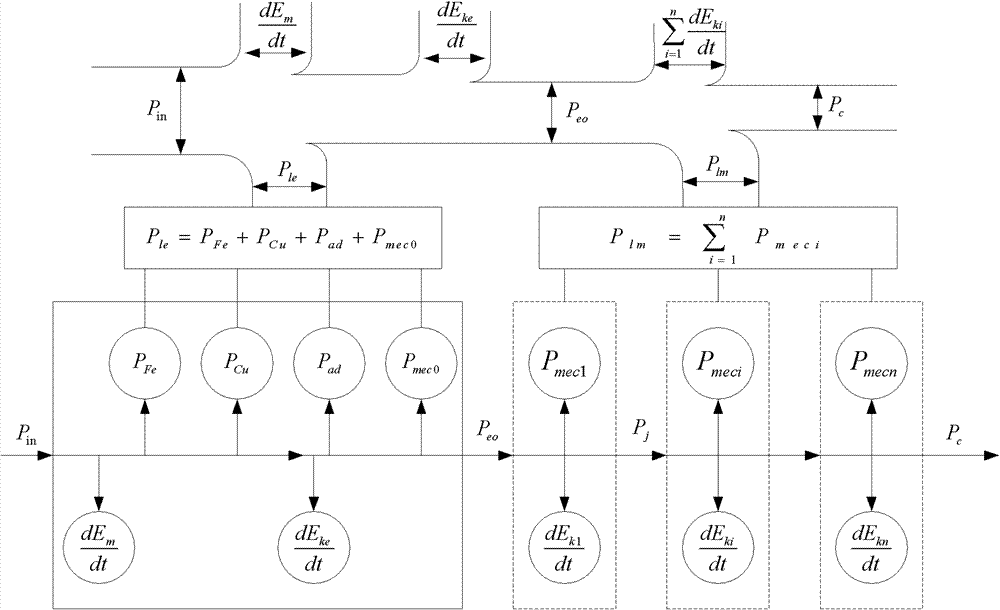

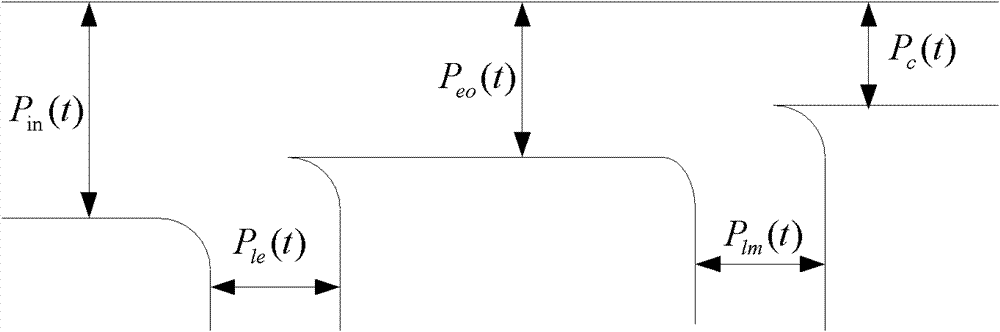

Online detection method of energy consumption information in machining process of main drive system of machine tool

A technology of main transmission system and processing process, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., and can solve the problems of complex changes in energy parameters, complex changes in the processing process, and many energy flow links and energy consumption links of machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

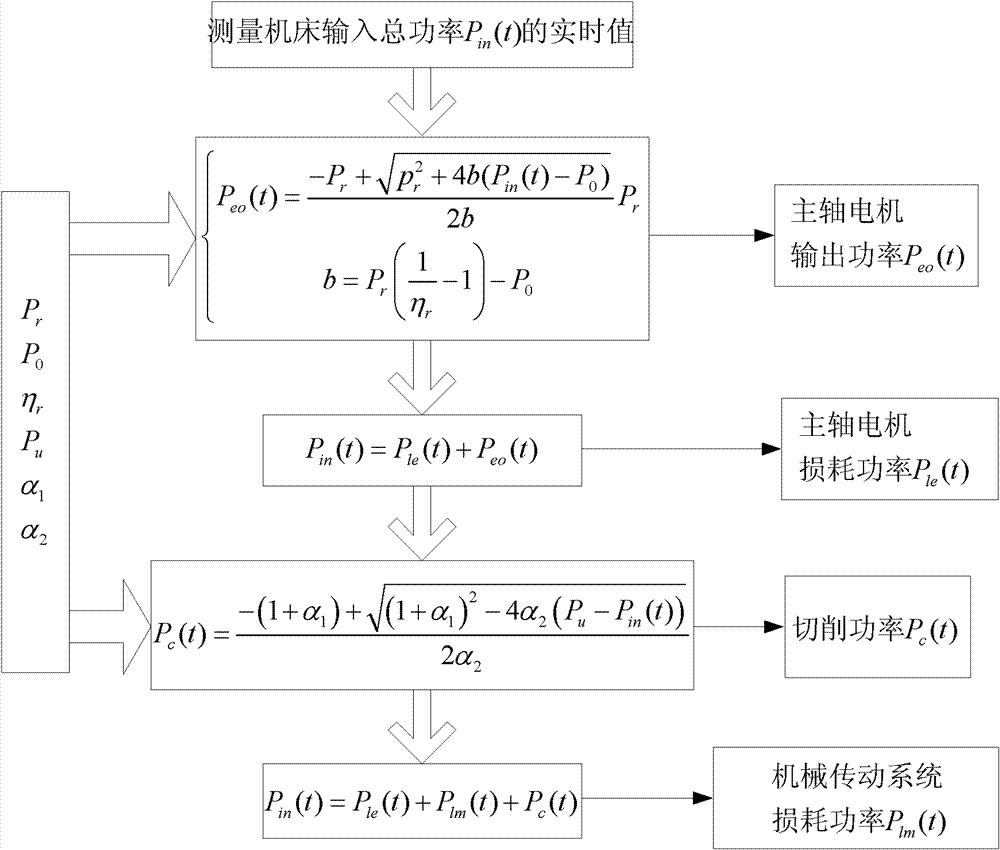

Method used

Image

Examples

Embodiment

[0094] On a common lathe that a model is C620-1, adopt the method of the present invention to detect the energy consumption information in its main transmission system processing process online, its process is as follows:

[0095] A. Obtain the basic data of the C620-1 lathe:

[0096] Firstly, the no-load experiment and cutting experiment were carried out to obtain the basic data needed to detect the energy consumption information of the main drive system of the C620-1 lathe; during the experiment, the power sensor EDA9033A was used to measure the total input power of the C620-1 lathe. The torque sensor TQ201 is used to measure the cutting torque and rotational speed of the main drive system of the C620-1 lathe during processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com