Method for obtaining energy efficiency of main electromechanical driving system in machining process of numerically-controlled machine tool

A main drive system, CNC machine tool technology, applied in general control systems, control/regulation systems, digital control and other directions, can solve the problems of difficult on-site energy efficiency, difficult on-site model parameters, difficult to obtain on-site production, etc., and achieve online detection process. Simple and easy to operate, broad application prospects, and the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

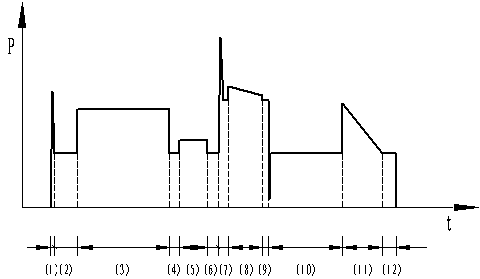

[0080] Using the model based on input power (Ⅱ) to process a certain shaft part (the shape and size of the part is as follows figure 1 The energy efficiency of the main drive system in the machining process is measured and calculated. The power sensor EDA9033A used to measure the input power is installed at the entrance of the main motor, and the data sampling period is 20ms. At the same time, the actual energy efficiency is obtained through the torque sensor TQ201 installed in the cutting area and the watt-hour meter installed at the entrance of the main drive system to provide accuracy verification.

[0081] Table 3 C2-6136HK / 1 CNC lathe parameters

[0082]

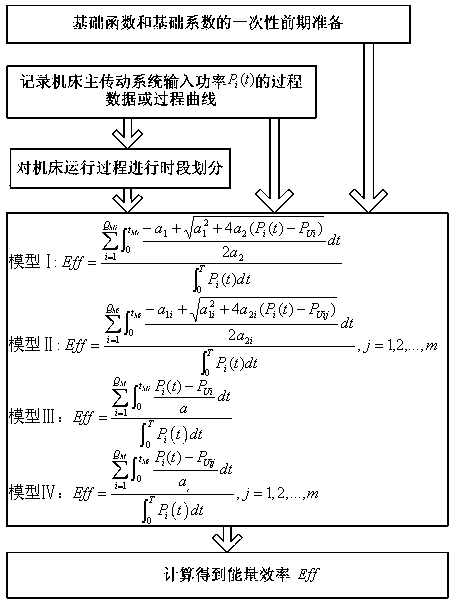

[0083] 1-1) Acquisition of basic functions and basic coefficients

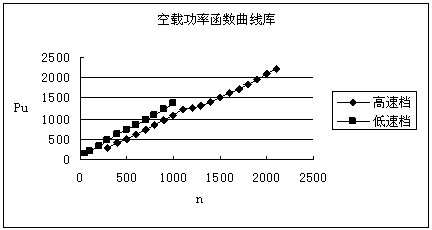

[0084] As mentioned above, to apply model (II) to obtain the energy efficiency of machine tools, the basic functions and basic coefficients that need to be prepared include the no-load power function and load loss factor table functions .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com