Automatic rivet selecting and sending system

An automatic, nail-feeding technology, applied in the field of automatic nail selection and nail feeding systems, can solve the problems of the limited number of rivets, the inability to separate the nails from the nails and the storage of the nails, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples.

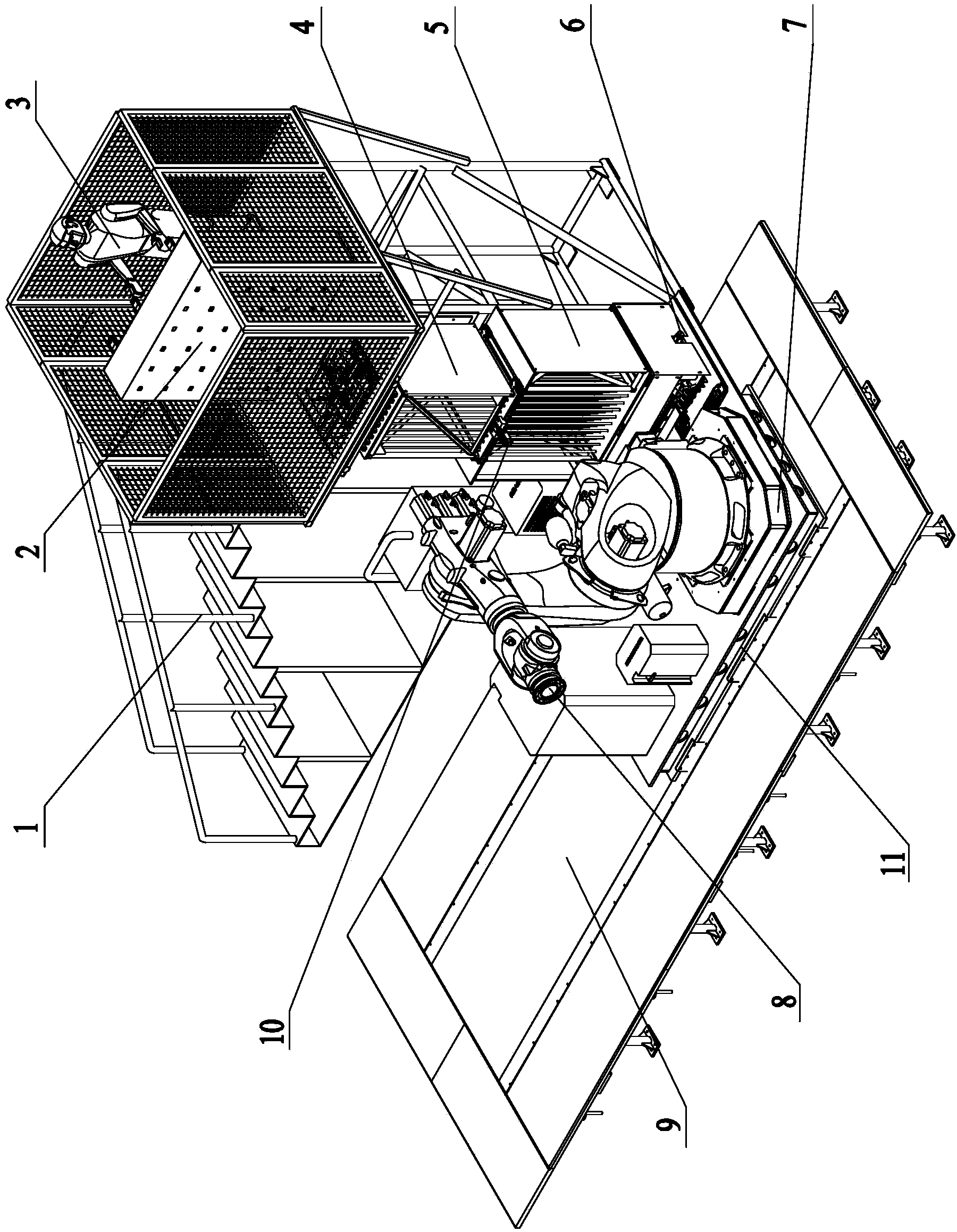

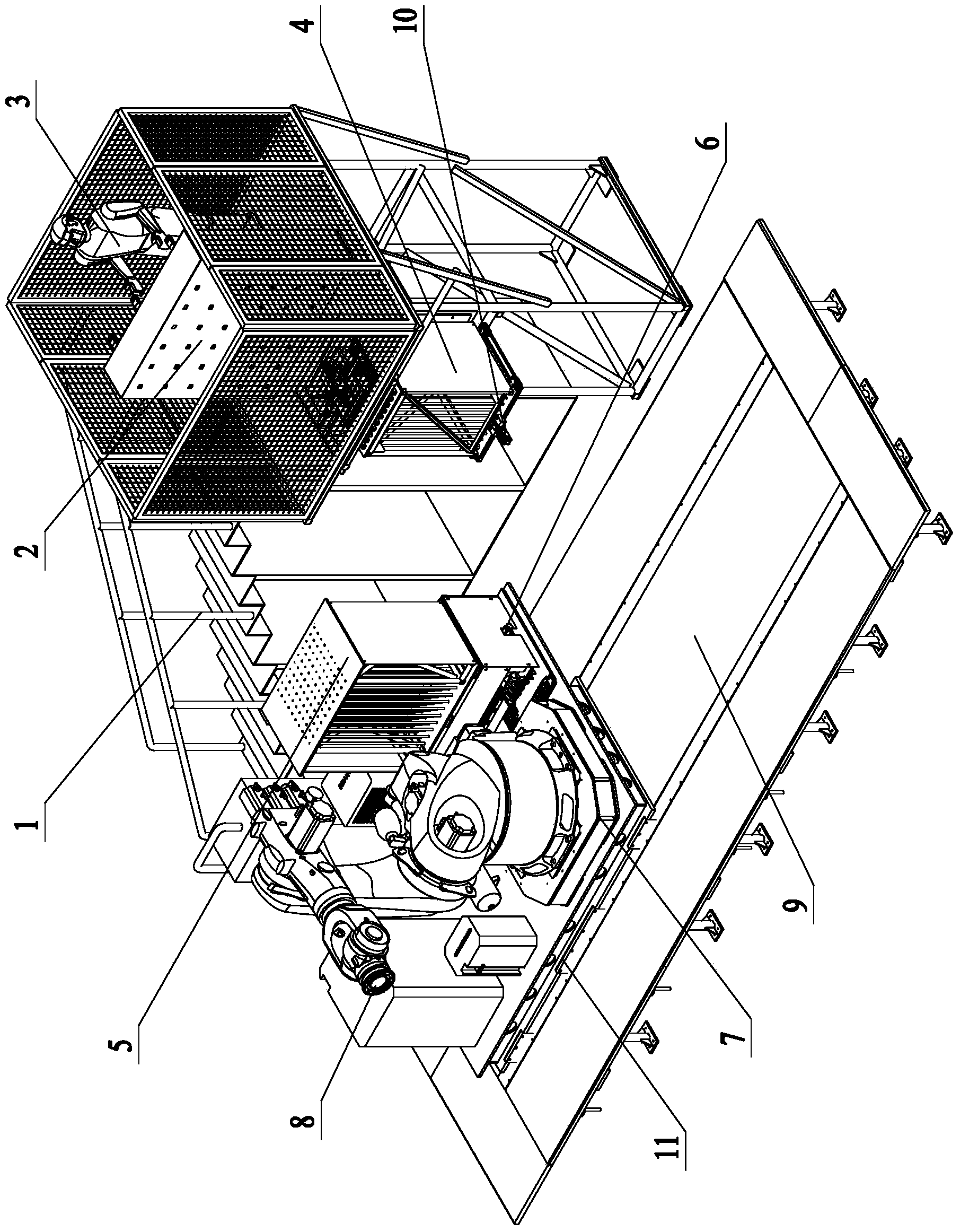

[0013] The automatic nail selection and delivery system includes a fixed material station bracket 1, a vibrating plate loading rack 2, a fixed material station silo 4, a mobile material station silo 5, an automatic nail selection module 6, an automatic riveting robot load module 7, Automatic drilling and riveting end effector 8, automatic riveting robot unit load-bearing ground rail 9, discharging cylinder 10 and automatic riveting robot unit load-bearing slide plate 11, vibrating plate loading rack 2 and fixed material station are fixedly installed on the fixed material station bracket 1 The silo 4 and the fixed material station silo 4 are installed under the vibrating plate loading rack 2. The vibrating plate outlet of the vibrating plate loading rack 2 and the nail storage pipe inlet of the fixed material station silo 4 are connected through the aisle. One side of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com