Ball injecting de-blocking hydraulic tubing anchor

A technology for hydraulic tubing and unsealing, which is used in wellbore/well components, earth-moving drilling, etc., can solve the problems of large lifting load, exceeding the maximum lifting load of the workover rig, and being unusable, so as to avoid the risk of blowout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

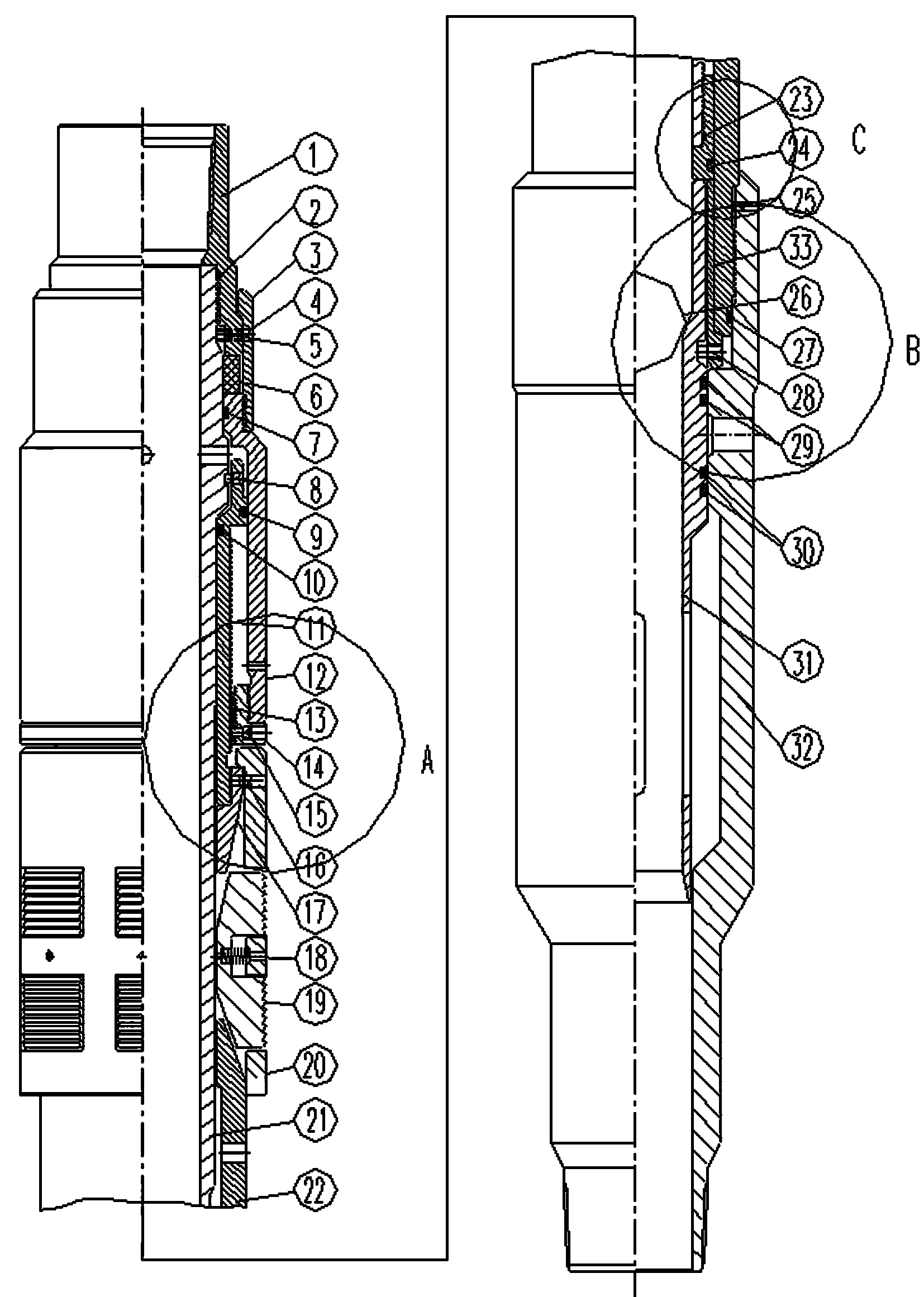

[0020] see Figure 1~4 The present invention will be further described below in conjunction with embodiment.

