Cabinets with cable entries for various cable bundle thicknesses

A technology for wire inlets and cable bundles, which is applied in the direction of cabinets/cabinets/drawer components, etc., can solve the problems of difficult to seal the wire inlets tightly, and achieve the effect of fire prevention and rodent prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

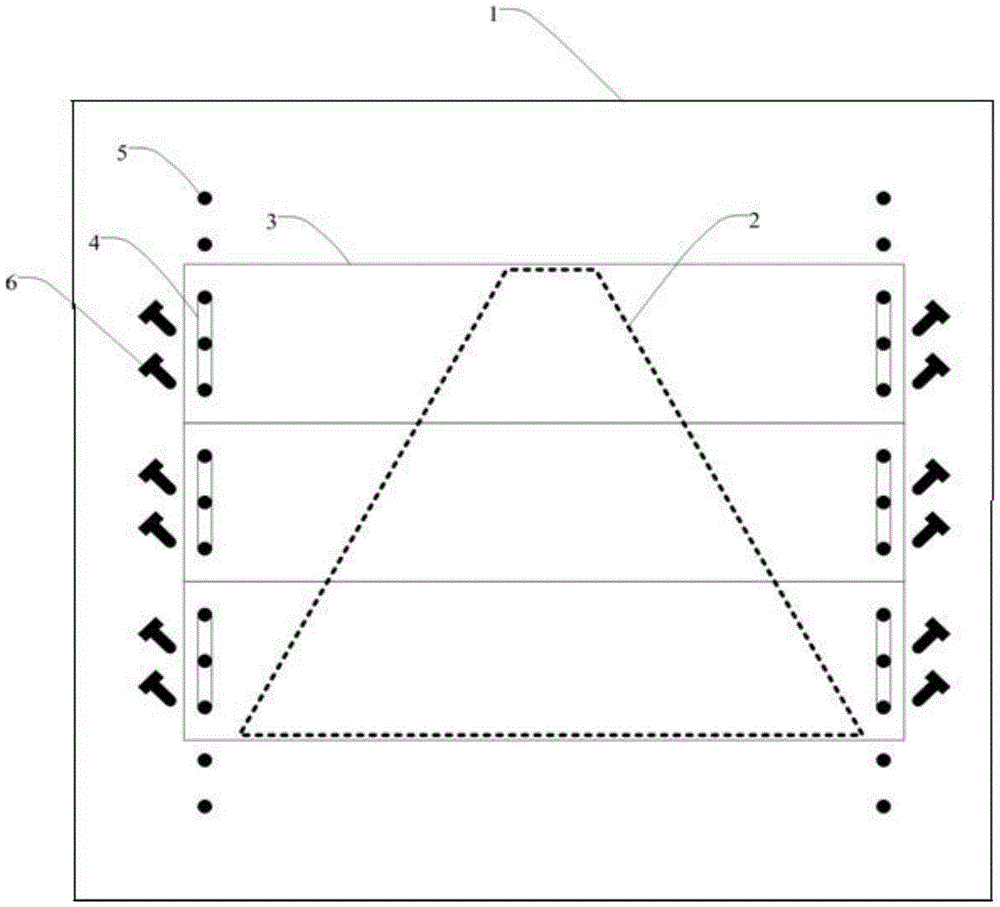

[0010] Specific implementation mode one: combine figure 1 Describe the present embodiment, the cabinet with the wire inlet hole that adapts to the thickness of various cable bundles described in this embodiment includes a cabinet door, and the cabinet door includes a door panel 1, N sliding cover plates 3 and M bolts 6 ; The door panel 1 is provided with a trapezoidal wire inlet hole 2, and a row of threaded fixing screw holes 5 are arranged at equal intervals on the door panel 1 on both sides of the trapezoidal wire inlet hole 2;

[0011] Both sides of each sliding cover plate 3 are respectively provided with cover plate screw holes 4, the width of the cover plate screw holes 4 is the same as the width of the fixed screw hole 5, the position of the cover plate screw holes 4 on both sides of the sliding cover plate 3 Corresponding to the positions of the two rows of fixing screw holes 5 on the door panel 1 respectively;

[0012] The bolt 6 is used to fix the sliding cover pla...

specific Embodiment approach 2

[0014] Specific Embodiment 2: This embodiment is a further limitation of the cabinet with wire inlet holes that adapt to the thickness of various cable bundles described in Specific Embodiment 1. In a row of fixing screw holes 5 adjacent two The spacing is a quarter of the width of the sliding cover.

specific Embodiment approach 3

[0015] Specific embodiment 3: This embodiment is a further limitation of the cabinet with wire inlet holes adapting to the thickness of various cable bundles described in specific embodiment 2. The screw holes 4 on the cover plate are elongated, and the The length of the cover plate screw hole 4 is half of the length of the sliding cover plate 3 .

[0016] In this embodiment, there are multiple sliding cover plates 3, and the cover plate screw holes 4 on both sides are elongated. After the fixing bolts are loosened, they can slide back and forth, and the distance that can slide back and forth exceeds one-half of the width of the sliding cover plate 3. , so that the sealing position of the cover plate can be continuously adjusted throughout the entire trapezoidal height range.

[0017] The bottom fixing screw holes 5 with threads are arranged on both sides of the cable inlet hole of the cabinet. The spacing between the bottom fixing screw holes is 1 / 4 of the width of the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com