Sampling device for geological survey

A sampling device and geological survey technology, applied in the sampling device and other directions, can solve the problems of multiple manpower and material resources, easily affecting work efficiency, etc., and achieve the effects of low cost, simple structure and reduced investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

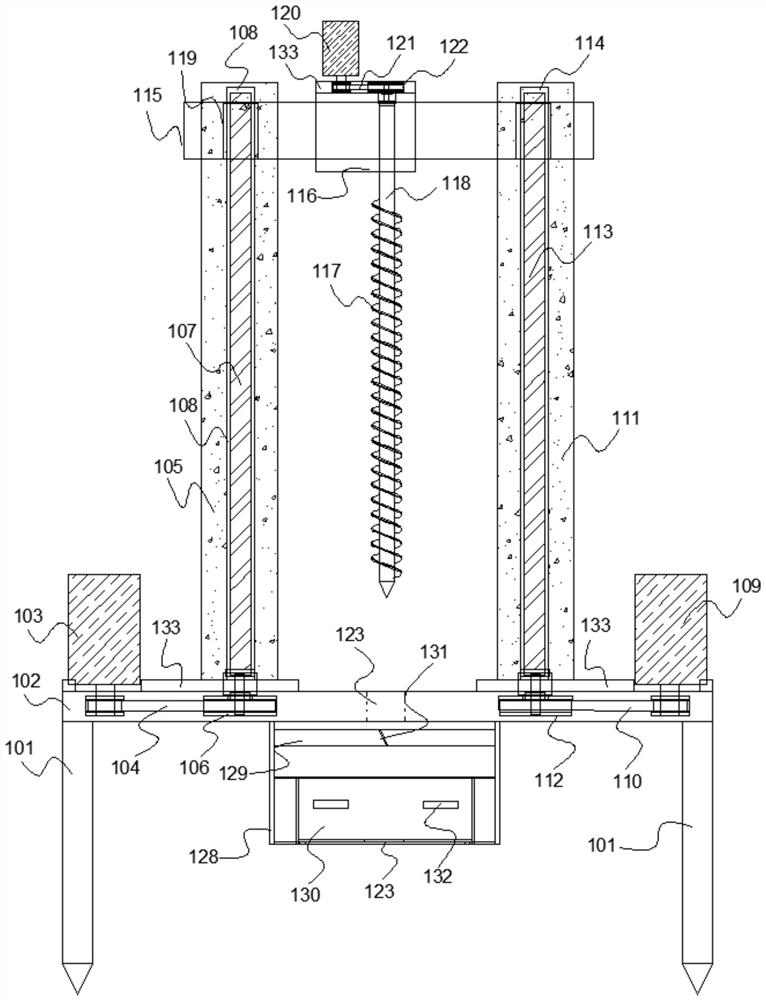

Embodiment 1

[0047] Embodiment 1: After the sampling device for geological survey is assembled, confirm the site to be surveyed, place the sampling device for geological survey on the site to be surveyed, insert the support legs 101 into the soil layer of the site to be surveyed, and keep the sampling device for geological survey in place. Stable, then start the motor forward rotation drive of the first rotating motor 103, the second rotating motor 109 and the third rotating motor 120, the first rotating motor 103 drives the left lead screw 107 of the left lifting part to rotate, and the second rotating motor 109 drives the right The right lead screw 113 of the lifter rotates, and the synchronous rotation of the left lead screw 107 and the right lead screw 113 drives the fixing seat 116 to descend, that is, drives the sampling drill rod 118 on the fixing seat 116 to descend, and the sampling drill rod 118 rotates in the third rotation simultaneously. Driven by the motor 120, it rotates by i...

