Efficient dual-cylinder even compression dustbin

A technology of uniform compression, dustbin, applied in the direction of trash cans, garbage collection, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

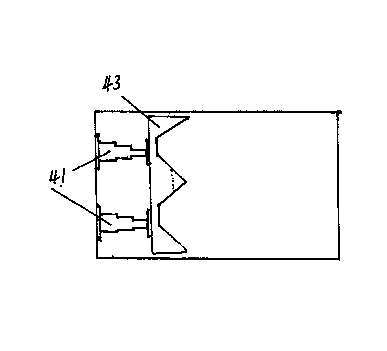

[0009] In order to solve the existing single-point load-bearing problem, the two compression cylinders can be distributed in parallel, the bottoms of the two cylinders are respectively welded to the dustbin body, and the tops of the two cylinders are respectively welded to the compression head, which adds a bearing The compression head can be pushed out through the upper and lower ends to achieve a stronger driving force and a more stable driving force, which will not cause friction and collision between the compression head and the dustbin due to uneven driving force, resulting in poor compression effect , even without compression. The compression head is designed in a w shape. This shape is to prevent the garbage from concentrating on the lower part when it is pushed forward, so as to concentrate on one point, resulting in insufficient compression of the upper part of the garbage. The w shape can also disperse the garbage, spread it forward and compress it, and improve The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com