Control method for achieving instant-freezing storage and refrigerator

A control method and a technology for an instant freezing compartment, which are applied in the control of instant freezing storage and in the field of refrigerators, can solve the problems of uneven temperature drop overcooling, loss of food nutrition, shallow depth of overcooling, etc., and achieve uniform and uniform temperature drop. Storage requirements, effect of uniform temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

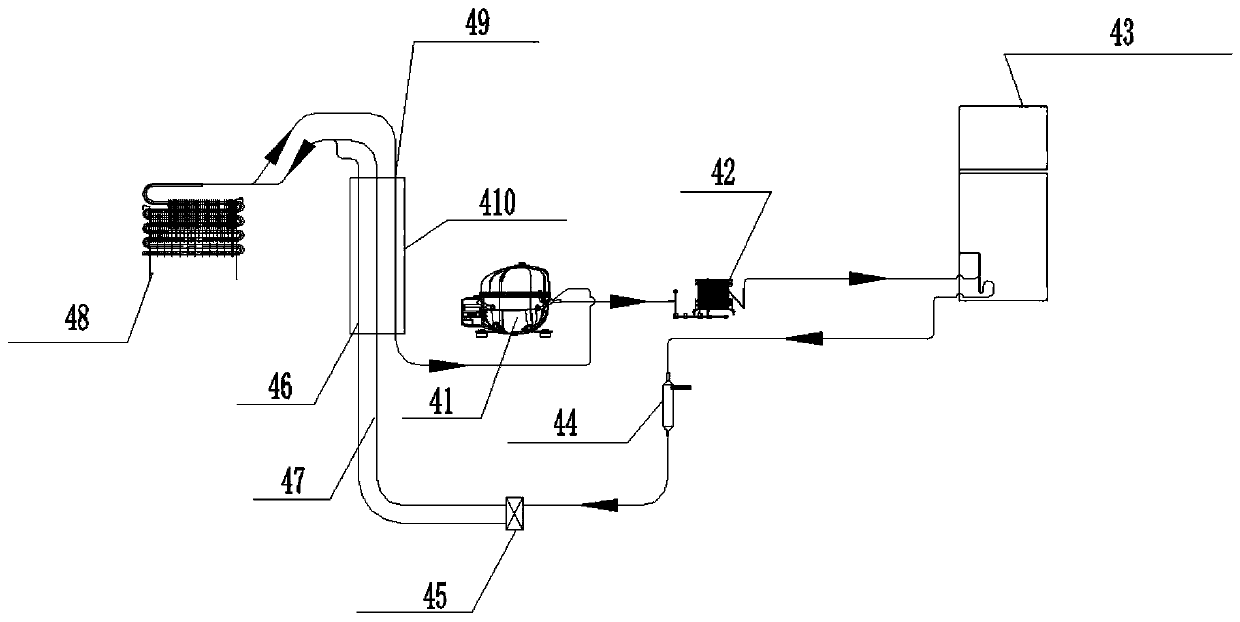

[0052] Such as Figure 4 As shown, the present embodiment provides a kind of instant freezing storage refrigerator, comprising:

[0053] The instant freezing chamber 2 is used to accommodate cooling objects and implement instant freezing storage on them.

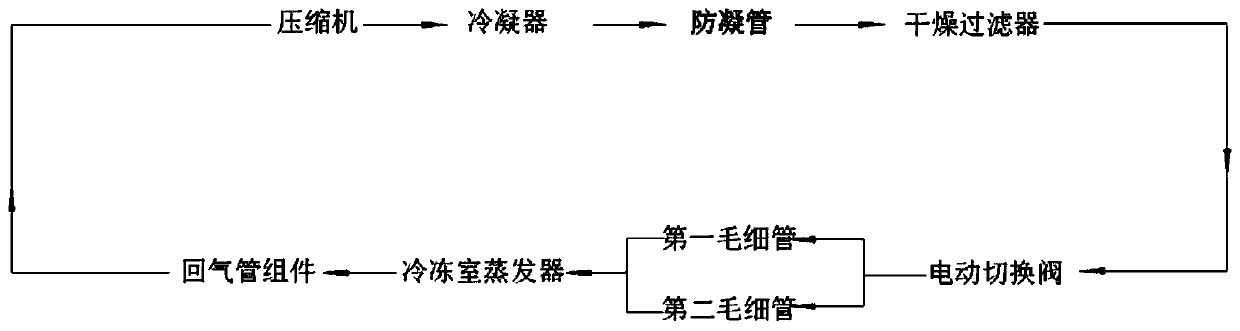

[0054] The refrigeration system 4 is used to provide cold air to the instant freezing chamber 2 in a controlled manner, so as to lower or maintain the temperature of the instant freezing chamber 2 according to various preset temperatures. Specifically include: compressor 41, condenser 42, anti-condensation pipe 43, dry filter 44, electric switching valve 45, first capillary tube 46, second capillary tube 47, freezer evaporator 48, return air pipe assembly 49, return air exchange Hot section 410.

