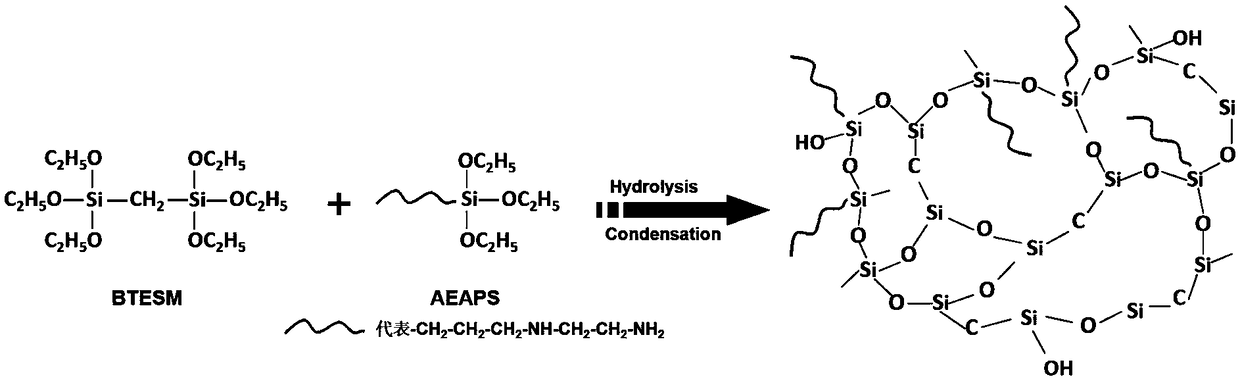

Preparation method of ultrathin silicon-based alcohol water separation film with thickness smaller than 50 nm

A separation membrane and silyl alcohol technology, which is applied in the field of separation membrane preparation, can solve the problems of inability to precisely control the preparation process, small flux, and large thickness of the separation layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of BTESM / AEAPS sol: Add 24.494gIPA into a 100mL beaker, then add 0.500gBTESM and 0.078gAEAPS and stir for 2min, add 3.808g of water dropwise while stirring, continue stirring for 2min, then add 1-2 drops of 68wt% concentrated nitric acid dropwise , transfer the beaker to a constant temperature water bath at 50°C, continue stirring for 2 hours to obtain silica sol and dilute its concentration to 0.2wt% with IPA;

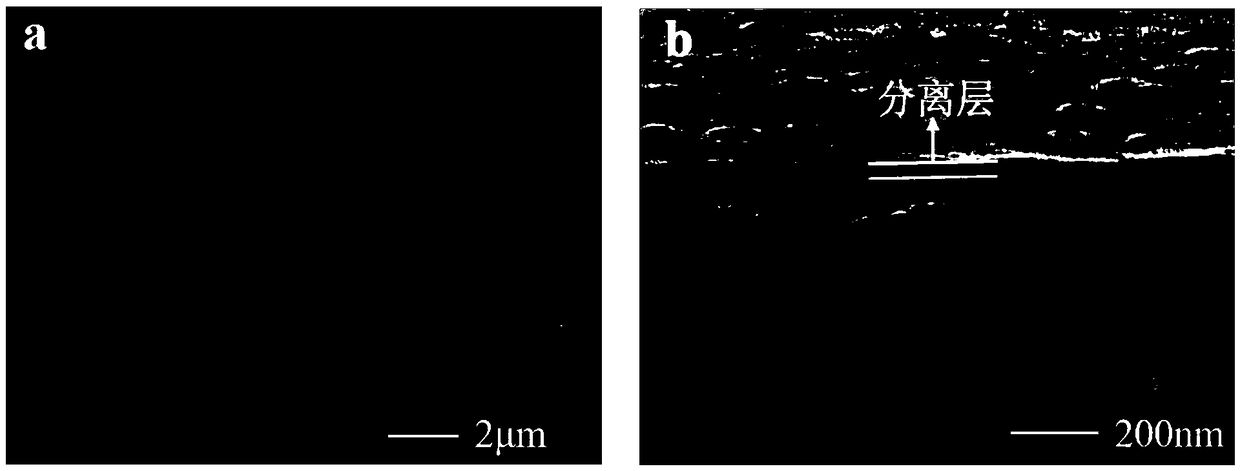

[0019] (2) Pour the sol prepared in step (1) into an ultrasonic nebulizer. The sol is dispersed into droplets with a diameter of 1-2 μm by 2.4 MHz ultrasonic waves, and then enters the deposition chamber with the argon gas at a flow rate of 300 mL / min. Drops are sprayed vertically upwards from the spray port and then deposited on the PA / PS composite film support. The support is placed horizontally directly above the spray port and fixed on a flat glass plate. The temperature of the support is maintained at 80°C by a heating device. , the next de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com