A plastic composite pipe with steel mesh skeleton and its construction method

A technology of composite pipe and steel mesh, which is applied in the direction of pipe, rigid pipe, pipe laying and maintenance, etc., can solve the problems of corrosion resistance, temperature resistance and impact resistance, rigid dimensional stability and poor creep resistance, and durable mechanical strength Low-level problems, to achieve good dimensional stability, uniform and reliable composite, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

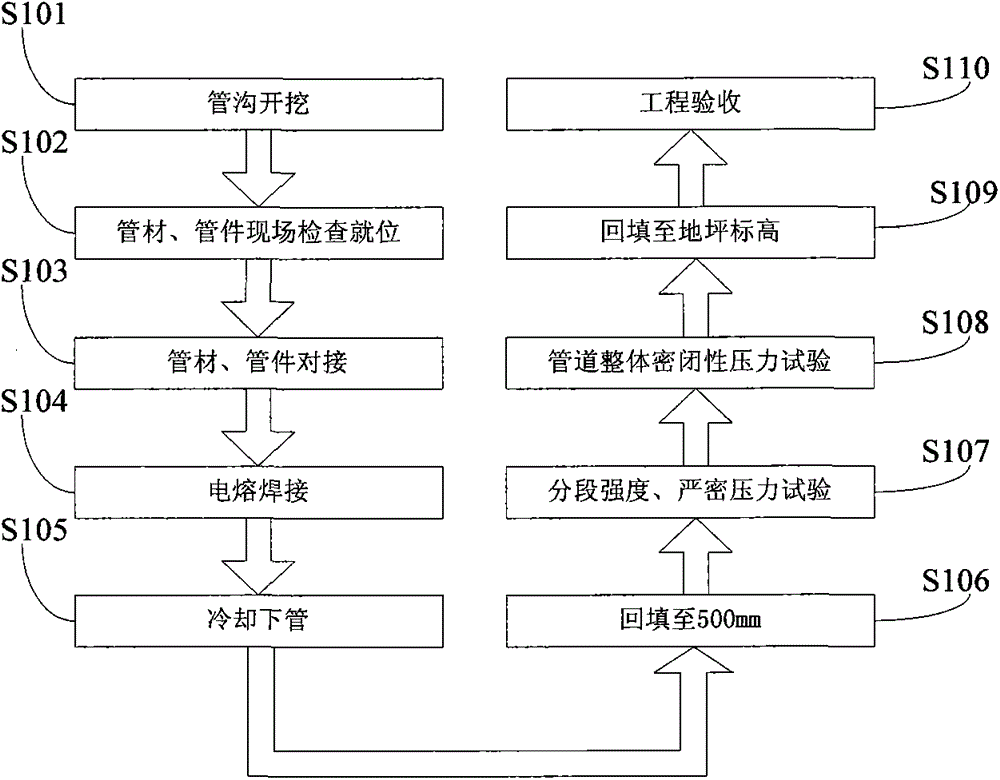

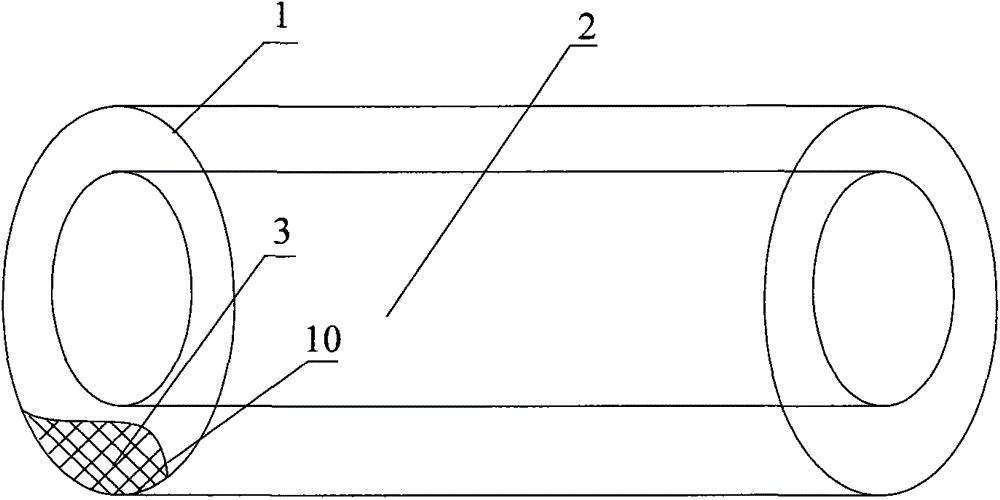

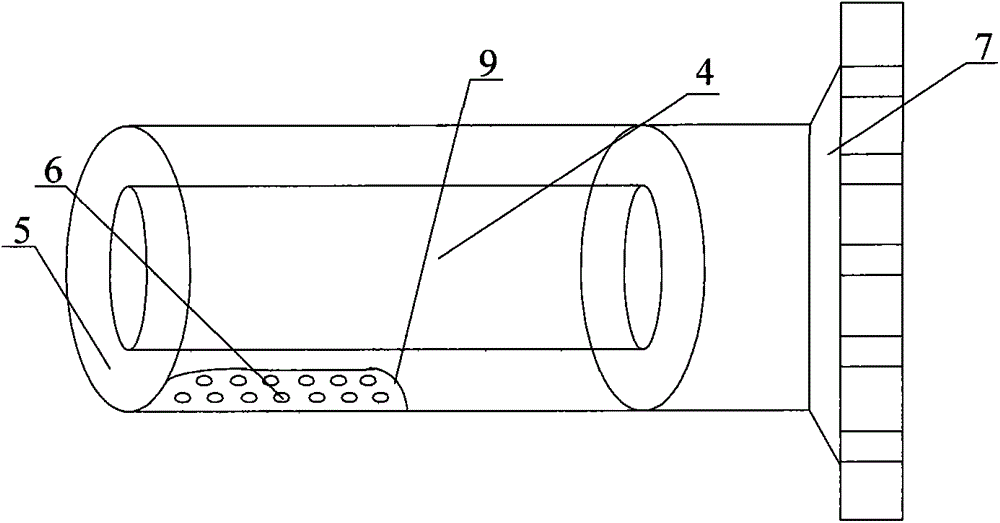

[0012] A plastic composite pipe with a steel mesh skeleton, mainly composed of a pipe wall 1, a pipe body 2, a pipe reinforcement skeleton 3, a pipe fitting body 4, a pipe fitting wall 5, a pipe fitting reinforcement skeleton 6 and a connecting flange 7, wherein the pipe The reinforcing frame 3 is embedded in the middle of the pipe wall 1 of the pipe body 2; the pipe reinforcing frame 6 is embedded in the middle of the pipe wall 5 of the pipe body 4; the connecting flange 7 is arranged on the pipe body 2 and the pipe body 4 connection location.

[0013] Further, the pipe reinforcing skeleton 3 is specifically configured as a tubular steel wire mesh 10 formed by winding and welding, which is conducive to improving the strength of the pipe main body 2 and further improving the service life.

[0014] Further, the tubular steel wire mesh 10 of the pipe reinforcement frame 3 specifically adopts the tubular steel wire mesh 10 of the pipe reinforcement frame 10 intersecting at 45 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com