Concrete Vibration Quality Monitoring Feedback Data Real-time Graphical Digital Communication Method

A technology of feedback data and communication methods, which is applied in the direction of error prevention/detection, electrical components, and transmission systems using return channels, and can solve problems such as increasing the probability of operator misoperation, reducing construction efficiency, and quality problems in concrete molding. Achieve accurate and efficient correction of defects, solve data packet loss, and improve the quality of vibrating operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

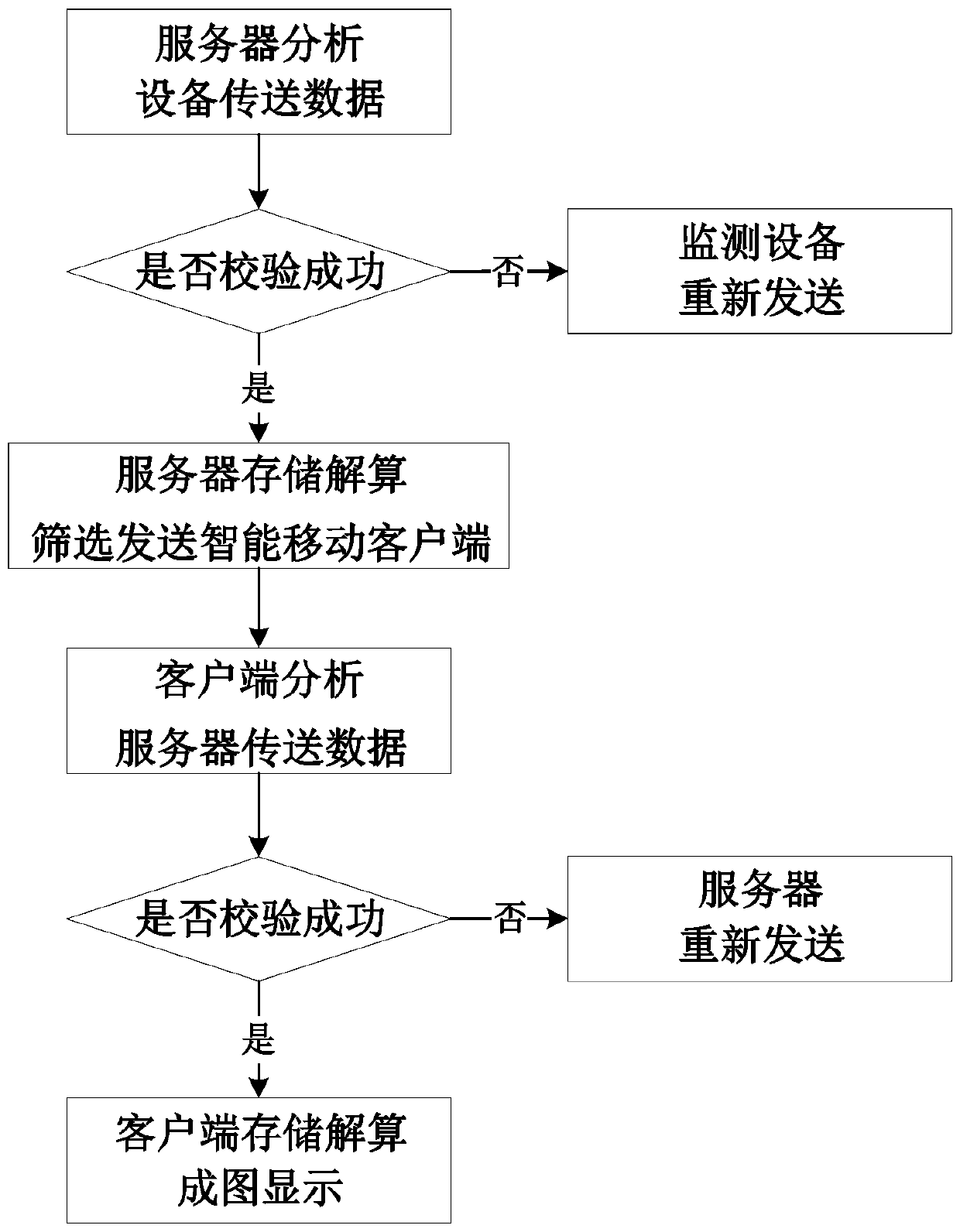

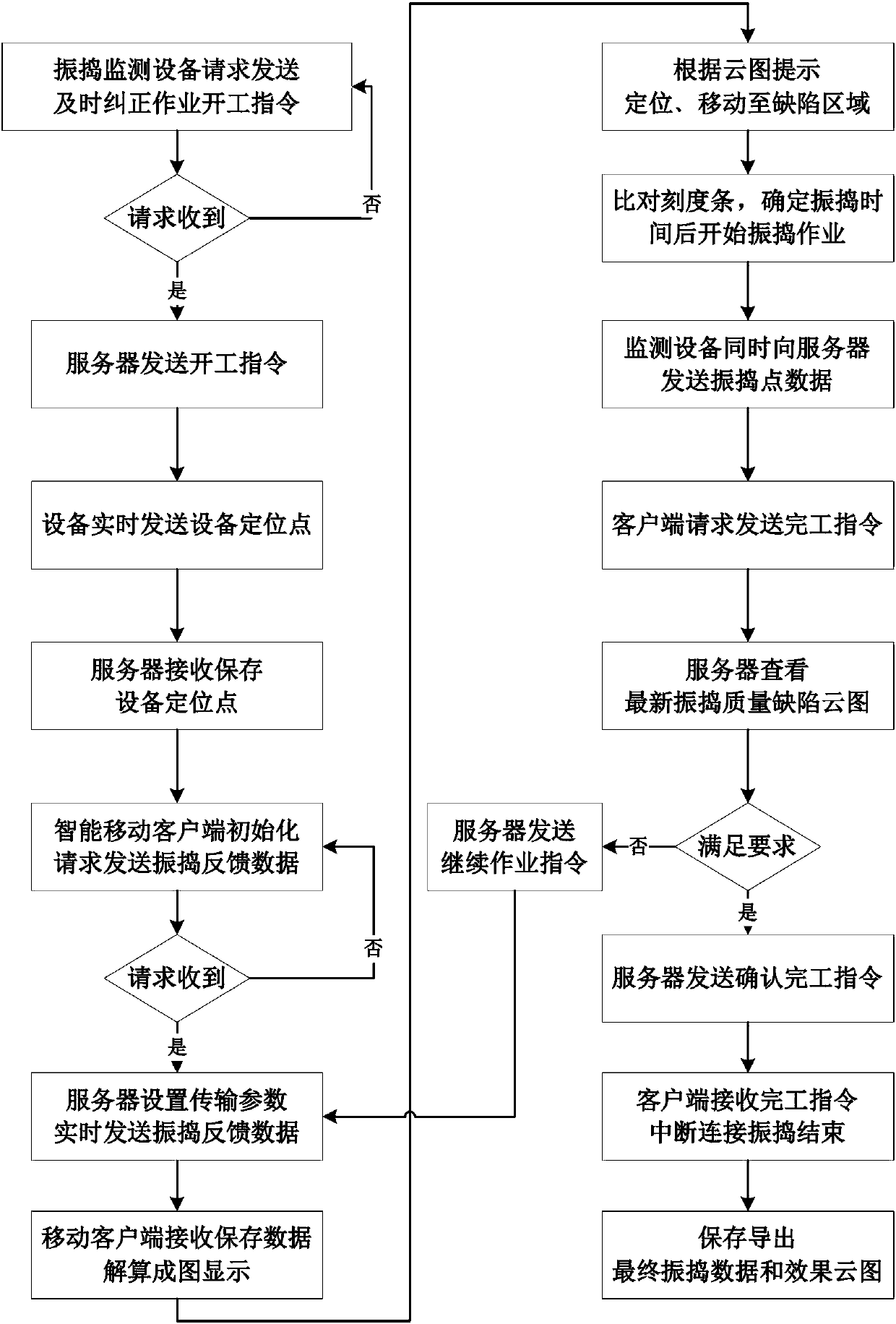

[0047] Such as Figure 1-2 As shown, a graphical digital communication method for monitoring feedback data of concrete vibrating quality according to the present invention includes the following steps: 1) After the vibrating operation is completed, the concrete vibrating monitoring equipment sends a request for correcting defects in time to the monitoring center server, Repeat the request until the server responds; 2) After receiving the request, the server sends a start-up instruction to the monitoring equipment; 3) After receiving the instruction, the monitoring equipment sends the device positioning data to the server in real time, and sends the vibration point data at the same time after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com