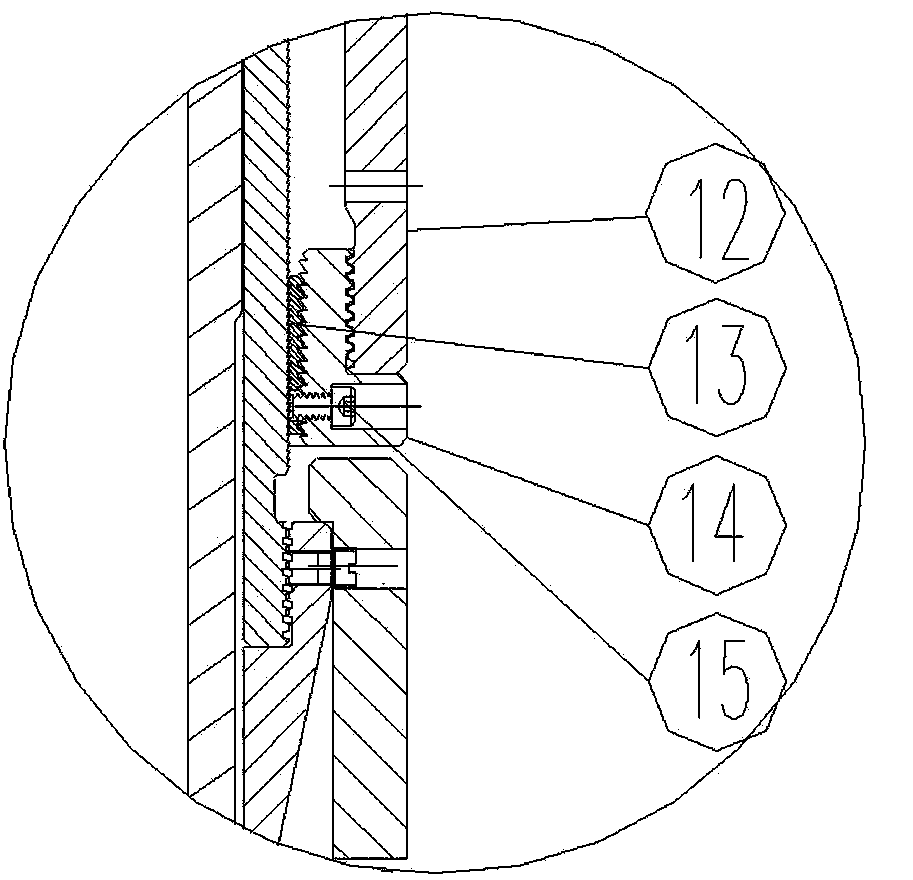

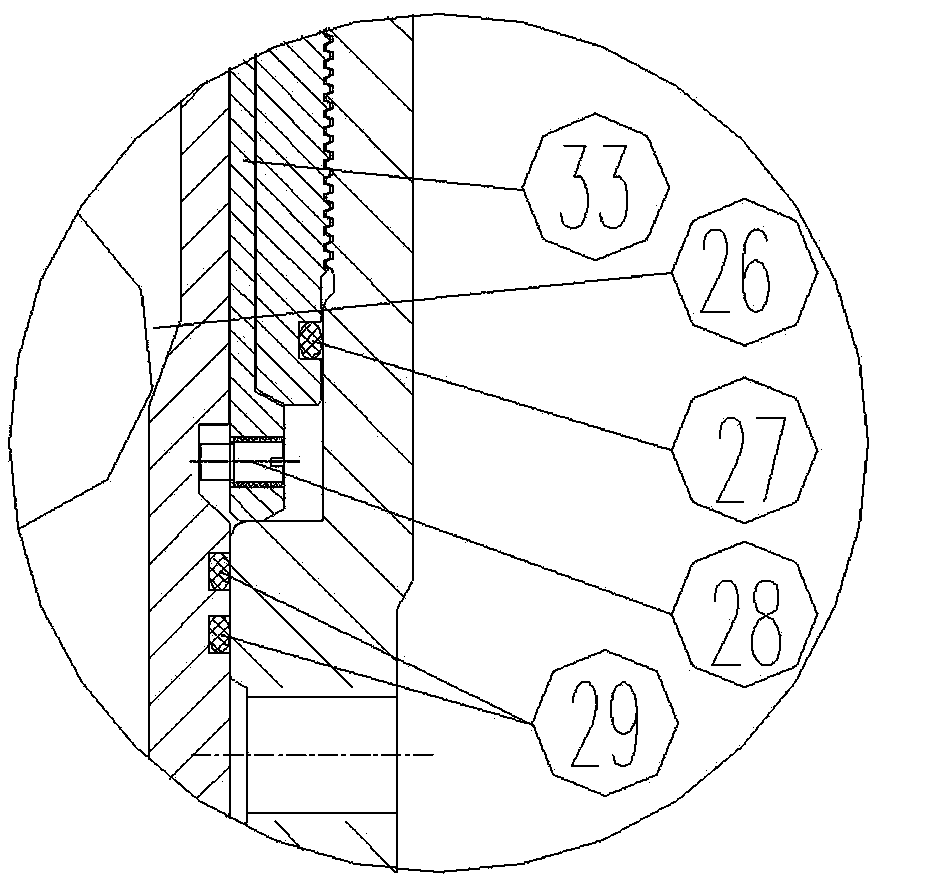

[0021] A kind of oil drilling and production equipment, especially a kind of ball-pitching unsealing type hydraulic oil pipe anchor, comprising a lower joint 32, a central pipe 21 and an upper joint 1 sleeved on the central pipe 21, characterized in that: the central pipe 21 The outer wall is connected with the piston 11 through the second shear pin 8, and a piston liner 12 is set on the outer wall of the piston 11. The inner wall of the piston liner 12 and the outer wall of the piston 11 form a piston cylinder, and a lock ring 13 is arranged on the piston. The lower end of the cylinder is threadedly connected with the piston liner 12, the lower end of the lock ring 13 is connected with a lock ring back ring 14, and the lower end of the piston 11 has a two-way slip connected to the center pipe 21 through elastic parts 19. The inner two ends of the two-way slips 19 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com