Automatic chain cut-off machine

A cutting machine and chain technology, applied in the direction of metal chains, etc., can solve the problem of inaccurate calculation of the number of chain links, and achieve the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

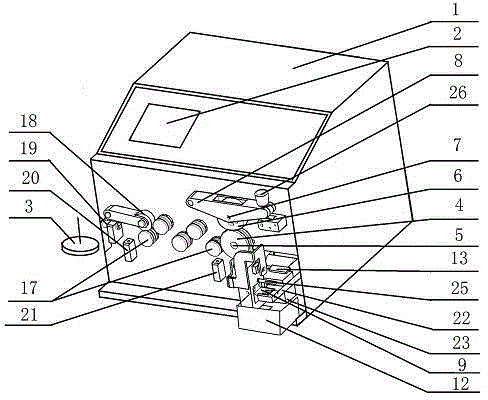

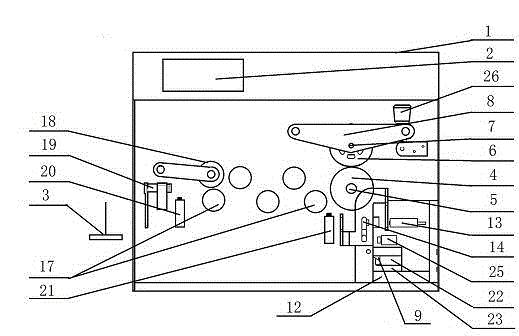

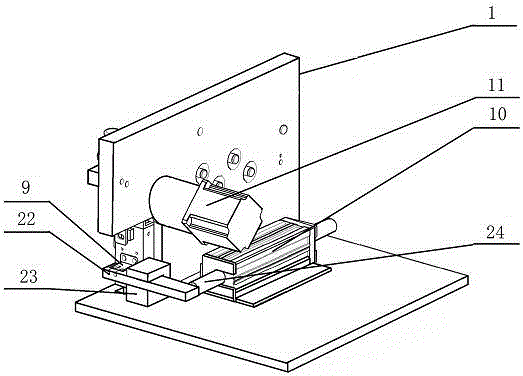

[0026] Such as Figure 1 to Figure 5 The automatic chain cutting machine shown includes a frame 1 and a PLC control unit 2 arranged on the frame 1. A wheel 3 is arranged on one side of the frame 1, and the chain is placed on the wheel 3, and the wheel 3 passes through the shaft It can be rotated. The drive wheel 4 is set on the frame 1. The drive wheel 4 is fixed on the rotating shaft 5, and the rotating shaft 5 is driven by the motor 11. The motor 11 is set as a servo motor to make the transmission more accurate. The motor 11 and PLC The control unit 2 is connected and controlled by the PLC control unit 2. A pressing wheel 6 for pressing the chain is arranged above the driving wheel 4. The pressing wheel 6 is arranged on the pressing bracket 8 by a pin 7 and a lock for locking the pressing bracket 8 is arranged on the frame 1. The tightening component, for example, the locking component can be rotated and fixed with a nut 26; as a preferred way, a groove 15 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com