Roller-type LED panel fixing bracket

A fixed frame and roller-type technology, applied in the field of fixed frame, can solve problems such as difficult to put in, time-consuming and labor-intensive, hard damage of LED panel, etc., and achieve a stable effect in the process of putting in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

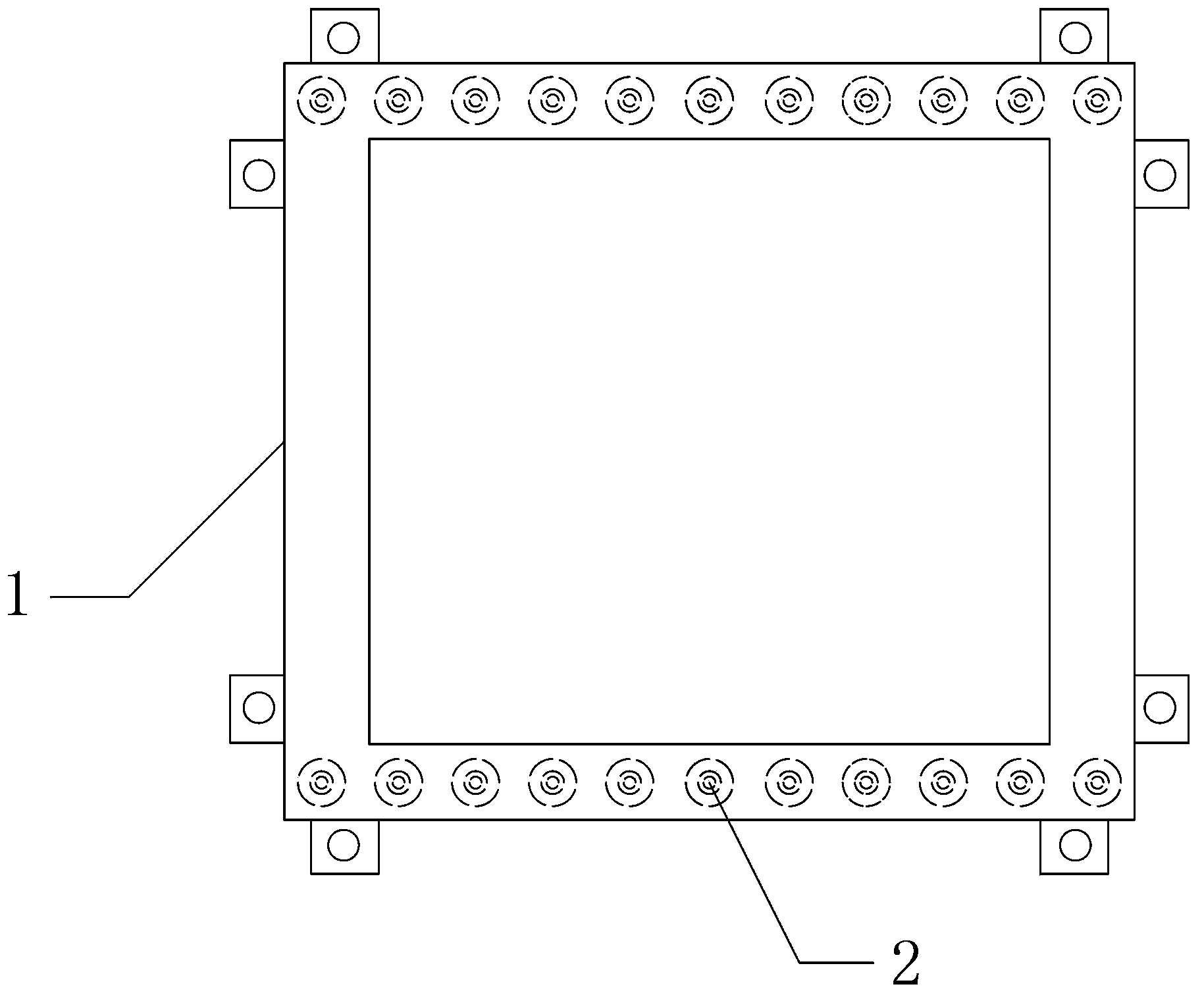

[0009] Such as figure 1 A roller-type LED panel fixing frame is shown, the fixing frame 1 is a rectangular frame, and the frame of the fixing frame 1 is processed with a ring groove with the same shape as the fixing frame 1, and the direction of the notch of the ring groove is toward the center of the fixing frame (1). direction; the roller 2 is installed in the ring groove; the bottom of the ring groove on at least one side of the frame of the fixed frame 1 and the wall of the ring groove are detachably fixedly connected; the roller 2 adopts a bearing roller, and the surface of the roller is made of soft rubber material;

[0010] The present invention adopting the above-mentioned technical solution realizes the insertion of the LED panel from the side by adopting the detachable manner of the ring groove and the side, that is, firstly remove the bottom of the detachable ring groove, and then insert the LED panel into the ring groove, at this time the ring groove The inner roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com