Underframe of a railway concave flat car

A flat car, railway technology, applied in the direction of railway car body parts, chassis, transportation and packaging, etc., can solve the problems of low vertical rigidity of the chassis, fixed wheeled goods, can not use nailed triangle gear, etc., to increase the height range, increased stiffness, and the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

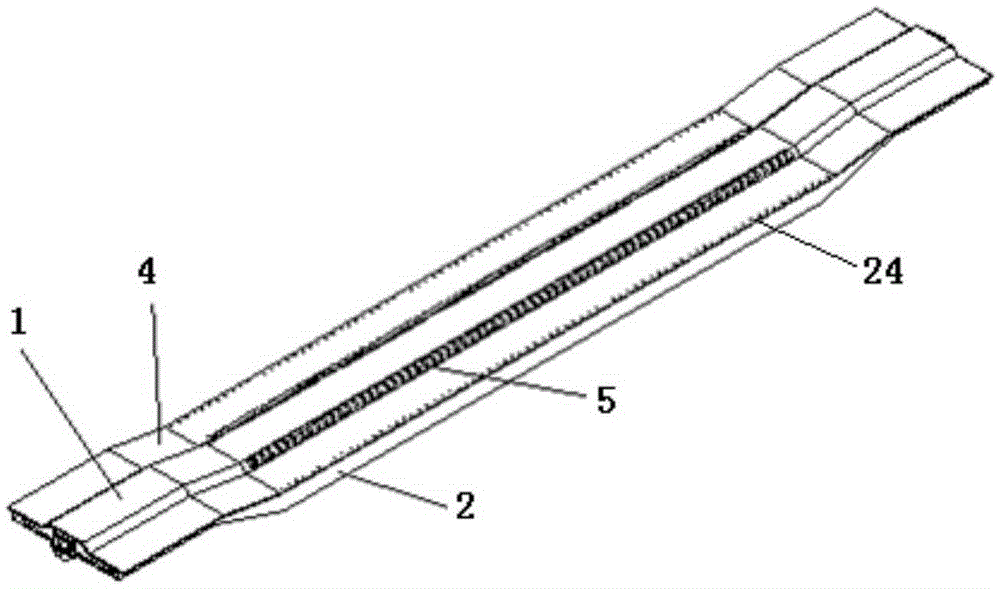

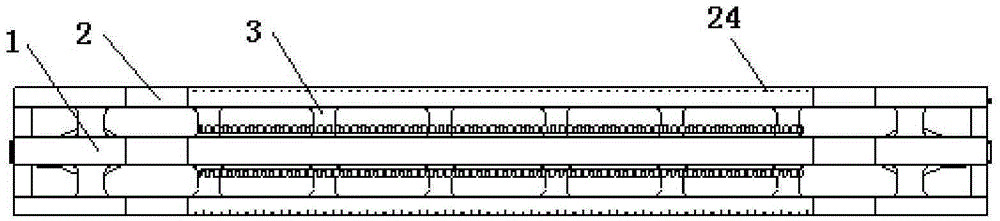

[0018] like figure 1 , figure 2 As shown, the present invention includes a middle beam 1, side beams 2, several transverse beams 3, a floor 4, two draw-in grooves 5 and a lower cover plate (not shown in the figure), wherein the middle beam 1 and the side beams 2 Both are concave structures in the middle, with slope transitions in the middle and both ends. The side beam 2 is fastened on both sides of the center beam 1 through several transverse beams 3 in parallel, the floor 4 is fastened to cover the center beam 1, the side beam 2 and the transverse beam 3, and the card slot 5 is fastened to the center beam 1 On the floor 4 on both sides of the concave bottom in the middle, the lower cover plate is fastened and connected under the concave bottom in the middle of the middle beam 1 and the side beam 2 .

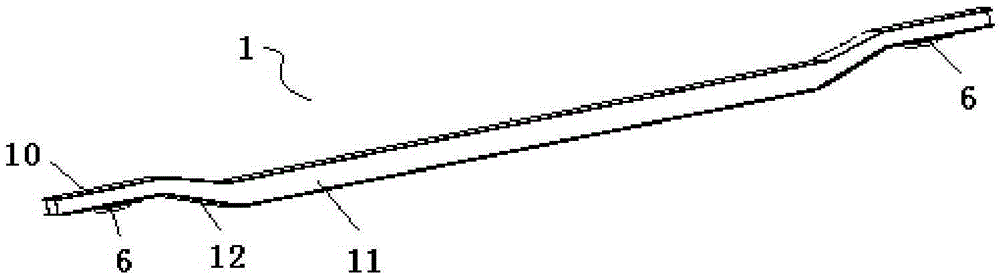

[0019] like image 3 As shown, the center s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com