High-altitude supporting mold of structureless floor slab

A technology without structure and slab, applied in the direction of building structure, formwork/formwork/working frame, and on-site preparation of building components, etc., it can solve the problem of increased usage of building materials, increased construction difficulty, increased construction cost, etc. problems, to achieve the effect of reducing the amount of erection materials, high construction risk, and high erection height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure of the high-altitude formwork for the unstructured floor slab of the present invention is described in conjunction with the accompanying drawings and embodiments.

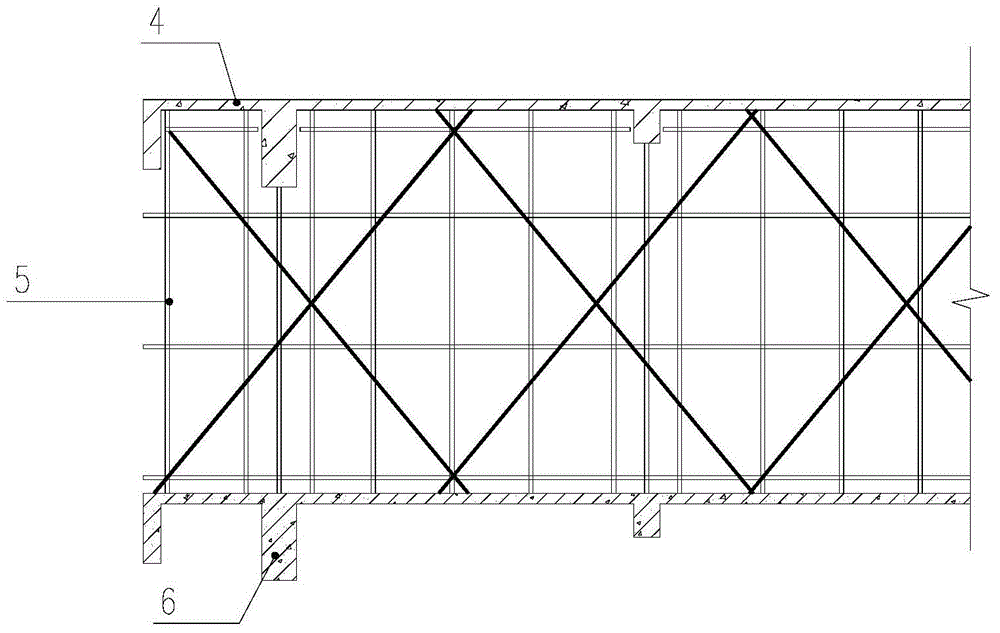

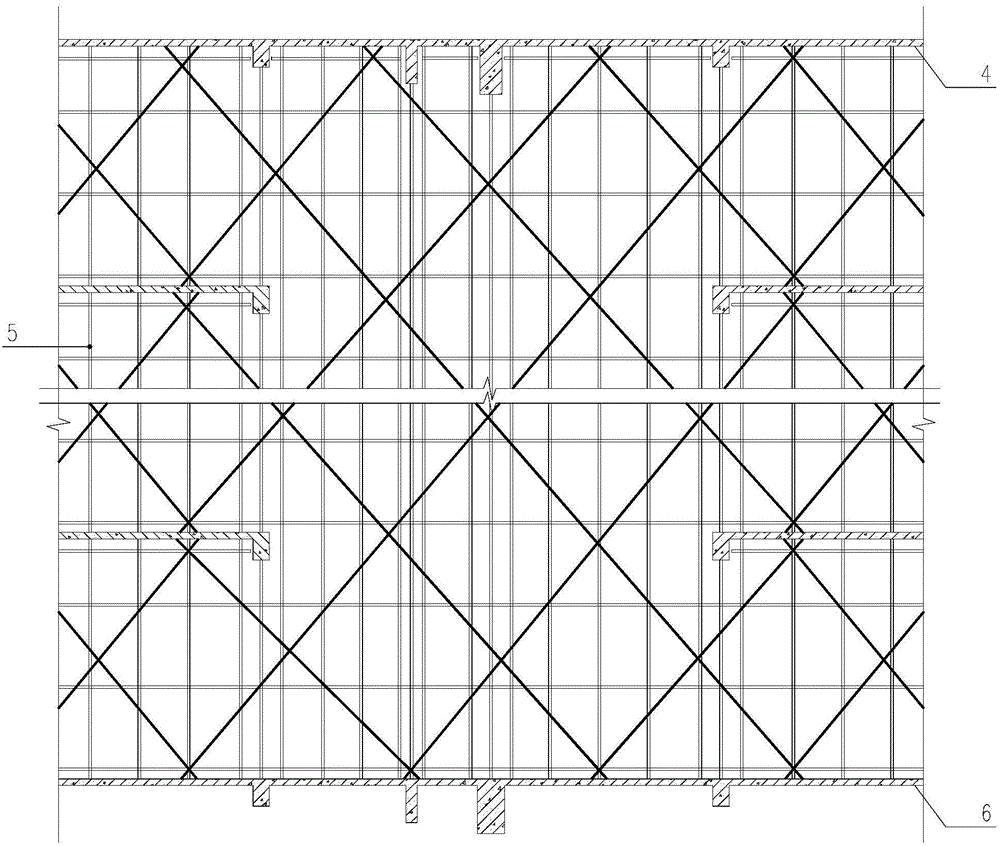

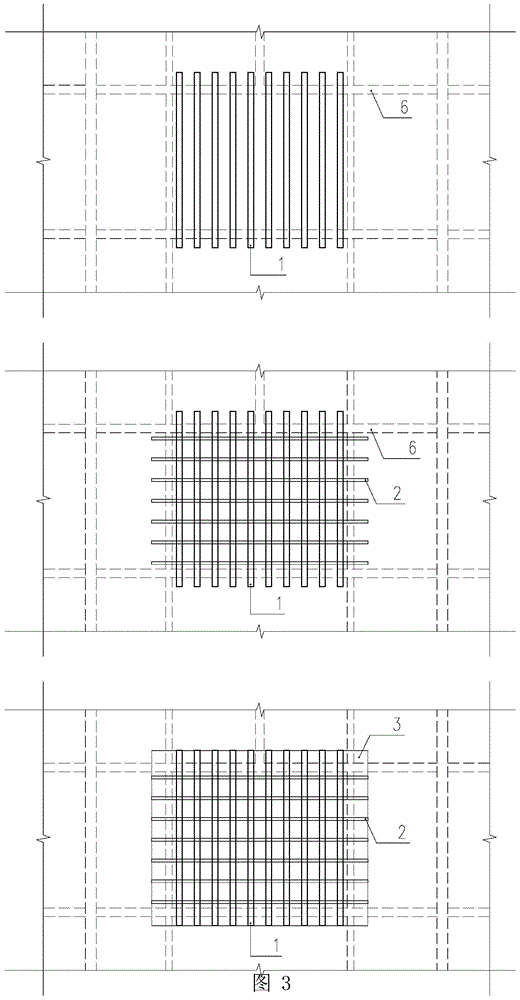

[0015] Such as image 3 , 4 As shown, the structure of the high-altitude formwork for the non-structured floor of the present invention is that the structure of the high-altitude formwork is to set up a temporary platform on the frame base structure floor 6 around the non-structured floor area, and set up a supporting frame body successively on the temporary platform 5. Construction floor structural beam slab 4, the temporary platform includes main steel beam 1, secondary steel beam 2, and scaffolding slab 3, and main steel beam 1 is erected on the horizontal structure floor of the framework structure around the non-structural floor area 6, the two sides of the main steel beam 1 are fixed to the floor 6 of the basic structure of the frame, the secondary steel beam 2 is built on the main steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com