[0055] The control system 5 is used to control the refrigeration system 4 to provide cold air to the instant freezing chamber 2, and control the temperature adjustment device 54 to adjust the temperature of the instant freezing c...

Embodiment 2

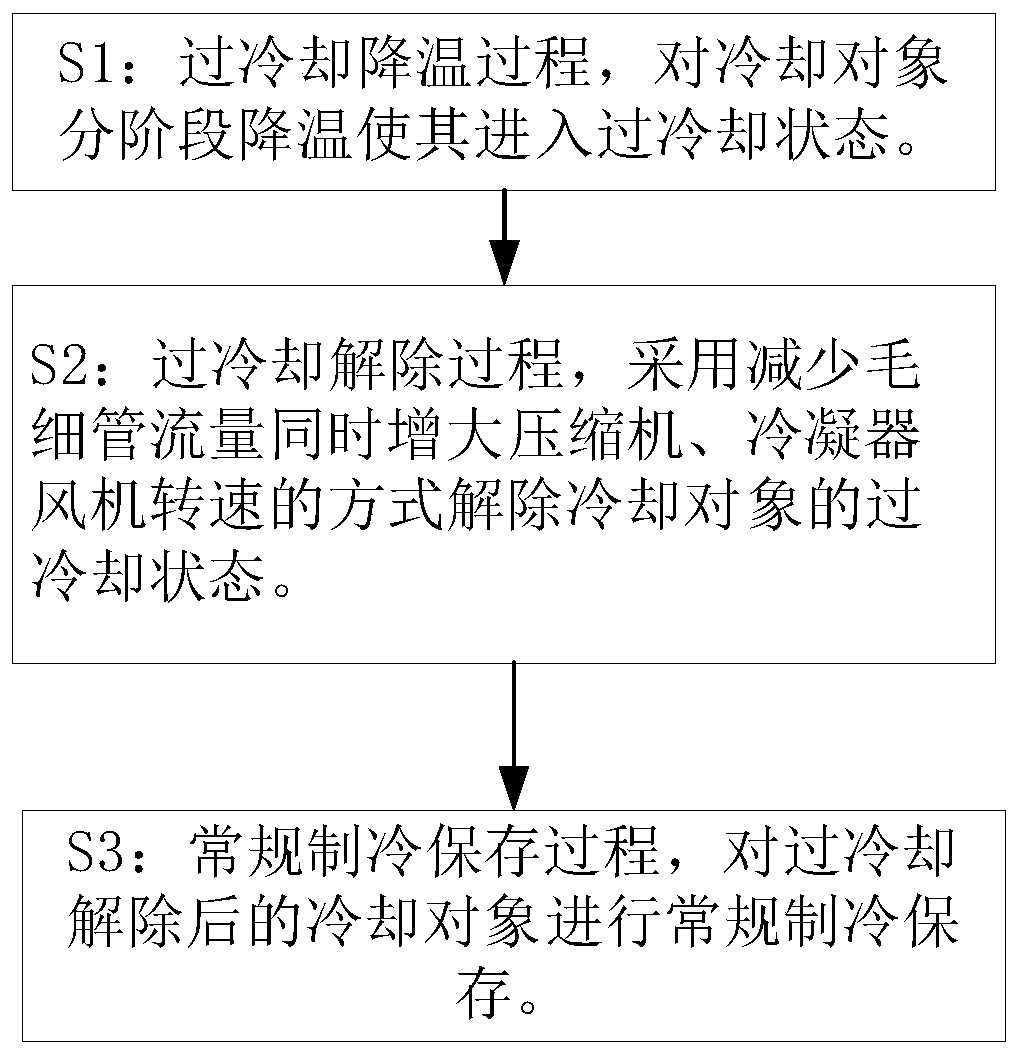

[0065] Such as figure 1 As shown, the present embodiment provides a method for controlling instant freezing storage, including:

[0066] S1: Carry out the supercooling and cooling process, and lower the temperature of the cooling object in stages to make it enter the supercooling state.

[0067] specific:

[0068] S11: preset the duration of step S11 to be t1, preset the first cooling target of the cooling object to be T1, and adjust the instant freezing chamber 2 with T1 as the target, wherein the control system 5 controls the compressor 41 to rotate at a speed of M2 through the frequency conversion board 55 To run, control the condenser fan to run at the speed P1, and control the electric switching valve 45 to switch to the first capillary 46, so that the flow rate of the capillary is V1. During the temperature adjustment process, the temperature sensor 53 detects the real-time temperature inside the instant freezing chamber 2, and when it is detected that the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com