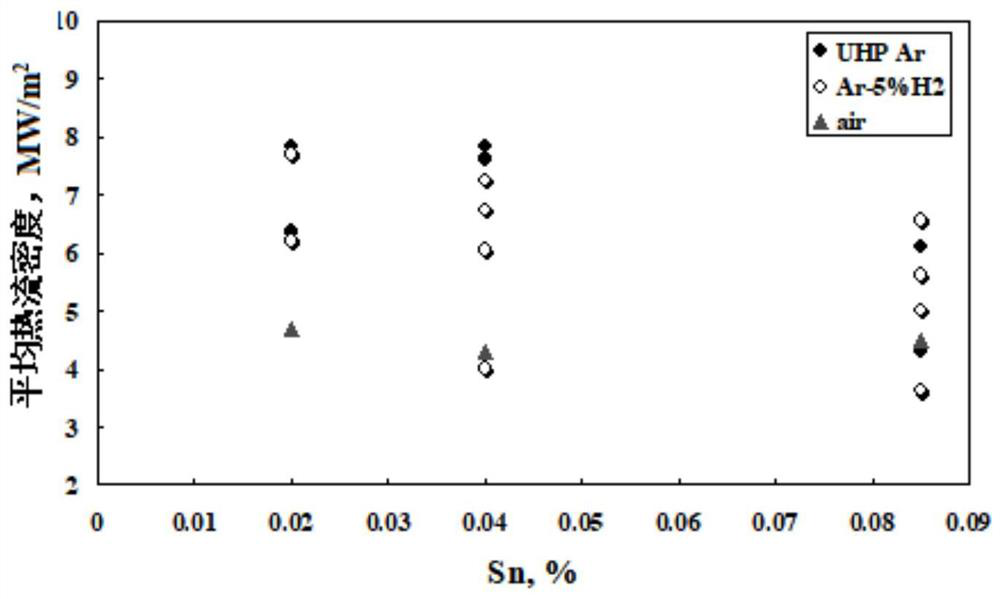

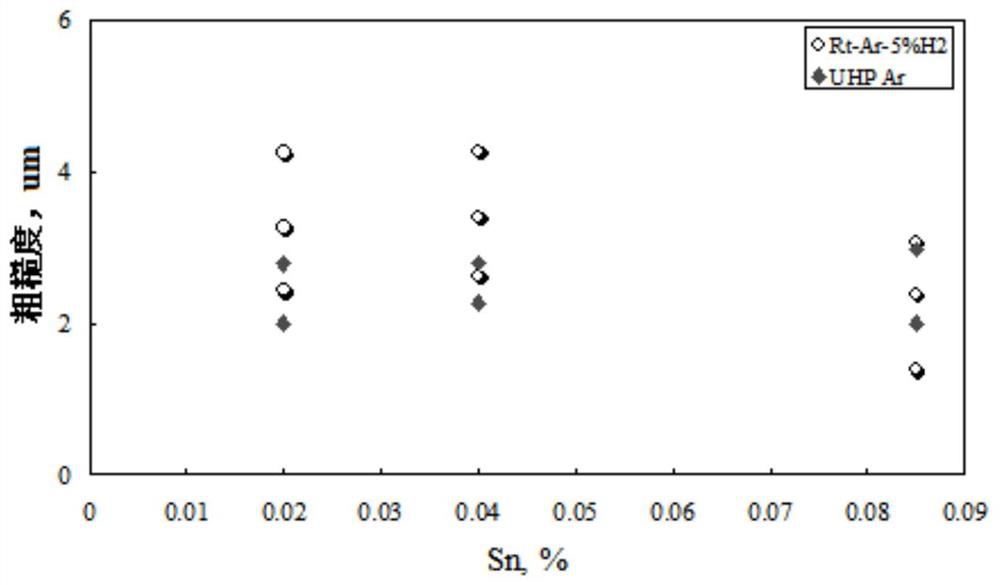

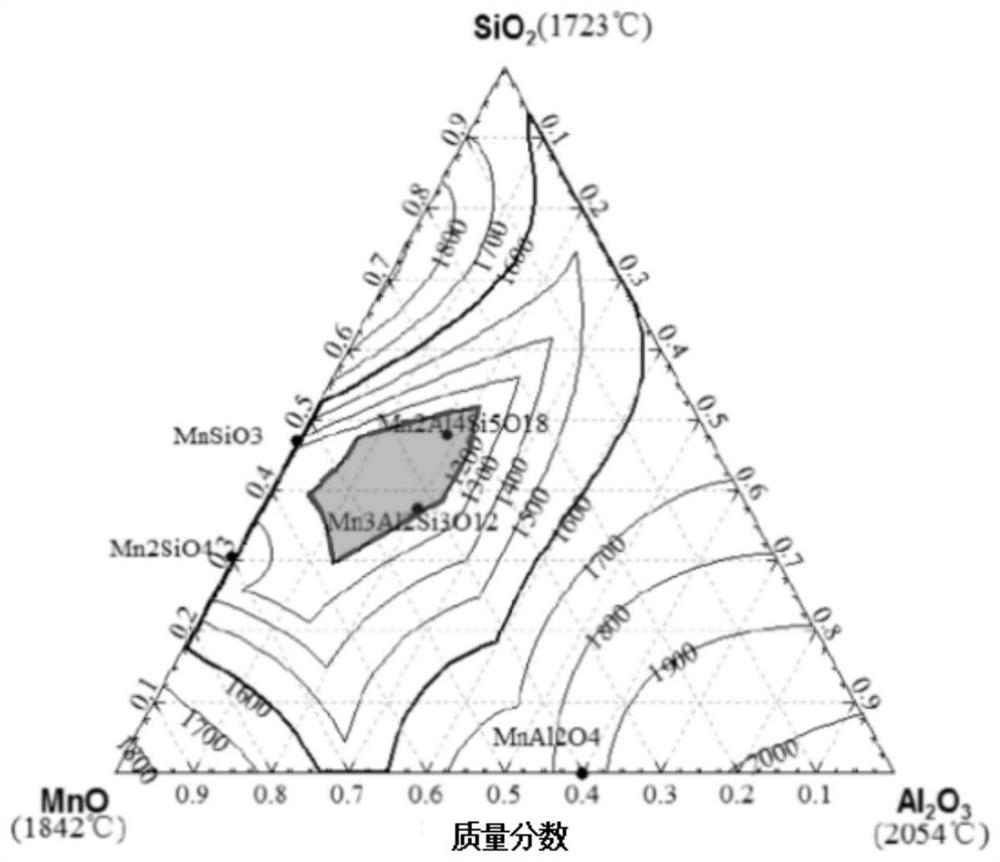

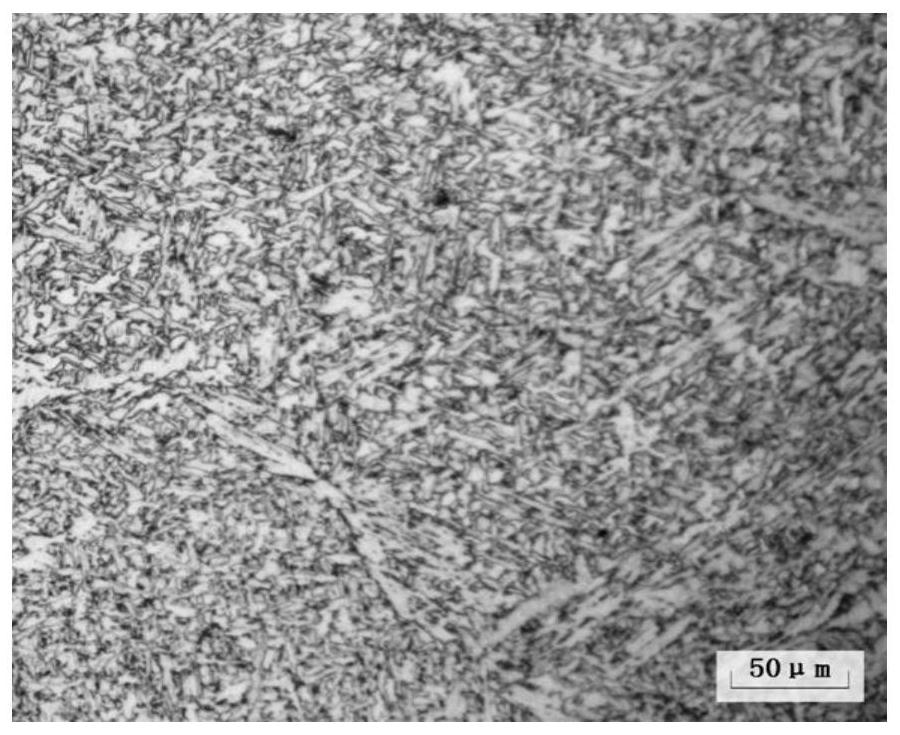

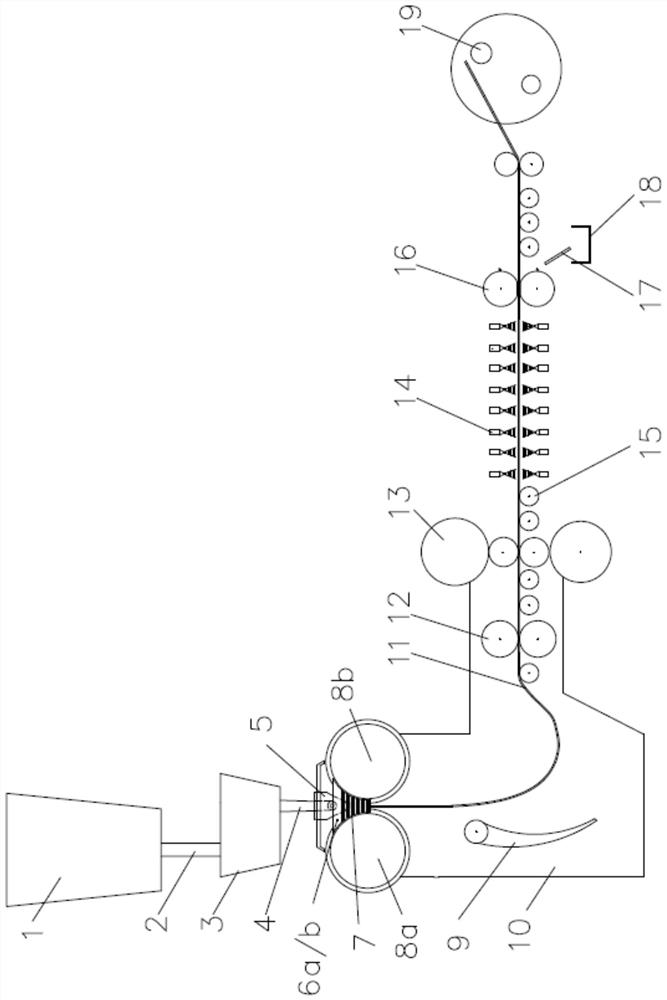

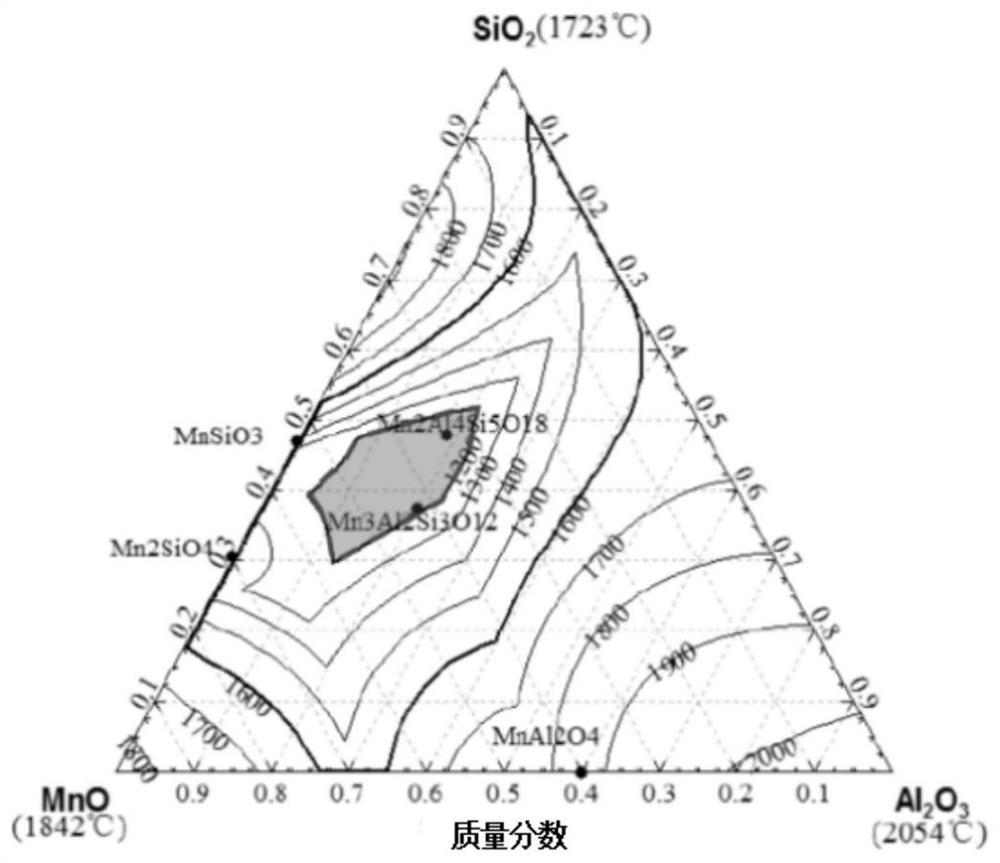

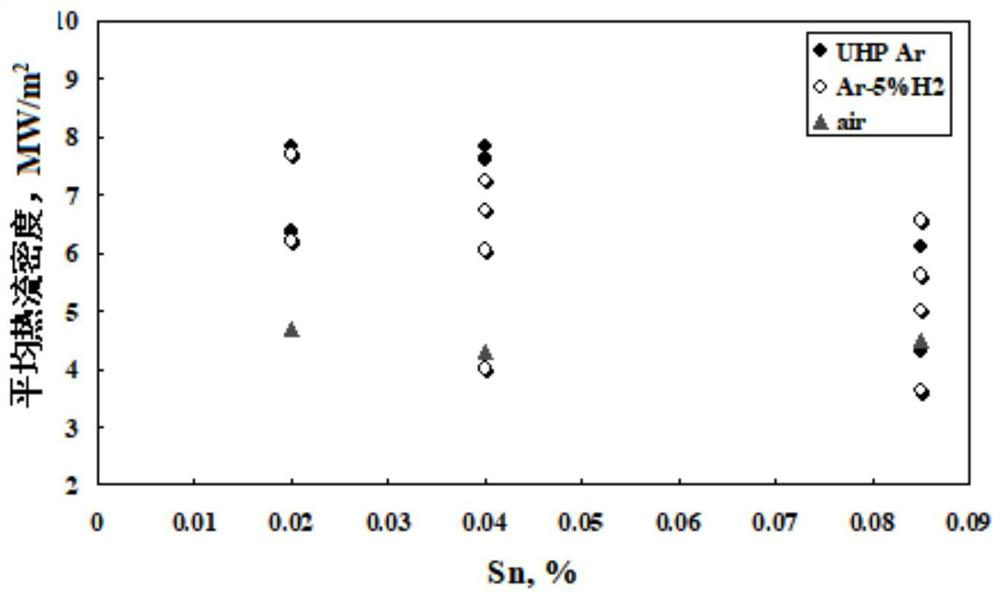

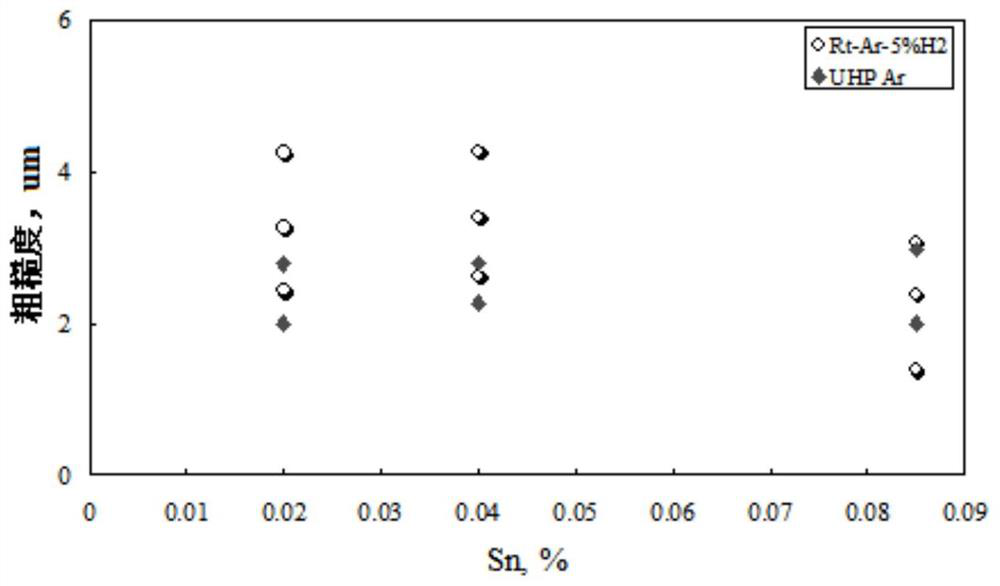

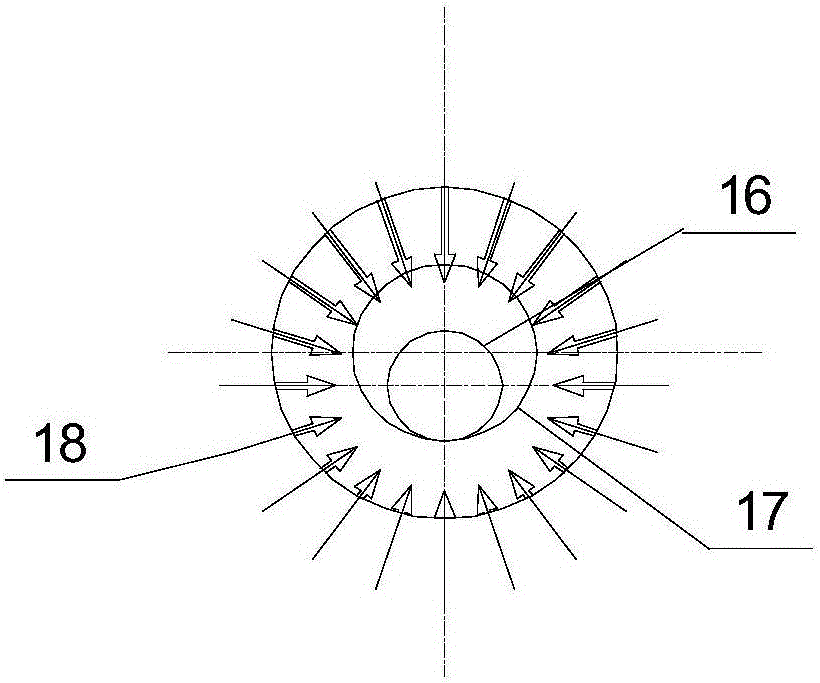

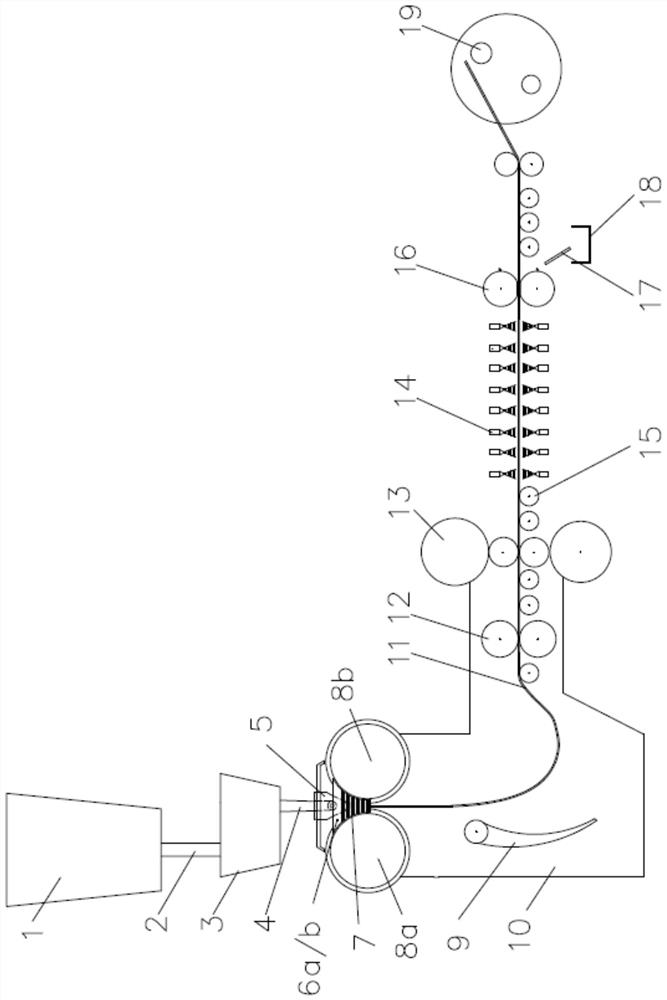

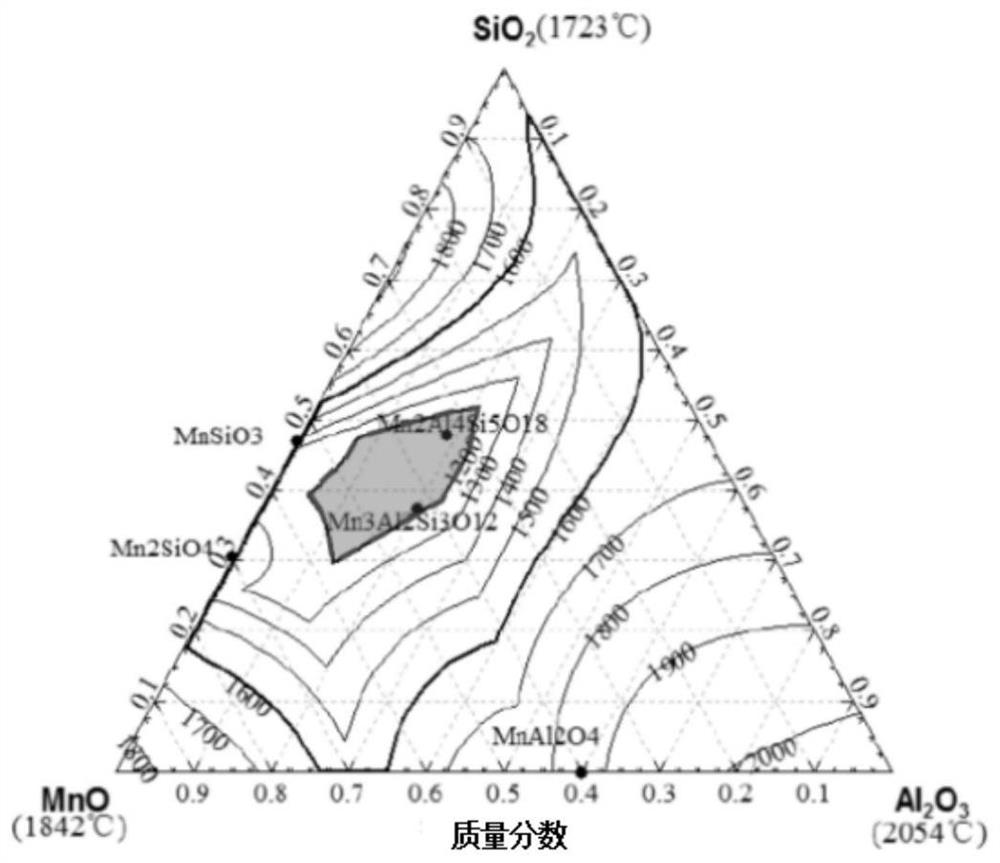

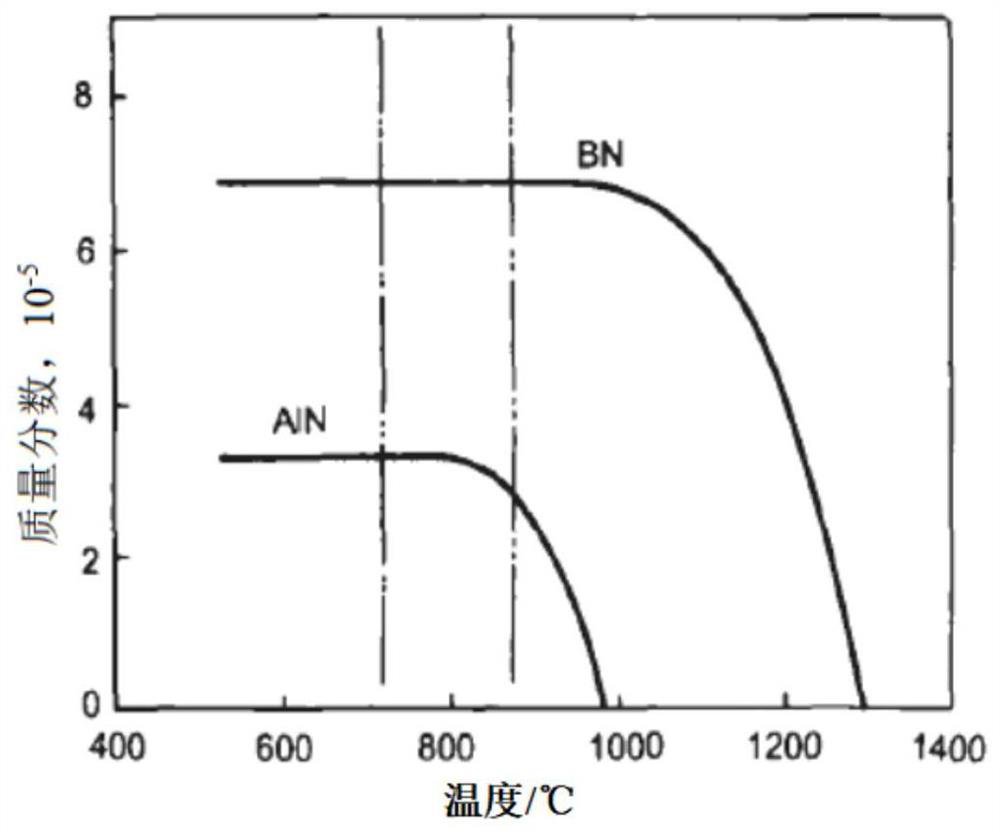

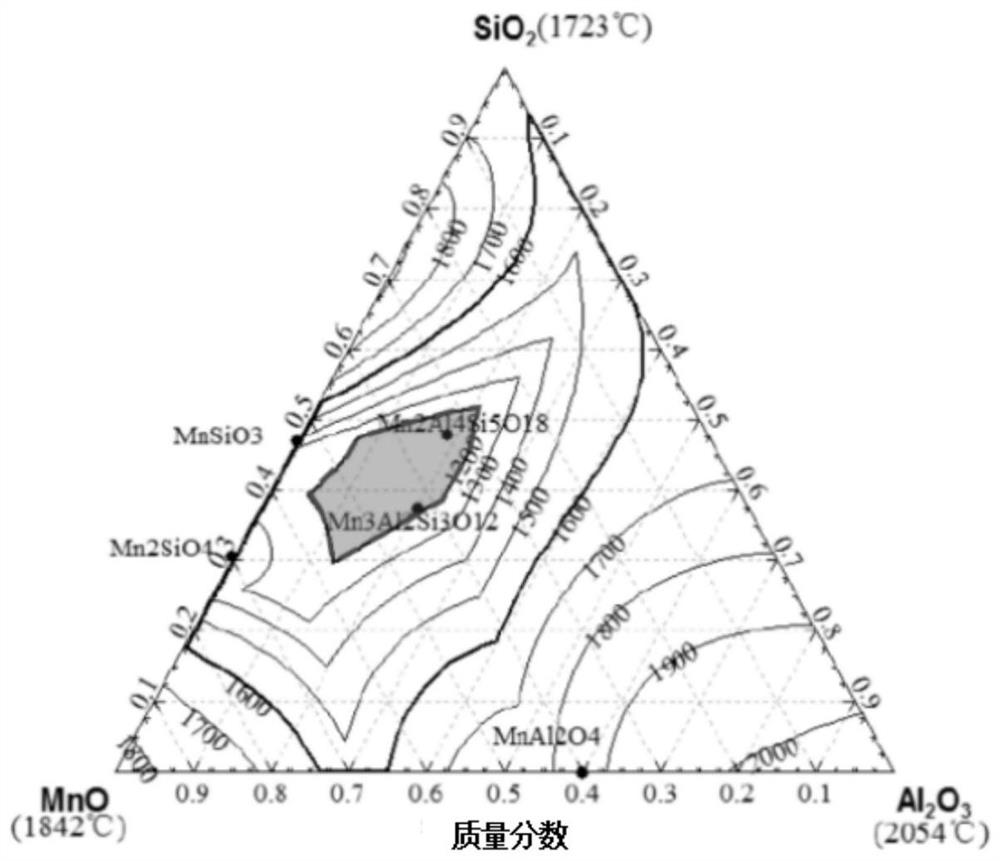

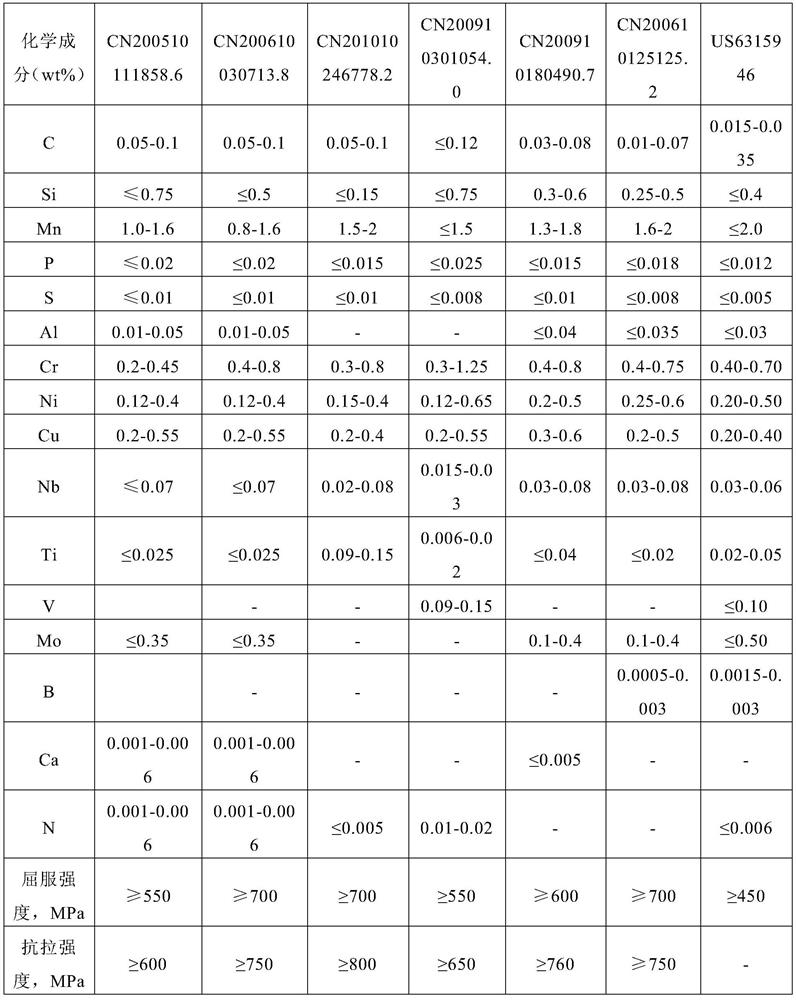

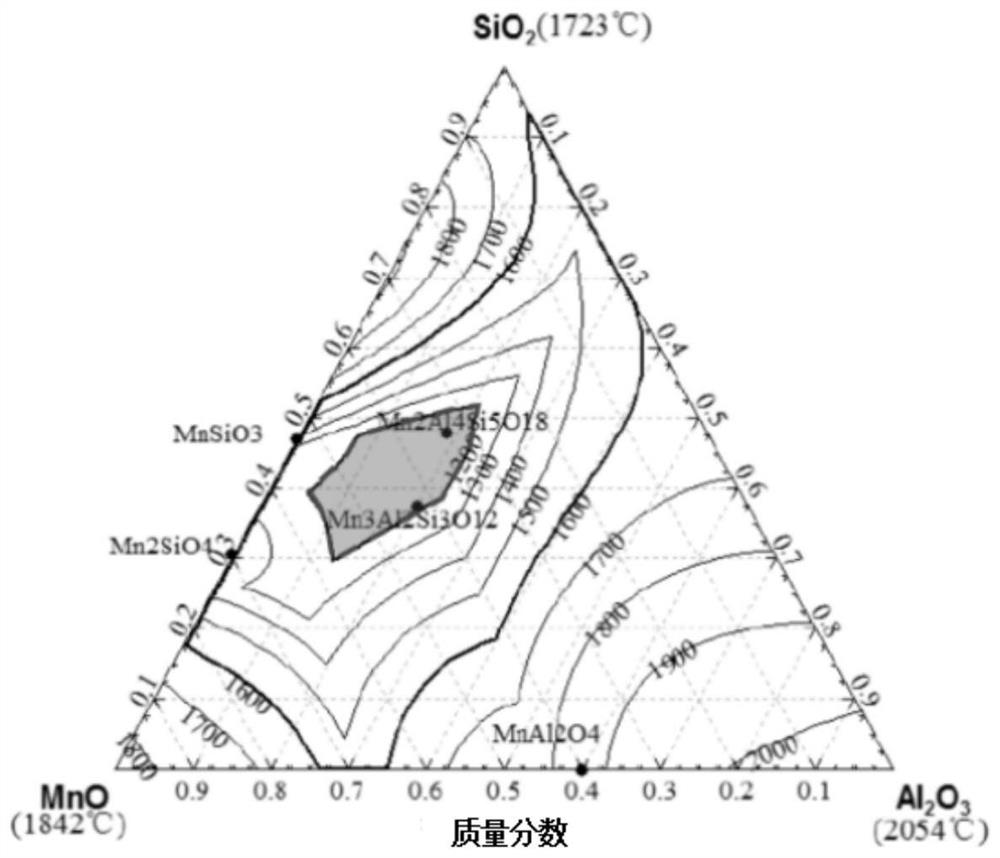

The invention discloses a method for producing a martensitic steel strip through twin-roll thin-strip continuous casting. According to the method, scrap steel is adopted as a raw material, smelting ofmolten steel is carried out by fully utilizing residual elements such as Sn and Cu in the scrap steel, and microalloy elements such as Nb / Mo are selectively added into the steel; in the smelting process, the alkalinity of slag, the types and melting points of inclusions in the steel, the content of free oxygen in the molten steel and the content of acid-soluble aluminum Als are controlled; then strip steel with a thickness of 1.5-3 mm is cast through twin-roll thin-strip continuous casting, and the strip steel directly enters a lower closed chamber with a non-oxidizing atmosphere after beingdischarged out of a crystallization roller and enters an online rolling mill under the closed condition to be subjected to hot rolling; the strip steel is cooled to 300 DEG C or below in a rapid gas atomization cooling manner after being rolled; and finally coiling is carried out to obtain a steel coil; and isothermal tempering treatment can also be carried out, or aging treatment can be carried out in a continuous annealing production line.

