Reciprocating compressor provided with leaf spring

一种压缩机、往复式的技术,应用在压缩机板簧领域,能够解决未提供线性压缩机等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

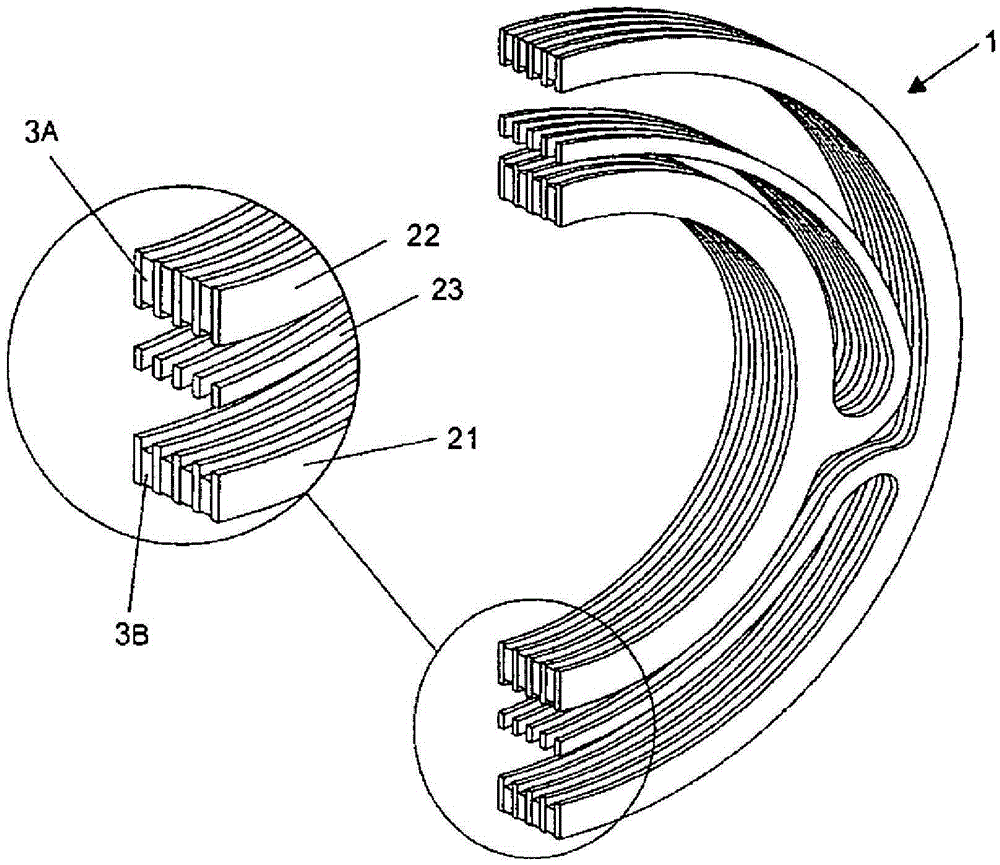

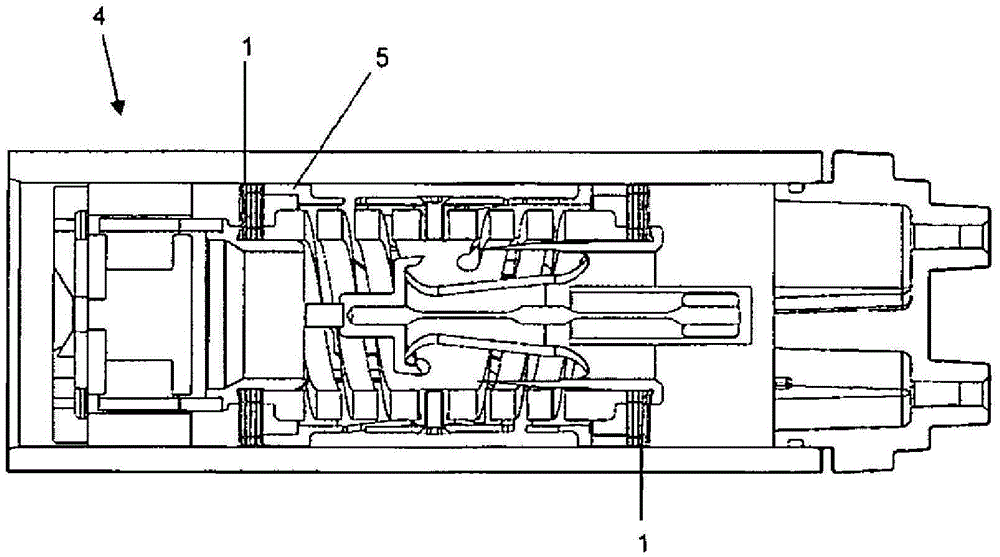

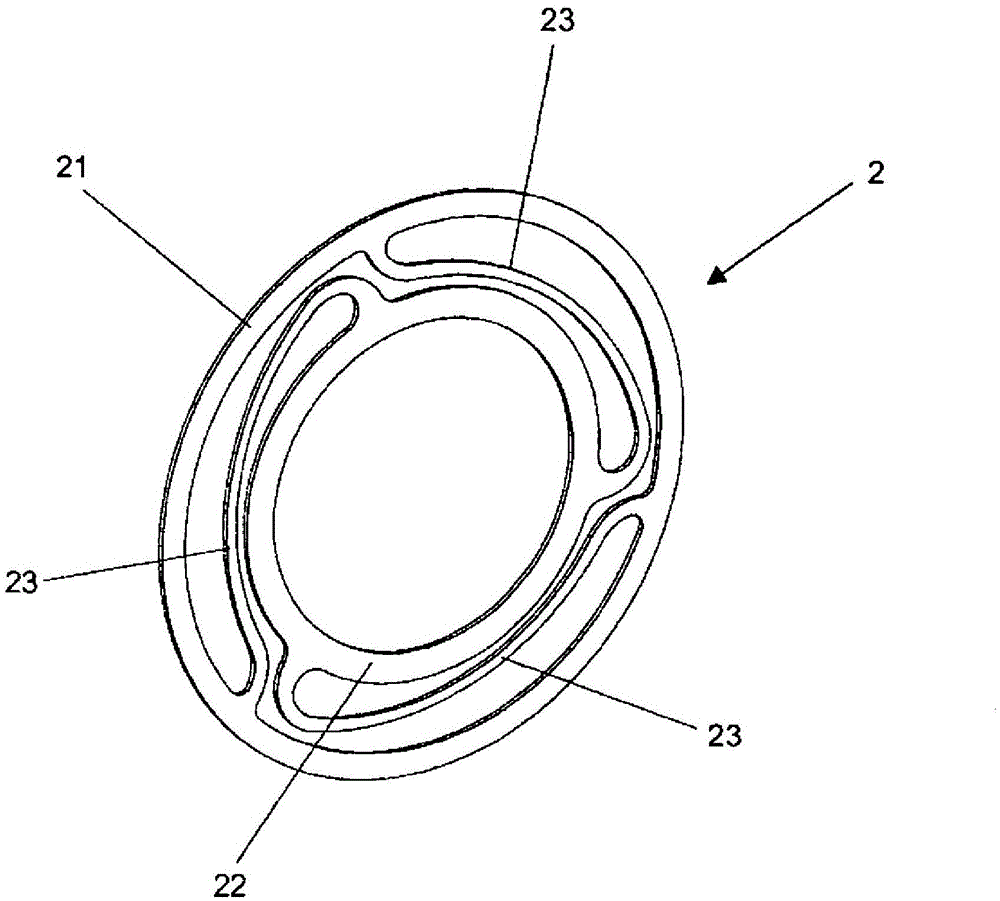

[0032] According to the concept and purpose of the present invention, the present invention discloses a leaf spring 1, which can be incorporated into a compressor based on a resonant oscillation mechanism. The leaf spring mainly includes leaf springs arranged adjacently and spaced apart from each other by means of spacers, Each pair of leaf springs is provided with a spacer located between at least two springs integrated into the pair of leaf springs.

[0033] Also according to the present invention, each leaf spring defines two supporting areas and an axial elastic area, and only the supporting areas of the leaf springs are "connected to each other". Therefore, the axial elastic area of the leaf spring (when the axial elastic areas of the leaf spring are related to each other, the leaf springs conform to themselves) and the axial elastic areas of other adjacent leaf springs do not have any type of physical contact.

[0034] This concept prevents the leaf spring from being block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com