A Double Electromagnetic Mechanism Control Mechanism for Compression Switch

A technology of pressing switches and control mechanisms, which is applied in the mechanical field, can solve the problems of high heat generation and low reliability, meet the needs of ensuring the automation of mechanical actions, and overcome the effects of large volume and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

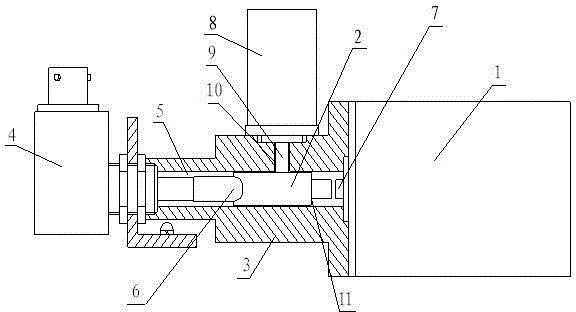

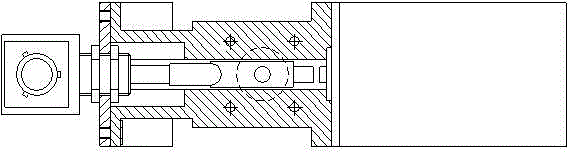

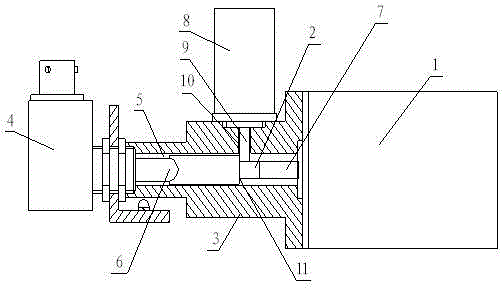

[0016] see Figure 1-Figure 4 , the dual electromagnetic mechanism control mechanism of the compression switch of the present invention includes a compression electromagnetic component 1, a locking core 2, and an installation connector 3. The installation connector 3 includes a through hole 5 that is consistent with the movement direction of the compression switch 4, and the lock The tight core 2 is arranged in the through hole 5, one end of the lock core 2 is in contact with the switch push rod 6 of the pressure switch 4, and the pressure push rod 7 of the pressure electromagnetic component 1 is located at the other end of the lock core 2 The compression push rod 7 retracts naturally without external force, and the switch push rod 6 naturally extends without external force; it is characterized in that the control mechanism also includes an unlocking electromagnetic component 8, and the unlocking push rod of the unlocking electromagnetic component 8 The rod 9 protrudes natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com