Degradable composite mulching film forming process

A molding process and mulching technology, which is applied in metal processing, application, household appliances, etc., can solve the problems of affecting the winding efficiency of the mulching film, loosening, uneven heating and cooling of the mulching film surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

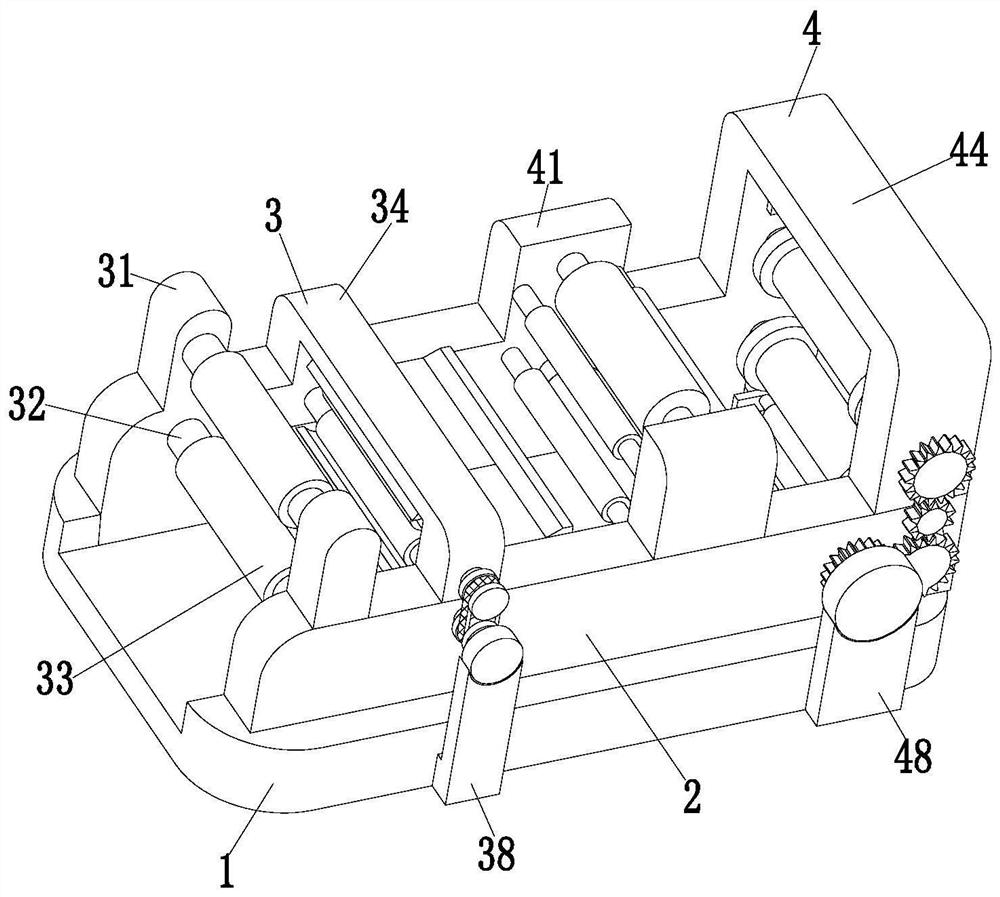

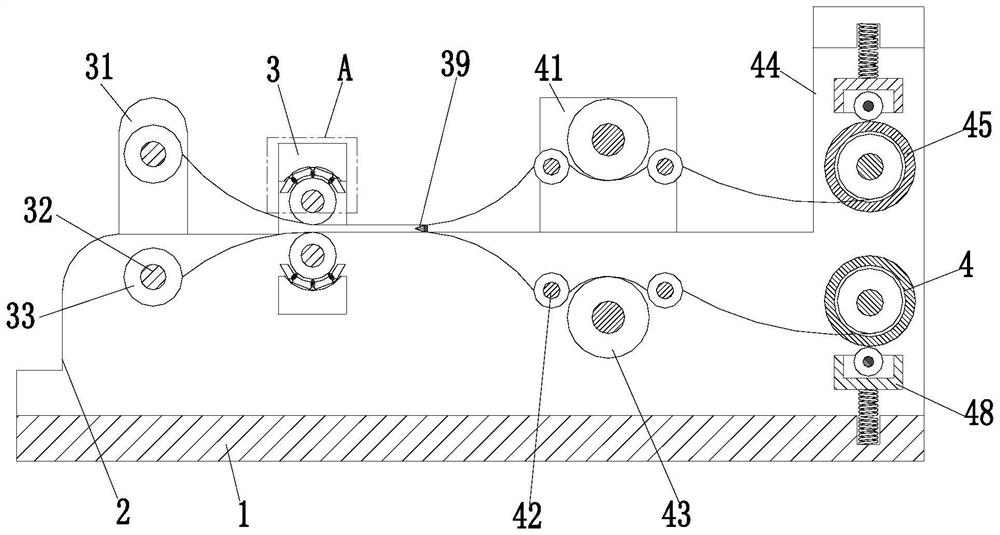

[0031] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and To facilitate its practice, but not as a limitation of the invention.

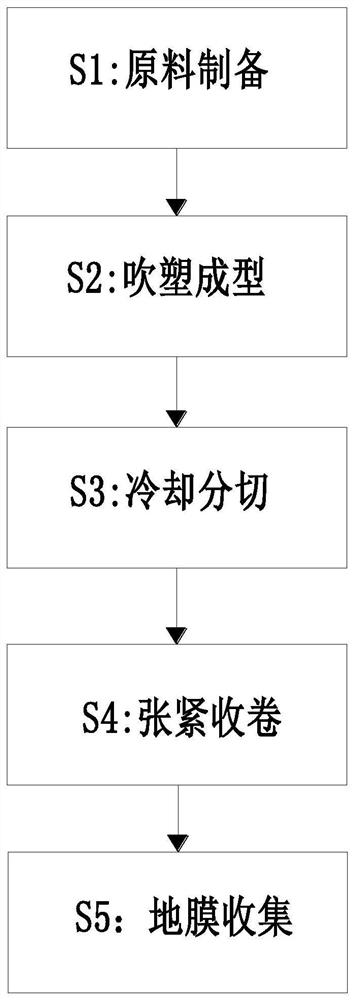

[0032] See attached Figure 1-7 As shown, a degradable composite mulch forming process, the degradable composite mulch forming process specifically includes the following steps:

[0033] S1. Raw material preparation: Weigh degradable raw materials of corresponding weight, mix them uniformly, heat, melt and granulate, and then dry them;

[0034] S2. Blow molding: Add the dried molten particles into the extruder, and blow molding through the mold tube to obtain a degradable composite film;

[0035] S3. Cooling and cutting: the blow-molded high-temperature composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com