System and method for intelligent switching of vehicle system for blast furnace charging system

An intelligent switching and blast furnace technology, applied in the field of control, can solve the problems of not being able to adapt to dynamic changes, not being able to optimize the amount of material loaded on the feeder, and a single scheduling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

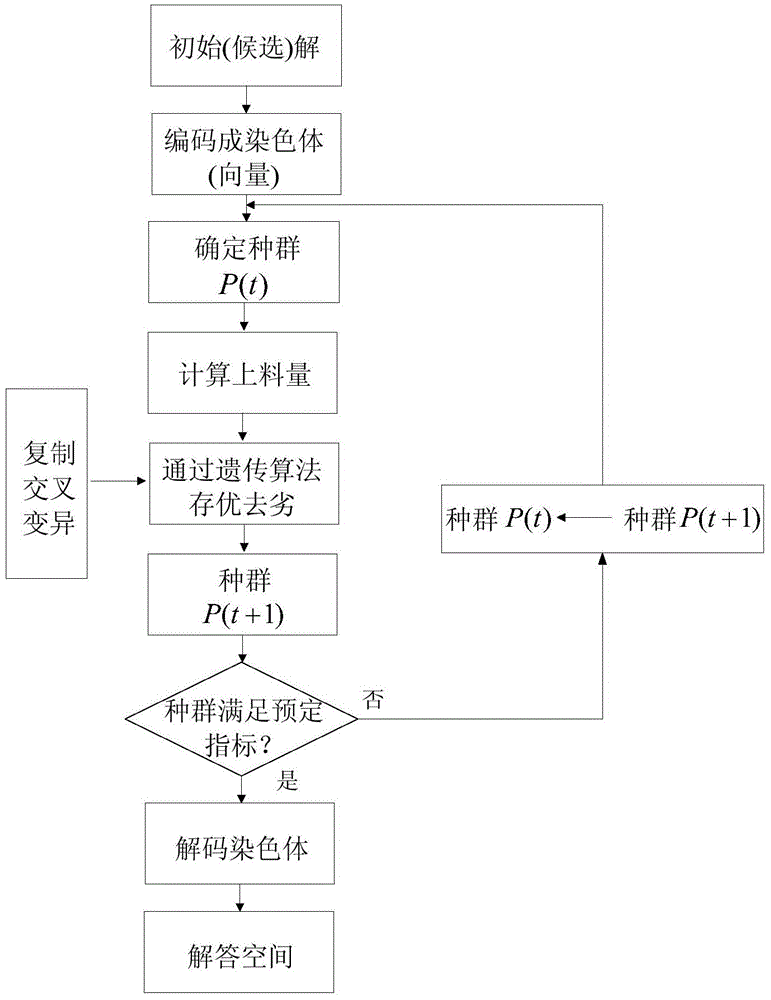

[0059] An embodiment of the present invention provides a car-made intelligent switching system for a blast furnace feeding system, including an encoding module, an initial population generation module, a selection module, a crossover module, a variation module, and an optimization module;

[0060] The coding module assigns the coke amount a to the right concentrating hopper of the blast furnace 1 , The amount of coke distribution in the left concentrating hopper of the blast furnace a 2 , Blast furnace right concentration bucket ore distribution b 1 , Blast furnace left concentration bucket ore distribution b 2 , Car system x as the decision variables are respectively encoded with real numbers; the initial population generation module substitutes the randomly generated decision variables into the objective function Generate initial population individuals;

[0061] The selection module selects the parent individuals from the initial population individuals according to the f...

Embodiment 2

[0082] This embodiment provides a method for intelligent switching of the vehicle system of the blast furnace charging system, which includes the following steps:

[0083] Coding step: adjust the coke amount a in the right concentrating hopper of the blast furnace 1 , The amount of coke distribution in the left concentrating hopper of the blast furnace a 2 , Blast furnace right concentration bucket ore distribution b 1 , Blast furnace left concentration bucket ore distribution b 2 , vehicle system x are used as decision variables to carry out real number encoding respectively;

[0084] Initial population generation step: Substituting randomly generated decision variables into the objective function Generate initial population individuals;

[0085] Selection step: select the parent individual population from the initial population individuals according to the fitness ratio method, and the calculation function of the fitness is

[0086] Crossover step: Randomly select tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com