Material for preparing semi-flexible fluorescent pavement, and application method thereof

An application method and semi-flexible technology, applied in the field of materials for preparing semi-flexible fluorescent pavement, can solve the problems such as the inability to meet the requirements of vehicle road strength and bearing capacity, the inability of pavement materials to meet the lighting requirements, and the limitation of the use range of fluorescent pavement, etc. Driving safety performance, improving anti-skid effect, long luminous time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

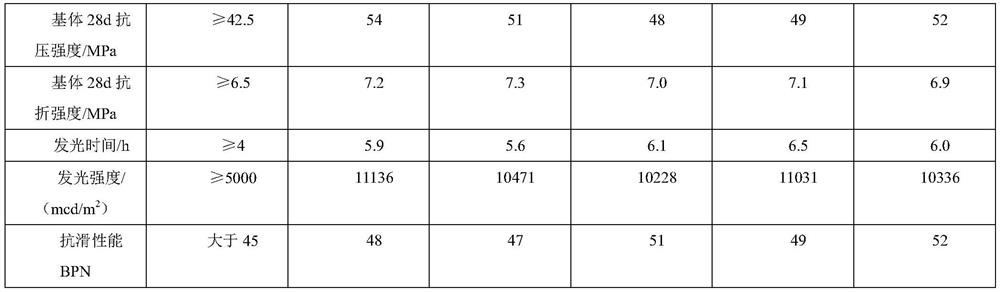

Embodiment 1

[0034] A material for preparing semi-flexible fluorescent pavements, all in parts by weight, comprising: 0.68 parts of white Portland cement, 0.24 parts of superfine sand, 0.11 parts of water reducer, 0.05 parts of fly ash, yellow 0.22 parts of green fluorescent stone particles, 0.24 parts of glass microspheres, 0.5 parts of water, 0.02 parts of SD emulsion, 0.01 parts of polyvinyl alcohol; 1.2 parts of SBS modified asphalt, 4.1 parts of coarse aggregate, 0.42 parts of fine aggregate, limestone powder 0.33 parts, high viscosity modified additive 0.012 parts;

[0035] The weight percentage of the asphalt mixture is 70%, and the weight percentage of the fluorescent concrete mortar is 30%.

[0036] A kind of application method for preparing the material of semi-flexible fluorescent road surface, its specific steps are:

[0037] Step 1: Stir the yellow-green fluorescent stone particles and reflective glass beads in a mixer at a speed of 145±5 revolutions / min and 55±5 revolutions / mi...

Embodiment 2

[0043] A material for preparing a semi-flexible fluorescent pavement, all in parts by weight, consisting of: 1.24 parts of white Portland cement, 0.32 parts of superfine sand, 0.16 parts of water reducer, 0.08 parts of fly ash, yellow 0.25 parts of green fluorescent stone particles, 0.22 parts of glass microspheres, 0.54 parts of water, 0.02 parts of SD emulsion, 0.02 parts of polyvinyl alcohol; 1.5 parts of SBS modified asphalt, 4.4 parts of coarse aggregate, 0.56 parts of fine aggregate, limestone powder 0.32 parts, high viscosity modified additive 0.016 parts;

[0044] The weight percentage of the asphalt mixture is 73%, and the weight percentage of the fluorescent concrete mortar is 27%.

[0045] A kind of application method for preparing the material of semi-flexible fluorescent road surface, its specific steps are:

[0046] Step 1: Stir the yellow-green fluorescent stone particles and reflective glass beads in a mixer at a speed of 155±5 revolutions / min and 60±5 revolut...

Embodiment 3

[0052] A material for preparing a semi-flexible fluorescent pavement, all in parts by weight, consisting of: 0.96 parts of white Portland cement, 0.33 parts of superfine sand, 0.15 parts of water reducer, 0.07 parts of fly ash, yellow 0.26 parts of green fluorescent stone particles, 0.25 parts of glass microspheres, 0.6 parts of water, 0.03 parts of SD emulsion, 0.03 parts of polyvinyl alcohol; 1.8 parts of SBS modified asphalt, 4.8 parts of coarse aggregate, 0.76 parts of fine aggregate, limestone powder 0.42 parts, high viscosity modified additive 0.017 parts;

[0053] The weight percentage of the asphalt mixture is 80%, and the weight percentage of the fluorescent concrete mortar is 20%.

[0054] A kind of application method for preparing the material of semi-flexible fluorescent road surface, its specific steps are:

[0055] Step 1: Stir the yellow-green fluorescent stone particles and reflective glass beads in a mixer at a speed of 140±5 revolutions / min and 55±5 revoluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com