A disc air suction seed metering device

A seed metering device and air-suction technology, which is applied to the parts of the planter, can solve the problems of large seed metering pulsation, poor uniformity and high manufacturing cost, and achieve the advantages of good seed metering uniformity, convenient processing and manufacturing, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

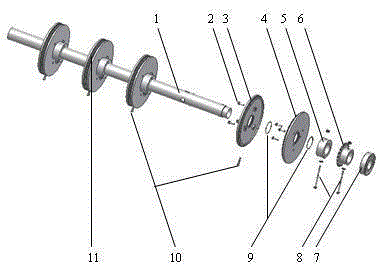

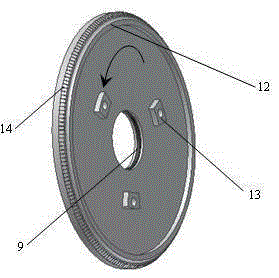

[0009] For the structural composition of a disc air-suction seeding device used for sowing wheat and other row crops, refer to the attached figure 1 . Each sowing row has a group of disks, each group of disks consists of a left disk 3 and a right disk 4 with equal outer diameters, and is mounted on the hollow shaft 1 at equal intervals. Three protrusions 13 with screw holes are processed on the inner side of each disc. The left disc 3 and the right disc 4 are assembled together by three screws 2. The height of the protrusions 13 controls the height of the seed suction seam 11 between the two discs. Width, the central shaft hole of each disc has a groove along the circumference, and the rubber sealing ring 9 is inlaid in the groove. The right disc 4 of each group of discs is installed with a fixed hub 5 through screws, and the fixed hub is fixed with a long bolt 8. 5. Installed and fixed on the hollow shaft 1, the disk rotates with the rotation of the hollow shaft 1, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com