Owner:BAOSHAN IRON & STEEL CO LTD

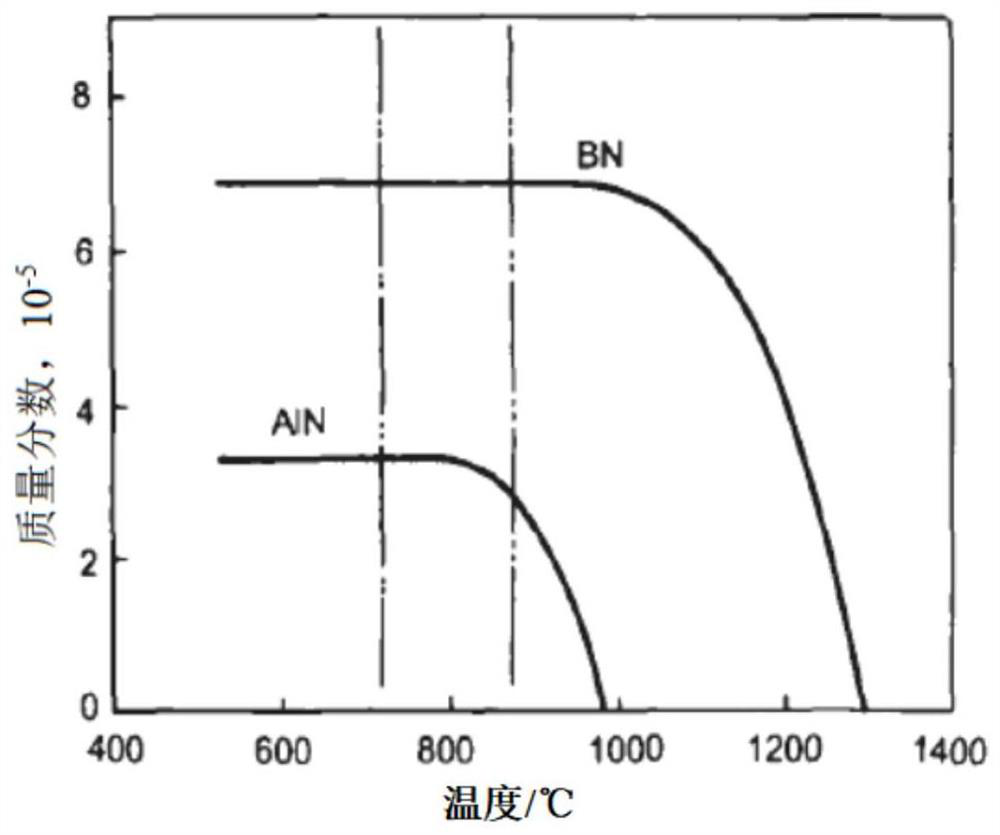

Martensitic steel strip and manufacturing method thereof

The invention discloses a martensitic steel strip and a manufacturing method thereof. The martensitic steel strip is prepared from the components in percentage by weight: 0.16-0.26% of C, 0.1-0.5% ofSi, 0.4-1.7% of Mn, less than or equal to 0.02% of P, less than or equal to 0.007% of S, 0.004-0.010% of N, less than 0.001% of Als, 0.001-0.006% of B, 0.007-0.020% of total oxygen [O]< T>, and the balance of Fe and inevitable impurities; the conditions that Mn / S is greater than 250, and one or two of 0.01-0.08% of Nb or 0.1-0.4% of Mo are included need to be met at the same time. Nb, Mo and B elements are selectively added; the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process. According to the martensitic steel strip and the manufacturing method thereof, the yield strength of the martensitic steel strip is 700-1200 MPa, tensile strength is 1000-1800 MPa, elongation is 3-12%, the martensitic steel strip can be widely applied to the field of high-strength automobile steel, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

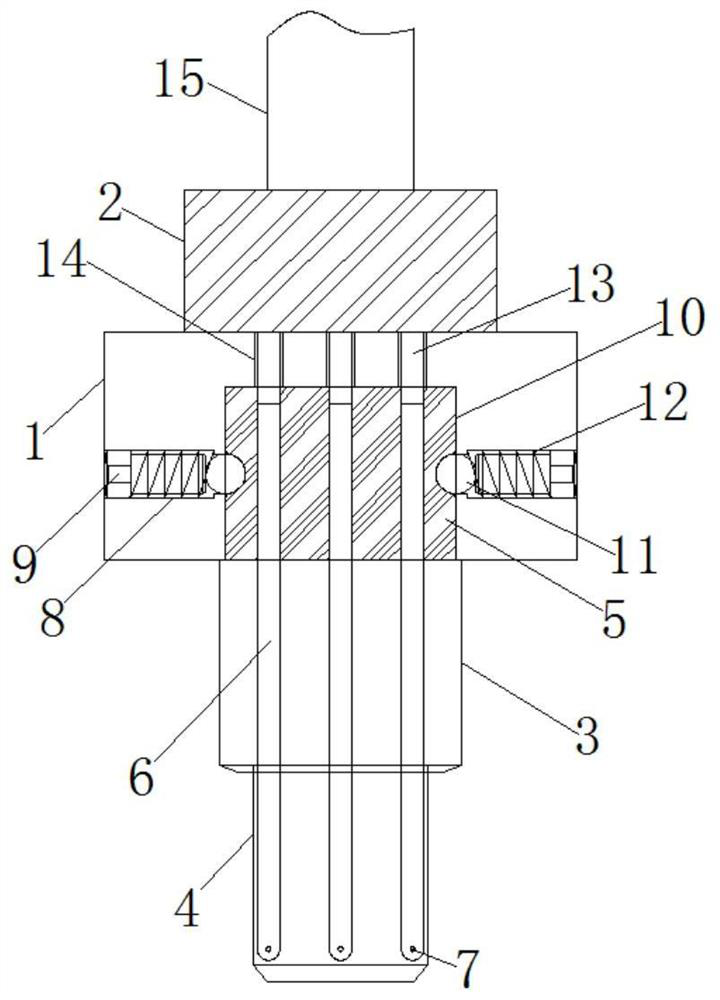

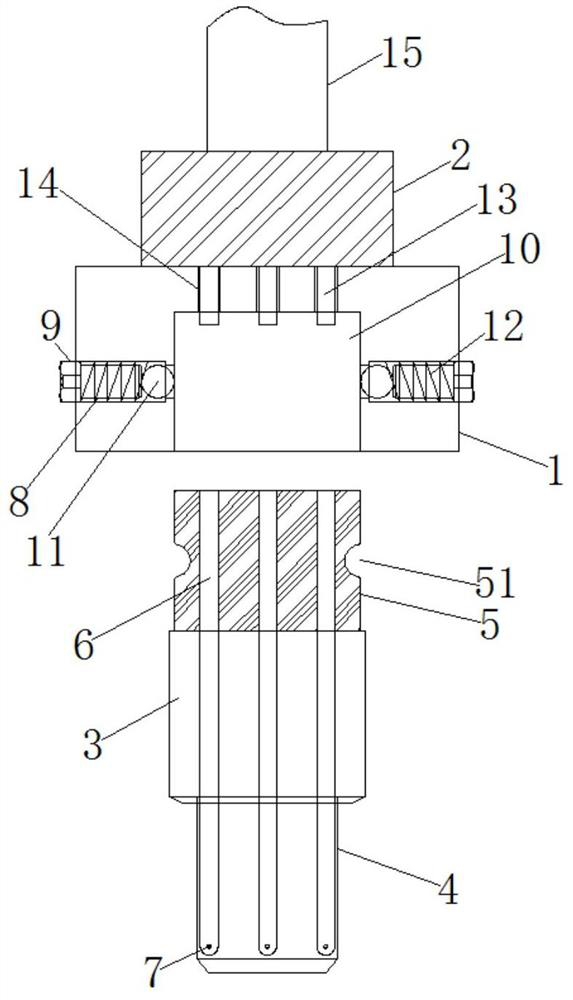

Metal cutting tool for high-speed cutting

InactiveCN112440150AEasy to installPlay a shock absorbing roleMaintainance and safety accessoriesTool bitEngineering

The invention relates to the technical field of metal cutting tools, in particular to a metal cutting tool for high-speed cutting, and overcomes the defects of poor stability and easiness in deformation and damage in the prior art. The metal cutting tool comprises a mounting seat, a tool handle and a tool bit; a cooling box and a driving spindle are fixed to the top of the mounting seat through bolts; a liquid spraying pipeline is fixedly connected to the bottom of the cooling box through a flange plate; a mounting groove is formed in the mounting seat; screw holes and through holes are formedin the inner wall of the mounting groove; the screw holes and the through holes communicate with the interior of the mounting groove; and positioning steel balls are embedded into the screw holes. Through arrangement of the structures such as locking screws, damping springs, positioning steel balls, mounting blocks and hemispherical grooves, the mounting mode of the tool is simplified, the damping springs in the tool can play a role in damping the tool after being mounted, the overall stability of the tool is improved, and the machining precision of the tool is ensured.

Owner:江苏海博工具产业研究院有限公司

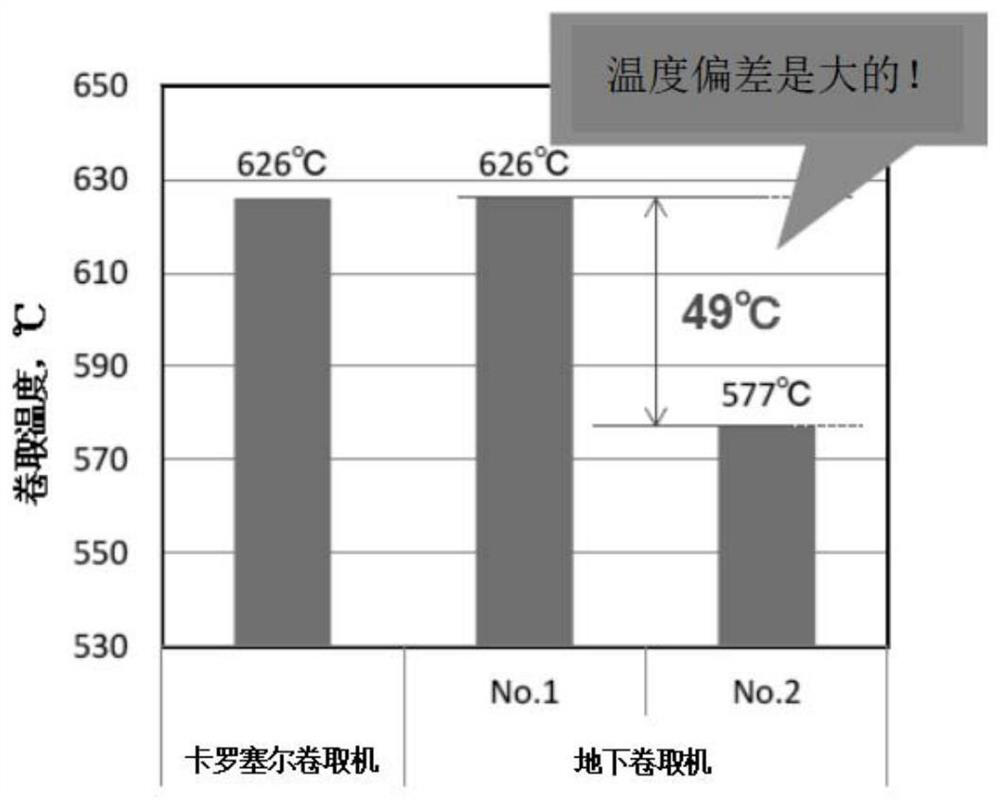

Method for producing high-corrosion-resistance steel through twin-roll thin-strip continuous casting

The invention discloses a method for producing high-corrosion-resistance steel through twin-roll thin-strip continuous casting. The method comprises the following steps of (a) smelting: carrying out smelting according to the following chemical components in percentage by weight, 0.02-0.06% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, smaller than or equal to 0.02% of P, 4.0-6.0% of Cr, 1.0-3.0% of Ni, smaller than or equal to 0.007% of S, 0.004-0.010% of N, smaller than 0.001% of Als, greater than 250 of Mn / S, 0.007-0.020% of total oxygen [O]T and the balance of Fe and inevitable impurities; (b) continuous casting: adopting a twin-roll thin-strip continuous casting process; c) protecting in a lower closed chamber; d) online hot rolling; e) cooling after rolling: cooling the rolled strip steel ina gas atomization cooling manner; and f) strip steel coiling: directly coiling the cooled hot-rolled strip steel into a coil after the end with poor quality of the cooled hot-rolled strip steel is cutoff by an end shear, and controlling the coiling temperature of the hot-rolled strip to be 600-700 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

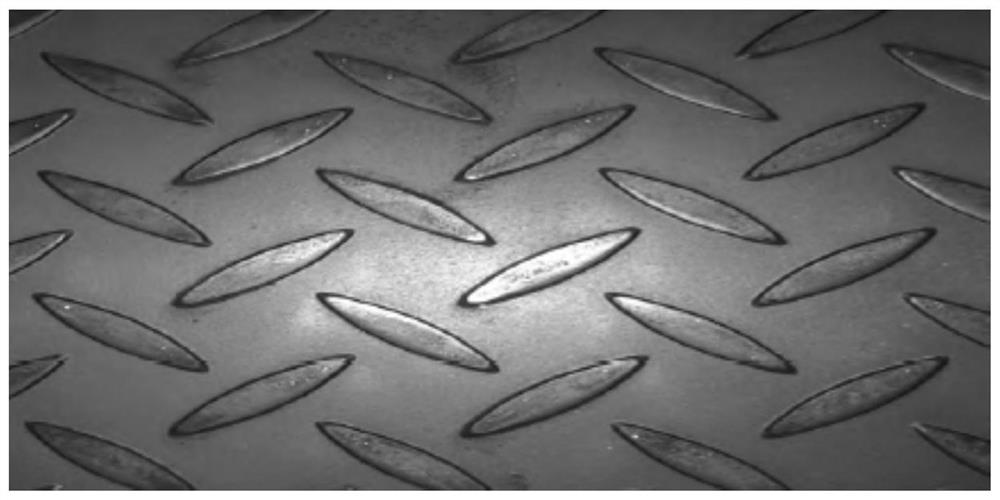

Method for producing thin-gauge riffled plate/strip through thin-strip continuous casting

The invention discloses a method for producing a thin-gauge riffled plate / strip through thin-strip continuous casting. According to the method, the alkalinity of slag, the types and melting points ofinclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in a smelting process; then a cast strip with a thickness of 1.5-3 mm is cast through twin-roll thin-strip continuous casting, and cast strip steel directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of a crystallization roller and enters an online rolling mill under the closed condition to be subjected to hot rolling; a rolled steel strip is cooled in a gas atomization cooling manner; and finally a steel coil is obtained through coiling. The steel coil can be directly used as a hot-rolled riffled plate / strip, and can also be used as a finished riffled plate / strip after being subjected to edge trimming and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

