Spraying scalding machine

A dipping and scalding technology, which is applied in slaughtering, poultry processing, food science, etc., can solve problems such as uneasy depilation, impact on product quality, and impact of waste water on the environment, so as to improve the scalding effect, reduce the waste of resources, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

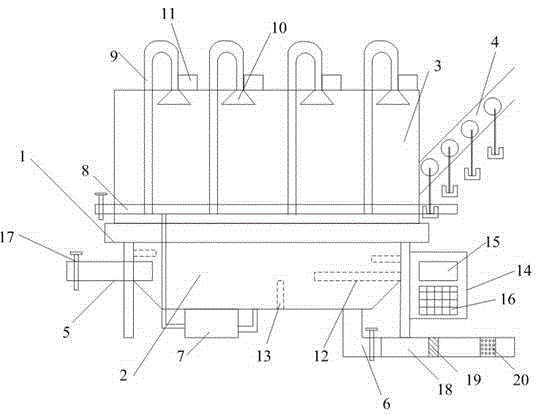

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a frame 1, a hot water tank 2 fixed at the bottom of the frame, a heat preservation tank cover 3 fixed on the top of the hot water tank, and a conveyor belt 4, and is characterized in that: the front end of the hot water tank 2 is provided with a water inlet pipe 5, The lower part of the rear end is provided with an outlet pipe 6; the bottom of the hot water tank 2 is provided with a motor 7; one end of the motor 7 is connected to the bottom of the hot water tank 2 through a pipeline, and the other end is connected to the water diversion pipe 8 arranged on the side of the heat preservation tank cover 3; The water diversion pipe 8 is connected with 8-12 spray pipes 9; the other end of the spray pipe 9 is connected to the top of the heat preservation tank cover 3, and is connected with the nozzle 10 in the heat preservation tank cover 3; the heat preservation tank cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com