Multiple strand combing weft shuttle

A technology of shuttle body and coil, which is applied in the direction of shuttle, textile, textile and paper making, etc. It can solve the problems of monotonous pattern change and slow speed of textile fabrics, and achieve the effect of changing fabric patterns and accelerating weaving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

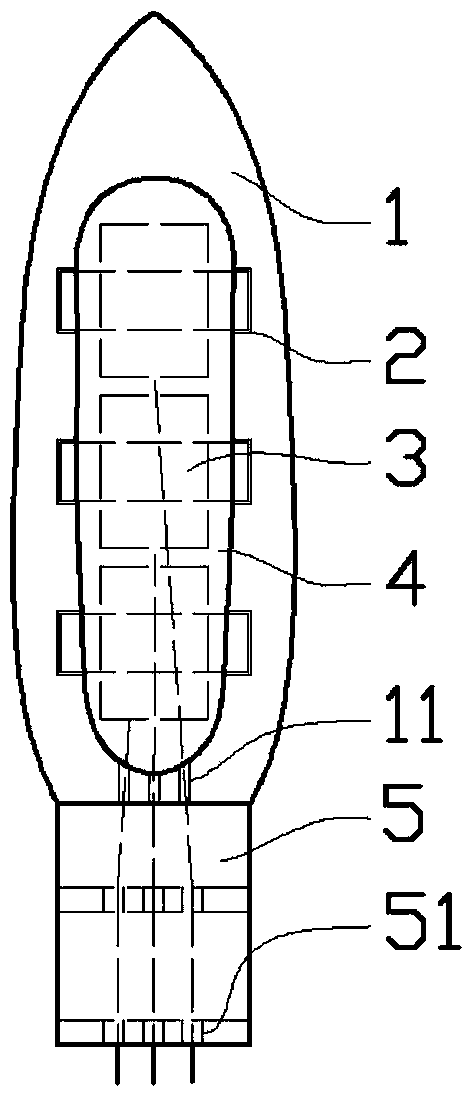

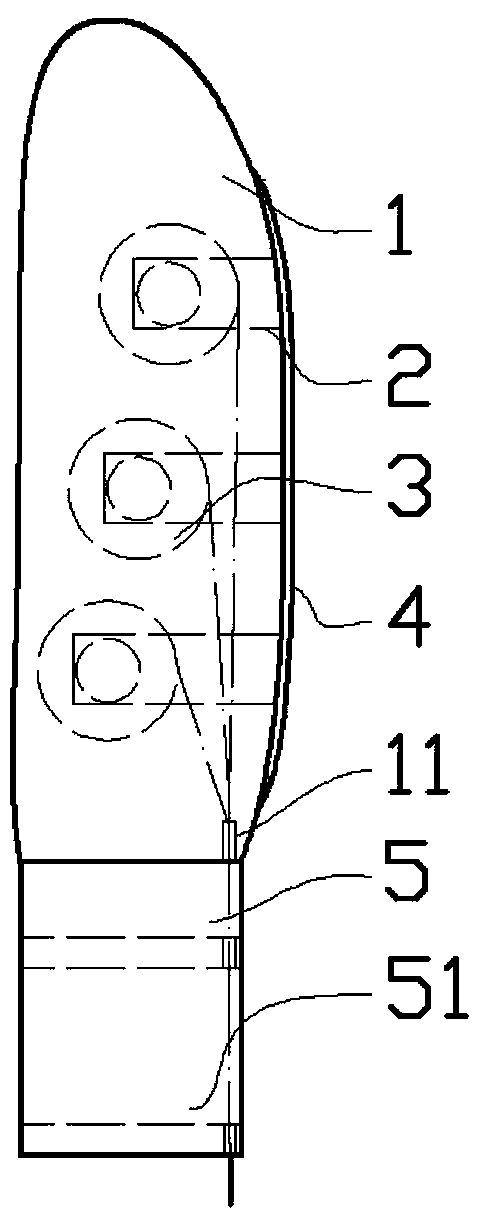

[0012] Such as figure 1 and figure 2 As shown in the embodiment, the multi-thread carding weft shuttle includes a shuttle body 1, an installation groove 2, and a coil 3; the shuttle body 1 is shuttle-shaped, and an installation cavity is processed inside, and three installation grooves are designed in the installation cavity 2. The coil 3 is rotatably assembled in the installation groove 2, and the installation grooves 2 at the front and rear positions are arranged in steps; the tail of the shuttle body 1 is processed with threading holes 11 corresponding to the installation grooves . Silk threads are wound on the coils 3 , and the silk threads corresponding to each coil 3 pass through the respective threading holes 11 .

[0013] The multi-thread carding weft shuttle structure can be used on manual shuttle looms or mechanical shuttle looms; the weft shuttle ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com