A mattress durability comprehensive testing machine

A comprehensive test and durability technology, applied in the testing, measuring devices, instruments and other directions of machines/structural components, can solve the problems of structural redundancy, low measurement accuracy, and imperfect functions, and achieve cost savings, reliability and reliability. Stability, saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

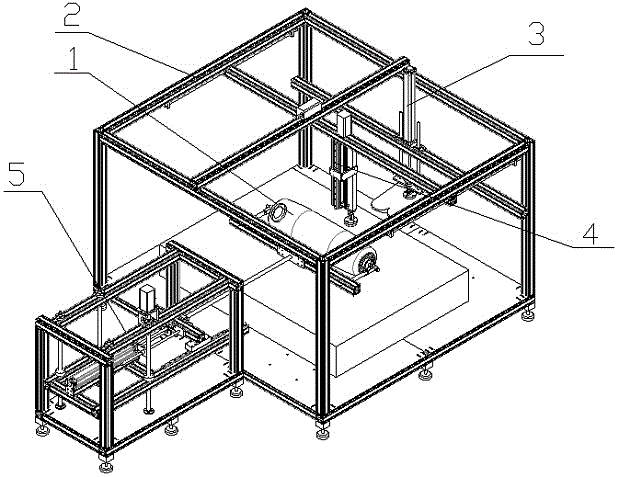

[0024] see figure 1 , a mattress durability comprehensive testing machine is characterized in that it includes a roller part 1, a frame part 2, an edge loading part 3, a center loading part 4 and a cylinder part 5; the roller part 1 is placed on the frame part 2 On the inspection platform in the middle, the cylinder part 5 is installed in the side frame part 2, the roller part 1 is connected to the cylinder part 5 through the push plate 41 on the cylinder part 5, the side loading part 3 and the center loading part Part 4 is mounted on frame part 2 .

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, the difference is:

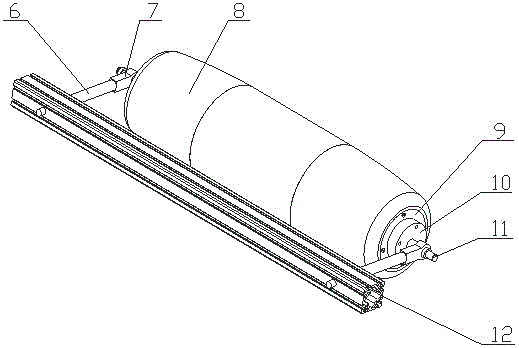

[0027] The structure of the drum component 1 includes a drum connecting rod 6, a joint bearing 7, a drum 8, a drum end cover 9, a flange 10, a mandrel 11 and a connecting aluminum profile 12; one end of the drum connecting rod 6 is fixed on the connecting aluminum On the profile 12, the other end is connected with the joint bearing 7; the two ends of the drum 8 are fixed with the drum end cover 9, the mandrel 11 passes through the drum 8 and the drum end cover 9, and the two ends of the mandrel 11 are respectively connected to the flange 10, and are connected with joint bearing 7 respectively.

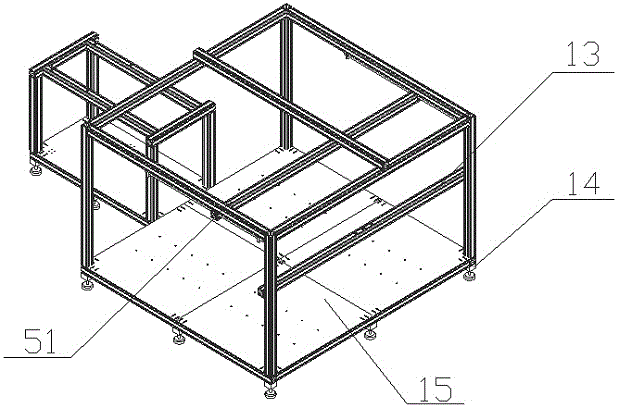

[0028] The structure of the frame part 2 includes an outer frame, a support profile 13, a support foot 14 and a base plate 15; the support profile 13 is placed on the outer frame, and several steel plates are put together to form a base plate 15 to bear the test mattress.

[0029] The structure of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com