Rotating and locking protection device

A technology of protective device and rotary buckle, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of increased misoperation, complicated structure, and easy obstruction of operation by the protective cover, so as to reduce the probability of misoperation and reduce the complexity of operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

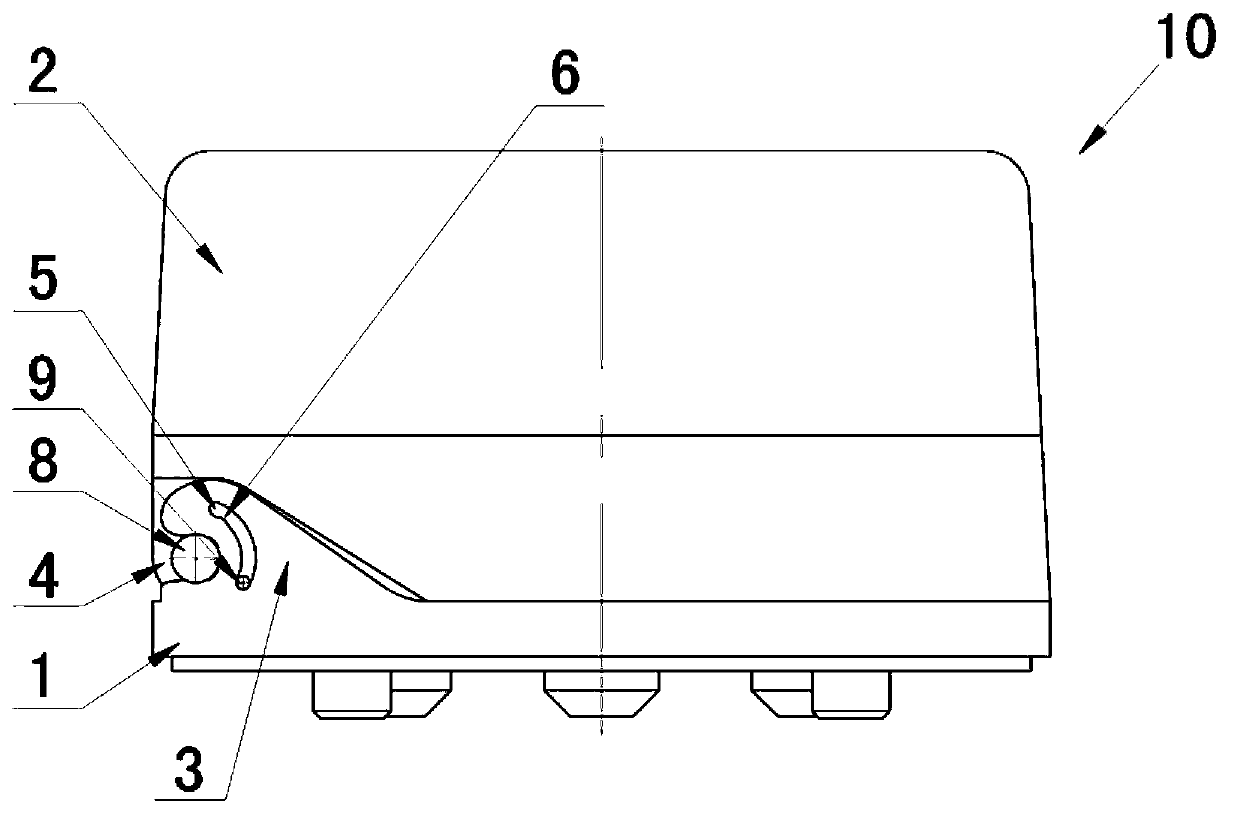

[0028] figure 1 It is a schematic structural diagram of the rotating fastening protection device according to the first embodiment of the present invention.

[0029] The rotation buckle protection device 10 includes a fixed structure and a rotation structure buckled with the fixed structure. Embodiment 1 is the application of the rotation buckle protection device 10 in the protection of a transfer switch. like figure 1 As shown, the fixed structure is the mounting plate 1 of the transfer switch, and the rotating structure is the protective cover 2 of the handle of the transfer switch.

