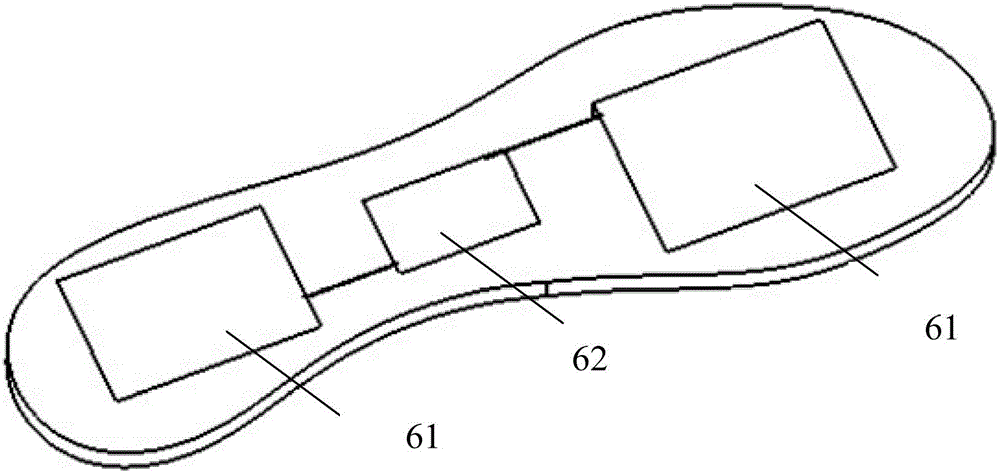

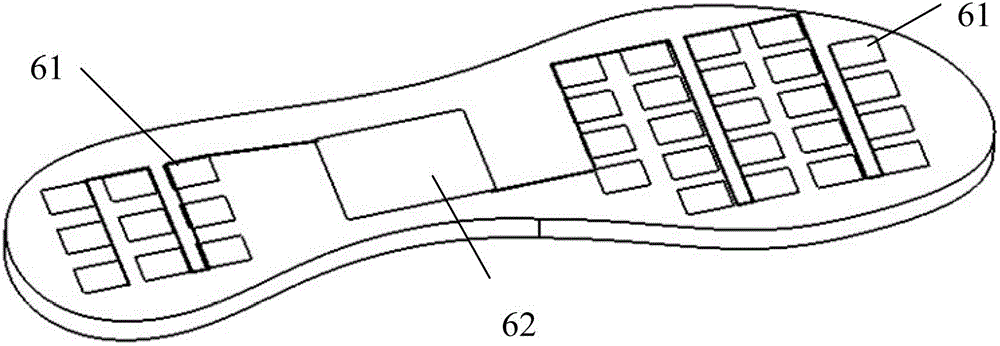

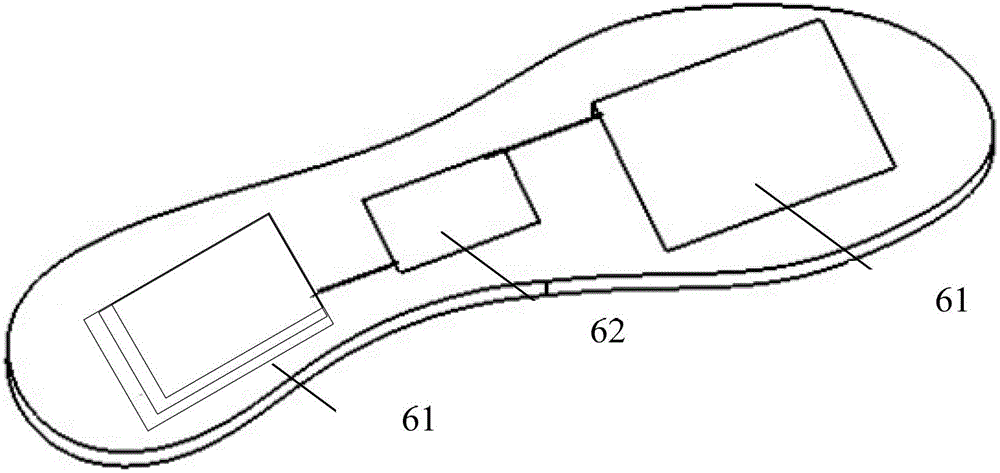

luminous shoes

A technology of light-emitting shoes and light-emitting devices, applied in the field of light-emitting shoes, can solve the problems of no mechanical utilization, frequent replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the above-mentioned high-power nano friction generator will be described in detail below. The method comprises the steps of:

[0059] (1) Preparation of a substrate with nanowires

[0060] ZnO nanowires are vertically grown on one surface of the substrate to obtain a substrate with nanowires.

[0061] The substrate that can be used in the present invention may be a silicon substrate, a gold-plated or chrome-plated glass substrate, or the like.

[0062] The present invention adopts a conventional hydrothermal method to grow zinc oxide nanowire arrays, for example, a mixture of hexamethylenetetramine (HMTA) and zinc nitrate hexahydrate (ZnNO3·6(H2O)) is used as a culture medium, at an appropriate temperature For example, zinc oxide nanowire arrays are grown on silicon substrates at 80-95°C. Specifically, in a specific embodiment, a zinc oxide seed layer with a thickness of 30-50 nm is formed on one surface of the silicon substrate by conventio...

Embodiment 1

[0083] Such as Figure 6 and 7 As shown, the size of the high-power nano triboelectric generator in this embodiment is 4.5cm (length) × 1.2cm (width), which includes the first electrode layer 1 (aluminum layer with a thickness of 0.1mm) stacked in sequence, high molecular polymer Layer 2 (1 mm thick polyvinylidene fluoride), and triboelectrode layer 3. The friction electrode layer 3 includes a friction film layer 31 (1.0mm thick coated paper (specification 200g / m 2 )) and a second electrode layer 32 (copper layer with a thickness of 0.1 mm), the friction film layer 31 is arranged opposite to the polymer layer 2 . The surface of the polymer layer 2 opposite to the triboelectrode layer 3 is provided with a plurality of nanopores 4 (with a width of about 60 nm, a depth of about 8 μm, and an average hole spacing of 9 μm). The first electrode layer 1 and the second electrode layer 32 are voltage and current output electrodes of the triboelectric generator.

[0084] The preparat...

Embodiment 2-3

[0095] Embodiment 2 and 3 adopt the method substantially identical with embodiment 1 to prepare, difference is listed in the following table:

[0096] Table 1

[0097]

[0098]

[0099] Using a stepper motor with periodic oscillation (0.33Hz and 0.13% deformation) makes friction generator 2# and 3# undergo periodical bending and release, and the maximum output voltage and current signal of friction generator 2# reach 900V and 850μA respectively , the maximum output voltage and current signal of friction generator 3# reached 680V and 450μA respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com