Washing machine

A washing machine and machine body technology, applied in the field of washing machines, can solve the problems of less clothes, waste of energy and water, and inability to make full use of washing machines, so as to achieve the effect of saving energy and water resources, meeting environmental protection and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

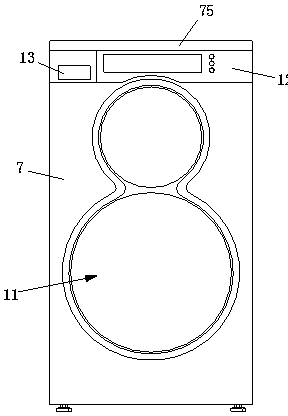

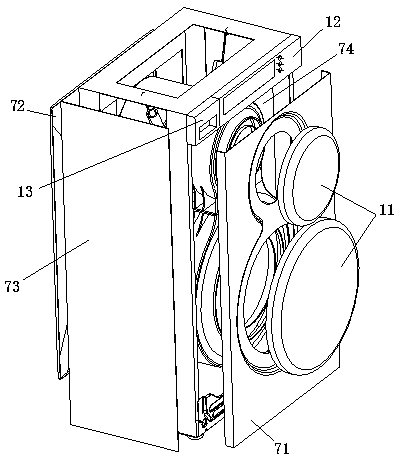

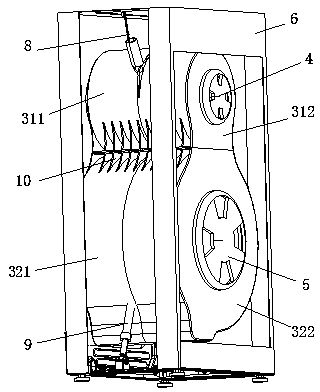

[0021] Such as figure 1 - Figure 4 The shown washing machine includes a body, in which there are first and second washing inner tubs 1 and 2 arranged up and down in the horizontal direction, and first and second washing inner tubs 1 and 2 are arranged outside the first and second washing inner tubs 1 and 2. The outer barrels 31, 32, the first and second outer barrels 31, 32 are separately injection molded and connected into one body through the connecting piece 10, the first and second outer barrels 31, 32 isolate the first and second washing inner barrels 1, 2 The first and second outer cylinders 31 and 32 are also provided with first and second motors 4 and 5 to drive the first and second washing inner tubs 1 and 2 to rotate respectively. Specifically, the first and second motors 4 and 5 respectively drive the first and second washing inner tubs 1 and 2 to rotate throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com