Double-rolling-drum washing machine

A washing machine and double-drum technology, applied in the field of washing machines, can solve the problems of less clothes, energy and water waste, time-consuming and labor-intensive problems, and achieve the effect of saving energy and water resources, meeting environmental protection and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings:

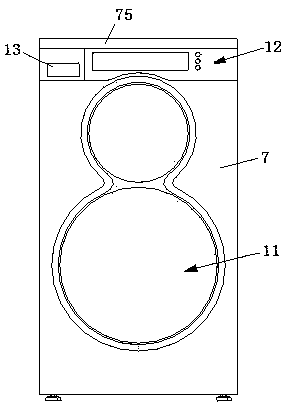

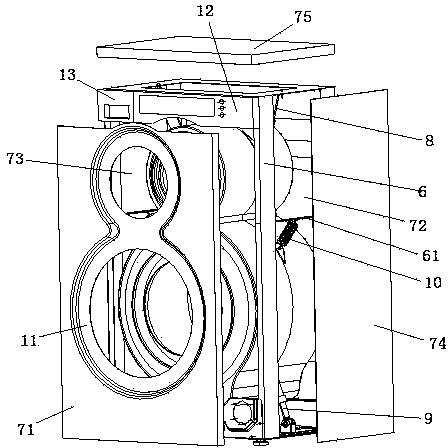

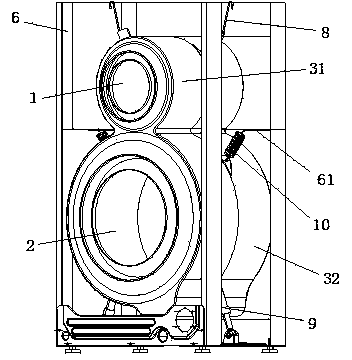

[0021] like figure 1 - Figure 5 The shown double-drum washing machine includes a body, the body is provided with first and second washing inner tubs 1 and 2 arranged up and down in a horizontal direction, and the outer parts of the first and second washing inner tubs 1 and 2 are integrally injection-molded. The outer barrel 3, the outer barrel 3 separates the first and second washing inner barrels 1, 2 into independent spaces, and the outer barrel 3 is also provided with first and second washing inner barrels 1, 2 to rotate respectively. Two motors 4 and 5 , specifically, the first and second motors 4 and 5 respectively drive the first and second washing inner tubs 1 and 2 to rotate through the first and second rotating bearings 41 and 51 to achieve the function of washing clothes. Preferably, the washing capacity of the first washing inner tub 1 is smaller than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com