Positioning plate with three-pin positioning structure

A technology of positioning structure and positioning plate, applied in the direction of positioning device, clamping, support, etc., to achieve the effect of ensuring positioning accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

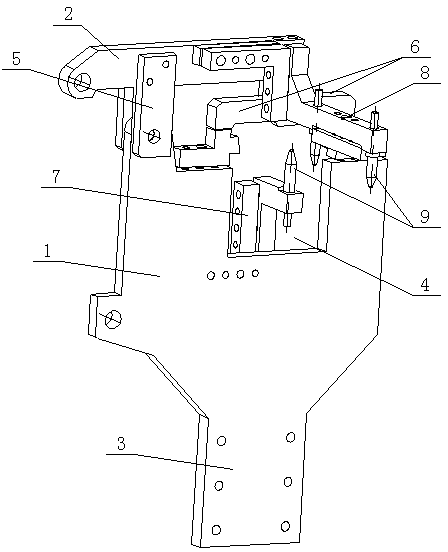

[0010] Such as figure 1 As shown, the positioning plate of the three-needle positioning structure according to the embodiment of the present invention includes an overturning beam 2 and a positioning plate 1, the bottom of the positioning plate 1 is a connecting plate 3 with a plurality of bolt holes, and the top of the positioning plate 1 A notch 4 is provided, the right side of the overturning beam 2 is hinged with the positioning plate 1 through the support plate 5, the overturning beam 2 is fixedly connected with the support plate 5, and the left side of the overturning beam 2 is connected with a The center of the door-shaped seat 6 is connected, and the door-shaped seat 6 is docked with the notch 4 of the positioning plate; the inside of the notch is provided with a first thimble fastener 7, and the top of the first thimble fastener 7 is installed There is an upwardly arranged thimble 9; a second thimble fixture 8 is provided on the outside of the flip beam 2, and two dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com