Shoe washing machine

A shoe washing machine and shoe body technology, which is applied in the field of shoe washing machines, can solve the problems of high cost and poor cleaning effect of shoe washing machines, and achieve the effect of overcoming high manufacturing costs and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

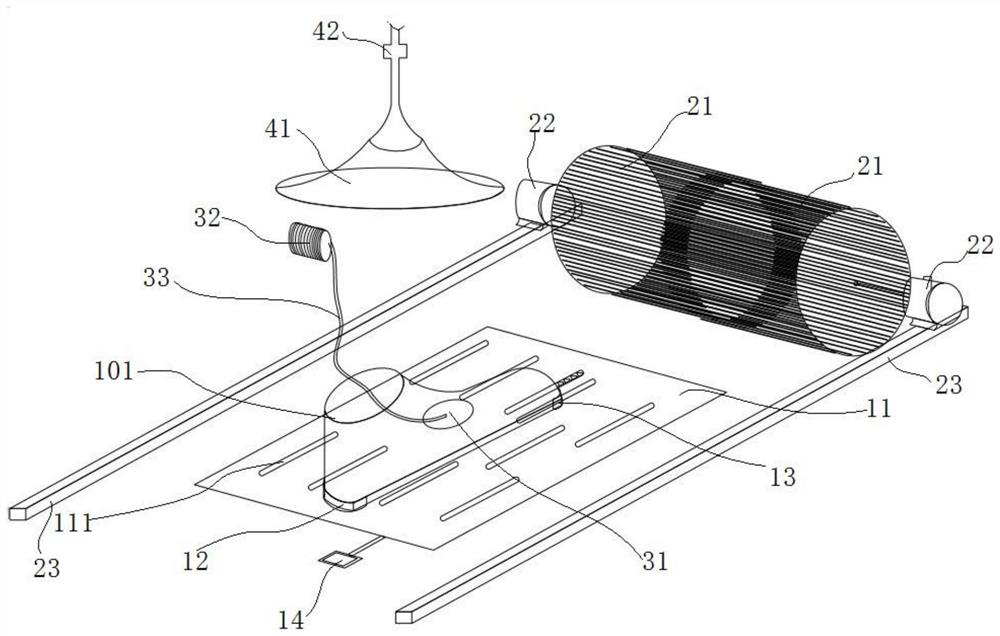

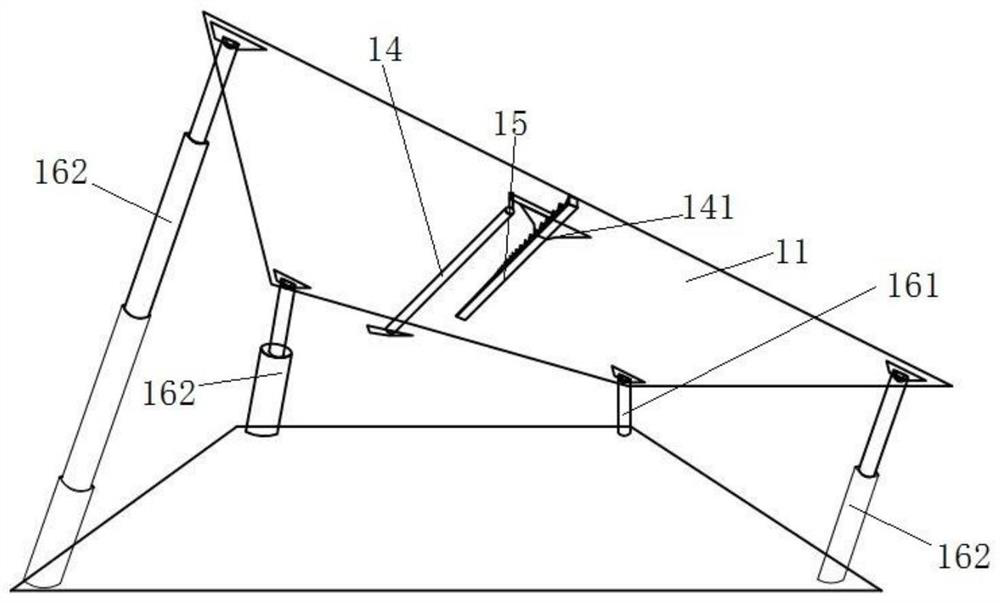

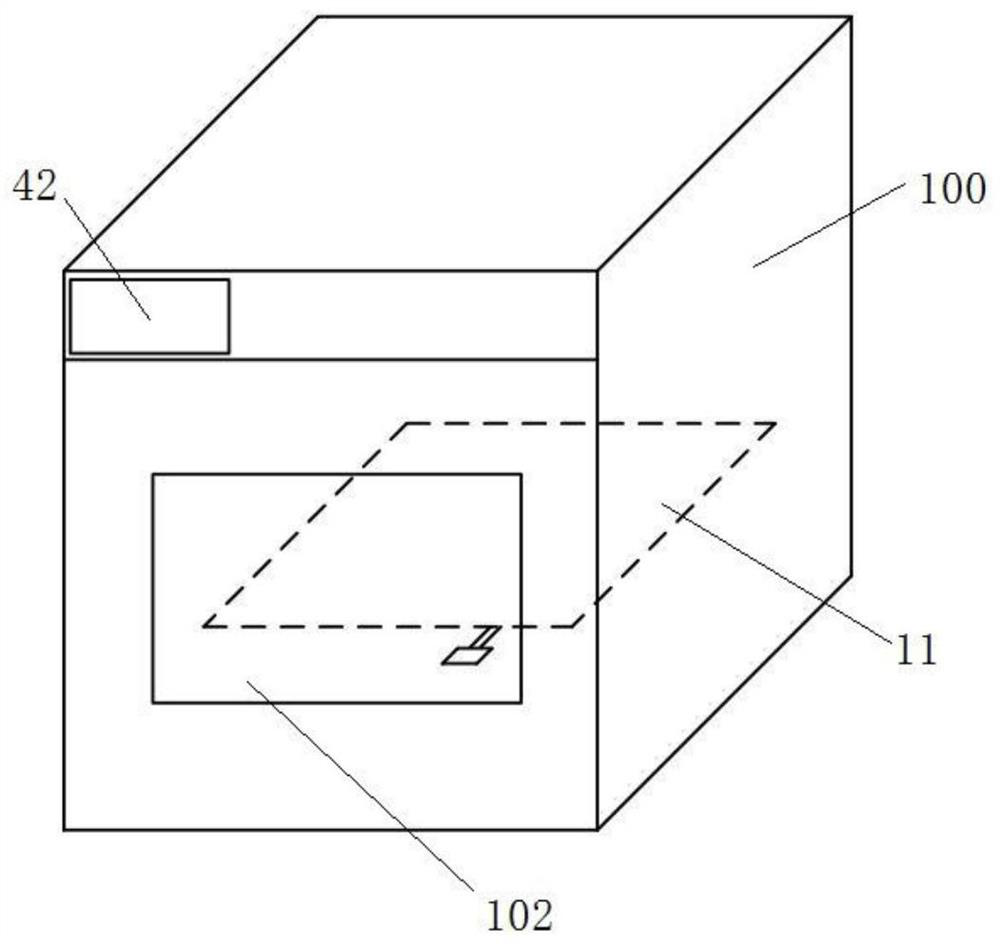

[0022] see in conjunction Figure 1 to Figure 5 As shown, according to an embodiment of the present invention, a shoe washing machine is provided, including an outer shell 100, and the outer shell 100 is provided with: a shoe body fixing assembly for placing and fixing the shoe body 101 to be cleaned; assembly, used to clean the outside of the shoe body 101 on the shoe body fixing assembly; the ultrasonic cleaning assembly, including the ultrasonic transducer 31, can be placed on the inside of the shoe body 101; the spray assembly, used to spray the shoe body 101 . In this technical solution, the rolling brush assembly can effectively clean the outer peripheral side of the shoe body 101, and the ultrasonic transducer 31 in the ultrasonic cleaning assembly is placed inside the shoe body 101 to achieve targeted Cleaning, so as to realize all-round and efficient cleaning of the shoe body 101, improve the cleaning effect, and effectively overcome the disadvantage of high manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com