a safety window

A technology for safety protection windows and sashes, which is applied in the direction of building fastening devices, wing leaf fastening devices, buildings, etc., which can solve the problems of aggravation, twisting, and easy deformation of the pull rod 5, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

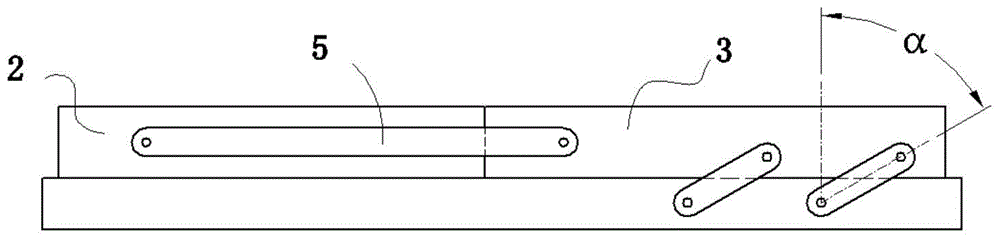

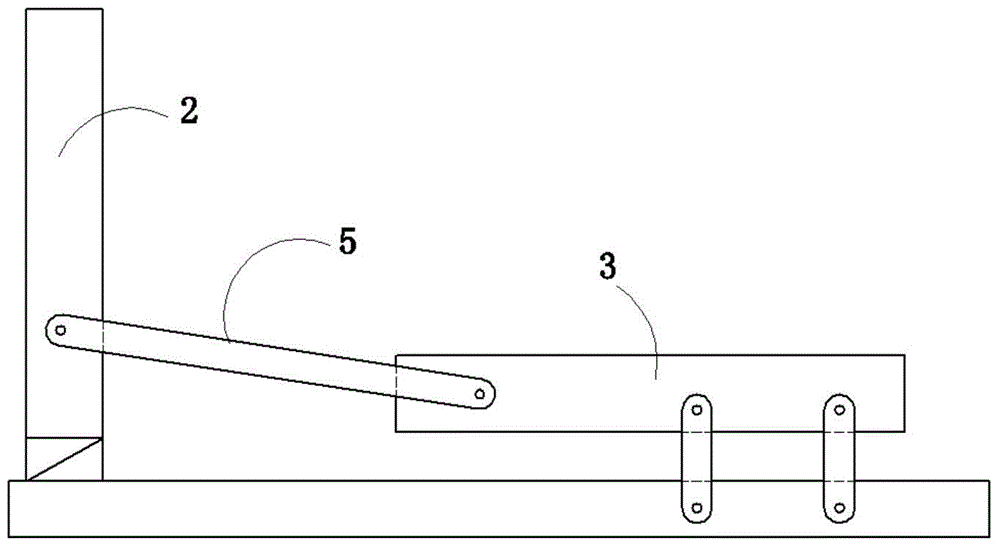

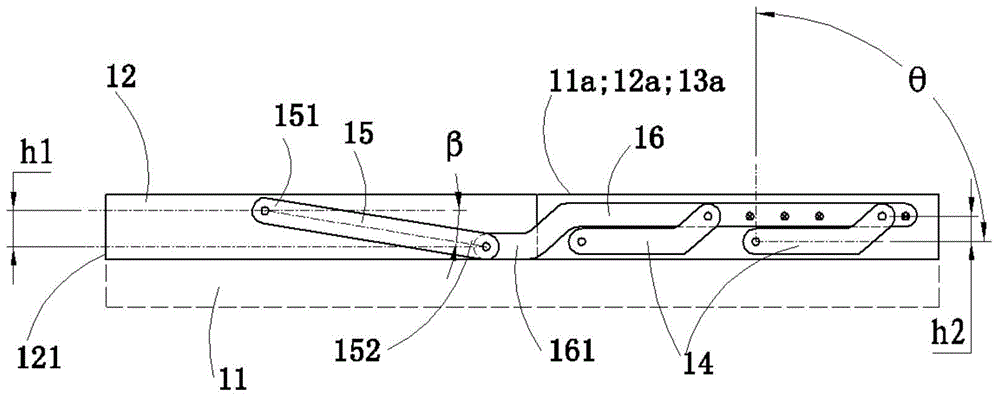

[0027] Such as Figures 3 to 6 A safety protection window shown includes a window frame 11, a first sash 12 and a second sash 13 assembled in the window frame 11; the window frame 11 has a front end face 11a, and the first sash 12 has Front end face 12a, the second sash 13 has a front end face 13a. A side 121 of the first sash 12 away from the second sash 13 is hinged to the window frame 11 .

[0028] At least one connecting rod 14 is hinged on the upper and lower sides of the second sash 13, and the other end of the connecting rod 14 is hinged on the upper or lower side of the corresponding window frame 11; in this embodiment, the first The upper and lower sides of the second sash 13 are hinged with two parallel connecting rods 14 to increase the degree of fixation of the second sash 13, thereby making the structure more reliable.

[0029] The first sash 12 and the second sash 13 are connected with a push rod 15 that can pull the second sash 13 to move laterally when the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com