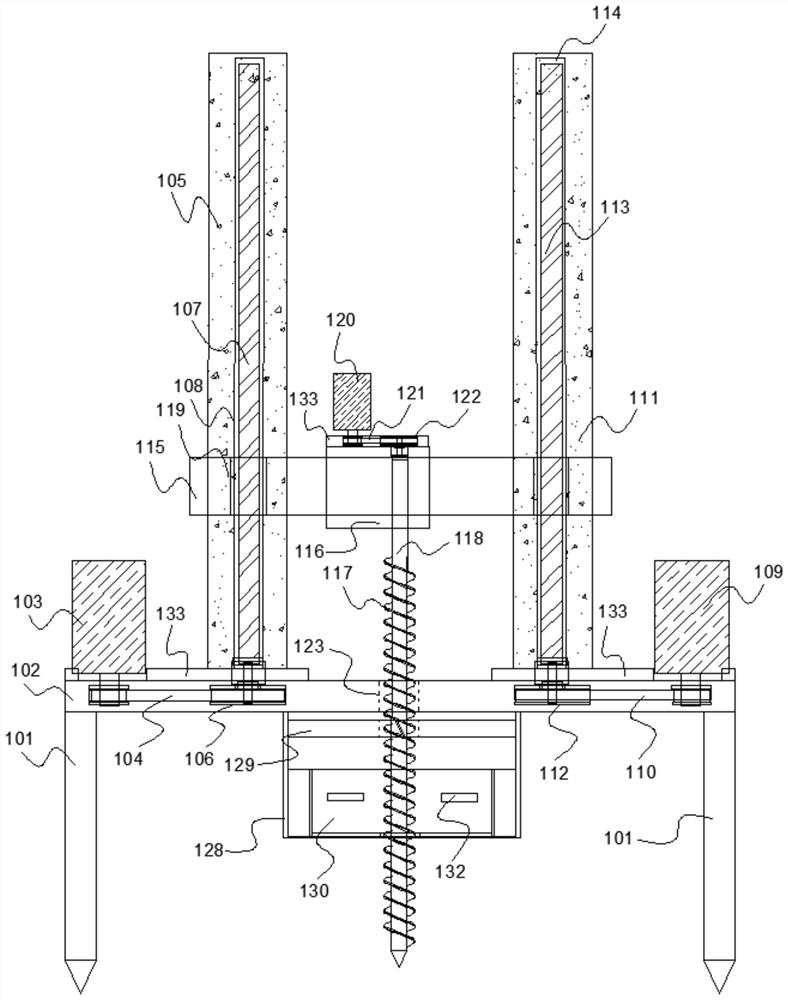

Embodiment 2

[0048] Embodiment 2, after the assembly of the sampling device for geological survey is completed, the site to be surveyed is confirmed, the sampling device for geological survey is placed on the site to be surveyed, the support legs 101 are inserted into the soil layer of the site to be surveyed, and the sampling device for geological survey is kept in place. Stable, then start the motors of the first rotating motor 103, the second rotating motor 109 and the third rotating motor 120 to drive forward, the first rotating motor 103 drives the first lifting rod 124 to descend, and the second rotating motor 109 drives the second lifting rod 126 descends, and the decline of the first elevating rod 124 and the second elevating rod 126 drives the sampling drill rod 118 to descend, while the sampling drill rod 118 rotates by itself under the drive of the third rotating motor 120, and passes through the sampling rack 129 and the sampling placement box successively. 130, stretches into t...

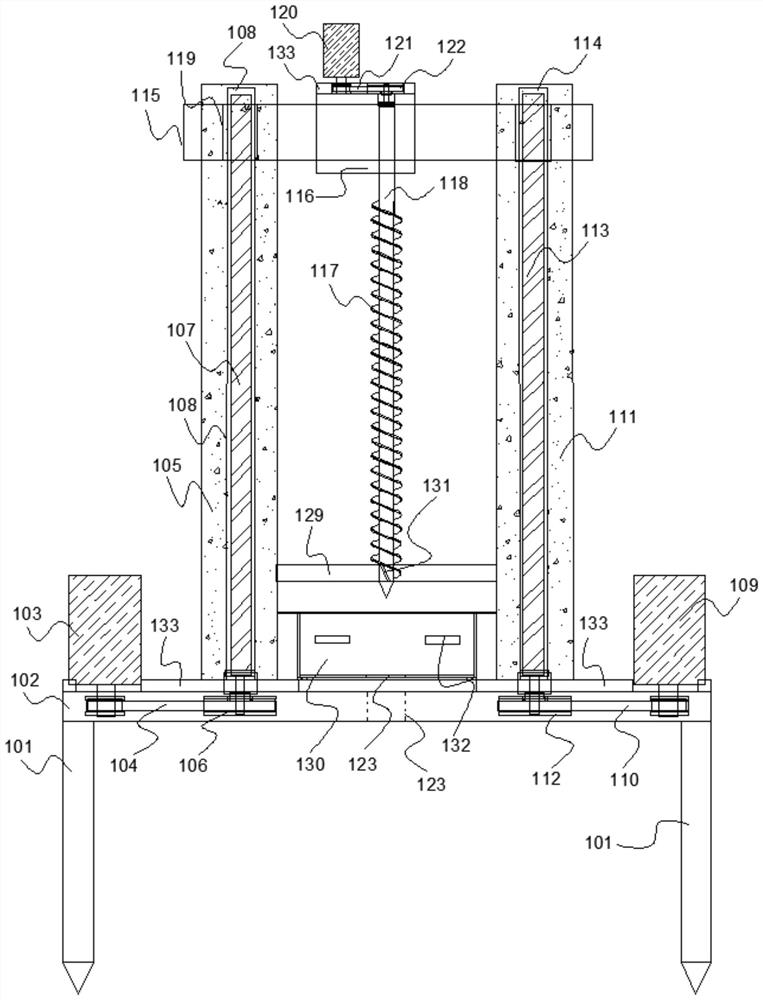

Embodiment 3

[0049] Embodiment 3, after the sampling assembly for geological survey is completed, the sample collection device can be dismantled separately; after confirming the site to be surveyed, the sampling device for geological survey is placed on the site to be surveyed, and the supporting legs 101 are inserted into the soil layer of the site to be surveyed, keeping The sampling device for geological survey remains stable, and then the motors of the first rotating motor 103, the second rotating motor 109 and the third rotating motor 120 are started to drive forward, and the first rotating motor 103 drives the left lead screw 107 of the left lifting part to rotate, and the first rotating motor 103 drives the left lead screw 107 of the left lifting part to rotate. Two rotation motors 109 drive the right lead screw 113 of the right lifting part to rotate, and the synchronous rotation of the left lead screw 107 and the right lead screw 113 drives the fixing seat 116 to descend, that is, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com