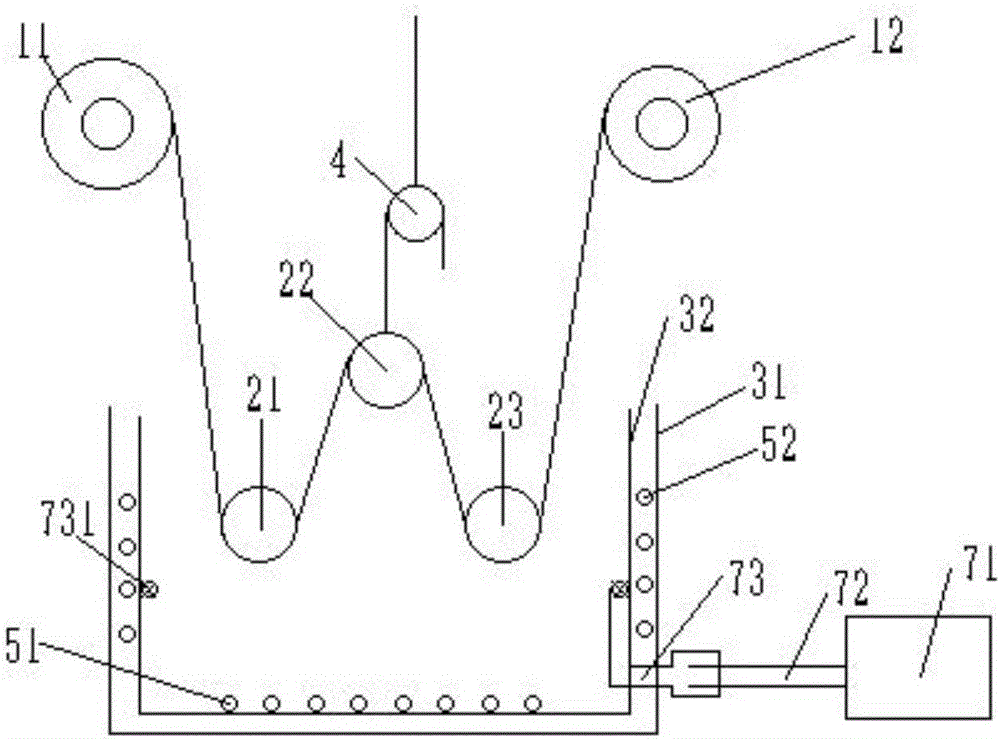

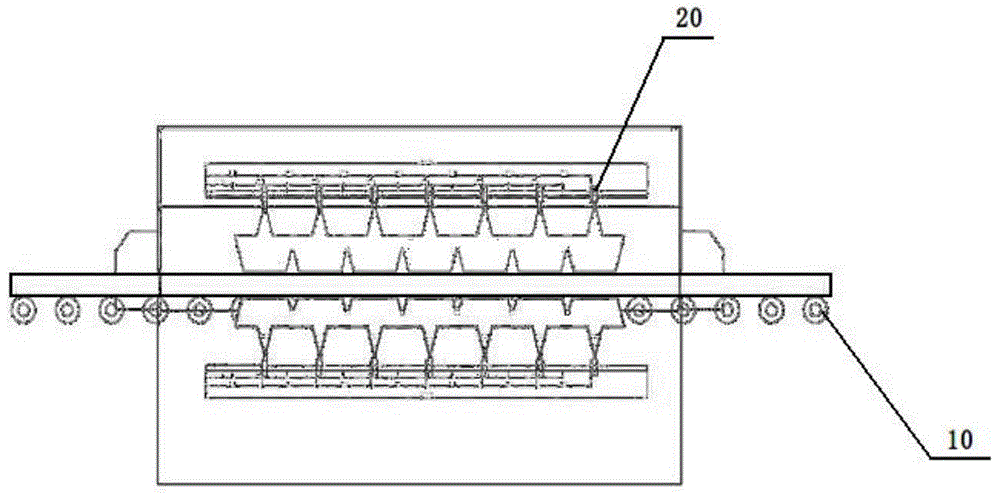

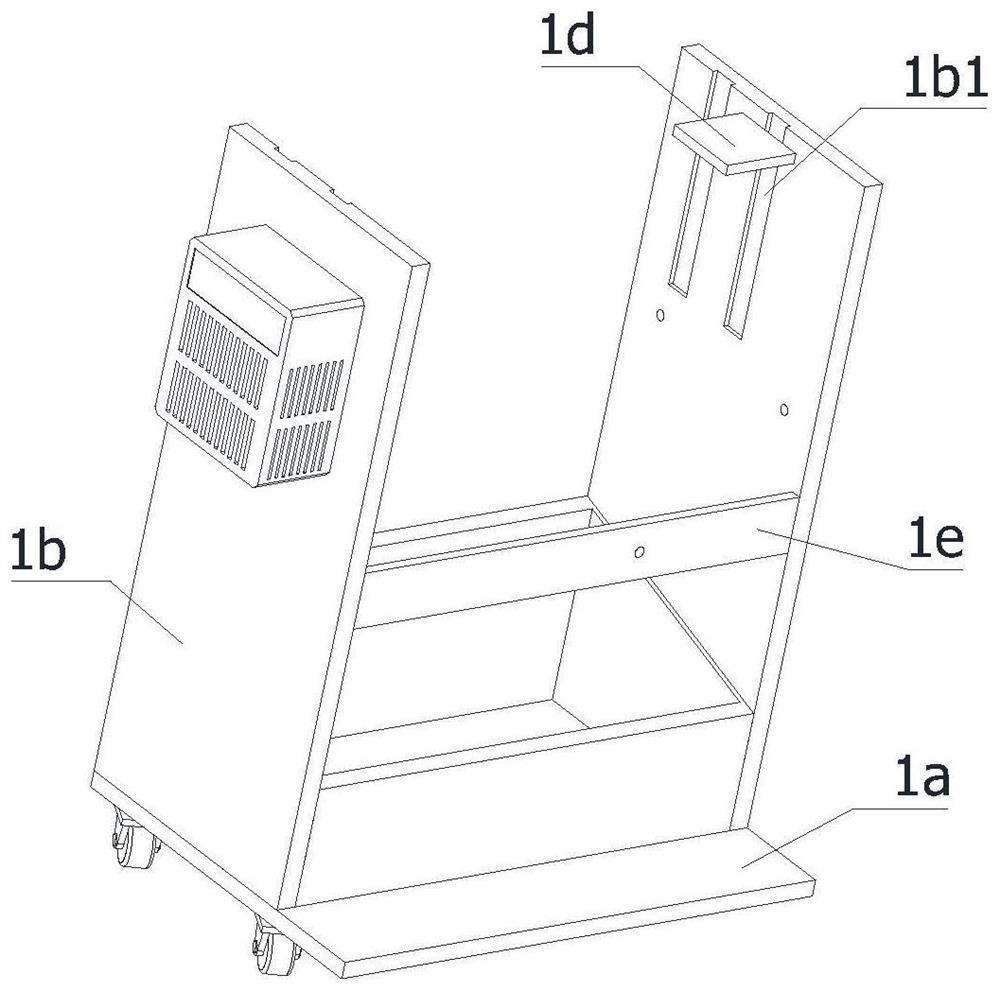

Horizontal door opening type jig dyeing machine and control system thereof

ActiveCN106048935AImprove dyeing effectEven by forceLiquid/gas/vapor open-width material treatmentLiquid/gas/vapor treatment machines driving mechanismsControl systemPulp and paper industry

The invention provides a horizontal door opening type jig dyeing machine and a control system thereof. The horizontal door opening type jig dyeing machine comprises winding rollers, cloth guide rollers, a dyeing vat combination, a controller and a heating system. The cloth guide rollers include a cloth guide roller a, a cloth guide roller b and a cloth guide roller c which are arranged above the dyeing vat combination in an inverted 'V' shape, and a tension detecting roller is arranged at the upper end of the cloth guide roller b. The winding rollers include a winding roller A and a winding roller B which are arranged at the front and back ends of the dyeing vat combination respectively. The heating system is arranged in the dyeing vat combination. The invention further provides a control system of the horizontal door opening type jig dyeing machine. The dyeing vat combination comprises a first dyeing vat and a second dyeing vat, and heating tubes are arranged between the first dyeing vat and the second dyeing vat, so that evenness in heating of dye liquor in the second dyeing vat without sharp falling of the temperature is guaranteed. Additionally, the dye liquor can be evener by the aid of a swing mechanism arranged below the second dyeing vat, and accordingly jig dyeing quality is improved greatly.

Owner:海安苏博机器人科技有限公司

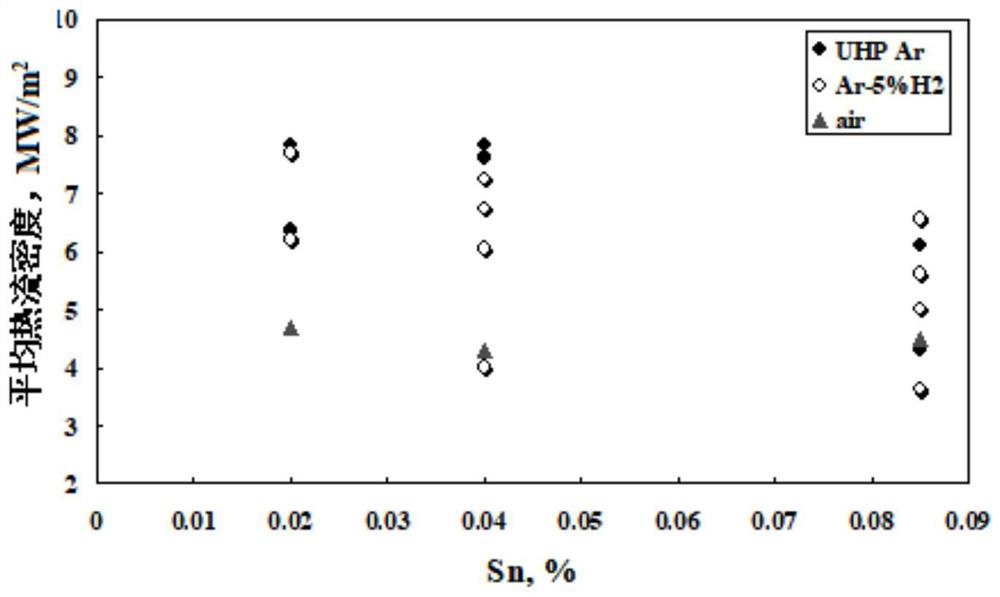

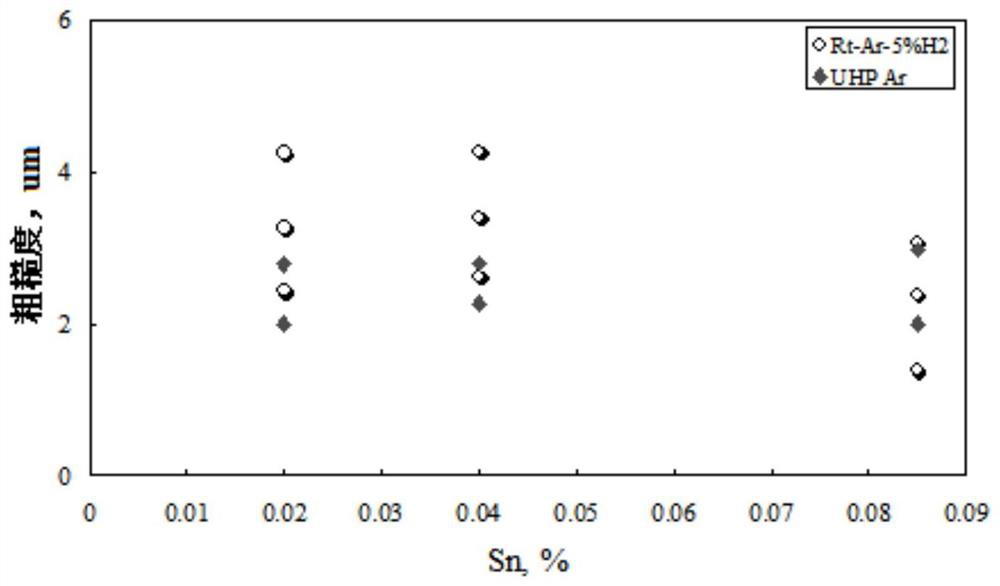

B-containing martensitic steel strip and manufacturing method thereof

The invention relates to a B-containing martensitic steel strip and a manufacturing method thereof. The B-containing martensitic steel strip comprises the following components in percentage by weight:0.16-0.26% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.007% of S, 0.004-0.010% of N, smaller than 0.001% of Als, 0.001-0.006% of B, 0.007-0.020% of total oxygen [O]T, the balance of Fe and inevitable impurities, one or two of 0.1-0.6% of Cu or 0.005-0.04% of Sn, one or two of 0.01-0.08% of Nb and 0.1-0.4% of Mo, and greater than 250 of Mn / S. According to the B-containing martensitic steel strip, residual Sn, Cu and other elements in scrap steel are used for smelting, and Nb / Mo and other microalloy elements and an element B are selectively added. According to the B-containing martensitic steel strip, the yield strength is 800-1200 MPa, the tensile strength is 1100-1900 MPa, the elongation is 3-12%, the martensitic steel strip can bewidely applied to the field of high-strength automotive steel, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-gauge riffled plate/strip and manufacturing method thereof

ActiveCN112522566AShort production processImprove efficiencyFurnace typesWork cooling devicesSmelting processMachine building

The invention discloses a thin-gauge riffled plate / strip and a manufacturing method thereof. Microalloy elements such as B are selectively added into steel; the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process; then, double-roller thin-strip continuous casting is carried out to cast strip steel with the thickness of 1.5-3 mm, and the strip steel directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of crystallization rollers and enters an online rolling mill under the closed condition to be subjected to hot rolling; and the rolled strip steel is cooled by adopting a gas atomization cooling mode,and the gas atomization cooling mode can effectively reduce the thickness of surface scale of the strip steel, improve the temperature uniformity of the strip steel and improve the surface quality ofthe strip steel. A finally produced steel coil can be directly used as a hot-rolled riffled plate / strip, can also be used as a finished riffled plate / strip after being trimmed and leveled, and can bewidely applied to the fields of buildings, machine manufacturing, automobiles, bridges, traffic, shipbuilding and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-gauge martensitic steel strip and manufacturing method thereof

ActiveCN112522633AShort production processImprove efficiencyHeat treatment process controlSmelting processMolten steel

The invention discloses a thin-gauge martensitic steel strip and a manufacturing method thereof. The thin-gauge martensitic steel strip is prepared from the following components in percentage by weight: 0.16-0.26% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, less than or equal to 0.02% of P, less than or equal to 0.007% of S, 0.004-0.010% of N, less than 0.001% of Als, 0.007-0.020% of total oxygen [O]<T>, and the balance of Fe and other inevitable impurities. Meanwhile, the thin-gauge martensitic steel strip meets the following requirements: the thin-gauge martensitic steel strip contains one or twoof 0.1-0.6% of Cu or 0.005-0.04% of Sn; the thin-gauge martensitic steel strip contains one or two of 0.01-0.08% of Nb and 0.1-0.4% of Mo; and Mn / S is greater than 250. The manufacturing method comprises the following steps: smelting molten steel by using residual Sn, Cu and other elements in scrap steel, and selectively adding Nb / Mo and other microalloy elements into the steel; in the smelting process, controlling the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in the molten steel and the content of acid-soluble aluminum Als; and thencarrying out double-roller strip continuous casting to cast a cast strip, and carrying out online hot rolling and gas atomization rapid cooling to obtain the thin-gauge martensitic steel strip.