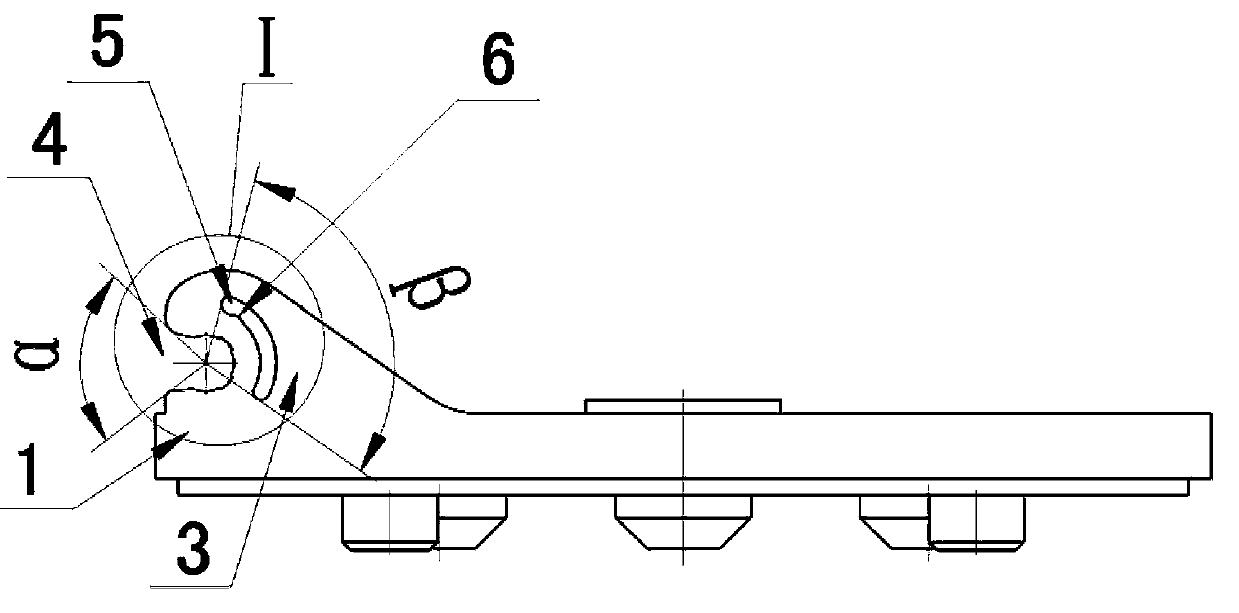

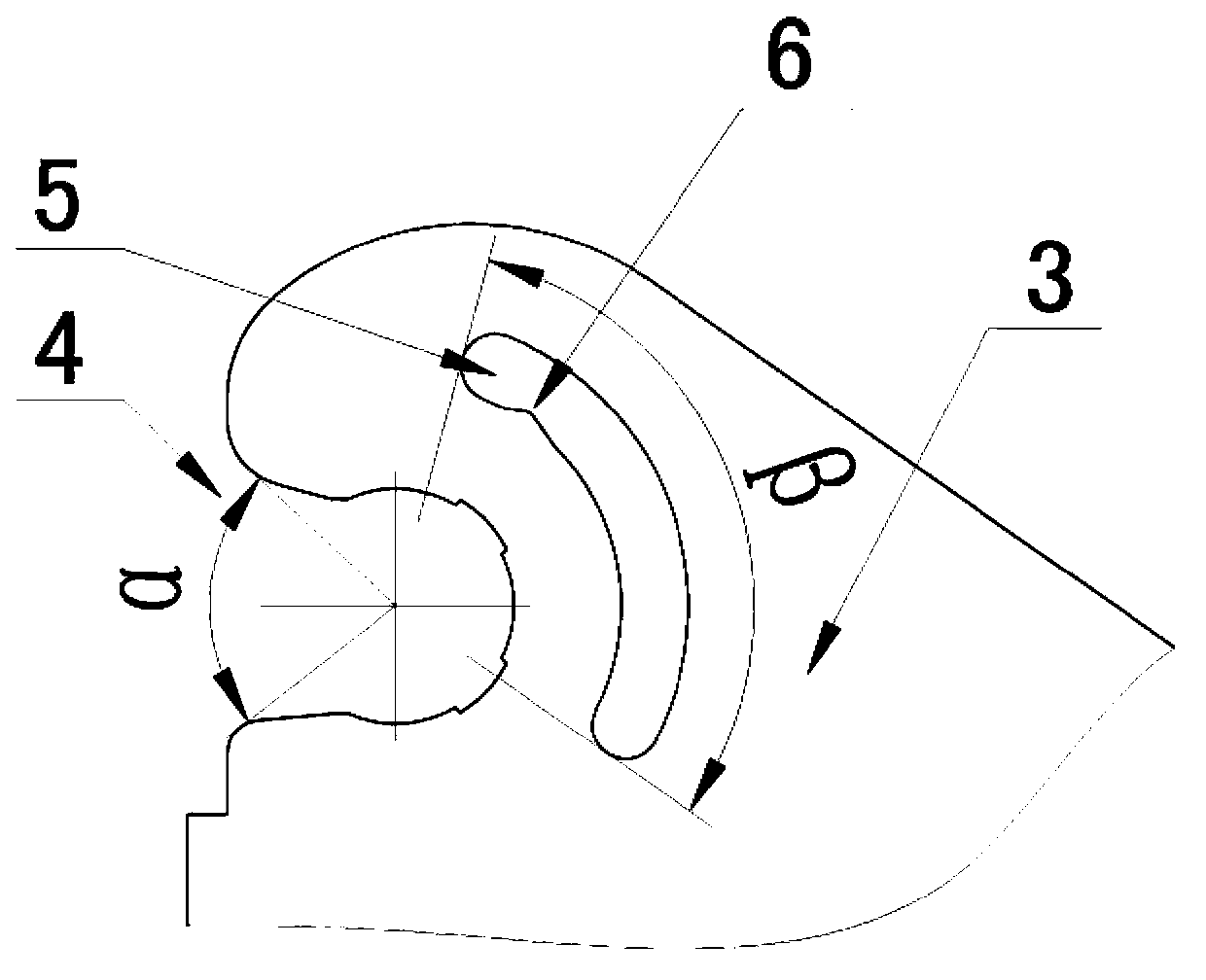

[0030] figure 2 It is a schematic structural diagram of the mounting board of Embodiment 1 of the present invention.

[0031] like figure 2 As shown, there is a positioning foot 3 on both sides of the mounting plate 1. The shape of the positioning foot 3 is like a right-angled trapezoid, that is, a wave shape. There is an open rotating port 4 on the positioning foot 3. There are a plural...

Embodiment 2

[0042] Image 6 It is a schematic diagram when the protective cover of the second embodiment of the present invention is closed.

[0043] Figure 7 It is a schematic diagram when the protective cover of the second embodiment of the present invention is fully opened.

[0044] like Image 6 , 7 As shown, in this embodiment, the rotary port 12 is closed, and there is a limiting groove 13 beside the rotary port 12 . There are a plurality of equidistant anti-slip bosses 14 on the limiting groove 13, and there are three in this embodiment. The other structures of the rotating fastening protection device 15 are the same as those in the first embodiment.

[0045] Figure 8 It is a partially enlarged view of the limiting groove of the second embodiment of the present invention.

[0046] like Figure 8 As shown, when the protective cover 19 is fully opened, the limit boss 16 slides to the point A of the limit groove 13, and stops there under the resistance of the anti-slip boss ...

Embodiment 3

[0053] Figure 9 It is a schematic diagram of the third embodiment of the present invention when the protective cover is closed.

[0054] Figure 10 It is a schematic diagram of the third embodiment of the present invention when the opening angle of the protective cover is 120°.

[0055] Figure 11 It is a schematic diagram of the third embodiment of the present invention when the opening angle of the protective cover is 90°.

[0056] like Figure 9 , 10 , 11, in this embodiment, the concave table 27 is a rectangle, the limit groove 28 is located on one side of the rotation port 21, and the angle between the two ends of the limit groove 28 and the center of the rotation port 21 is 14°. °. Since the limit groove is used to limit the maximum rotation angle of the protective cover, the protective cover in this embodiment can rotate between 0° and 120°. There are two middle anti-slip bosses 22 in the middle of the limit groove 28 . When the opening angle of the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com