Passenger transferring device

A technology for passenger conveying equipment and frames, which is used in transportation and packaging, escalators, etc., can solve problems such as difficulty in effectively utilizing the relative displacement between the truss and the building, and expanding the relative displacement between the truss and the building.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

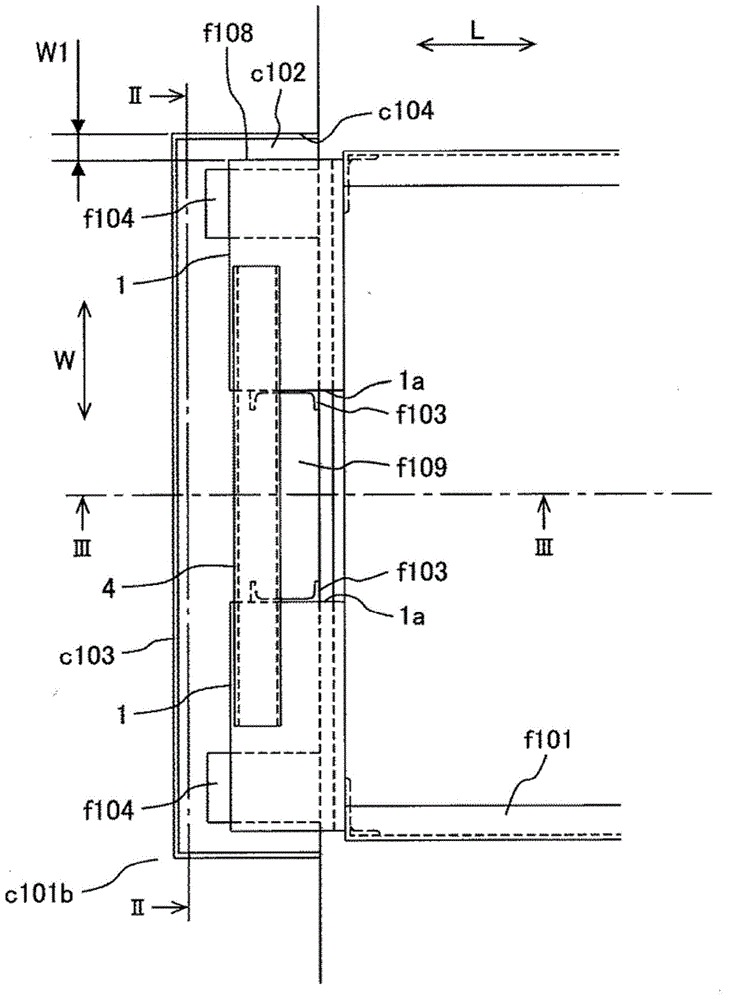

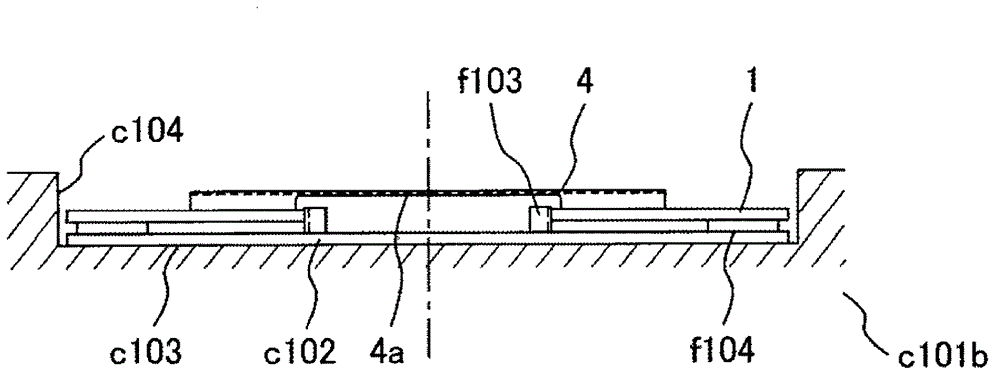

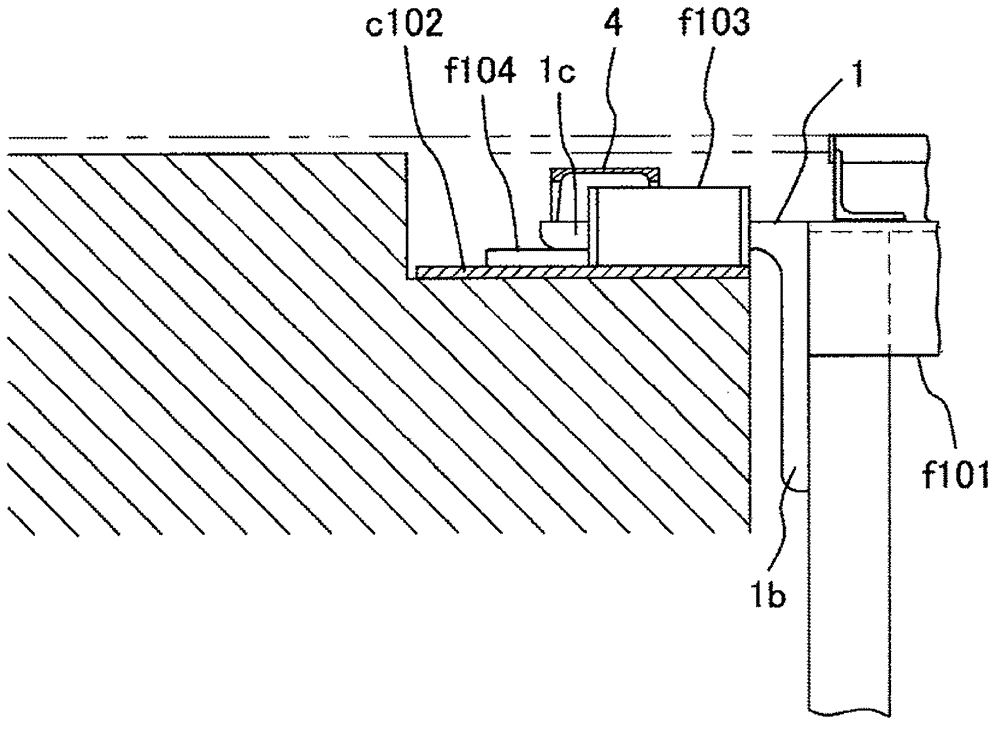

[0042] Refer to the following Figure 1 to Figure 3 The structure of the frame support part 1 of this embodiment is demonstrated. In describing this embodiment, refer to Figure 4 and Figure 5 , Figure 4 and Figure 5 The structure of the comparative example which has a movement restricting member on the outer side of a passenger conveyor is shown in .

[0043] figure 1 It is a plan view showing the support structure of the non-fixed side support portion of the passenger conveying equipment of this embodiment, figure 2 It is a side view of the supporting structure of the non-fixed side support part of the passenger conveying equipment viewed from the terminal direction of the passenger conveying equipment of this embodiment ( figure 1 II-II sectional view), image 3 It is a side view of the supporting structure of the non-fixed side support part of the passenger conveying equipment viewed from the width direction of the passenger conveying equipment of this embodimen...

no. 2 example