Owner:BAOSHAN IRON & STEEL CO LTD

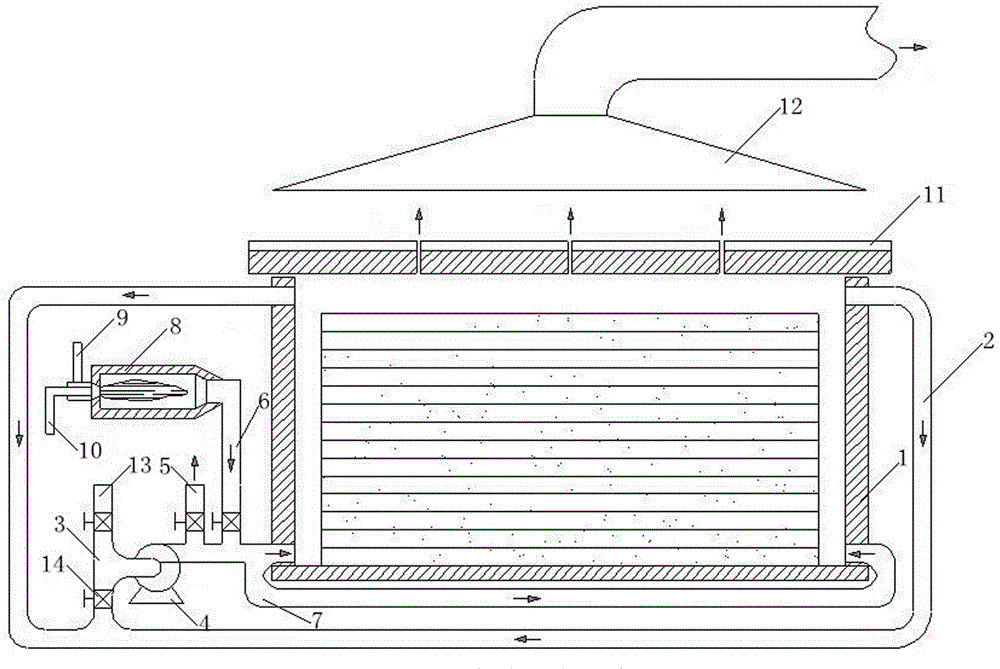

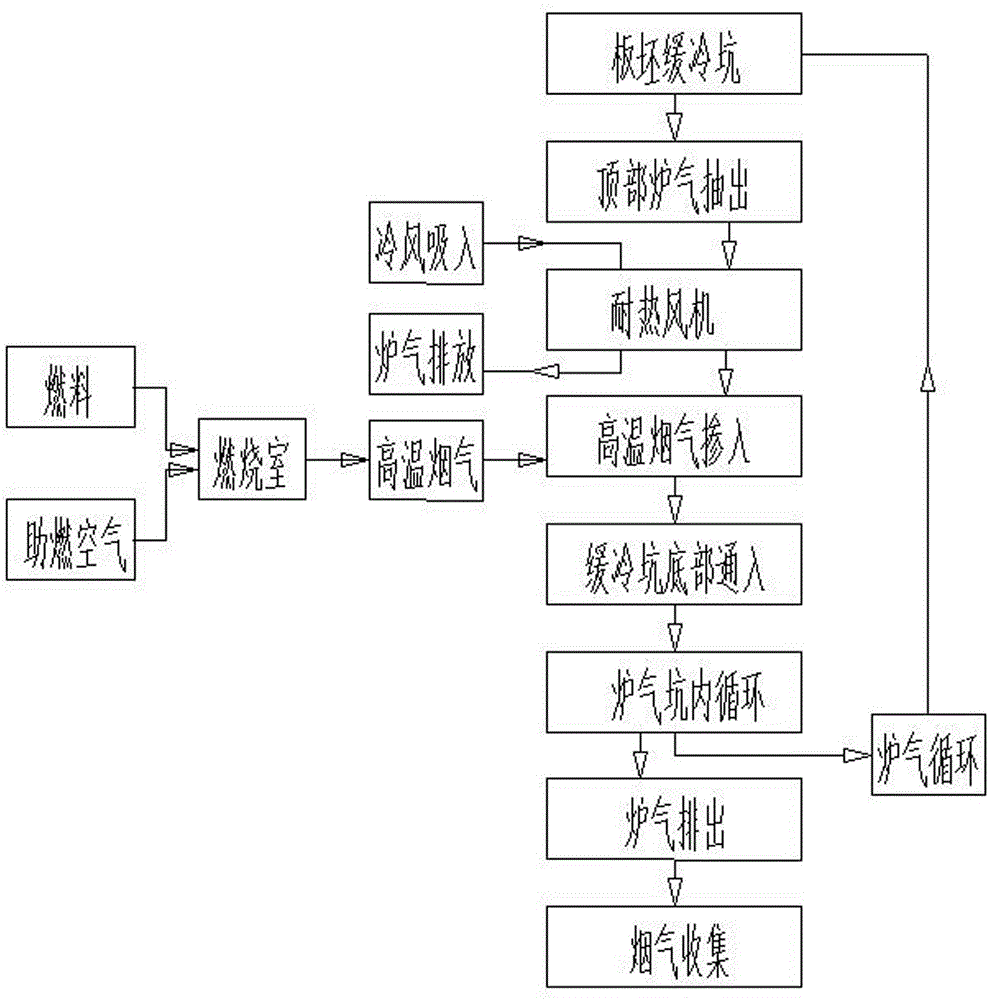

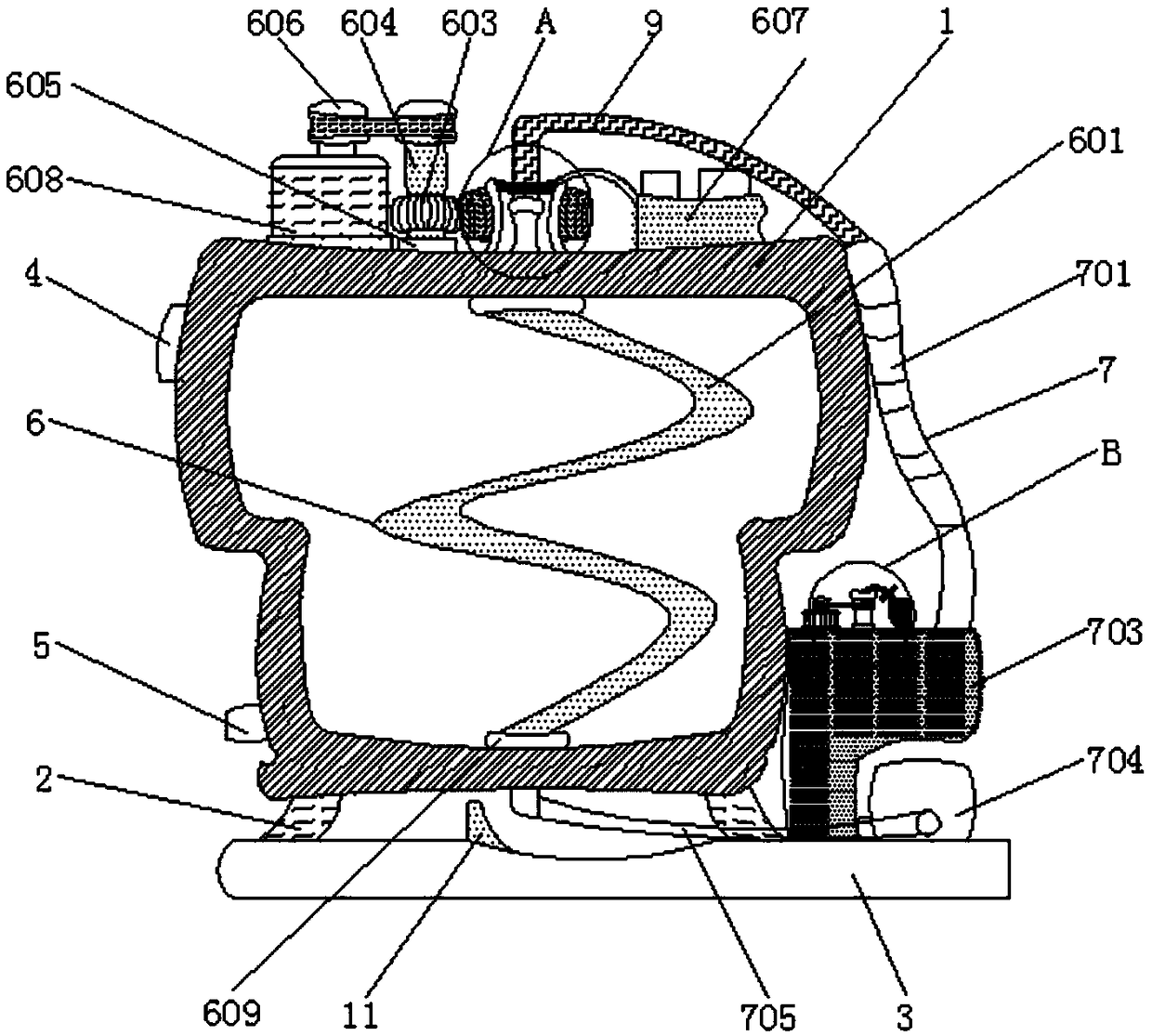

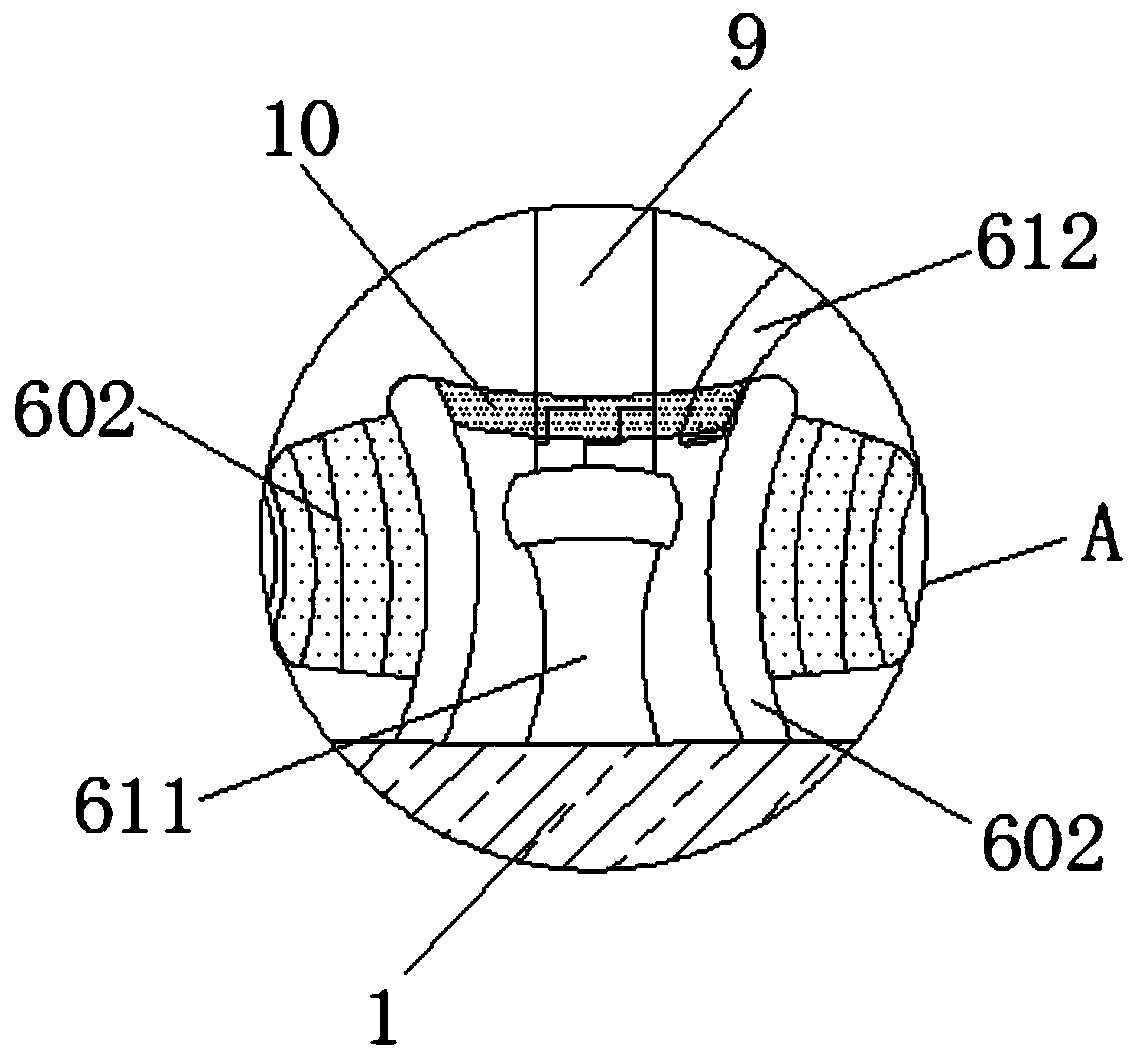

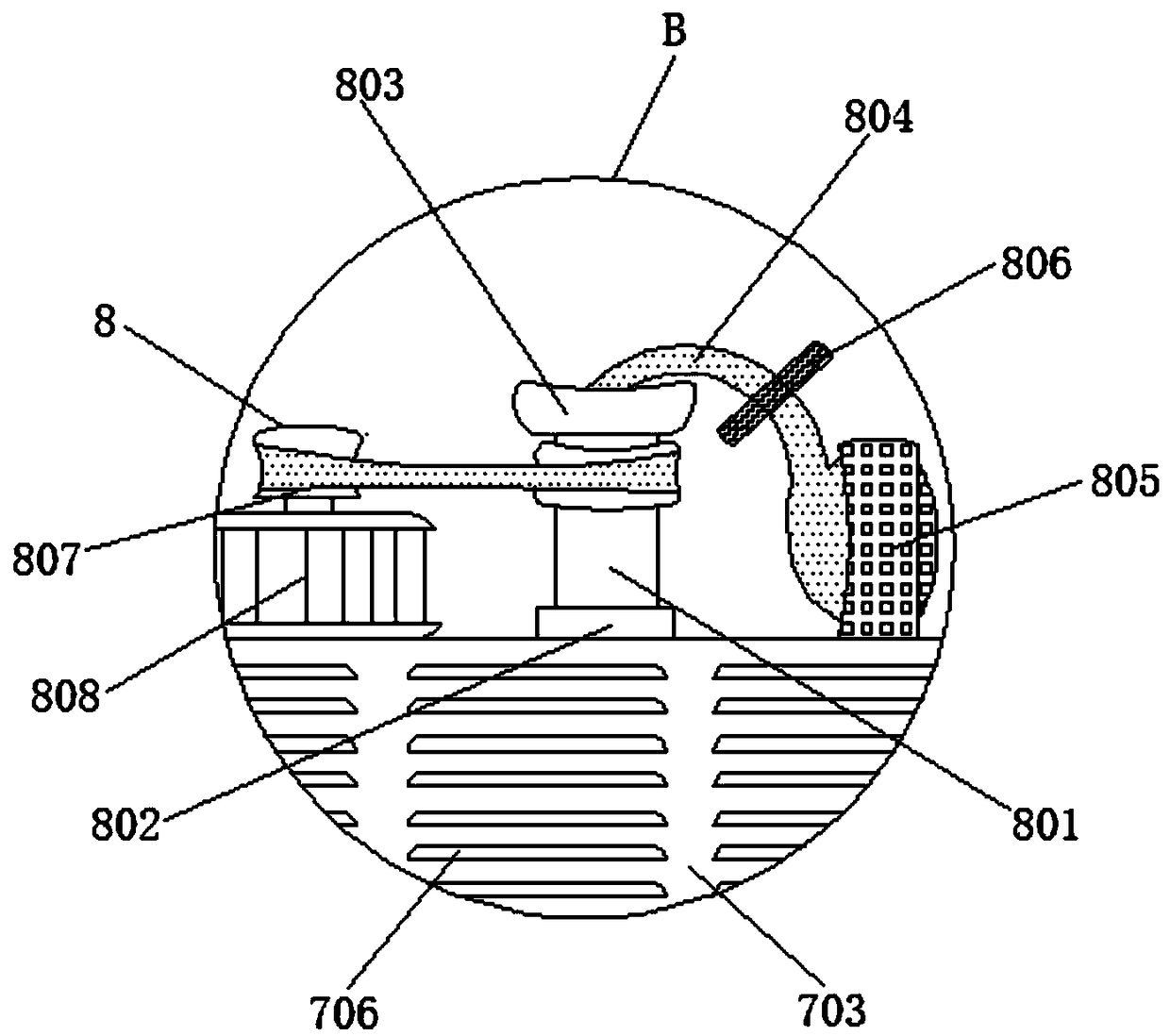

Slow-cooling temperature control device for stainless steel slabs and control method

ActiveCN104907518AEffective adjustment of cooling rateAvoid Temperature Uniformity EffectsTemperature controlProduction rate

The invention pertains to the technical field of metallurgy material, in particular to a slow-cooling temperature control device for stainless steel slabs and a control method.In a slow-cooling pit, temperature in the pit changes periodically within the range from 350 to 900 DEG C. In the way that temperature of the slow-cooling pit and slow-cooling speed of slabs are controlled by recirculation furnace gas, the slabs are uniformly cooled. The slow-cooling temperature control device for the stainless steel slabs and the control method have following beneficial effects: temperature of the stainless steel slabs in the slow-cooling pit is more uniform during a cooling process; internal stress produced from a cooling process of the slabs is decreased; occurrences of stainless steel slab cracks are effectively avoided; slow-cooling time of the stainless steel slabs in the slow-cooling pit is reduced by more than 20 %; slow-cooling productivity of the slabs is improved; and purposes of uniformly decreasing temperature of the stainless steel slabs in the slow-cooling pit at the front period and the late period of the slow-cooling pit are fulfilled.

Owner:NORTHEASTERN UNIV

Dairy product cooling device based on water cooling mode

ActiveCN108827030AImprove cooling effectFaster coolingStationary tubular conduit assembliesCold airMotor drive

The invention provides a dairy product cooling device based on a water cooling mode, and relates to the field of dairy product cooling. The cooling device solves the problem that the existing diary product cooling is large in water consumption and poor in cooling effect. The cooling device comprises a cooling box, and the bottom of the cooling box is welded to the top of a base through overhead legs, and the side wall of the cooling box close to the top is provided with a feeding port, and the side wall of the cooling box close to the bottom is provided with a discharging pipe in communication, and a water and air integrated cooling mechanism is arranged inside the cooling box. The cooling device introduces water to a water cooling pipe inside a cooling elbow to promote cooling, and an airpump introduces outside cold air into the cooling elbow through an air guide pipe. A gear motor drives the cooling elbow through a pulley to rotate inside a dairy product to promote uniform temperature reduction of the dairy product and also drive stirring of the dairy product to expose the portion with higher temperature to promote cooling.

Owner:青海雪峰牦牛乳业有限责任公司

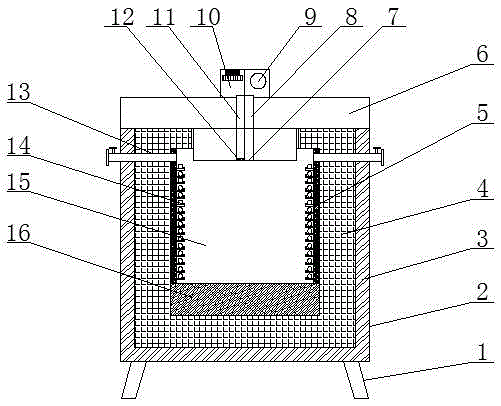

Heat preservation device for castings

InactiveCN105290384AEasy to control changesImprove insulation effectTemperature controlPositive pressure

The invention provides a heat preservation device for castings. The heat preservation device comprises a shell, a furnace cover, heating devices and a heat preservation chamber. Supporting legs are fixed to the bottom of the shell. A heat preservation layer is arranged on the inner side of the shell. A floor tile layer is arranged on the inner side of the heat preservation layer. The heat preservation chamber is arranged in the shell. A sand layer is arranged at the bottom of the heat preservation chamber. The heating devices are installed on the two sides of the heat preservation chamber. Refractory fiber layers are arranged on the outer sides of the heating devices. Air pipes are arranged on the two sides of the upper end of the heat preservation chamber. A circulating hot air device is installed above the furnace cover. A negative-pressure cavity of the circulating hot air device is connected with one end of an air return pipe. An air return port is connected to the other end of the air return pipe and located in the bottom end of the furnace cover. A positive-pressure cavity of the circulating hot air device is connected with one end of an air supply pipe. The other end of the air supply pipe is connected with an air supply port. Compared with the prior art, the heat preservation device for the castings has the following beneficial effects that temperature distribution is even, and temperature control is facilitated.

