Optimized coupled optical fiber sensor-based flat plate ultrasound source positioning method and system

A fiber optic sensor and positioning system technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, instruments, material analysis using acoustic wave emission technology, etc., can solve the problems of ultrasonic signal peak deviation, positioning deviation, large volume, etc., to achieve accuracy and effectiveness Linear positioning, improved positioning accuracy, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

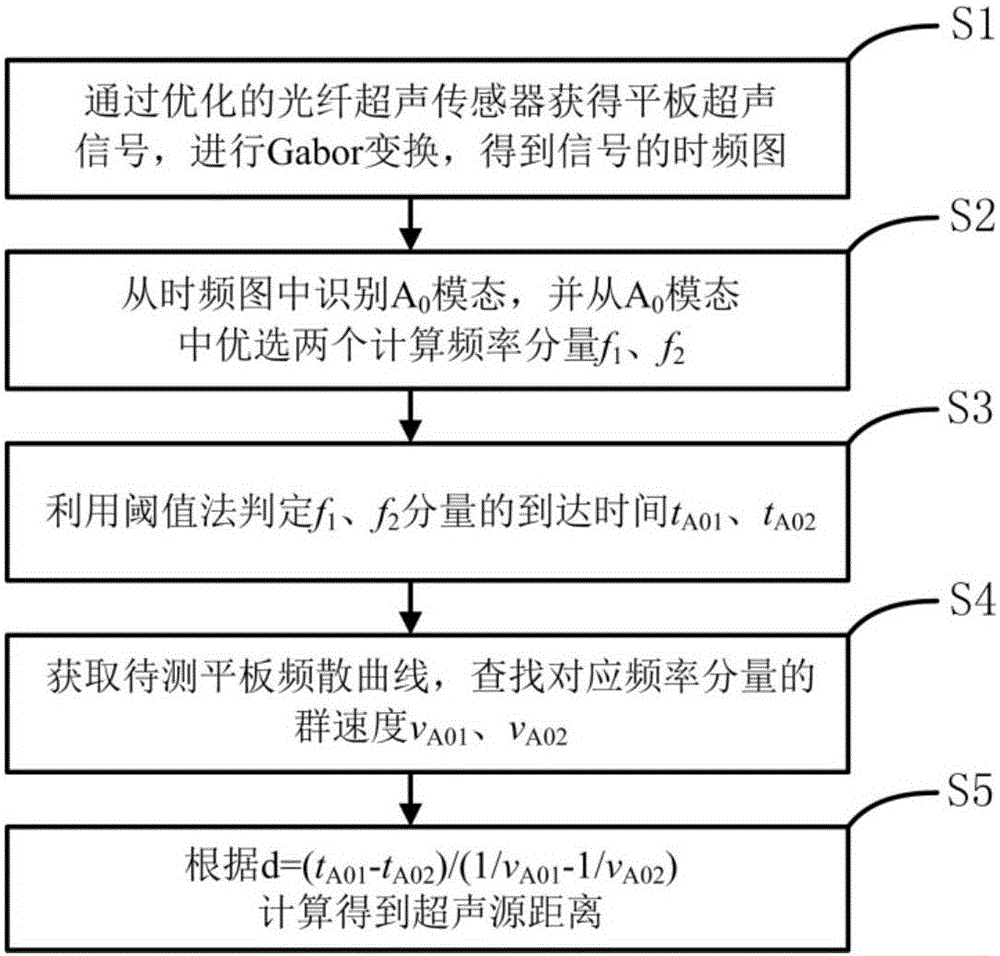

[0042] The present invention is based on an optimized coupled optical fiber sensor flat panel ultrasonic source positioning method, wherein the ultrasonic source is 20kHz-250kHz; as figure 1 As shown, it specifically includes the following steps: (1) Obtain the flat-panel ultrasonic signal through the optimized coupled optical fiber sensor 2, perform Gabor transformation, and obtain the time-frequency diagram of the signal; (2) identify A from the time-frequency diagram 0 modal, and from a 0 Optimal two calculated frequency components f in the mode 1 , f 2 ; (3) Use the threshold method to determine f 1 , f 2 The arrival time of the component t A01 , t A02 ; (4) Obtain the dispersion curve of the plate to be measured, and find the group velocity v of the corresponding frequency componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com