A fluff ironing device

A fluff and atomizing device technology, which is applied in the field of ironing devices for fluff ironing, can solve problems such as imperfect effects, and achieve the effect of improving the ironing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

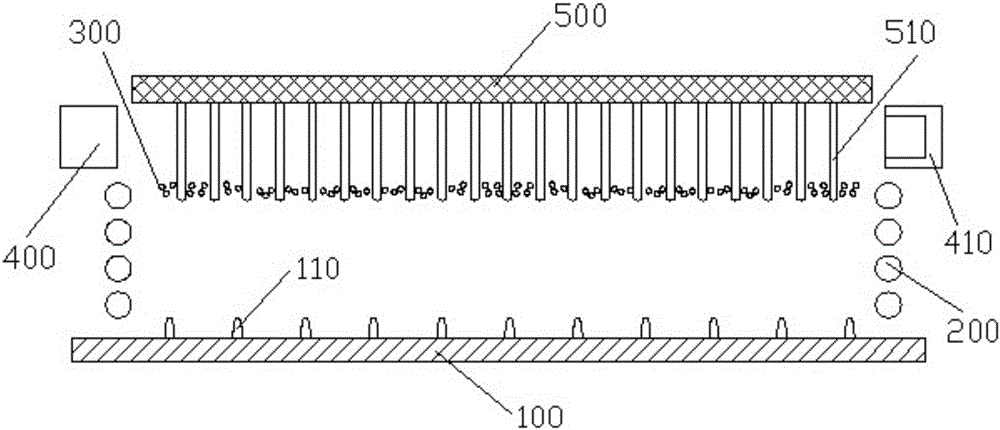

[0014] refer to figure 1 , in this embodiment, the fluff ironing device includes heat-conducting magnetic powder 300, a cooling plate 100, an induction coil 200, an atomizing device 110 and a heating component, the cooling plate 100 is thermally connected to a refrigerator, and the cooling plate 100 The fluff 510 side of the fluff fabric 500 is arranged in parallel, the spray side of the atomization device 110 faces the fluff 510 side of the fluff fabric 500, the space between the fluff fabric 500 and the refrigeration plate 100 has the induction coil 200 Enclosed, the heat-conducting magnetic powder 300 is evenly distributed on the plane inside the induction coil 200, the heating member is a microwave generator 400 arranged at one end of the fluff 510 of the fluff fabric 500, and the microwave emitted by the microwave generator 400 Parallel through the pile 510 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com