Machine tool fixture and machine tool using the machine tool fixture

A technology of machine tool fixtures and machine tools, which is applied in the direction of chucks, etc., can solve the problems of small alignment range, etc., and achieve the effect of large alignment range, convenient use, and convenient alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

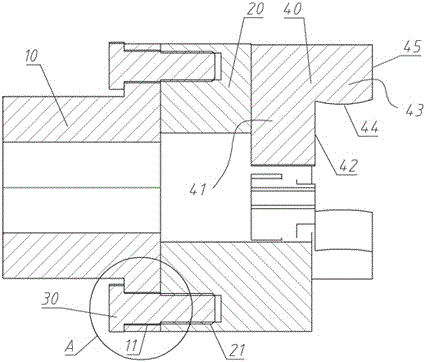

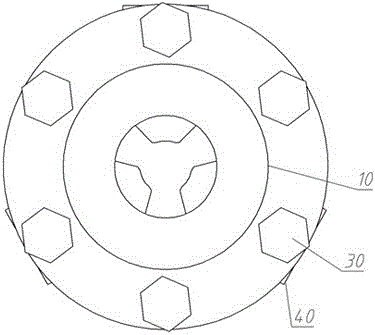

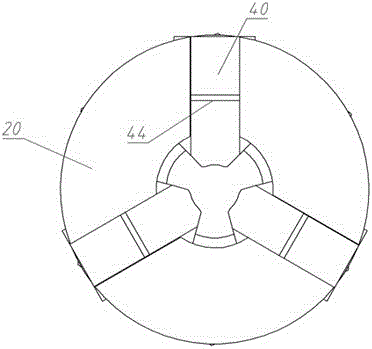

[0020] An embodiment of the machine tool fixture in the present invention is as Figure 1~Figure 4 As shown, it includes a spindle connection plate 10 for transmission connection with the spindle of the machine tool, a chuck 20 fixed on the spindle connection plate 10 by bolts 30 and three claws 40 arranged on the chuck 20 .

[0021] The main shaft connection plate 10 is provided with a flange structure, and the flange structure is provided with a bolt perforation 11 for the bolt 30 to pass through, and the chuck 20 is provided with a threaded hole 21, and the bolt 30 passes through the bolt hole. 11 is passed through and then screwed into the threaded hole 21 on the chuck 20 to realize the fixed and transmission connection between the main shaft connection plate 10 and the chuck 20 . The diameter of the bolt hole 11 on the main shaft connection plate 10 is larger than the diameter of the bolt 30, thereby forming a set gap δ between the bolt 30 and the inner wall of the bolt h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com