Path division conveying device for bar code packages

A transmission device, barcode technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of related errors in the next sequence process, lack of lane separation and verification design, inability to scan and collect data at one time, etc., to achieve reliable verification, The effect of quick and accurate lane separation and compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

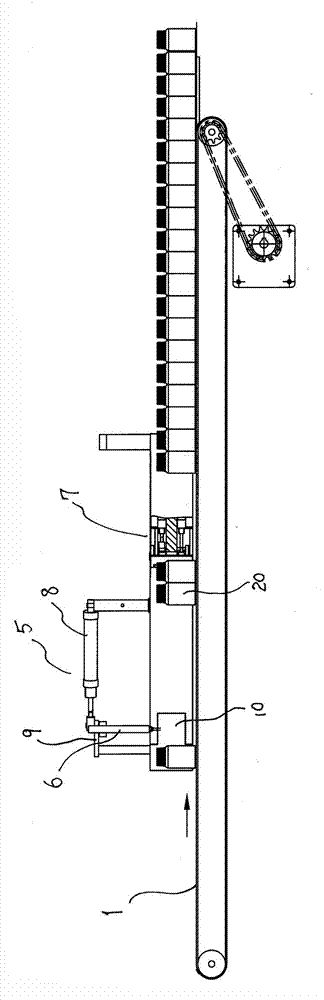

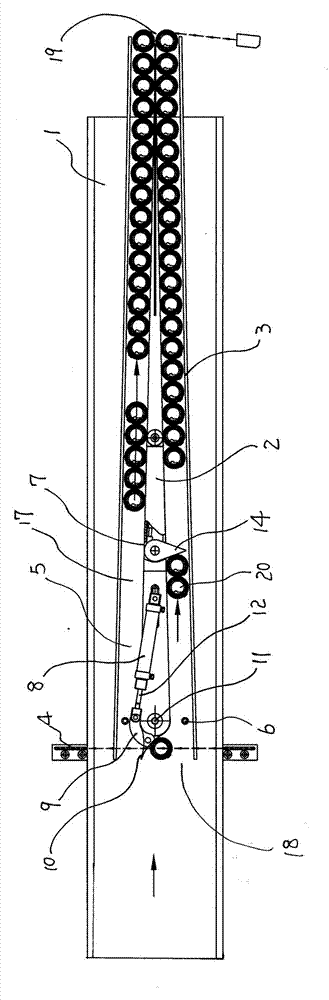

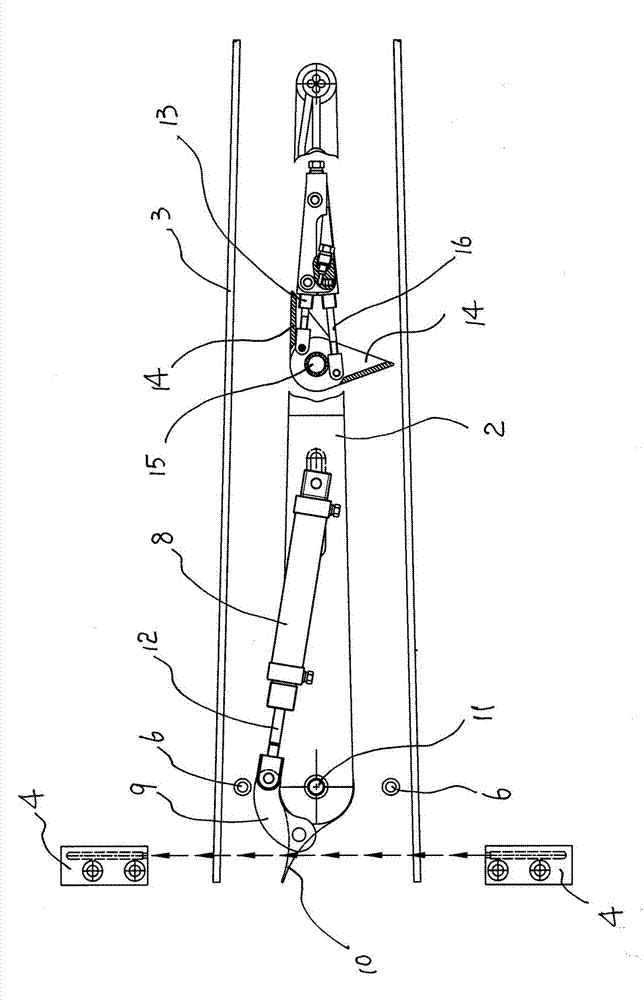

[0012] As shown in the figure, the present invention includes a conveyor belt 1 and a lane separation belt 2 and a guide plate 3 above the conveyor belt 1. The lane divider belt 2 and the guide plate 3 form two flow channels 17 on the conveyor belt 1, two The flow channel 17 as a whole has a width difference between its input end 18 and output end 19 , correspondingly, the lane divider 2 has a wider starting point and a narrower end point, so that the two flow channels 17 have the same width. The counting photoelectric switch 4 is set on both sides of the input end of the conveyor belt 1, the lane separation mechanism 5 controlled by the counting photoelectric switch 4 is set on the lane separation isolation belt 2, and the verification photoelectric switch 6 is set above each flow channel 17. An inspection and closing gate mechanism 7 controlled by an inspection photoelectric switch 6 is arranged in the road isolation zone 2 . The lane-dividing mechanism 5 includes a lane-div...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap