Underground coal mine deep-hole directional blasting cartridge

A technology of directional blasting and deep hole, which is applied in the direction of blasting tubes, blasting, weapon accessories, etc. It can solve the problem that the tube is easily blocked by scattered coal or rock blocks, and achieve the effect of reducing the probability of blast rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

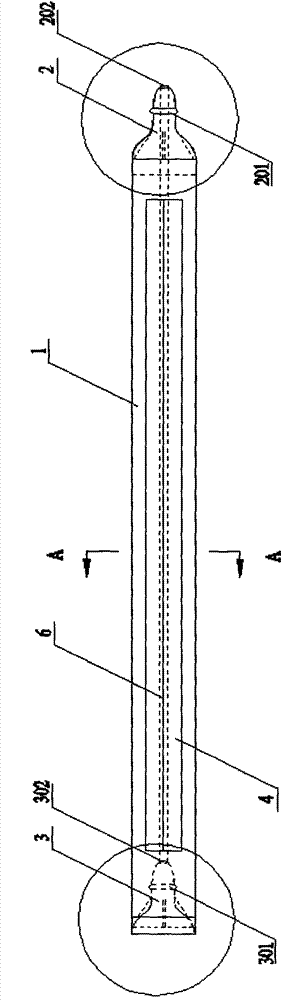

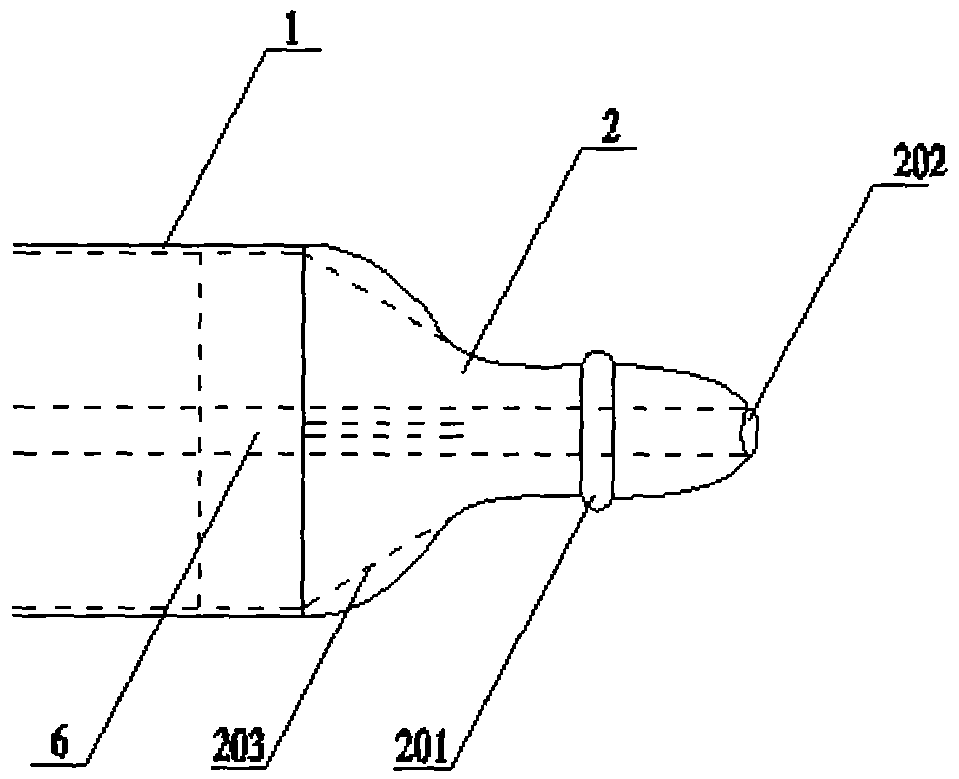

[0041] like figure 1 and 2 Shown is the preferred embodiment of the deep hole directional blasting quilt in the coal mine of the present invention.

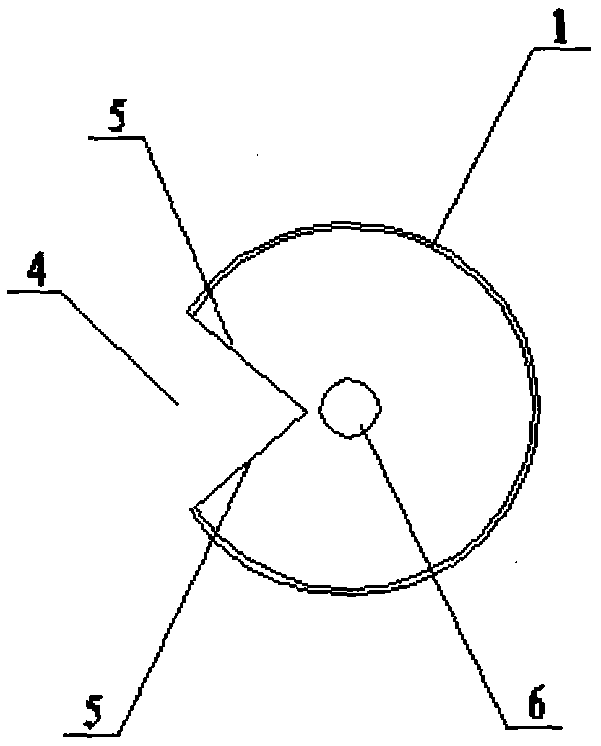

[0042] The underground deep hole directional blasting quilt in the coal mine includes a quilt main body 1, an upper connector 2 and a lower connector 3, and a cutout 4 is opened on one side of the quilt main body 1, and the cutout 4 is covered with a layer of metal sheet 5 , the metal sheet 5 is recessed inwardly to form a "V"-shaped groove, the bottom of the "V"-shaped groove radially points to the center of the circle along the circumference of the cylinder body 1, and is located at 1 / 2 radius.

[0043] In this embodiment, the bottom angle of the "V" groove is 60°-90°, preferably 75°....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com