Method for controlling mass concrete cooling introduced water flow

A technology of mass concrete and control method, applied in the direction of flow control, non-electric variable control, control/adjustment system, etc., can solve the problems of unfavorable concrete quality, undocumented concrete, temperature steep rise and drop, etc., to eliminate randomness , to achieve the effect of automatic calculation, uniform and stable temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

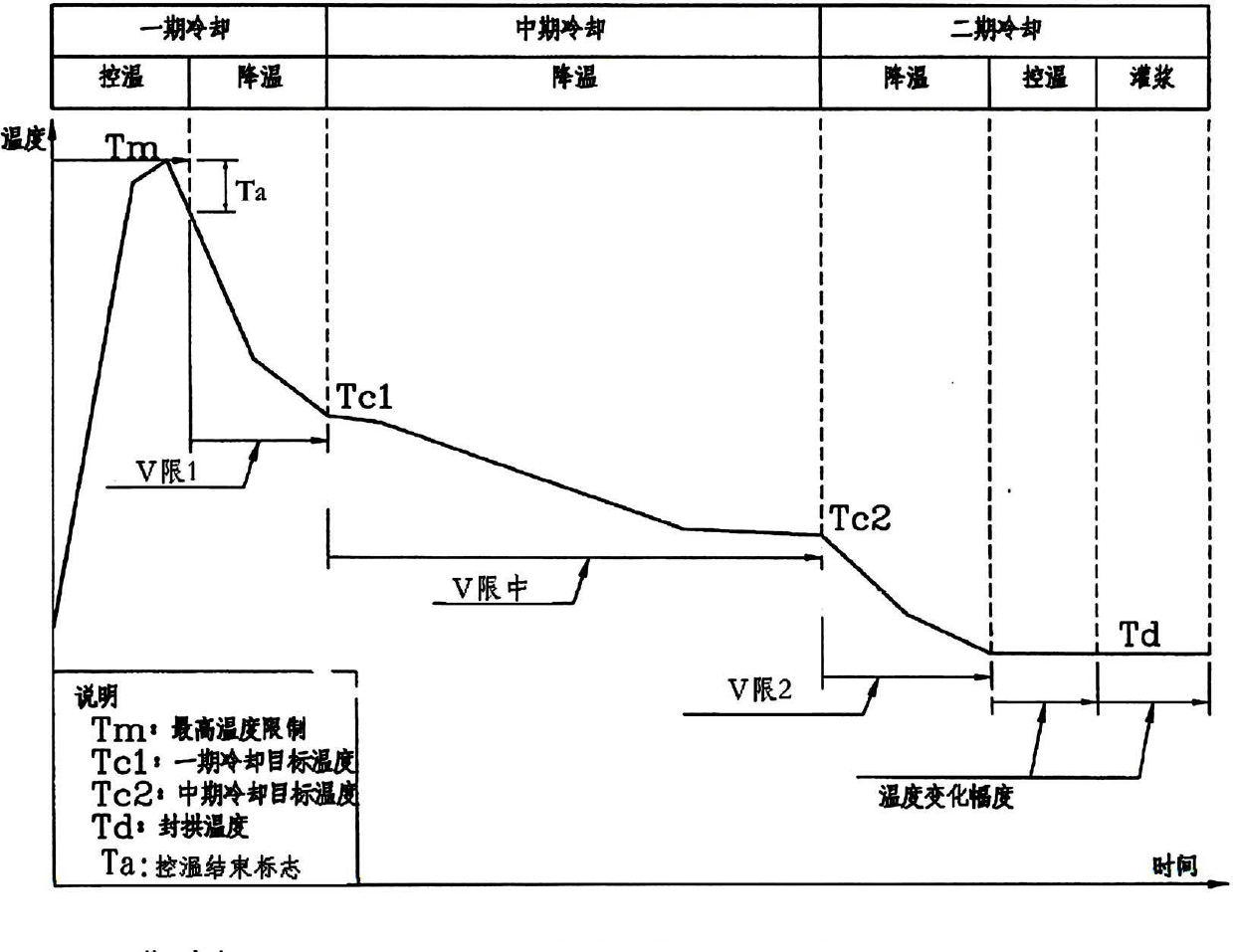

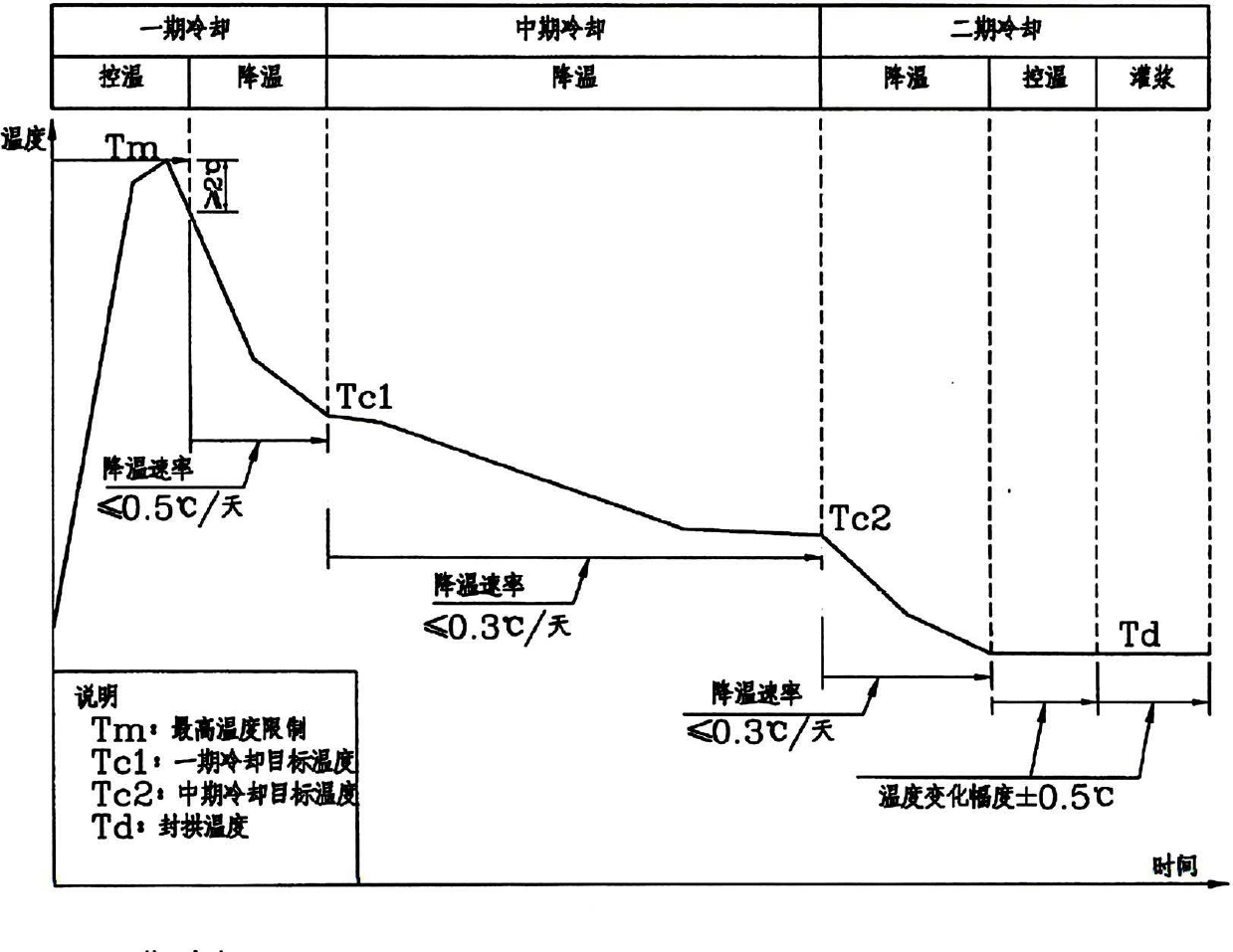

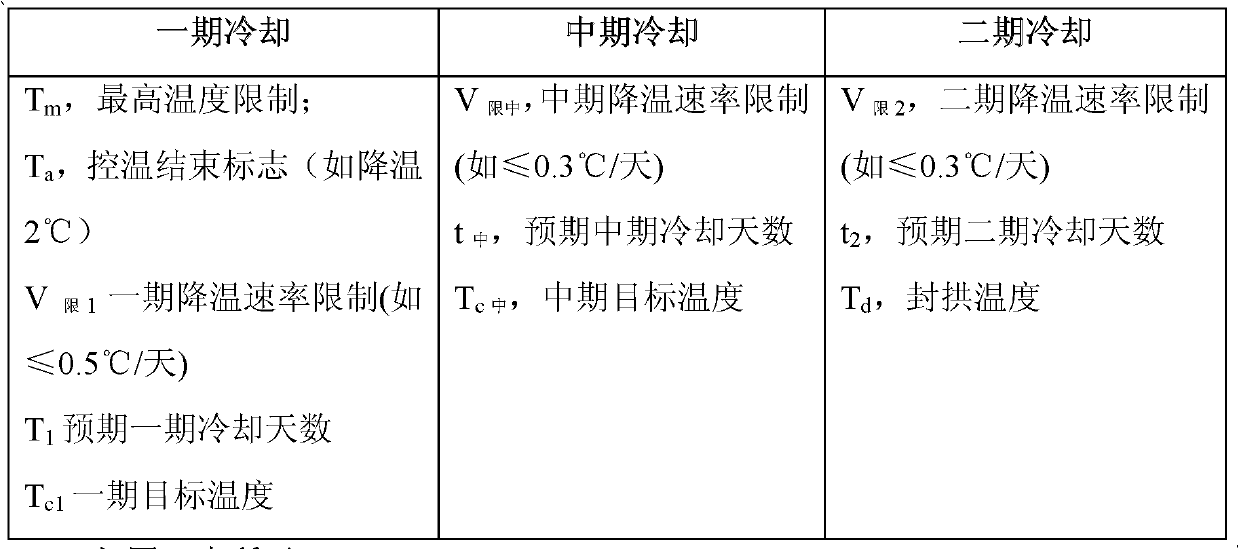

[0092] This control method is applied to a concrete dam of a hydropower station. The cooling and cooling are divided into three stages: primary cooling, intermediate cooling and secondary cooling. The primary cooling is divided into temperature control stage and cooling stage. The temperature control stage of primary cooling Directly carry out water cooling according to the maximum flow rate designed by the system, and use the control method of the present invention to control the flow rate from the cooling stage of the first stage to the middle stage and the second stage of cooling. The specific implementation is as follows:

[0093] A. Collect cooling water design parameters (take a certain part of the project as an example):

[0094] The power station measures the concrete temperature every 4 hours; the maximum flow of water Q max =7.5m 3 / h; lag coefficient ξ = 0.5; retroactive days t 0 = 3 days;

[0095] Control request parameters:

[0096]

[0097] B. Phase 1 coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com