Owner:CHONGQING TETAI MACHINE MFG CO LTD

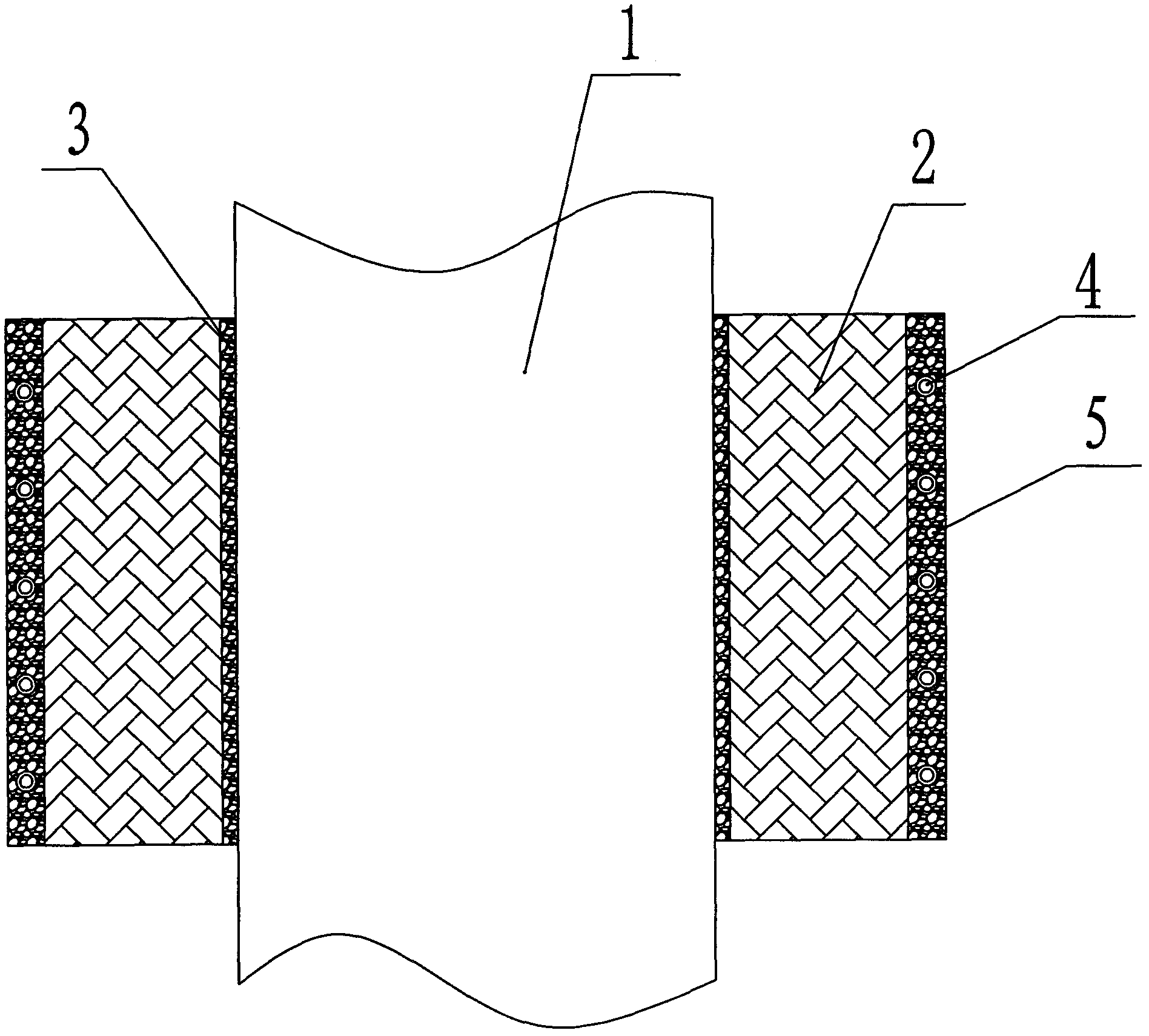

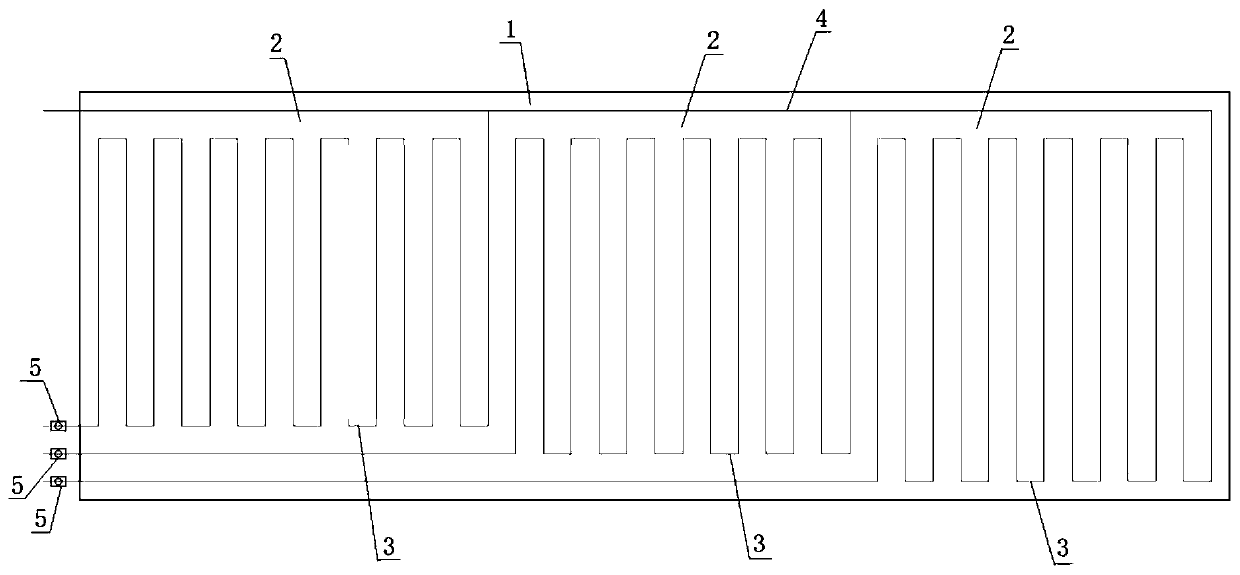

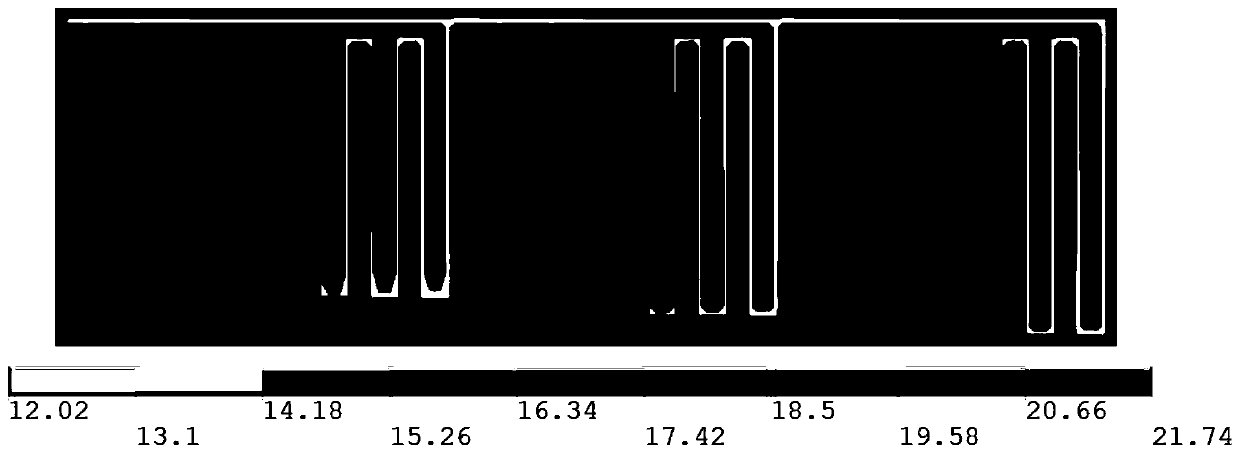

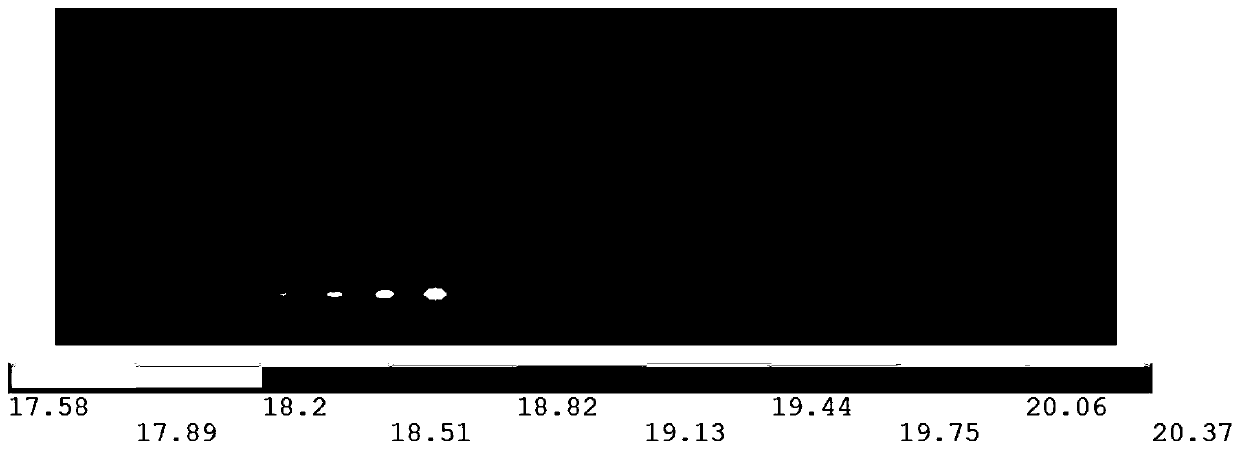

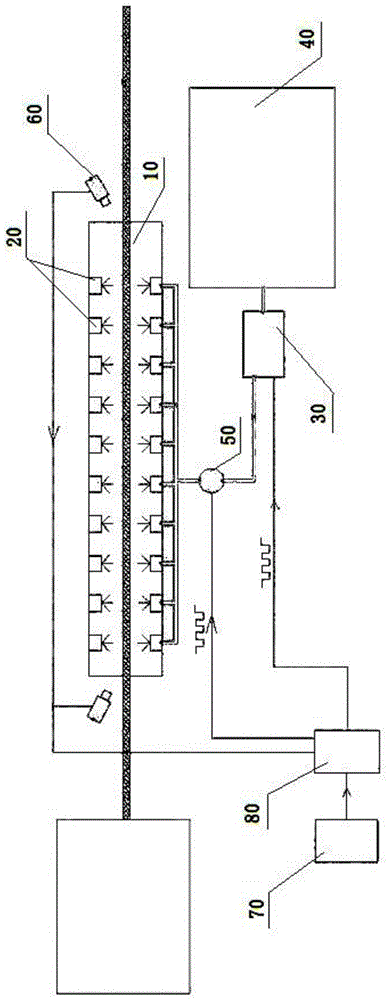

Concrete inside cooling system with cooling water pipes in multi-split arrangement and cooling method thereof

InactiveCN109837904AUniform temperature dropGuaranteed temperature uniformityFoundation engineeringTemperature stressStructural engineering

The invention relates to the field of engineering building, and discloses a concrete inside cooling system with cooling water pipes in multi-split arrangement. The concrete inside cooling system comprises a concrete soil block, wherein the inside of the concrete block is sequentially divided into a plurality of cooling units in the upstream and downstream directions; a cooling branch pipe is arranged in each cooling unit; a cooling water inlet pipe is also arranged inside the concrete block in the upstream and downstream directions; a water inlet of each cooling branch pipe is connected onto the cooling water inlet pipe; a water outlet of each cooling branch pipe is singly guided out to the outside of the concrete block; and a flow rate control valve is arranged in the water outlet position of each cooling branch pipe. The invention also discloses a cooling method of the concrete inside cooling system with cooling water pipes in multi-split arrangement. The concrete inside cooling system with cooling water pipes in multi-split arrangement and the cooling method of the system have the advantages that the defects of the conventional cooling water pipe arrangement are overcome, so that the temperature reduction amplitude of each part of the concrete is more uniform; the temperature differences and the temperature stress of each part of the concrete can be effectively reduced; andthe temperature crack occurring risk is reduced.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

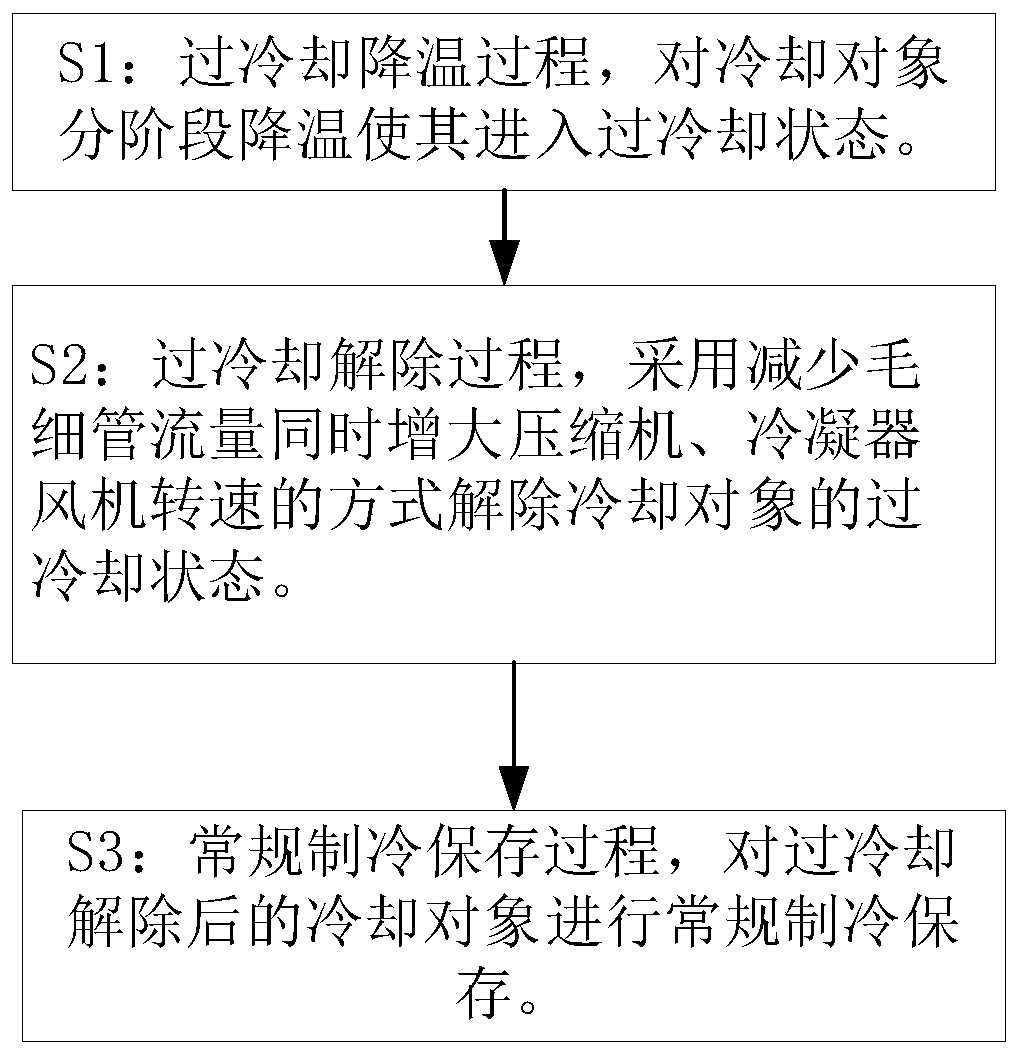

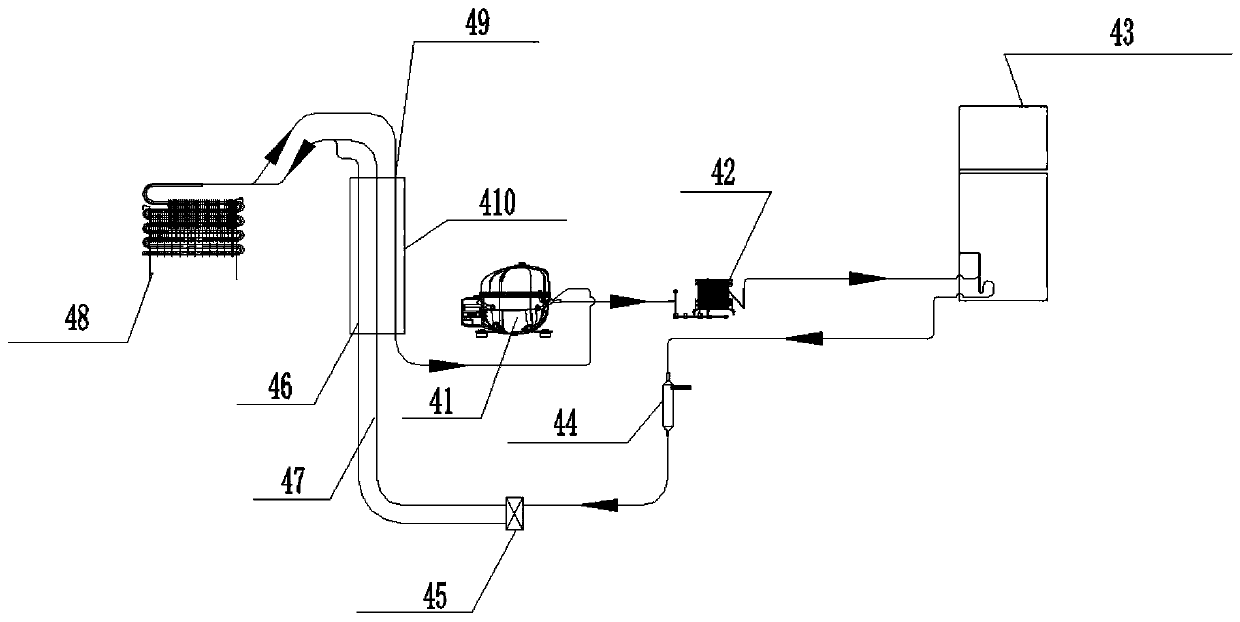

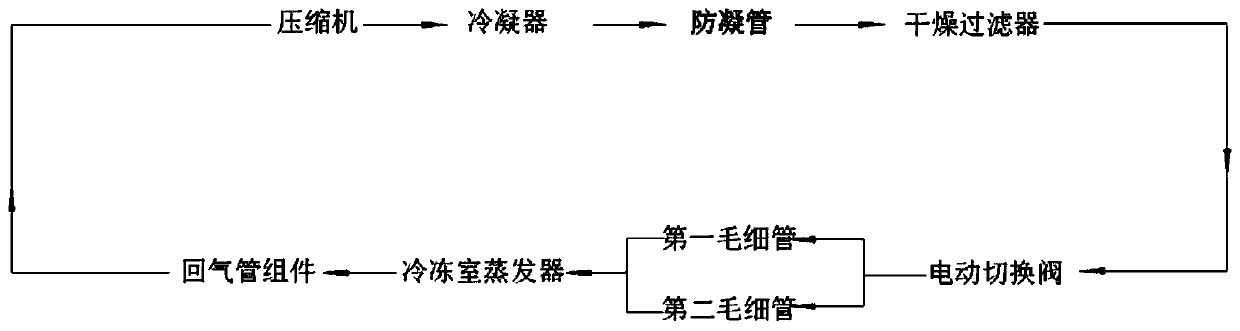

Control method for achieving instant-freezing storage and refrigerator

PendingCN110701858AUniform temperature dropIncrease nutritionLighting and heating apparatusCooling fluid circulationIceboxNutrition

The invention relates to a control method for achieving instant-freezing storage and a refrigerator. Instant-freezing storage on a to-be-cooled object is achieved through three processes of conductingovercooling temperature reduction, overcooling removal and conventional refrigeration storage on the to-be-cooled object. For the cooling temperature reduction process, the to-be-cooled object stablyenters an overcooling state by conducting stepwise temperature reduction control over an instant-freezing chamber; overcooling is removed through the mode of reducing the flow of capillary tubes andincreasing the rotating speed of a compressor and the rotating speed of a condenser fan at the same time, so that the to-be-cooled object quickly passes through a maximum ice crystal belt to be instantly frozen; by means of the conventional refrigeration storage process, the cooled object is easy to cut after being taken out, the situation that much juice of the to-be-cooled object flows out, andthen nutrition loss of the to-be-cooled object is caused is avoided, and the storage demand of users can be met.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD +1

High-strength fire-resistant and weather-resistant steel plate/strip and production method thereof

The invention relates to a high-strength fire-resistant and weather-resistant steel plate / strip and a production method thereof. The steel plate / strip comprises the following chemical components in percent by weight: 0.02-0.06% of C, 0.1-0.55% of Si, 0.4-1.7% of Mn, less than or equal to 0.03% of P, less than or equal to 0.007% of S, 0.30-0.80% of Cr, 0.10-0.60% of Cu, 0.20-0.60% of Mo, 0.01-0.08%of Nb, 0.004-0.010% of N, less than or equal to 0.001% of Als, 0.007-0.020% of total oxygen [O]T and the balance Fe and inevitable impurities, wherein Mn / S is greater than 250; and Pcm is smaller than or equal to 0.27%. The production method comprises the following steps of: selectively adding micro-alloy elements such as Mo / Nb / Cr into steel, and controlling the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als; then casting a cast strip through double-roller thin strip continuouscasting, and then feeding the cast strip into an on-line rolling mill for hot rolling; and after rolling, cooling the strip steel in a gas atomization cooling mode, and finally coiling the strip steeldirectly into a steel coil.

