Water-cooled reactor

A reactor, water-cooled technology, applied in the field of water-cooled structures, can solve problems such as unfavorable mass production, unrepairable, non-separation of water and electricity, and achieve the effects of overcoming high manufacturing costs, overcoming uneven heat exchange, and uniformly reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

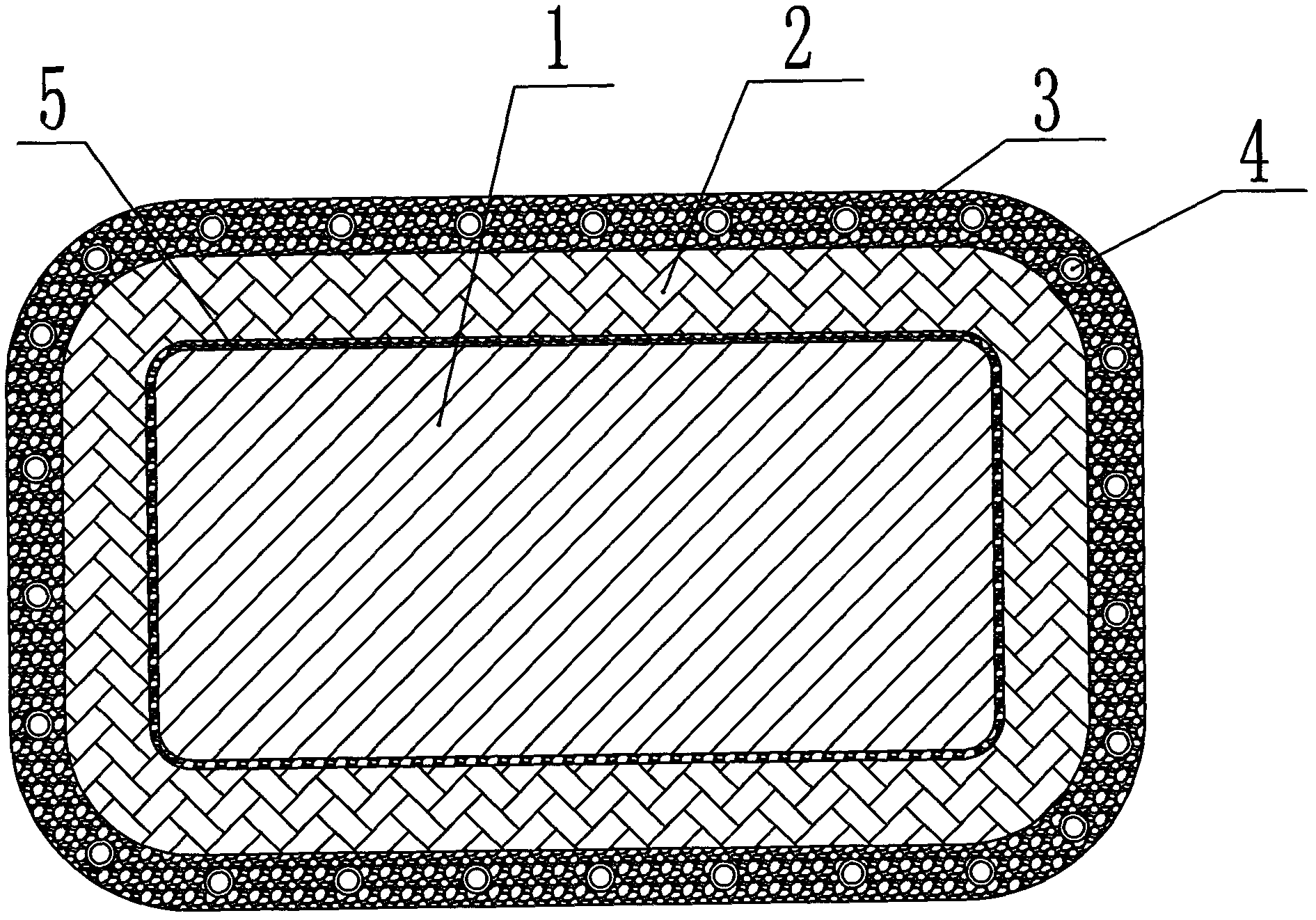

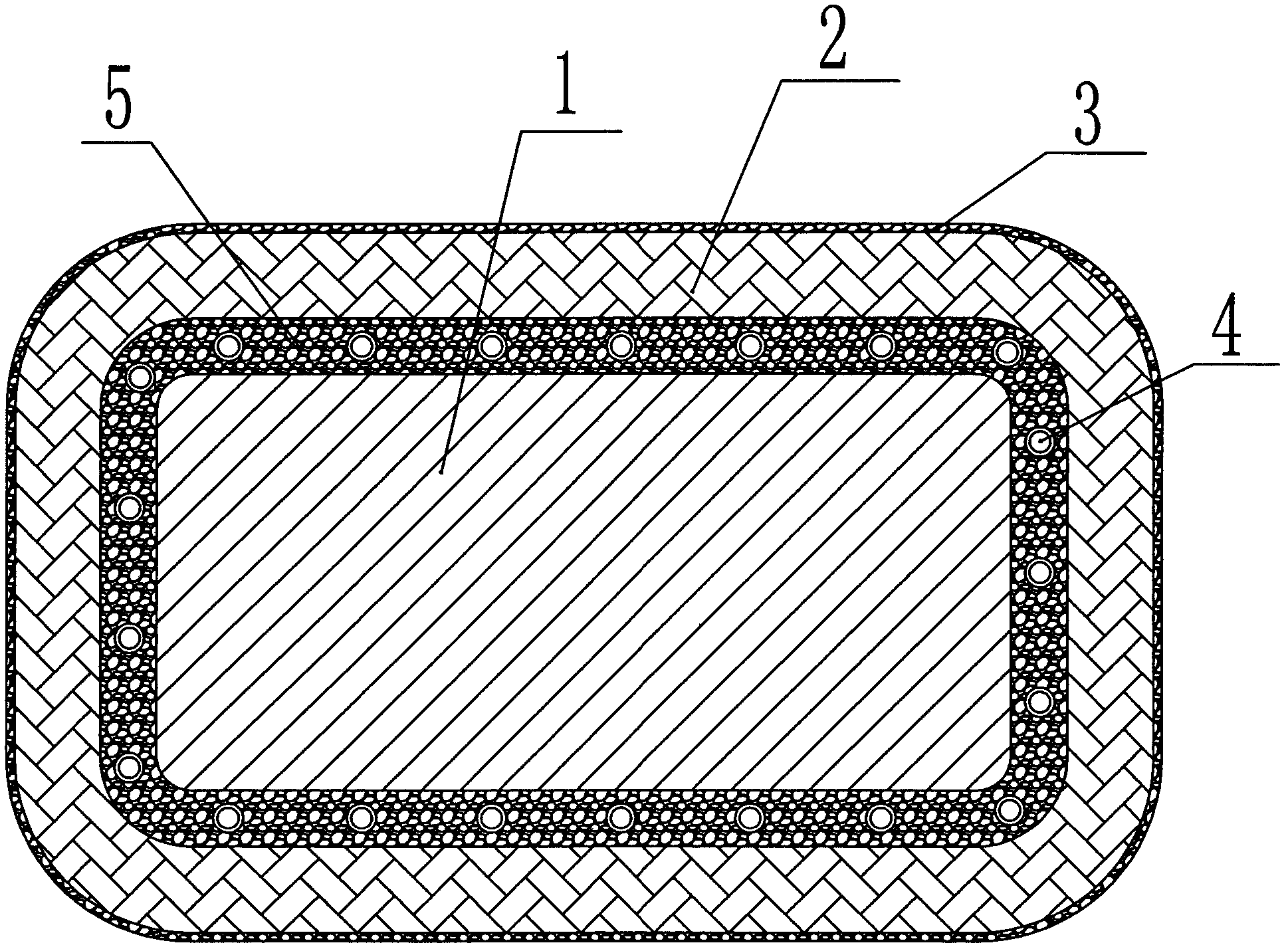

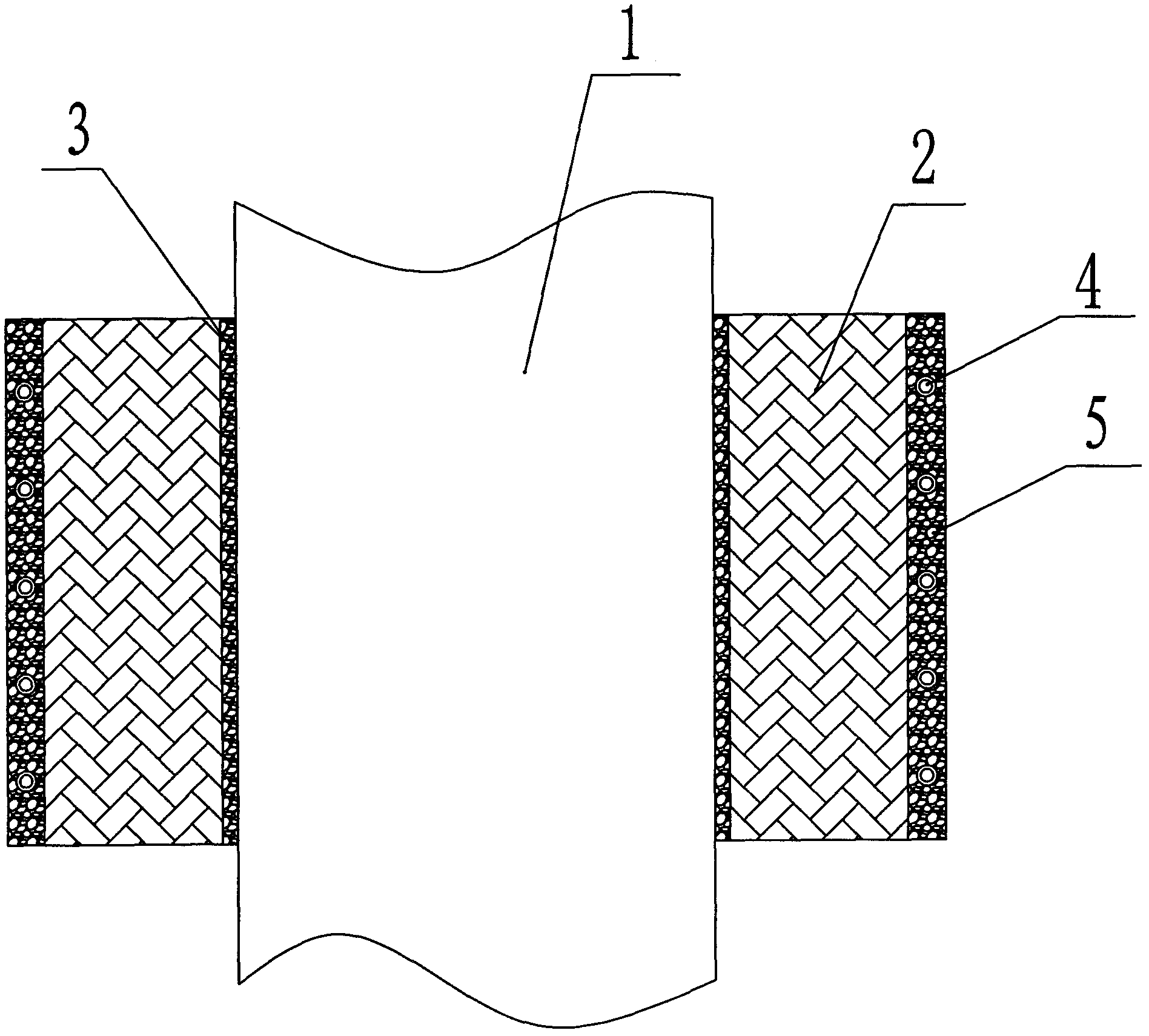

[0026] Such as figure 1 and image 3 As shown, the water-cooled reactor includes an iron core 1 and a conductive coil 2 arranged outside the iron core 1 . The conductive coil 2 is a set of electrical components arranged outside the iron core 1 and generates a magnetic field when energized, and is generally wound with multiple strands of wire to form a set of the conductive coil 2 . An epoxy resin layer 5 is arranged between the iron core 1 and the conductive coil 2 .

[0027] On the outside of the conductive coil 2, a cooling water pipe 4 with a circular cross section is evenly arranged in a circular manner, and the cooling water pipe 4 is provided with a water inlet and a water outlet (not shown in the figure). There is an insulating isolation gap between 4 and the conductive coil 2 . in figure 1 The cooling water pipe 4 shown is a structure arranged outside the conductive coil along the direction in which the iron core 1 and the conductive coil 2 extend up and down, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com