On-line Detection Method of Output Power of Spindle Motor of CNC Machine Tool with Frequency Conversion and Speed Regulation

A technology of spindle motors and CNC machine tools, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., and can solve problems such as online detection of spindle motors of CNC machine tools that are difficult to control by frequency conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

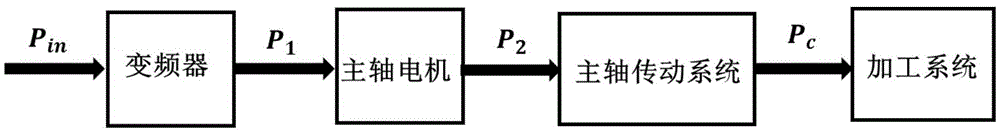

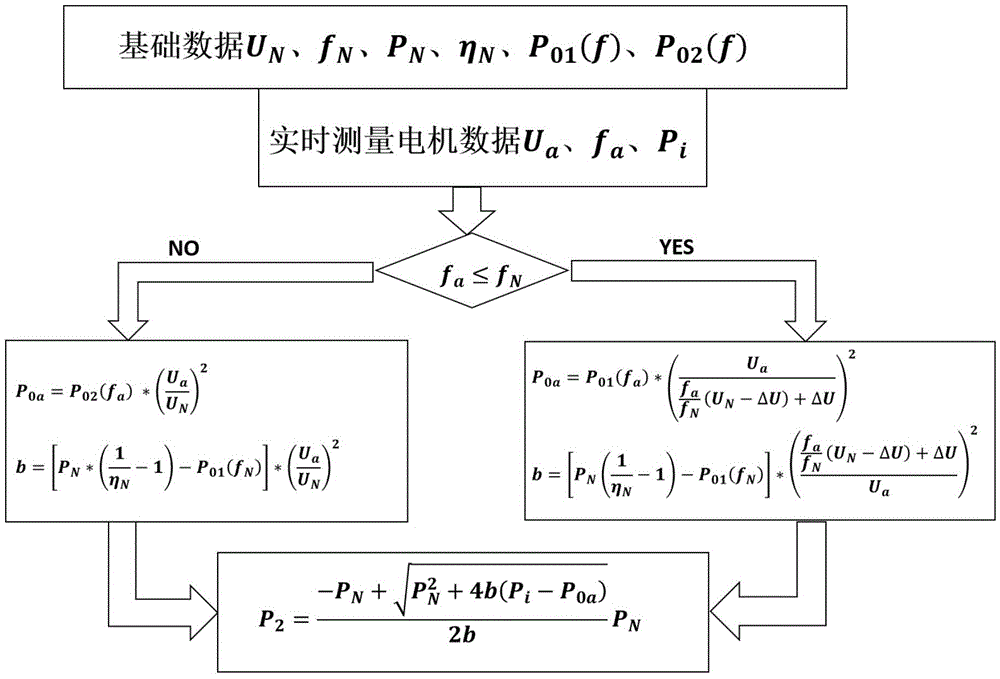

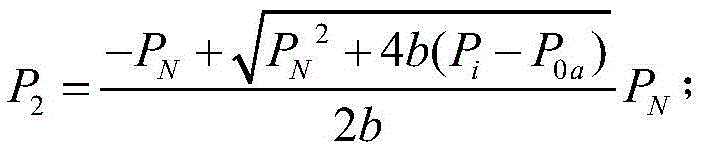

[0038] The main transmission system of frequency conversion speed control CNC machine tool is composed of three parts: frequency converter, spindle motor and spindle drive system, such as figure 1 As shown, P in is the total power input to the inverter, P 1 is the total power of the input spindle motor, P 2 is the output power of the spindle motor, P c is the total power input to the processing system. The spindle drive system transmits the energy of the spindle motor to the processing system to drive the actuator (tool or workpiece) to move. The processing system refers to the system composed of tools, workpieces, etc. The processing process refers to the process of processing the workpiece by the processing system. This process will cause changes in the energy loss of the main drive system. Because the spindle motor of the machine tool has been fixedly connected with the machine tool, it is necessary to measure the output power P of the spindle motor 2 raletively hard. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com