Owner:BAOSHAN IRON & STEEL CO LTD

Boron-containing high-reaming steel and production method thereof

The invention discloses boron-containing high-reaming steel and a production method thereof. The steel comprises the following chemical components of, in percentage by weight, 0.01%-0.05% of C, 0.2%-0.6% of Si, 0.8%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, less than 0.001% of Als, less than or equal to 0.0050% of Ca, 0.001%-0.006% of B, 0.007%-0.020% of total oxygen [O]T, Mn / S is large than 250 and the balance Fe and inevitable impurities. According to the steel, microalloy elements such as B are selectively added intothe steel; in a smelting process, the alkalinity of slag, a type and a melting point of an inclusion in steel, a content of free oxygen in molten steel and a content of acid-soluble aluminum Als are controlled; then, double-roller thin strip continuous casting is carried out to cast a cast strip with a thickness of 1.5-3 mm, and the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere and enters an online rolling mill for hot rolling under the closed condition; and after rolling, strip steel is cooled in a gas atomization cooling mode, and a produced steel coil canbe directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

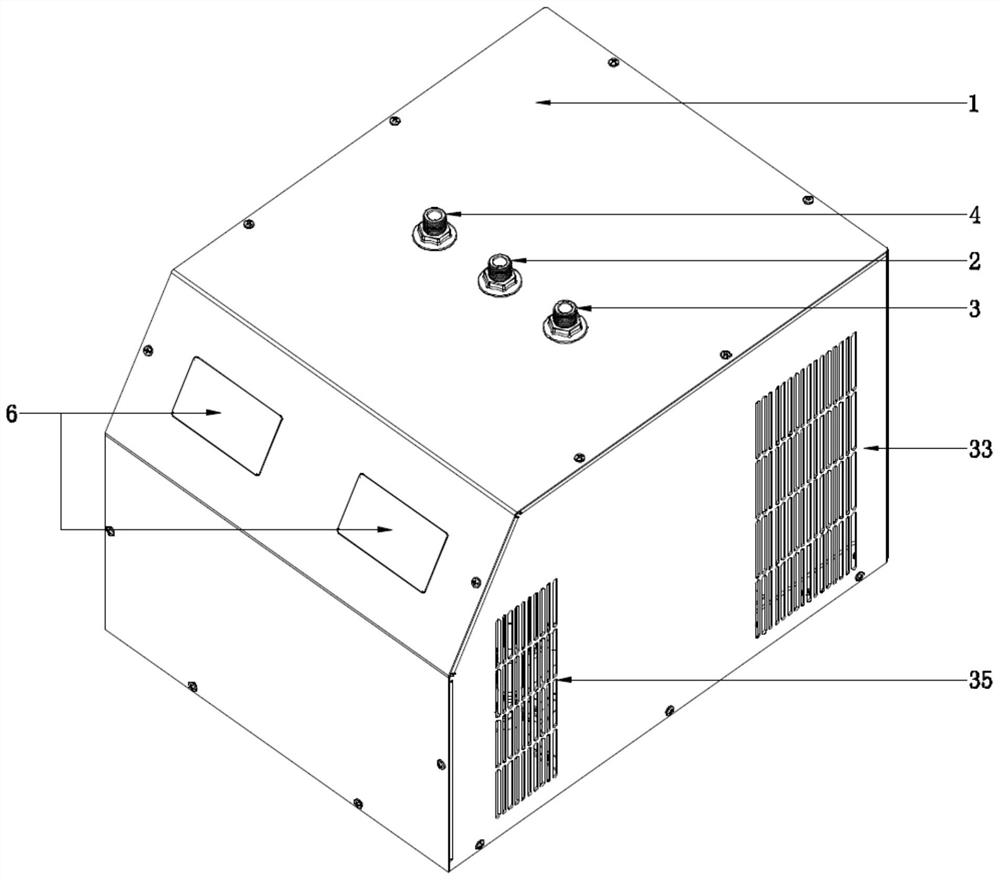

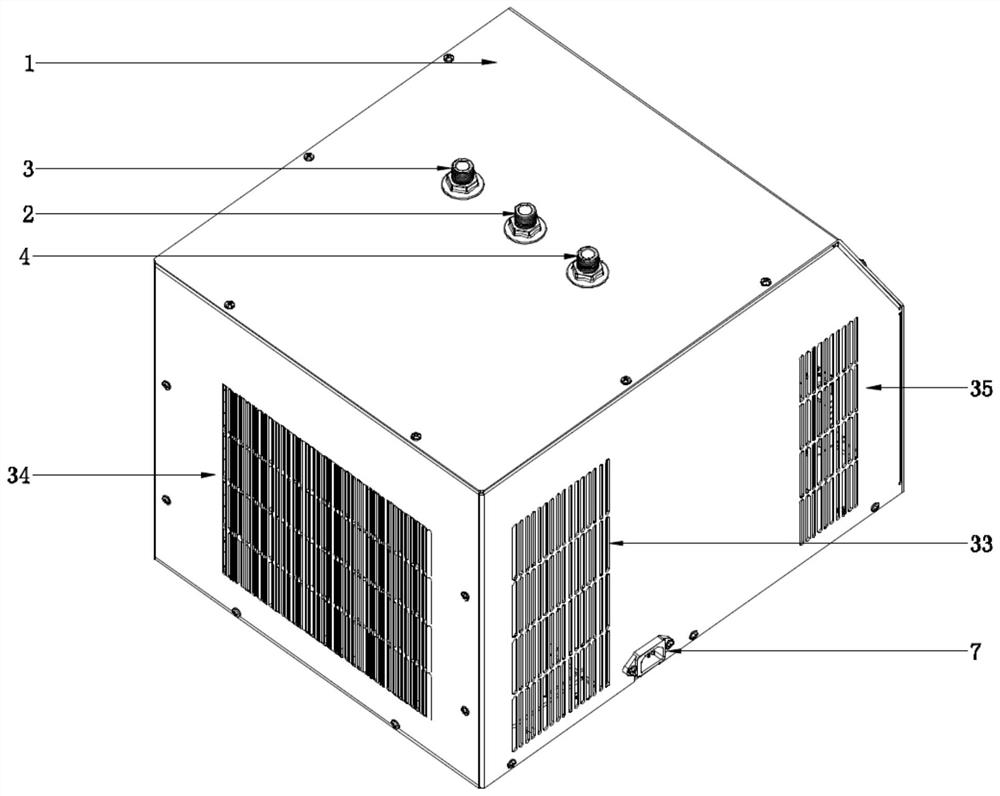

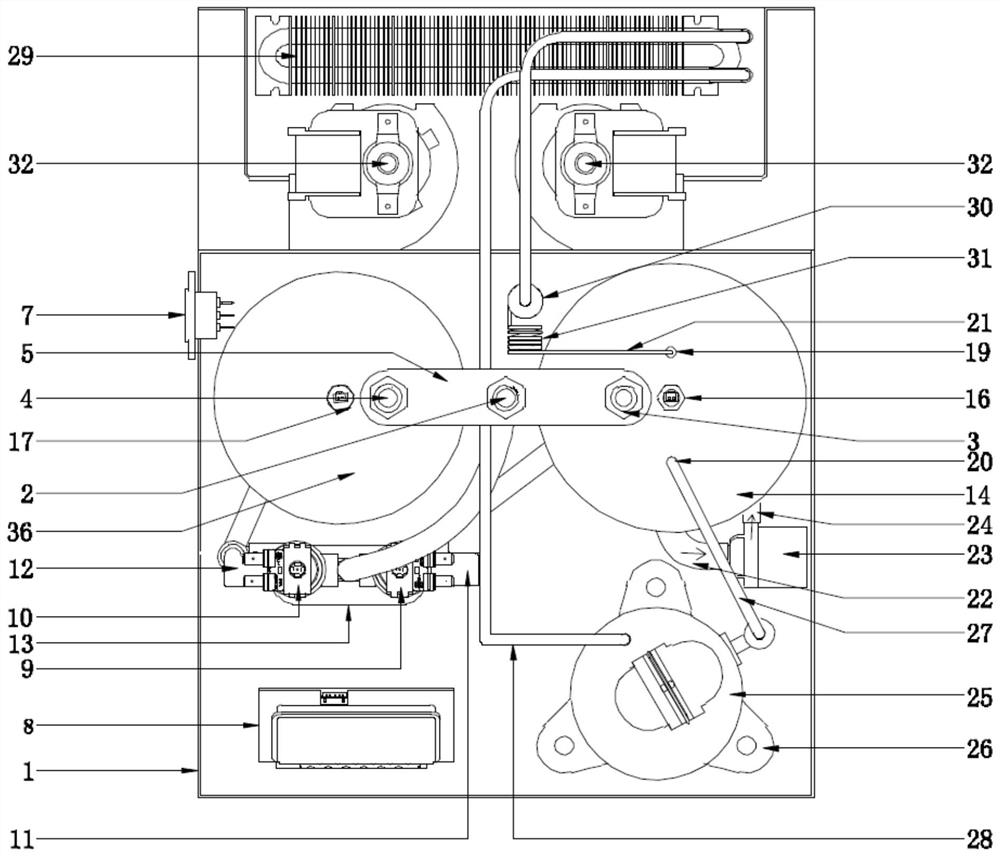

Quick cold and hot water dispenser

The invention discloses a quick cold and hot water dispenser. The quick cold and hot water dispenser comprises a shell, a venturi, a backflow cavity, a compressor, a condenser, an ice water bucket, aheating inner container and an electronic controller. A normal-temperature water inlet, an ice water outlet and a hot water outlet are formed in the upper portion of the shell, a fixing support is arranged among the normal-temperature water inlet, the ice water outlet and the hot water outlet, a display screen is installed on the front side of the shell, and a power supply base is arranged at thelower end of the left side of the shell. An electronic controller is fixed in the shell through a mounting bracket. An electromagnetic valve I and an electromagnetic valve II are arranged at the upperpart of the backflow cavity in parallel. Rapid refrigeration is realized by adopting an evaporation pipe built-structure, and requirements for rapid and large-quantity water are met; energy is fullyutilized and saved; a cold water barrel is provided with an internal circulating water device to prevent internal local areas from icing and achieve the effect of balanced cooling of water temperature; a cross-flow fan is adopted for heat dissipation of a condenser, and therefore, noise is lower, and comfort is higher.

Owner:XIAMEN AOHUASI ELECTRIC

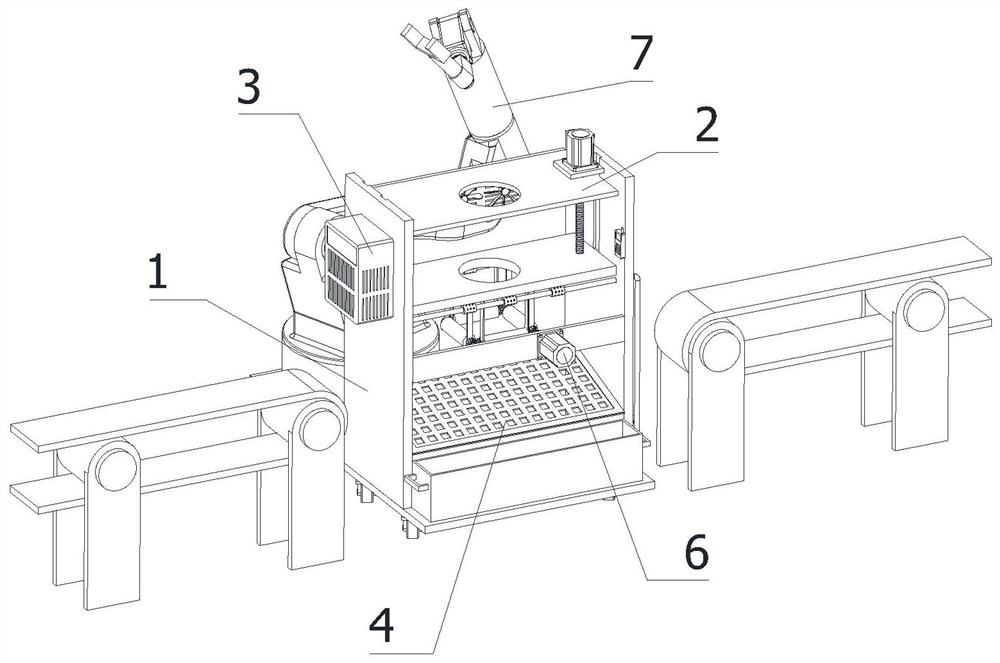

Aluminum profile quenching system and quenching method

InactiveCN104818371ARespond to processing requirementsNo deformationQuenching devicesWater sourceQuenching

The invention provides an aluminum profile quenching system. The system comprises a quenching table, a nozzle assembly, a water pump, a water groove, a ball valve controller, a temperature measuring unit, an operation panel and a control unit. The quenching table transmits and quenches aluminum profiles, and the nozzle assembly is arranged on the periphery of the quenching table and sprays water mist to the aluminum profiles; the water pump and the water groove are connected with the nozzle assembly through a pipeline and provide a water source; the ball valve controller is arranged between the water pump and the nozzle assembly, and can adjust the water mist spraying speed and / or flow of the nozzle assembly; the temperature measuring unit is arranged on a feeding opening and a discharging opening of the quenching table to detect the first temperature T1 of aluminum profiles obtained before quenching and the second temperature T2 of the aluminum profiles obtained after quenching; the operation panel is used for inputting parameters of the aluminum profiles; and the control unit receives parameters sent by the operation panel and the first temperature T1 and the second temperature T2 sent by the temperature measuring unit and outputs an instruction to the ball valve controller according to the parameters, the first temperature T1 and the second temperature T2 so as to adjust the mist spraying speed and / or flow of the nozzle assembly. Therefore, according to the quenching requirements of different aluminum profiles, the quenching cooling condition can be adjusted in real time, and the profiles are prevented from deforming.

Owner:中亿丰金益(苏州)科技有限公司

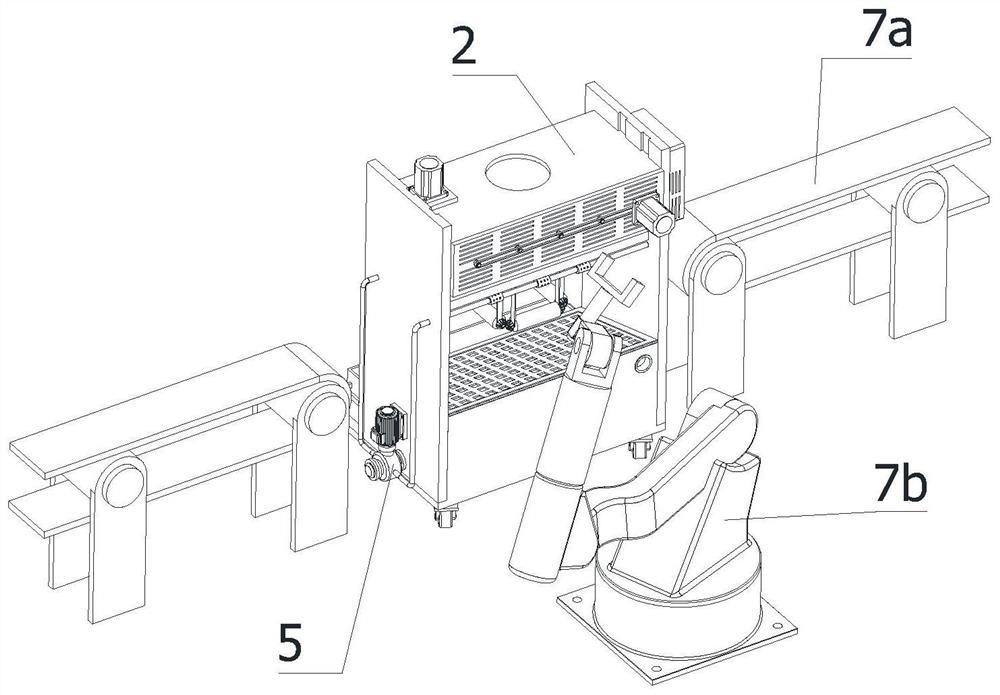

Automatic cooling device for large shaft workpieces after quenching

PendingCN113088644AUniform temperature dropSolve the burning problemFurnace typesCleaning using toolsThermodynamicsEngineering

The invention relates to the technical field of quenching cooling, in particular to an automatic cooling device for large shaft workpieces after quenching. The automatic cooling device comprises a rack, a lifting assembly, a cooling assembly, a brush head assembly, a spraying assembly, a filtering assembly and a material moving assembly, the workpieces are placed on the lifting assembly through the material moving assembly, and the lifting assembly drives the workpieces to be placed on the cooling assembly. The cooling assembly precools a workpiece, when the temperature is reduced to a set threshold value, the spraying assembly secondarily cools the workpiece and washes off oil stains on the workpiece, the brush head assembly cleanly scrubs off the oil stains on the workpiece, the oil stains scrubbed off by the brush head assembly are separated through the filtering assembly, and after the workpiece is scrubbed clean, the lifting assembly drives the workpiece to return to the top of the rack to take down the workpiece, through the operations, the problem that the workpiece is burnt out due to uneven cooling intensity is solved, through cooling of the multiple assemblies, the temperature of the workpiece is evenly reduced, the cost expenditure is reduced, and the percent of pass is increased.