[0063] In this embodiment, on the basis of the structure of the first embodiment, the length of the second side 1c of the frame support portion 1 is further extended. The length of overlap between the building side support portion c103 and the frame body support portion 1 (hereinafter referred to as “overlap allowance”) can be extended by a length corresponding to the length of the extended portion of the second side 1c. Thus, in this embodiment, the shock resistance performance can be improved. In this manner, in this embodiment, there is a support structure for passenger conveyors in which the allowable overlap is extended.

[0064] Refer to the following Figure 7 to Figure 10 This embodiment will be described. Figure 7 It is a plan view showing the support structure of the non-fixed side support portion of the passenger conveying equipment of this embodiment, Figure 8 It is a side view of the supporting structure of the non-fixed side support part of the passenger con...

no. 3 example

[0078] In the first embodiment, the case where the two frame support parts are constituted by the L-shaped support angle steel fixed to the end of the frame f101 was explained as an example. The case where two frame support parts are constituted by an L-shaped support angle steel at the end of the frame f101 and a portion formed by extending a part of the main truss chord constituting the frame f101 will be described as an example.

[0079] In this embodiment, the L-shaped support angle steel is omitted, and the two frame body support parts ( not shown). At this time, the connection member 4 connects each part formed by extending a part of the main truss chord which is a frame support part. In addition, the movement restricting member restricts movement of a portion formed by extending a part of the main truss chord serving as the frame support portion. It should be noted that, in this embodiment, compared with the first embodiment and the second embodiment, there may be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com