Extruding type reinforcing steel bar automatic feeding and straightening mechanism

An automatic feeding and extruding technology, which is applied in the field of steel bar processing, can solve the problems of heavy operating cost, inability to effectively straighten universally twisted steel bars, and large frictional damage to the steel bar surface by straightening blocks, so as to achieve fast straightening process effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The extrusion-type steel bar automatic feeding and straightening mechanism of the present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

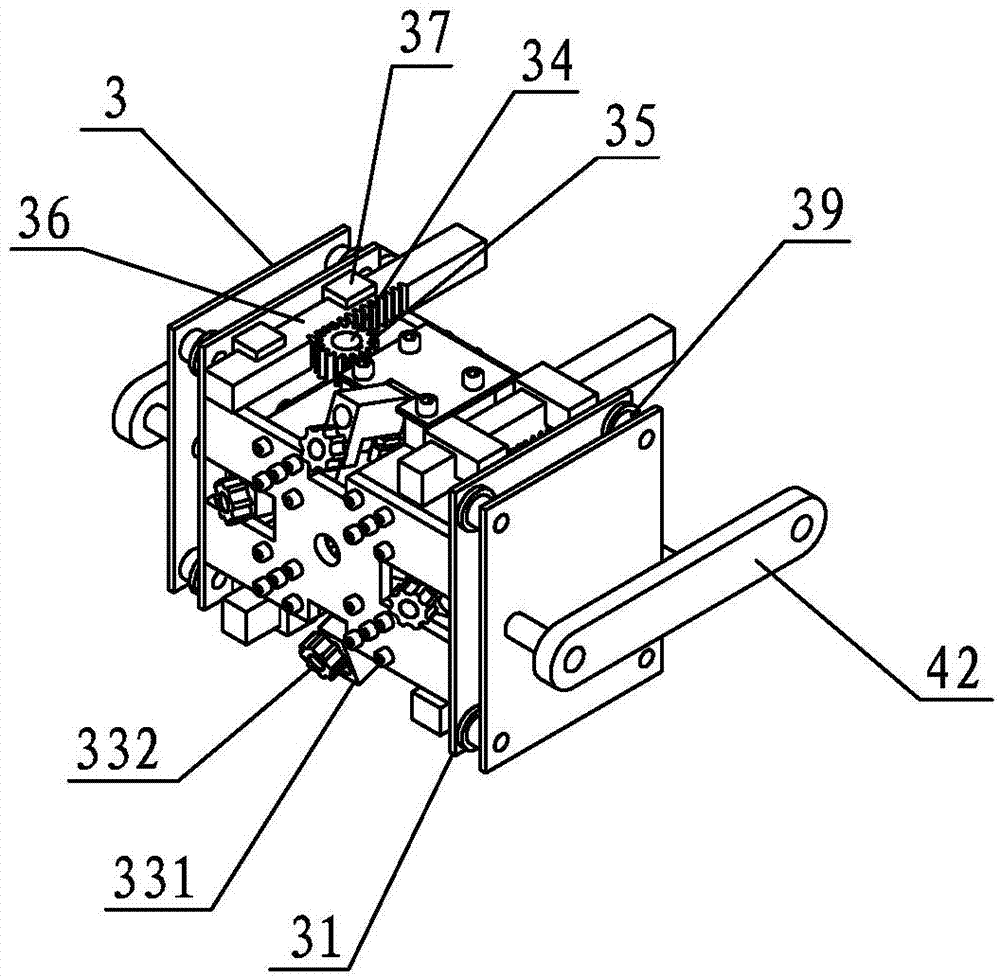

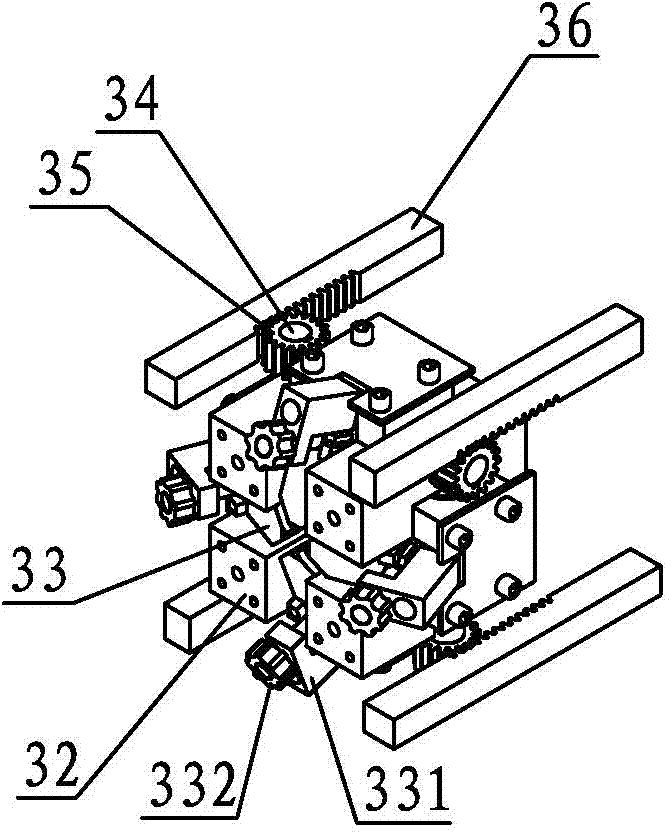

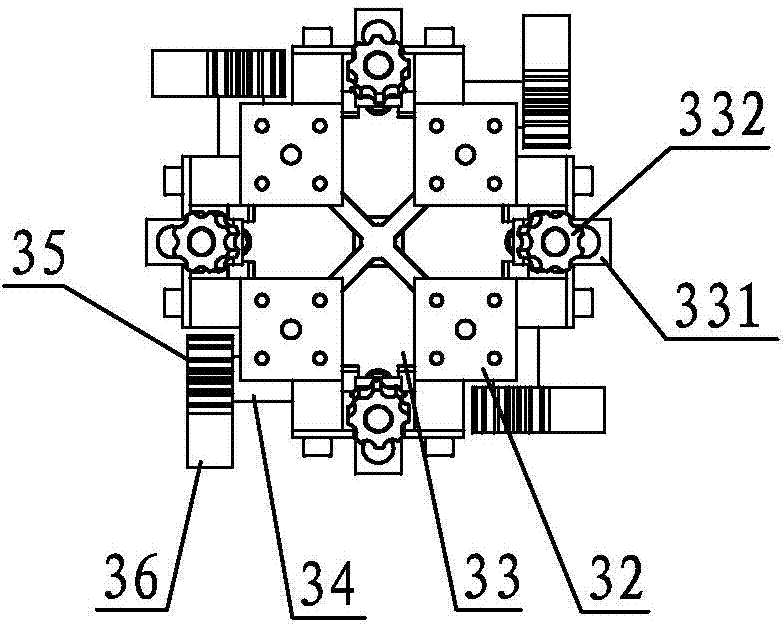

[0028] refer to Figure 1 to Figure 3 , the preferred embodiment provided by the present invention, an extrusion-type automatic feeding and straightening mechanism for steel bars, including a bracket 31, a connecting rod 42 for connecting a driving device is fixedly arranged on the bracket 31, and the driving device drives the straightening mechanism through the connecting rod 42 3 back and forth reciprocating motion. A sliding seat 32 is fixed inside the bracket 31, and palm pressing blocks 33 are slidably arranged between the sliding seats 32. There are at least two palm pressing blocks 33, which are evenly distributed around the steel bar 5. The straightening mechanism 3 of the present embodiment is preferably Four palm pressing blocks 33 are provided, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com