Owner:祁永幸

Hot-rolled steel plate/strip for sulfuric acid dew point corrosion resistance and manufacturing method thereof

ActiveCN112522599AShort production processImprove efficiencyProcess efficiency improvementAir preheaterPetrochemical

The invention discloses a hot-rolled steel plate / strip for sulfuric acid dew point corrosion resistance and a manufacturing method thereof. Residual Sn, Cu and other elements in steel scrap are fullyutilized for molten steel smelting, and Cr, Ti, Sb and other microalloy elements are selectively added; in a smelting process, the alkalinity of slag, a type and a melting point of inclusions in steel, a content of free oxygen in molten steel and a content of acid-soluble aluminum Als are controlled; and then a cast strip is cast by adopting double-roller thin strip continuous casting, directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged from a crystallization roller, and enters an online rolling mill for hot rolling under a closed condition, rolled strip steel is cooled by adopting a gas atomization cooling mode, and finally the strip steel is coiled. The steel can be widely applied to the field of products with sulfuric acid dew point corrosion resistance requirements in use environments such as tobacco baking equipment, air preheater heat exchange elements, conveying pipelines, flues, chimney manufacturing structural parts, boiler preheatersand economizer equipment in industries of petroleum, chemical engineering, electric power, metallurgy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Fire-resistant and weather-resistant steel plate/strip and production method thereof

ActiveCN112522638AIncrease production costShort production processHeat treatment process controlWeather resistanceStrip steel

The invention discloses a fire-resistant and weather-resistant steel plate / strip and a production method thereof. The fire-resistant and weather-resistant steel plate / strip comprises, by weight, 0.02-0.06% of C, 0.1-0.55% of Si, 0.4-1.7% of Mn, less than or equal to 0.03% of P, less than or equal to 0.007% of S, 0.30-0.80% of Cr, 0.10-0.60% of Cu, 0.20-0.60% of Mo, 0.004-0.010% of N, less than 0.001% of Als, 0.007-0.020% of total oxygen [O]T and the balance Fe and other inevitable impurities; and besides, the Mn / S ratio is greater than 250, and the Pcm is less than or equal to 0.27%. The produced fire-resistant and weather-resistant steel plate / strip can ensure that the steel can keep a high strength level at a high temperature, and also can reduce the mass of a building, improve the safety of the building and reduce the construction cost; and meanwhile, by utilizing the technological characteristics of thin-strip continuous casting, a fine grain layer with a certain thickness can be naturally formed on the strip steel surface on the basis of the fire resistance of the produced fire-resistant and weather-resistant steel plate / strip, and therefore the product has weather resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of thin hot-rolled steel plate/strip for sulfuric acid dew point corrosion resistance

ActiveCN112522585AShort production processImprove efficiencyProcess efficiency improvementAir preheaterPetrochemical

The invention relates to a thin hot-rolled steel plate / strip for sulfuric acid dew point corrosion resistance and a production method thereof. Residual Sn, Cu and other elements in scrap steel are used fully to smelt molten steel, and Cr, Ti, Sb and other microalloy elements and B element are selectively added into the steel. The production method comprises the steps of: in a smelting process, controlling the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als; and then casting a cast strip through double-roller thin strip continuous casting, feeding the cast strip into an on-line rolling mill for hot rolling under a closed condition, cooling strip steel in a gas atomization cooling mode after rolling, and finally conducting coiling. The steel disclosed by the invention can be widely applied to the field of products with sulfuric acid dew point corrosion resistance requirements inuse environments such as tobacco baking equipment, air preheater heat exchange elements, conveying pipelines, flues, chimney manufacturing structural parts, boiler preheaters and economizer equipmentin industries of petroleum, chemical engineering, electric power, metallurgy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

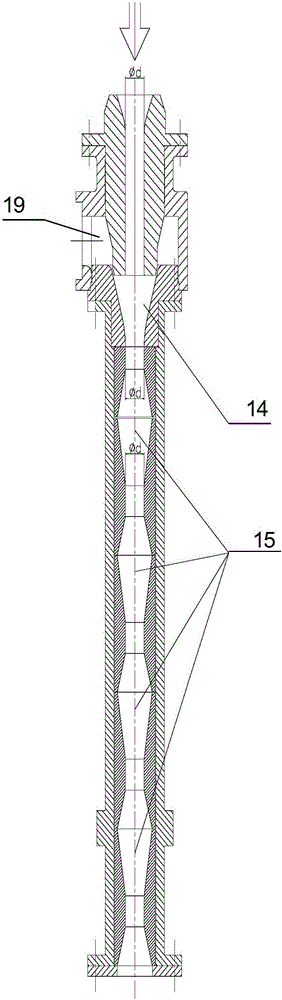

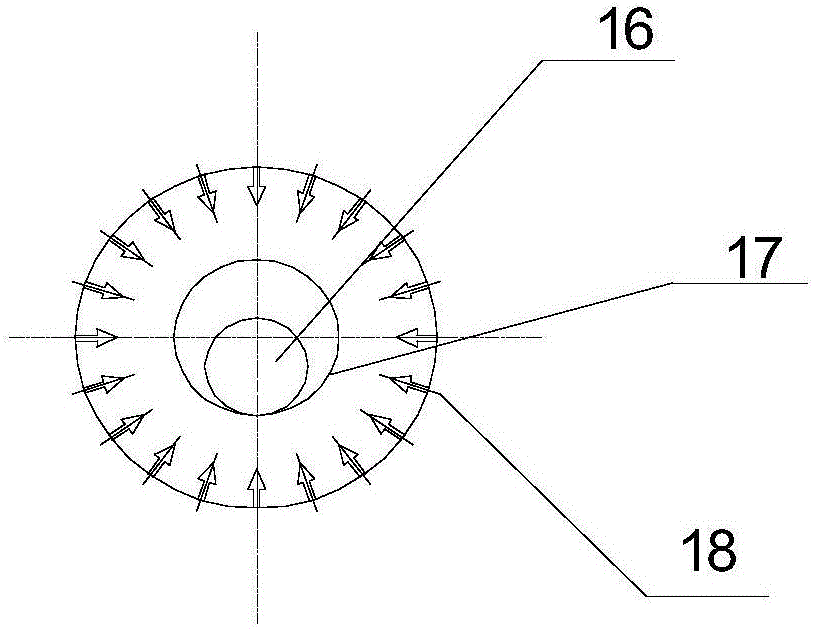

Cooler and water cooling method for bar rolling

ActiveCN105728479AReserve cooling capacityUniform temperature dropTemperature control deviceWork cooling devicesEngineeringFlare

The invention discloses a cooler for bar cooling. The cooler for bar cooling comprises a nozzle component and a sleeve component comprising a sleeve, a flared inner lined pipe is arranged at one end, close to the nozzle component, in the sleeve, and the end face, close to the nozzle component, of the inner lined pipe butts against the end face of the nozzle component. A first sleeve pipe and second sleeve pipes are arranged in the sleeve sequentially, the longitudinal section of the internal diameter of the first sleeve pipe is flared, a flare of the first sleeve pipe faces one side of the inner lined pipe, the longitudinal section of the internal diameter of every second sleeve pipe is flared, and a flare of every second sleeve pipe faces the first sleeve pipe. The minimum internal diameter of the flare of every second sleeve pipe is minimum aperture phi B through which a bar rolled piece passes, the minimum internal diameter phi C of a flare of the inner lined pipe is 1.3 times of the minimum aperture phi B through which the bar rolled piece passes, and the dimension of the minimum internal diameter phi D of the flare of the first sleeve pipe satisfies phi B<phi D<phi C. The invention further discloses a water cooling method for bar rolling.

Owner:SHANDONG IRON & STEEL CO LTD

High-corrosion-resistance steel and manufacturing method thereof

The invention discloses high-corrosion-resistance steel and a manufacturing method thereof. The high-corrosion-resistance steel is prepared from the chemical components in percentage by weight: 0.02-0.06% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, less than or equal to 0.02 % of P, 4.0-6.0% of Cr, 1.0-3.0% of Ni, less than or equal to 0.007% of S, 0.004-0.010 % of N, less than 0.001% of Als, 0.001-0.006% of B, greater than 250 of Mn / S, 0.007-0.020% of total oxygen [O]<T>, and the balance of Fe and inevitable impurities. Alloying elements such as Cr and Ni and an element B are selectively added intoplain carbon steel; the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process; double-roller thin strip continuous casting is adopted for casting a cast strip, the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere and enters an online rolling mill for hot rolling under a closed condition, and strip steel is cooled in a gas atomization cooling mode after rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing high-strength and high-corrosion-resistance steel through thin-strip continuous casting

The invention discloses a method for producing high-strength and high-corrosion-resistance steel through thin-strip continuous casting. The method comprises the following steps of a), performing smelting, wherein smelting is performed according to the following chemical components including, by weight, 0.02-0.06% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, less than or equal to 0.02% of P, 4.0-6.0% of Cr, 1.0-3.0% of Ni, less than or equal to 0.007% of S, 0.004-0.010% of N, less than 0.001% of Als, 0.007-0.020% of total oxygen [O]T and the balance Fe and inevitable impurities, meanwhile, the chemical components include one or two of 0.01-0.08% of Nb and 0.01-0.08% of V, and the Mn / S ratio is greater than 250; b), performing double-roller thin-strip continuous casting to obtain a cast strip; c),performing lower airtight protection, wherein the cast strip directly enters a lower airtight chamber after being discharged out of crystallization rollers, and non-oxidizing gas is introduced into the lower airtight chamber; d), performing online hot rolling, wherein the cast strip is fed to a rolling mill through pinch rolls in the lower airtight chamber to be rolled into strip steel; e) coolingthe strip steel by adopting a gas atomization cooling mode; and f) coiling the strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-strip continuously cast high-reaming steel and production method thereof

The invention discloses thin-strip continuously cast high-reaming steel and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.01-0.05% of C,0.2-0.6% of Si, 0.8-1.5% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.008% of N, smaller than 0.001% of Als, smaller than or equal to 0.0050% of Ca, greater than 250 of Mn / S, 0.007-0.020% of total oxygen [O]T and the balance of Fe and other inevitable impurities. In the smelting process, the alkalinity of slag, the types and meltingpoints of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled; then a cast strip with a thickness of 1.5-3 mm is cast through twin-roll thin-strip continuous casting, and the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of a crystallization roller and enters an online rolling mill under the closed condition to be subjected to hot rolling; strip steel is cooled in a gas atomization cooling manner after being rolled; and finally the produced steel coil can be directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

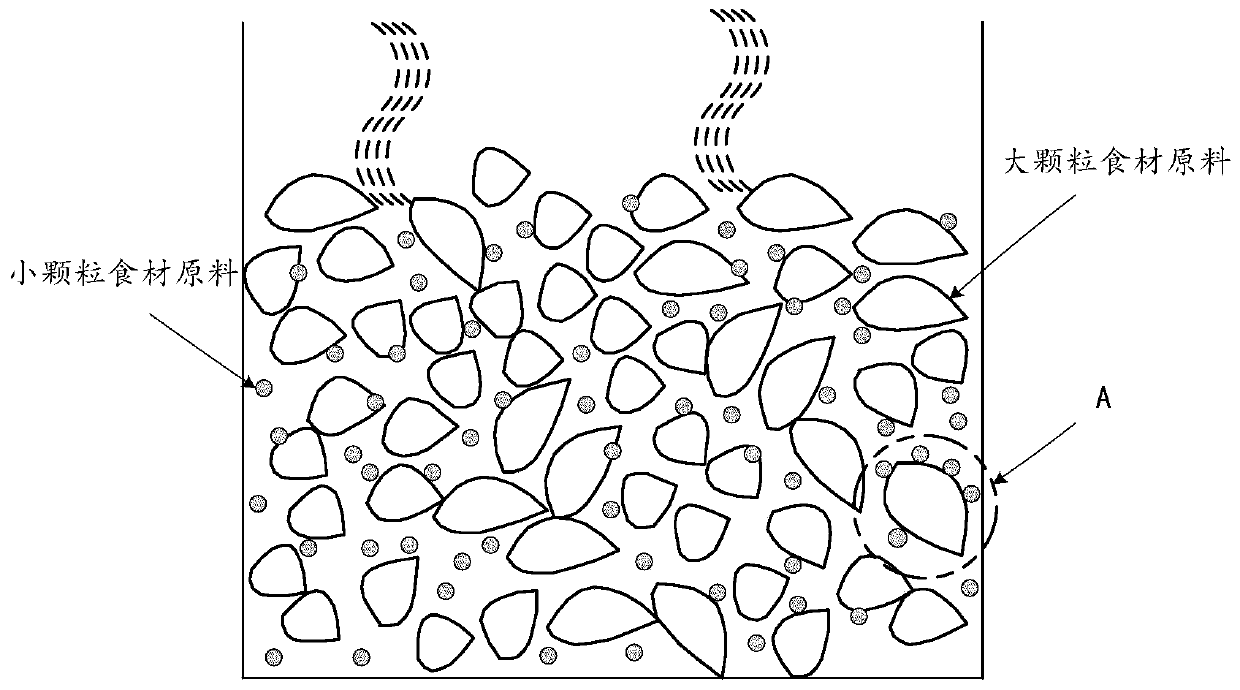

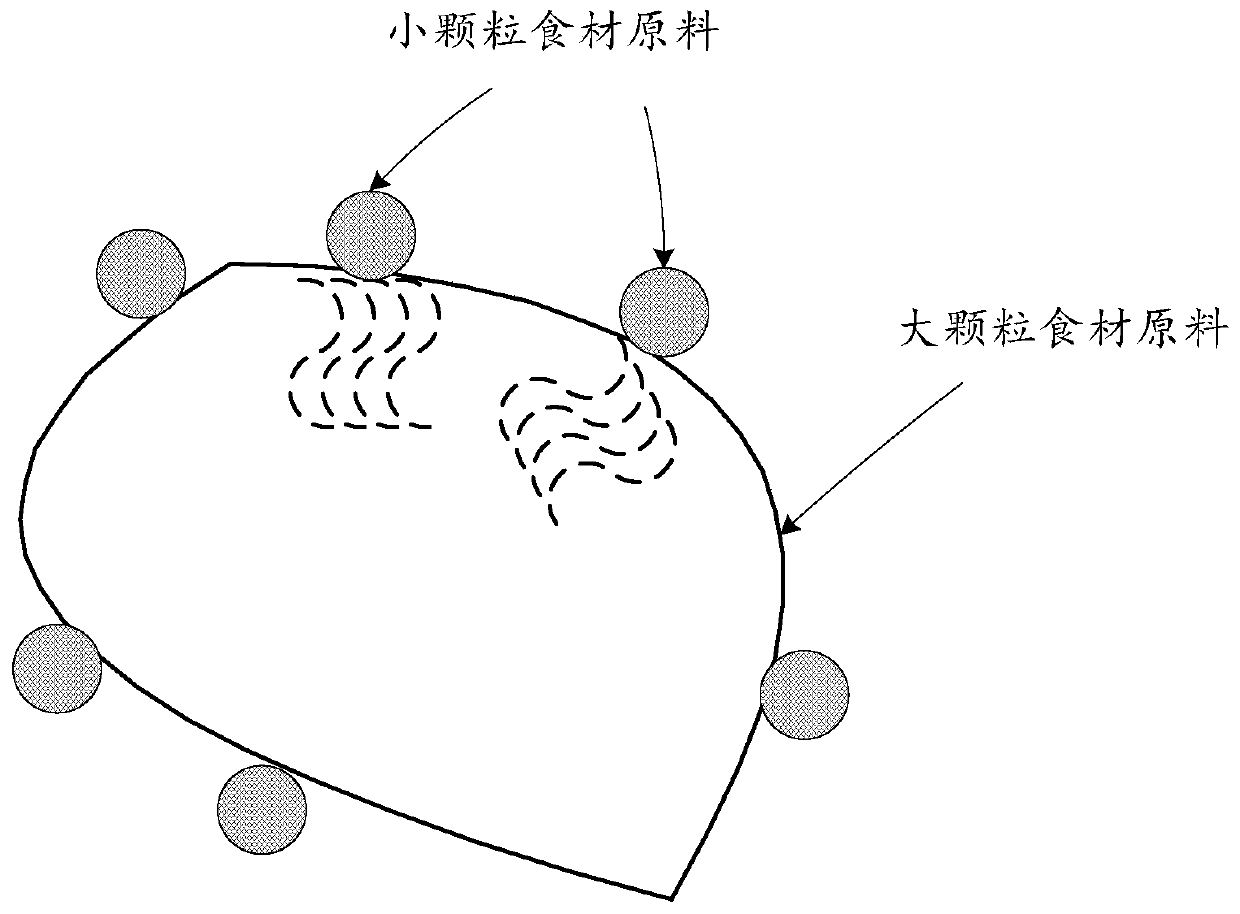

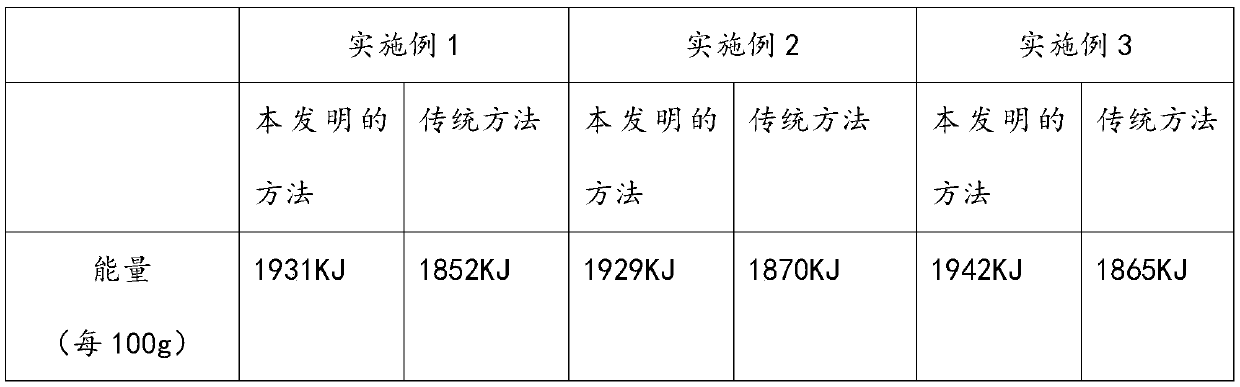

A kind of nano-scale solid beverage vegetarian food and preparation method thereof

ActiveCN106234906BReduce the risk of carbonationUniform temperature dropFood ingredientsCarbonizationFood material

The embodiment of the invention provides a preparation method of a nanometer-sized solid beverage vegetarian food. The preparation method comprises the following steps of: classifying and screening a variety of food raw materials according to the the contents of starch and protein, classifying the food raw materials into multiple categories and respectively processing in millimeter, micron and nanometer scales according to the different categories, and then respectively mixing, finally processing in the nanometer scale. According to the invention, the food materials with larger particles are mixed, and the principle of physical cooling is used, so that the problem of carbonization of the proteins and starch easily generated in the preparation process is solved.

Owner:马佳明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com